Knitting method of knitted fabric with hole and knitted fabric

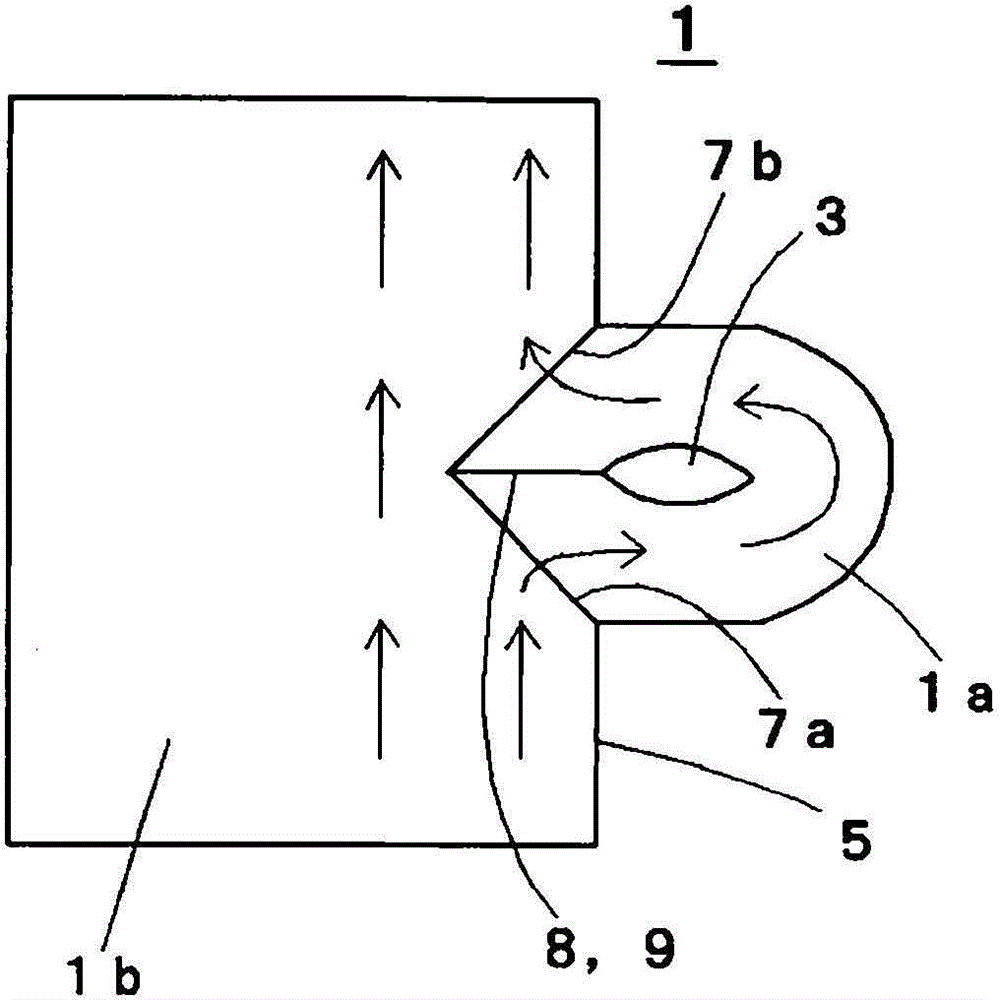

A technology of knitted fabrics and needle beds, which is applied to the knitting of knitted fabrics with holes and the field of knitted fabrics, which can solve problems such as broken threads and insufficient strength, and achieve the effect of preventing protrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

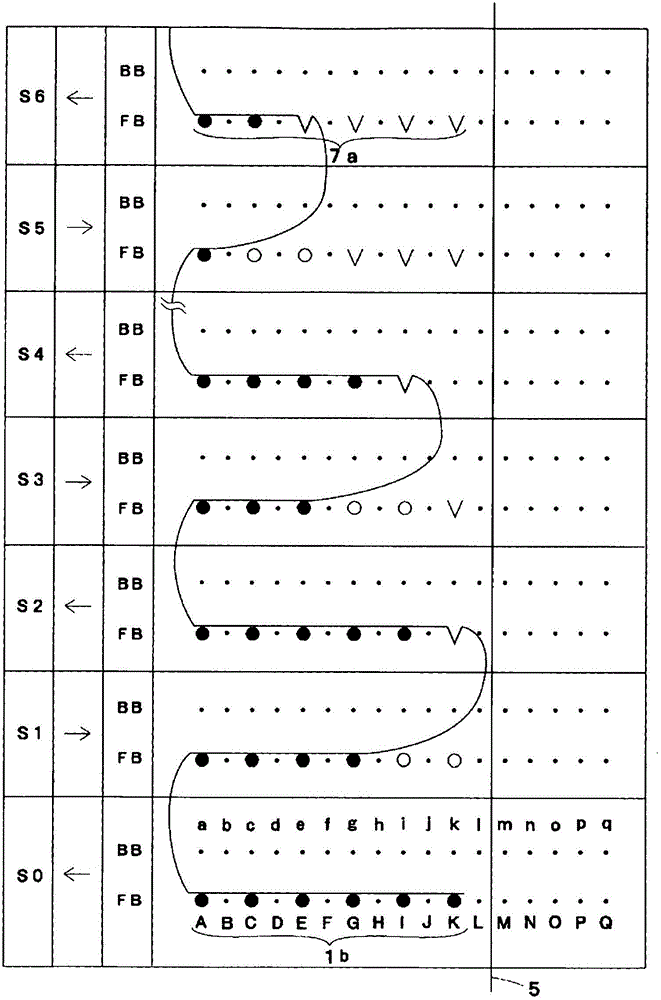

Method used

Image

Examples

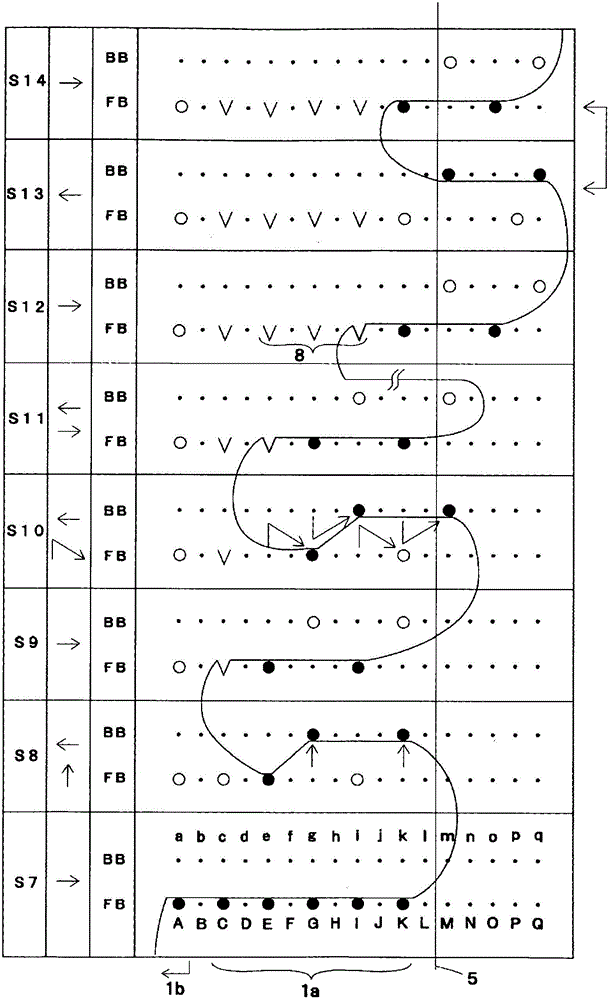

Embodiment 2

[0043] The hole forming portion 11 a in the second embodiment moves toward the outer side of the knitted fabric while forming heavy stitches with the terminal stitch 14 of the knitted fabric 10 b on the side end portion 15 side to join. After forming the row of stitches at the periphery of the hole 13 in the same manner as in the first embodiment, it is folded back to the original position, and widening stitches 17 for continuing the start stitches 17 of the knitted fabric 10c adjacent to the side ends 15 are formed at this time. The joining of the start end portion 18 and the end portion 19 of the hole forming portion 11a can be started from the inner side of the knitted fabric, as Figure 5 The hole 13 is simply formed to the inner side of the knitted fabric 10 as shown.

[0044] Image 6 In the knitting diagram of , the knitting from the position where branching starts is shown by T1 to T9. In addition, the position of the side end part 15 of the knitted fabric 10 is show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com