Accuracy control method for multi-deck construction of large offshore oil and gas modules

A precision control and deck technology, applied in shipbuilding, ship design, ships, etc., can solve problems such as sunken decks, hidden safety hazards in offshore oil and gas production, and affect the quality of oil and gas module construction, achieving the effect of improving construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The method of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] The method for controlling the construction accuracy of the multi-layer deck of the large-scale offshore oil and gas module of the present invention comprises the following steps:

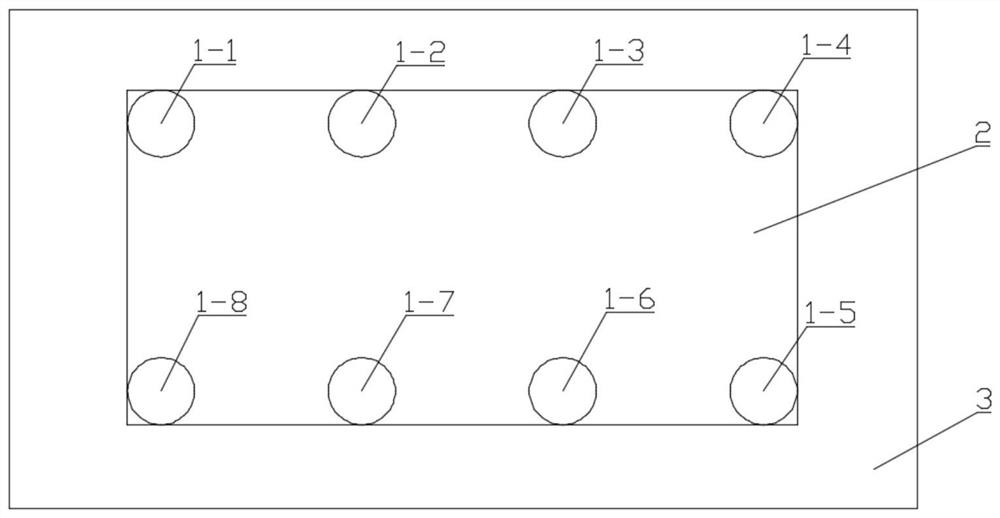

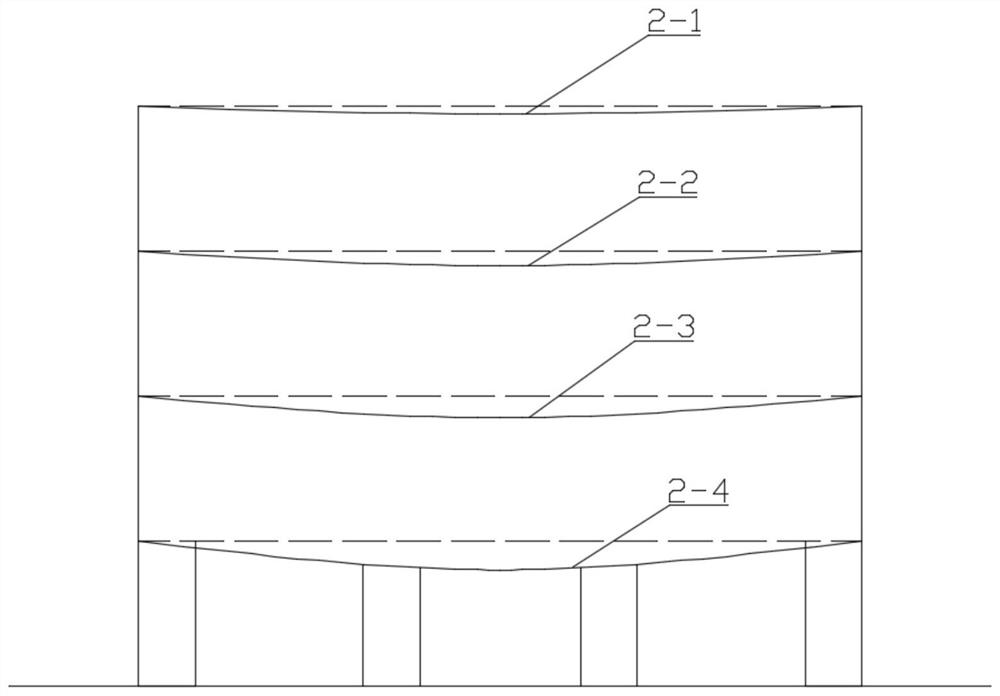

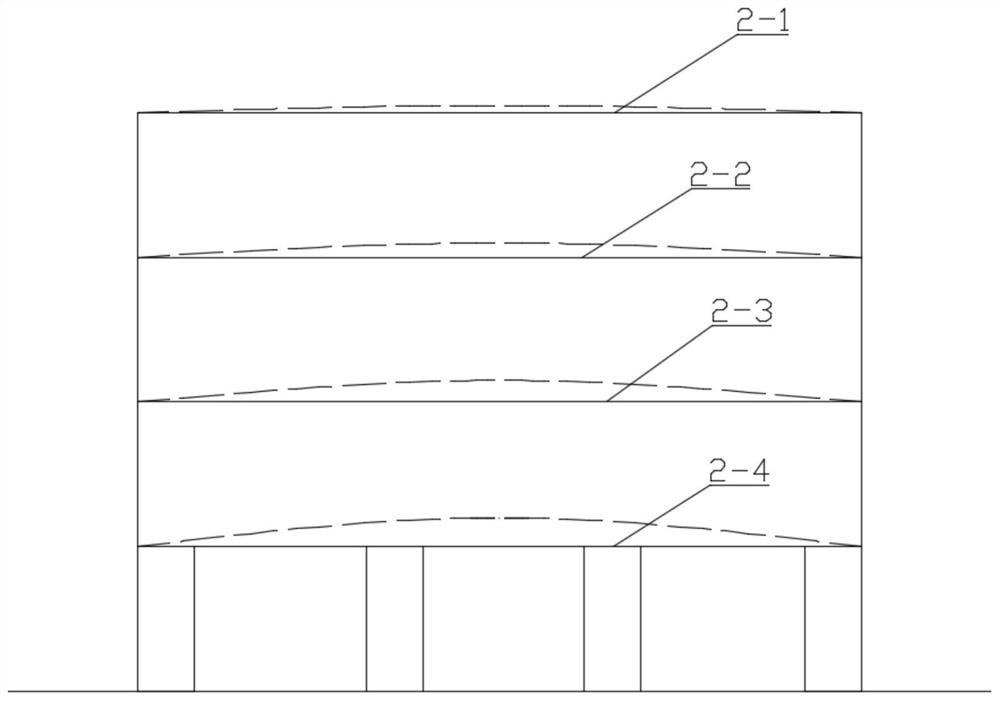

[0022] Step 1. Calculate the total weight G of each deck of the marine oil and gas module 2 and the equipment on each deck. i Add the total weight of each deck of the marine oil and gas module and the equipment on each deck to obtain the total weight G of the marine oil and gas module;

[0023] Take the four decks as an example: the mass of the steel used in the four decks is obtained through the design drawings, and the weight of the equipment installed on each deck is added on this basis to estimate the first deck (that is, the lowermost deck, Deck 2-1) and the weight G of the equipment on it as shown 1 , the weight of the second deck and its equipment G 2 , the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com