Trolley for transporting glass on track

A glass and track technology, applied in the field of glass transmission devices, can solve the problems of fragility, difficulty, and heavy glass weight, and achieve the effects of improving production efficiency, preventing glass breakage, and facilitating circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] A specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0008] In order to solve the above technical problems, the present invention provides a trolley for transporting glass on rails.

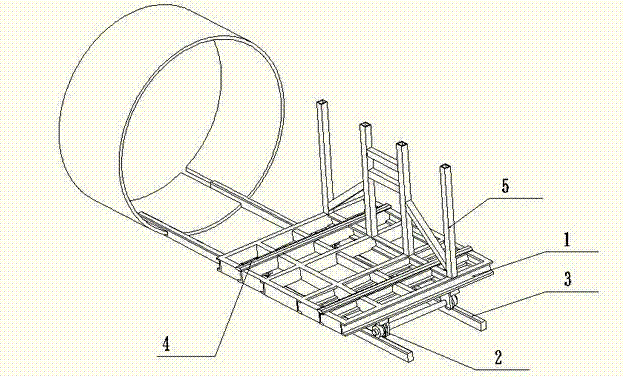

[0009] The trolley for transporting glass includes a bracket 1, and the bottom of the bracket 1 is fixed with a roller 2 matching with a track 3, and the roller 2 can slide along the track to drive the glass to the required process position. The upper surface of the bracket 1 is provided with a rubber pad 4, the rubber pad 4 can increase the friction between the glass and the glass, and the rubber pad can play a role in buffering vibration. The upper surface of the bracket 1 is provided with a column 5 to stop the glass, which can prevent the glass from sliding and detaching from the bracket 1 .

[0010] By adopting the trolley for transporting glass of the present invention, it is possible to conveniently reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com