Carrier units and processing modules for building printing machines

A printing press, modular technology, applied in printing presses, rotary presses, printing, etc., can solve the problems of technical consumption, expensive processing steps, etc., and achieve the effects of good availability, good handleability, and simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

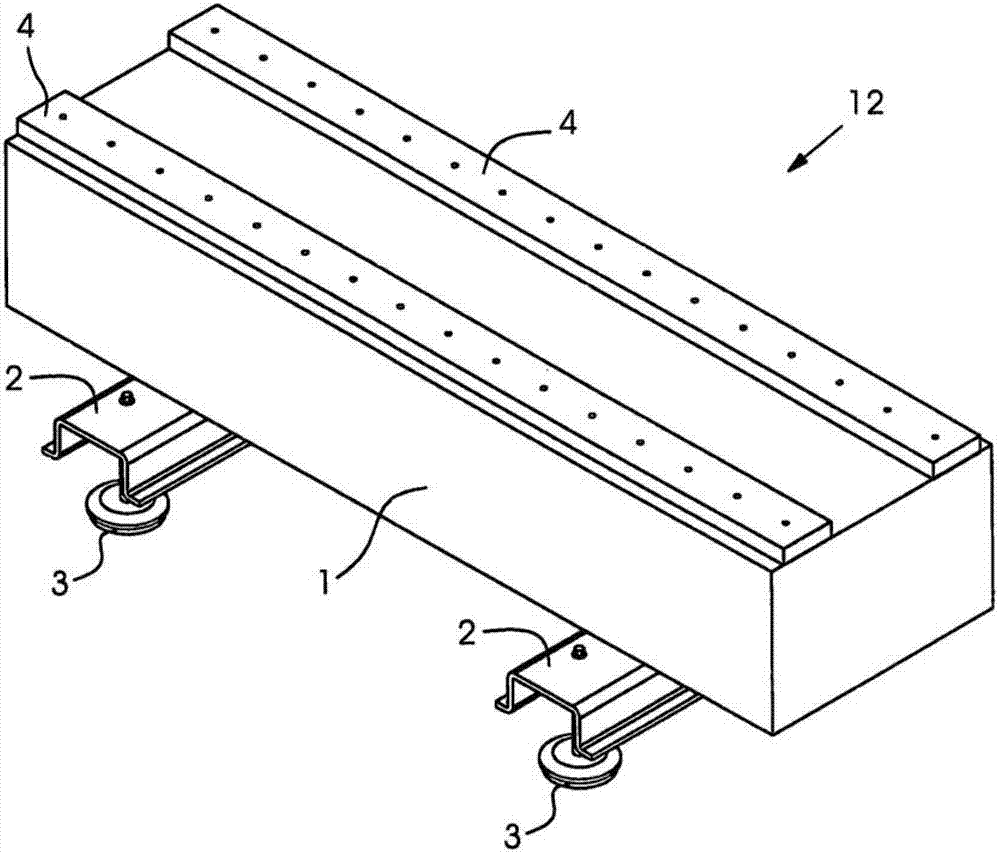

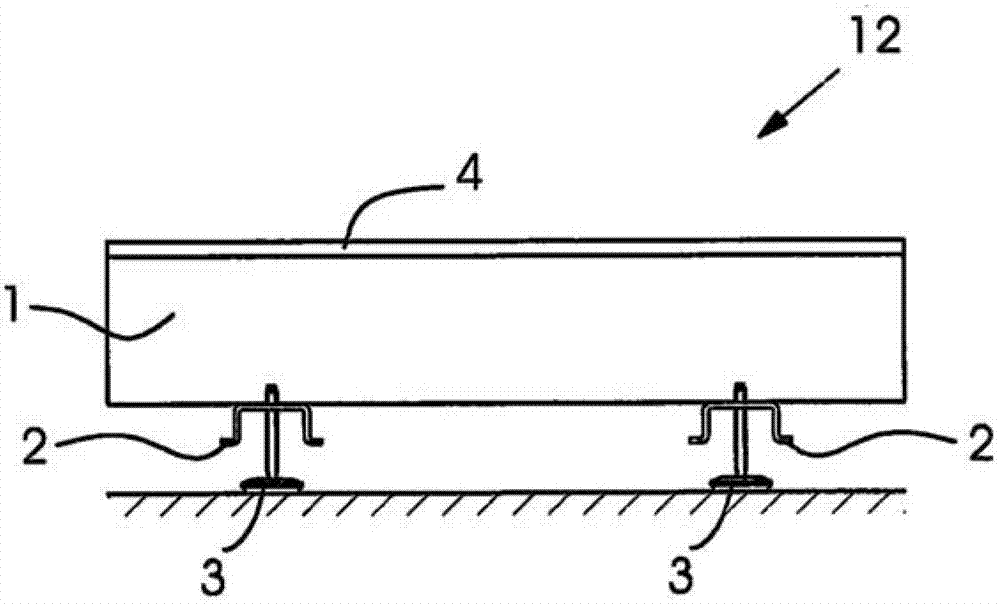

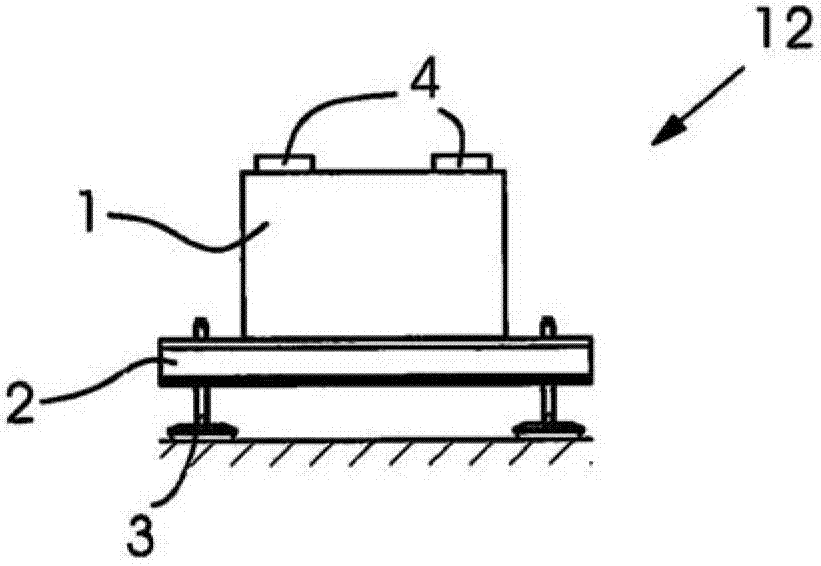

[0038] Figure 1a A carrier unit 12 is shown, which is formed by a block 1 , ie a solid rectangular stone. The solid cuboid 1 has on its upper surface two longitudinal guides 4 with a perforated array structure. The block 1 is fixed by four feet formed by the profile carrier 2 and the adjustable leveling element 3 . Height compensation can be achieved by twisting the leveling element 3 and the block 1 can thus be positioned horizontally. exist Figure 1b in a view and in Figure 1c The carrier unit 12 is shown in a side view.

[0039] exist Figure 2a Different variants of the longitudinal guide 4 are shown in to c. exist Figure 2a The central longitudinal guide 4 is arranged centrally on the block 1 as a raised element. in accordance with Figure 2b In a variant of , the longitudinal guide 4 is embodied as a groove centrally opened in the surface of the block 1 . according to Figure 2c , two longitudinal guides 4 are arranged on the surface of the block 1 in the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com