Dynamic rapid positioning device and method of using the same

A technology of positioning device and power device, applied in the direction of positioning device, clamping, support, etc., can solve the problems of a lot of time adjustment, alignment, low equipment utilization, poor safety and reliability, etc., and achieve easy to master, improve work efficiency, The effect of quick positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

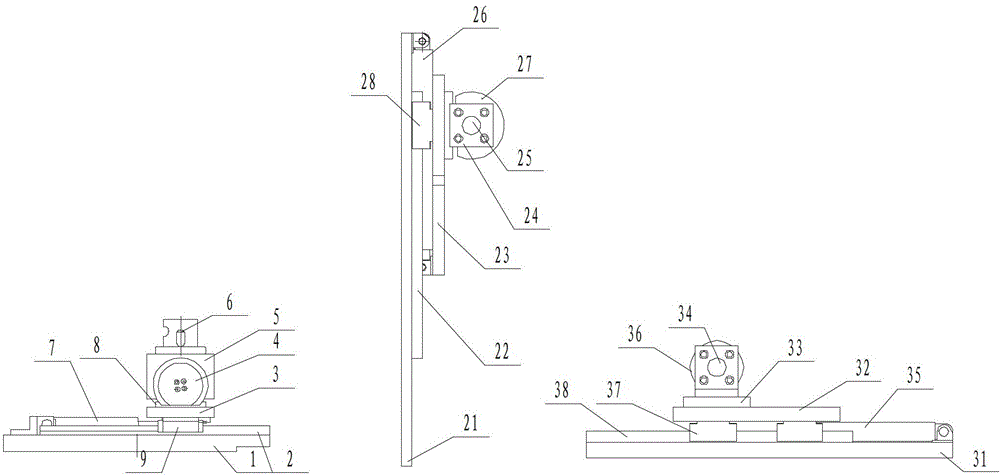

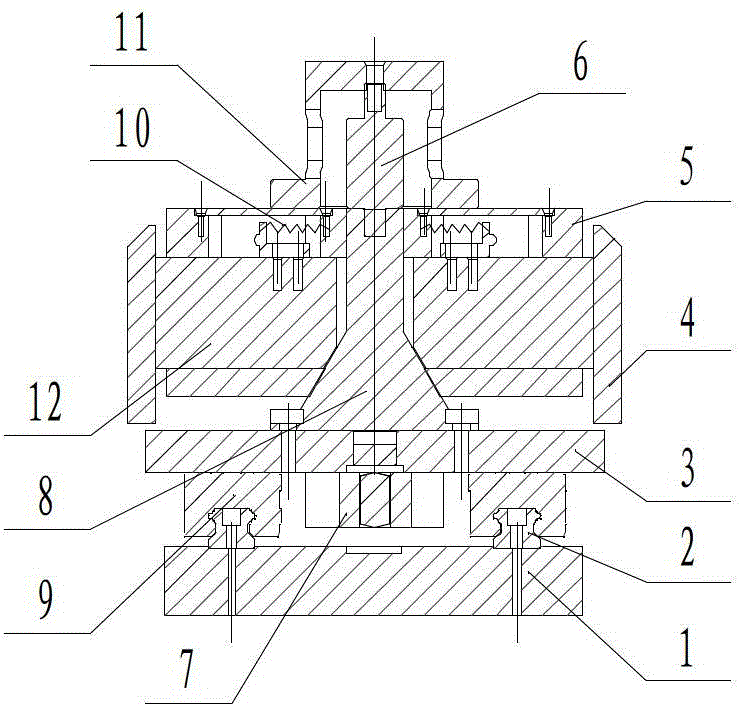

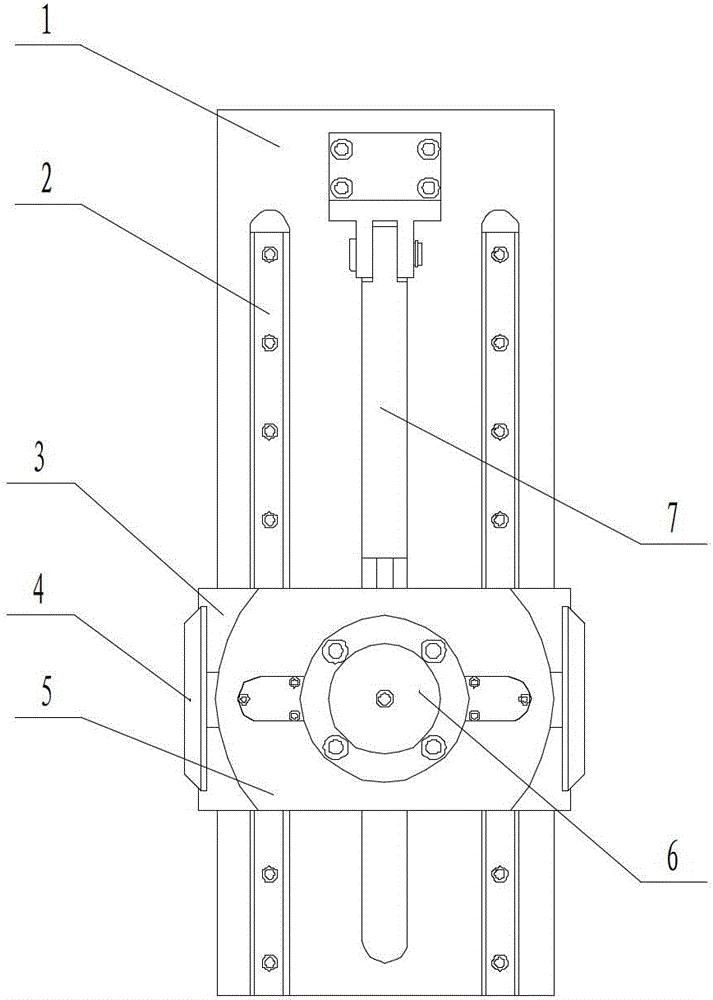

[0035] A dynamic fast positioning device, including fast front positioning, fast middle positioning and fast rear positioning; fast front positioning includes a front base plate 1, a front moving plate 3 and a forward oil cylinder 7, and the front base plate 1 is provided with a front rail 2, and the front moving The board 3 is provided with a front box body 5, a front top oil cylinder seat 11, a front top oil cylinder 6, a front guide positioning shaft 8, a return spring 10 and a front travel device 9, and two slide bars 12 are arranged symmetrically in the front box body 5. , the front positioning block 4 is fixed on the slide bar 12;

[0036] The fast mid-positioning includes mid-sole plate 21, mid-moving plate 23, mid-feed cylinder 26 and mid-horizontal oil cylinder 25. Mid-sole plate 21 is provided with mid-track 22, mid-sole plate 23 is provided with mid-moving device 28 and two mid-positioning units. Block 27; Fast rear positioning includes rear base plate 31, rear movi...

Embodiment 2

[0039] The front track 2, the middle track 22 and the rear track 38 are all racks, and the front traveling device 9, the middle traveling device 28 and the rear traveling device 37 are all gears, and the gears are respectively installed and fixed on the front moving plate 3 and the middle by the shaft and the shaft seat. On moving plate 23 and rear moving plate 32, others are identical with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap