Broad-gauge mechanical transmission comprehensive rail car

A technology of mechanical transmission and rail car, which is applied to the transmission device with reciprocating piston internal combustion engine, etc., can solve the problems of inability to drive on it, single function of rail car, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

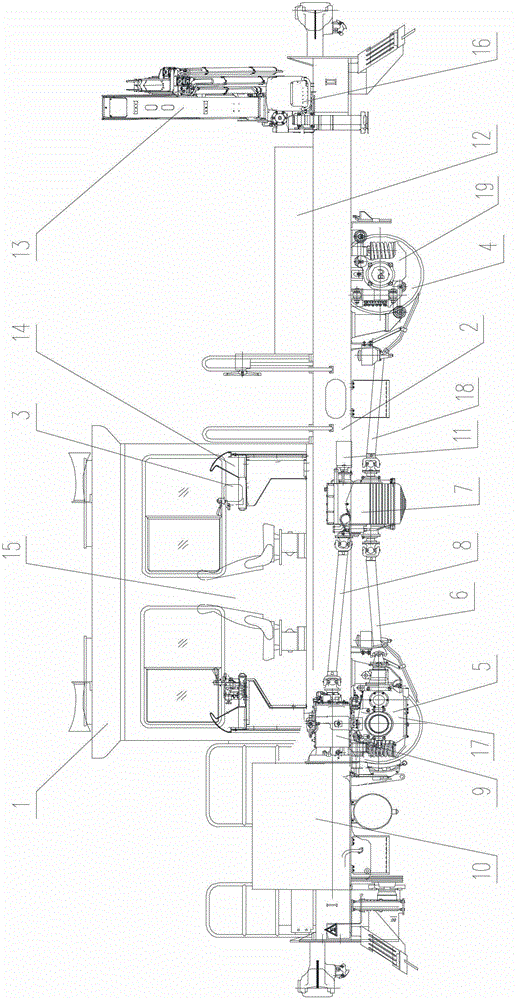

[0018] Attached below Figure 1-3 An embodiment of the present invention is described.

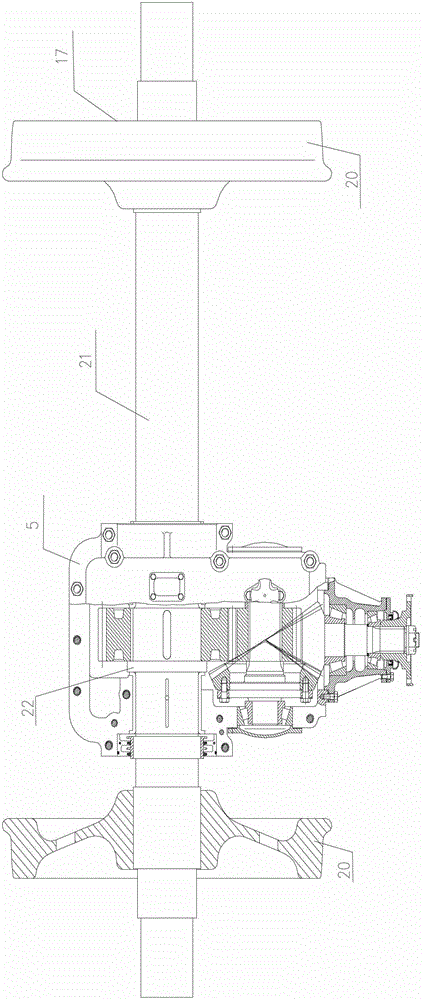

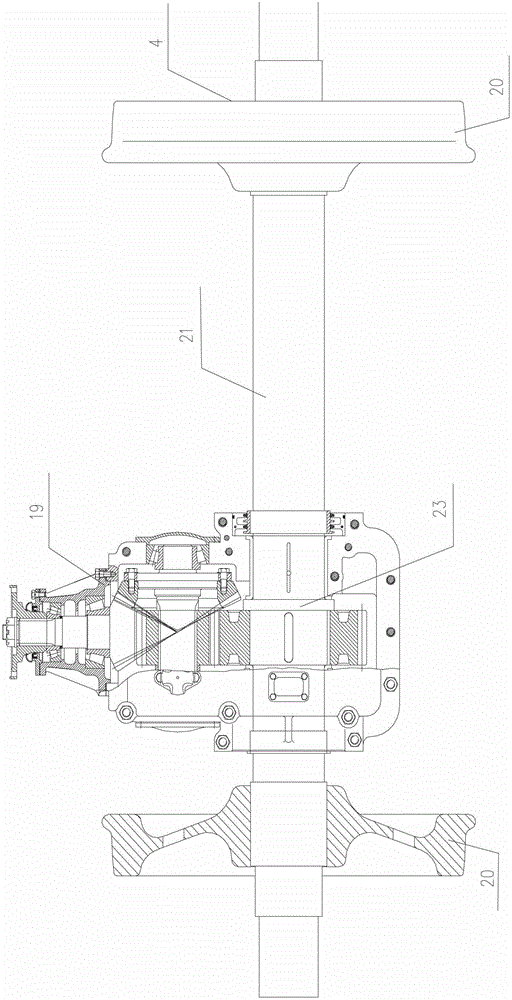

[0019] The wide-gauge mechanical transmission integrated rail car includes a car body 1 and a frame 2. The car body 1 is placed on the frame 2. A cab 15 is arranged on the car body 1. Electrical appliances are installed in the cab 15. Control system 3 and driver's console 14, specifically, two driver's consoles 14 are provided in the cab 15, which can drive in both directions, and a heating device, fan, driver's seat and fire extinguisher are also provided in the cab 15 . The bottom of the vehicle frame 2 is provided with a front wheel pair 17 and a rear wheel pair 4. Specifically, the front wheel pair 17 and the rear wheel pair 4 are formed by cold pressing of two wheels 20 and an axle 21. The two wheel inboard spacings of the front wheel pair 17 and the rear wheel pair 4 are 1440mm. Specifically, the distance between the end surface of the step I22 where the axle gearbox I5 is positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com