Roller element of tripod joint and tripod joint

A rolling element, three-pin shaft technology, applied in couplings, elastic couplings, mechanical equipment, etc., can solve problems such as infeasibility and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

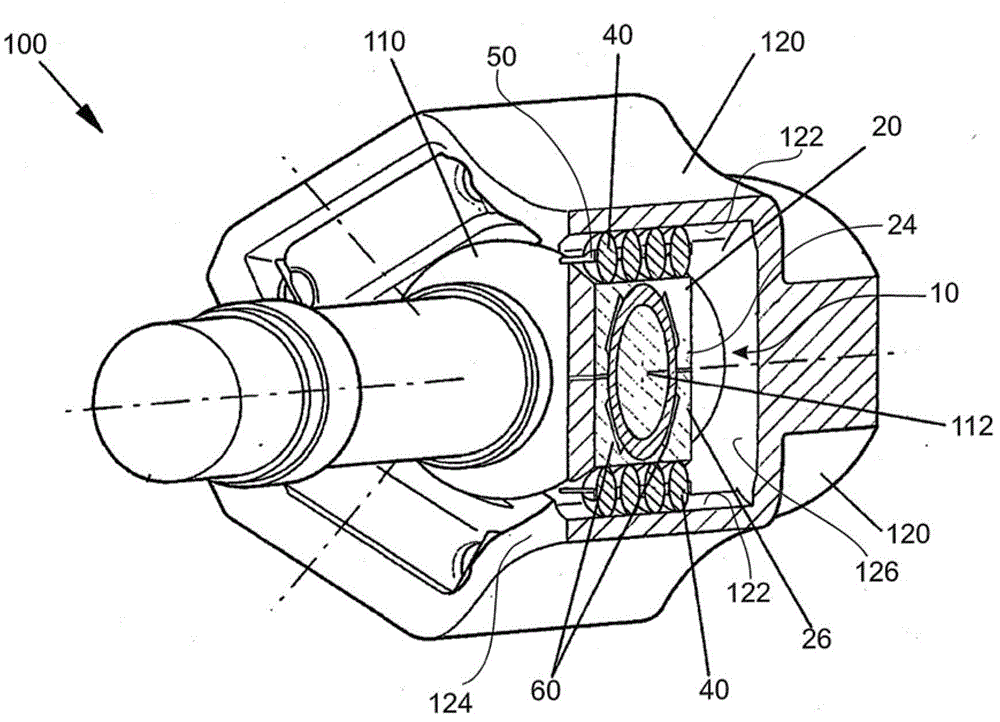

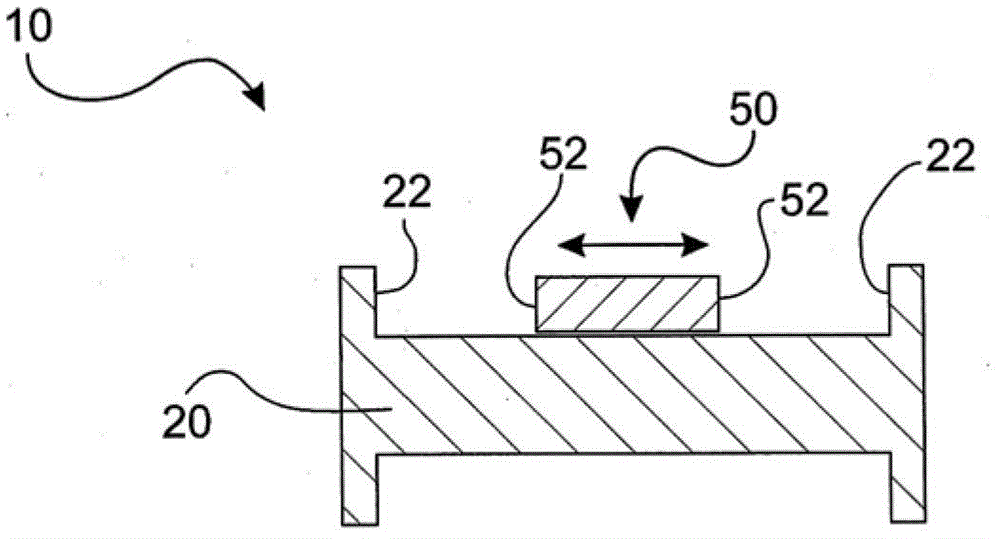

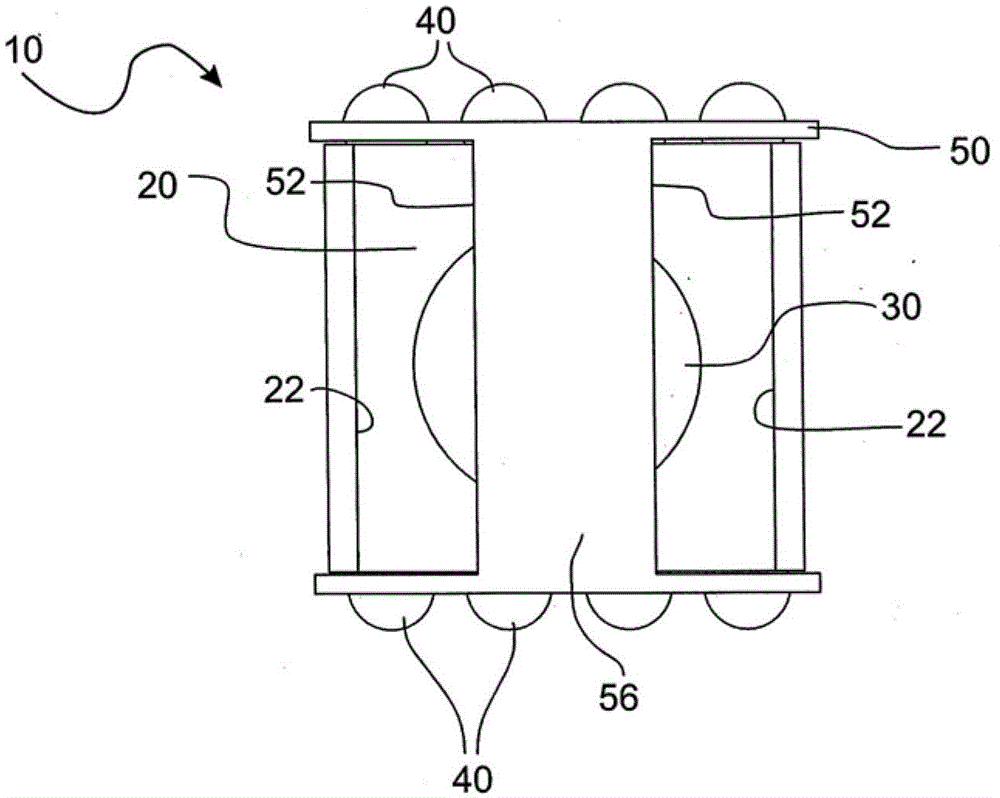

[0032] according to figure 1 The three-pin universal joint 100 of the present invention and the arrangement of the three-pin universal joint 100 of the present invention are briefly shown. The tripod joint 100 has a joint outer member 120 that surrounds the tripod drive shaft and thus also surrounds the tripod assembly 110 . To this end, the joint outer part 120 has a pot-shaped recess into which the tripod assembly 110 protrudes. The three-pin shaft assembly 110 in this embodiment has three pin shafts 112 respectively supported by the rolling elements 10 of the present invention. In this case, the bottom surface 126 and the end surface 124 are defined by the pot-shaped structure of the joint outer part 122 . The rolling element 10 of this embodiment is designed as a linear guide and accommodates a pin 112 of a tripod assembly 110 in its central receiving opening 30 . Housing 20 , in which receiving bore 30 is formed, is supported via rolling bodies 40 on raceway 122 in out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com