Drag type narrow tube wind gathering power generation system

A power generation system and narrow tube technology, applied in wind power generation, wind turbine components, wind engines, etc., can solve problems such as unseen expert literature and patent reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

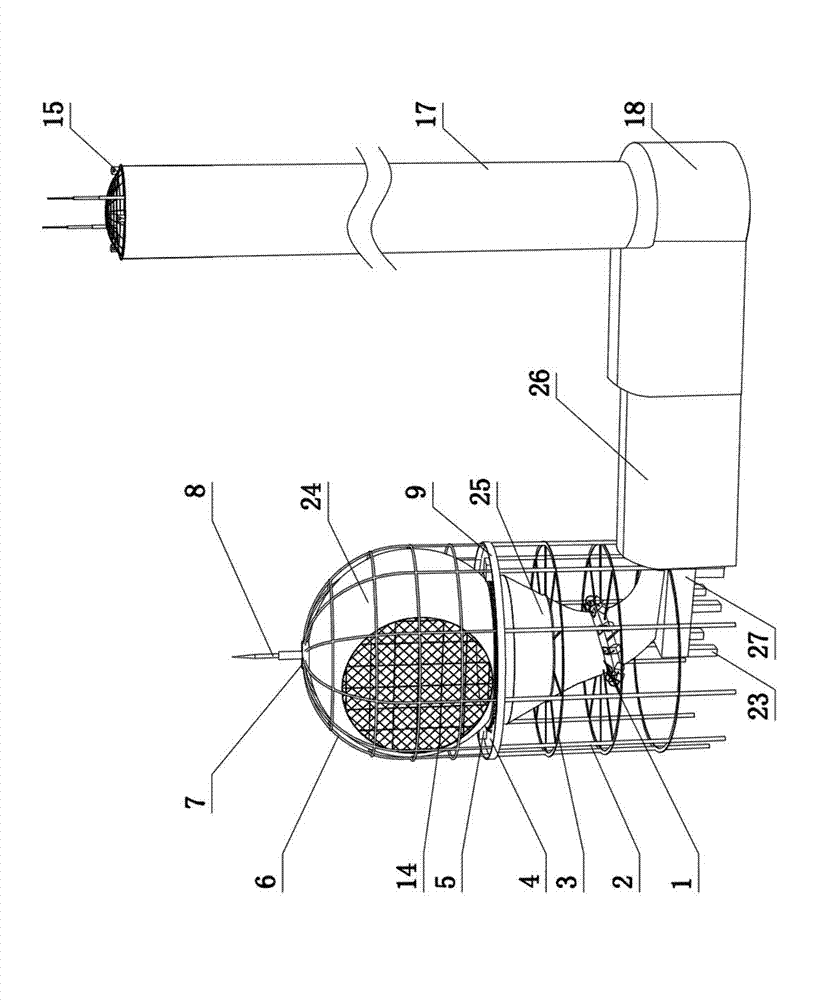

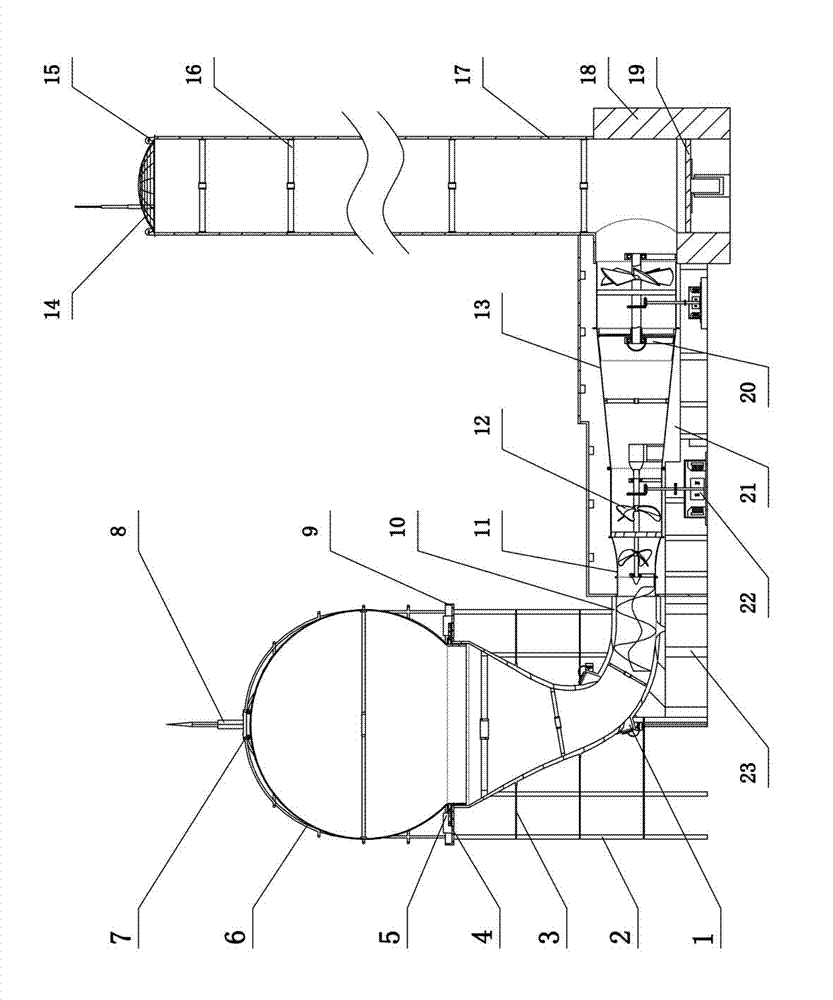

[0023] Refer to attached figure 1 , figure 2 As shown, a pull-up narrow tube wind gathering power generation system of the present invention is realized by the following technical solutions:

[0024]A pull-up narrow tube wind collecting power generation system of the present invention consists of a suction window 1, a main column 2, a ring beam 3, a platform 4, a direction adjustment device 5, an arc column 6, an intersection fixing seat 7, a lightning arrester 8, and a safety wall 9 , Regular plate shell 10, shell 11, wind power engine 12, induced draft tube 13, protective net 14, beacon light 15, hub support 16, tower body 17, tower base 18, opening and closing cover 19, support frame 20, Abutment 21, generator 22, attached column 23, spherical body 24, narrow tube body 25, mechanical room 26, and narrow tube abutment 27 are formed. The open section of the upper part of the narrow tube body 25 is arranged upwards at the center opening of the platform 4, and the narrow mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com