Device for drawing fabrics of fabric inspection machine

A cloth inspection machine and equipment technology, applied in the field of cloth inspection machines, can solve problems such as the inability to provide cloth 3 stably and the length of elastic cloth 3 cannot be measured, and achieve the effects of easy storage and movement, pollution prevention, and increased operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

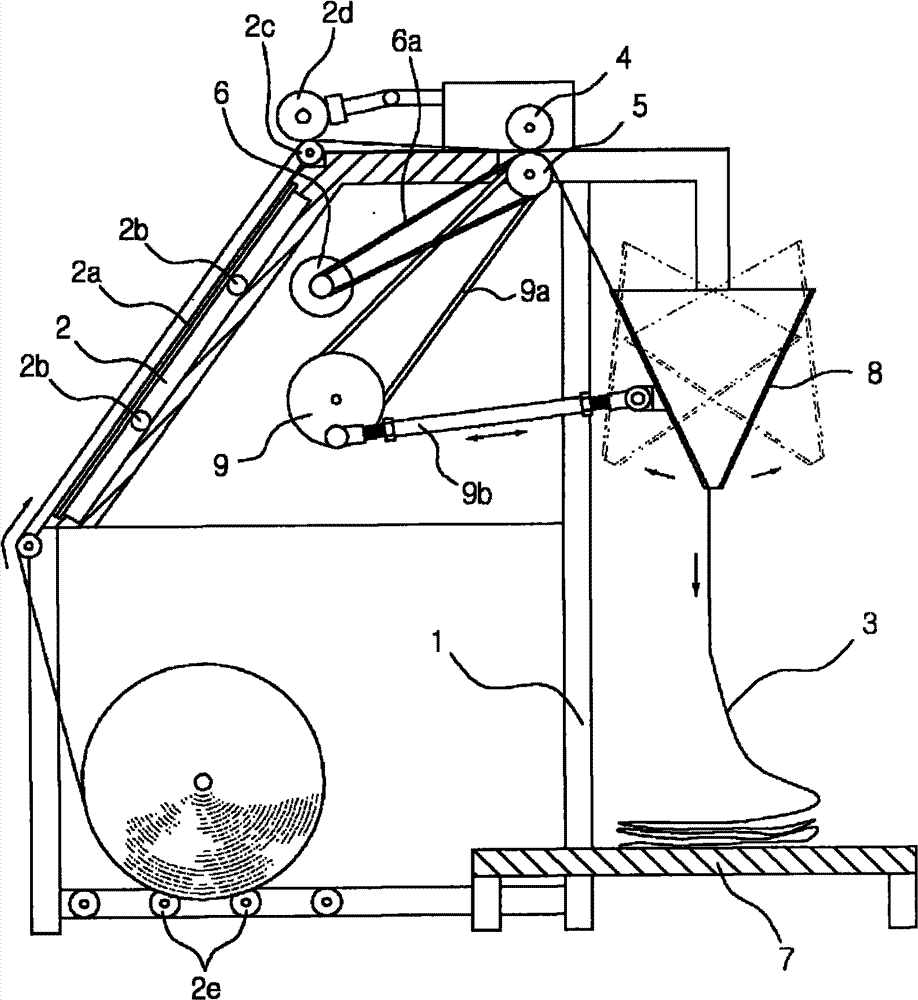

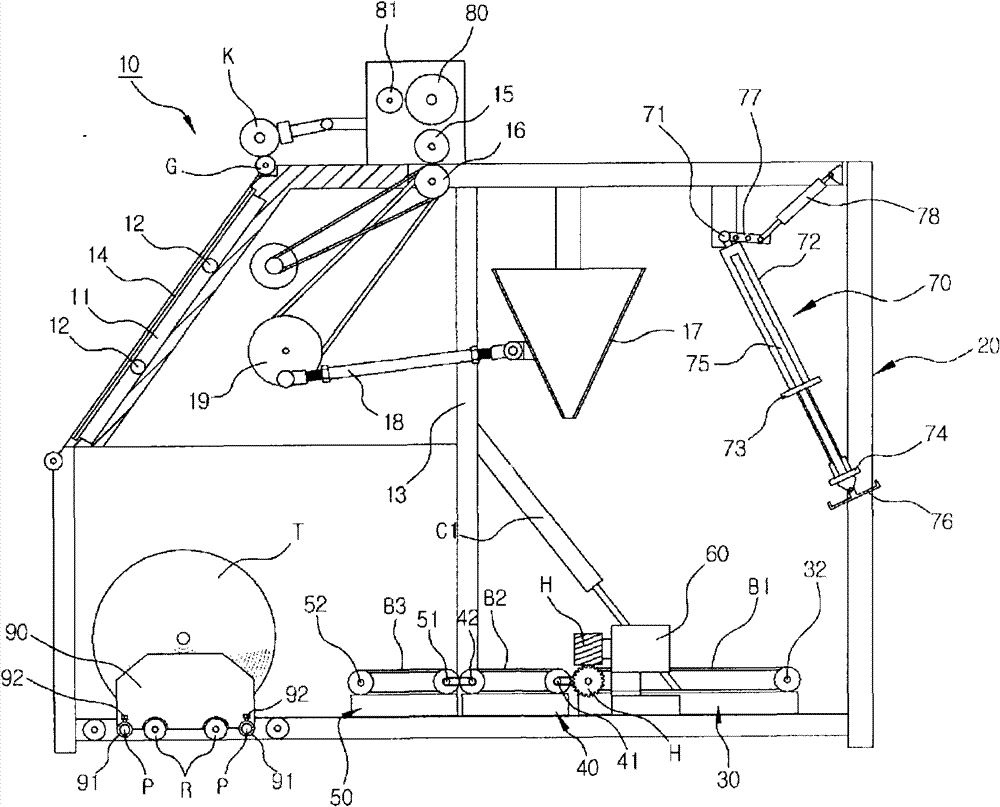

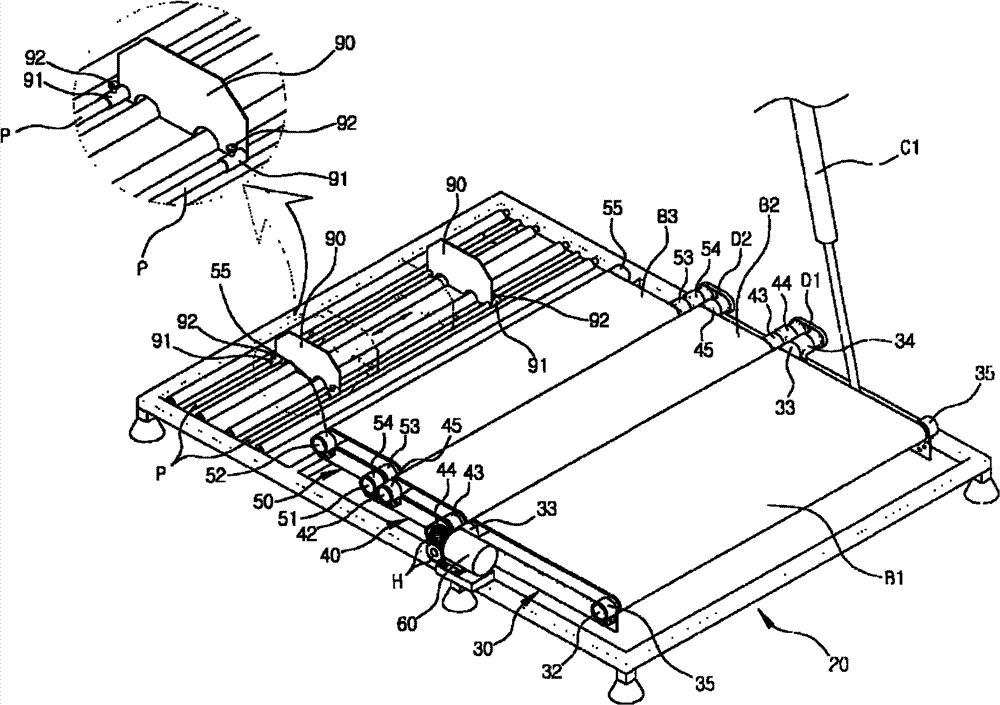

[0035] Hereinafter, the technical configuration of the present invention will be described with reference to the accompanying drawings.

[0036] Such as Figures 2 to 9 As explained in , the cloth inspecting machine includes: a tilting frame 14, which has a glass panel 11 and a fluorescent lamp 12 on a base 13; feed rollers 15, 16, which are installed on the base 13, for feeding cloth T; the operating base Seat 17, which is installed behind the base 13, is used to bind and bring together the cloth T in a zigzag shape; and a cam panel 19, which is used to drive and operate the base 17 using an eccentric lever 18, according to the cloth inspecting machine of the present invention. The cloth returning device comprises: a frame 20, which is installed behind the base 13; a first operating frame 30 and a second operating frame 30, 40, which are connected to the frame 20 using supporting shafts 31 and 41 respectively, so as to be placed on the operating frame Below 17, the first ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com