Road guardrail

A highway guardrail and guardrail technology, which is applied to roads, roads, road safety devices, etc., can solve the problems of weak impact resistance, easy accumulation of water, and insufficient impact resistance, and achieve the effect of protecting safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

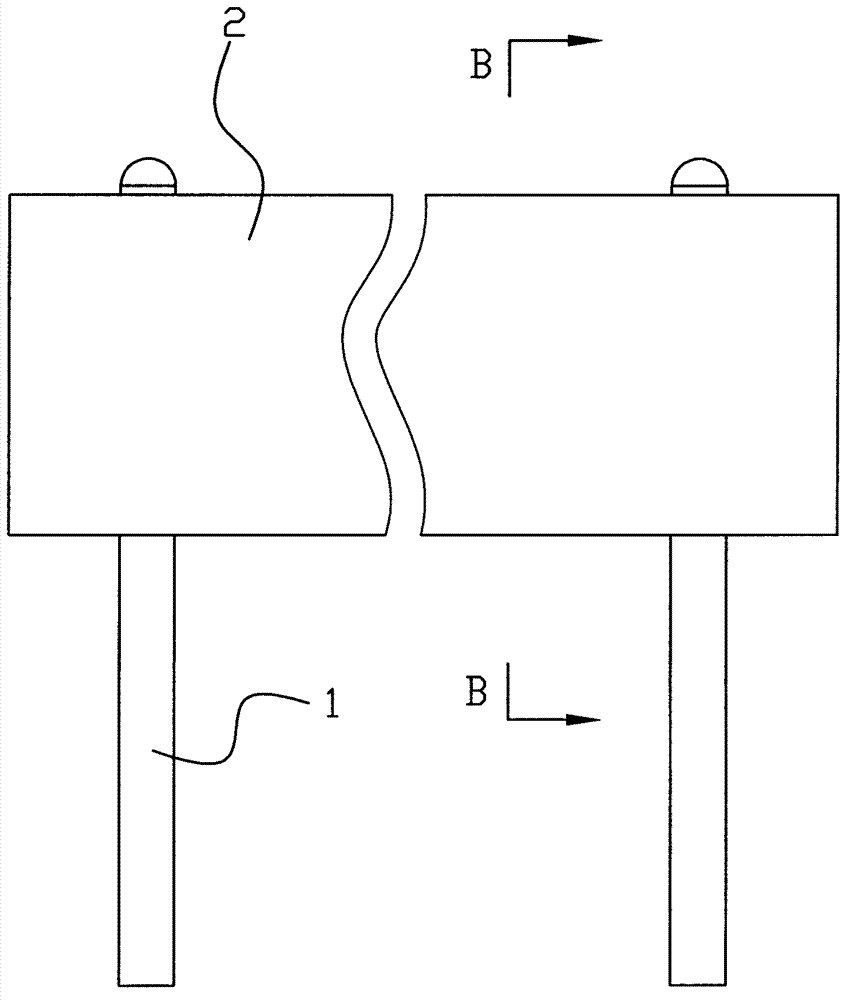

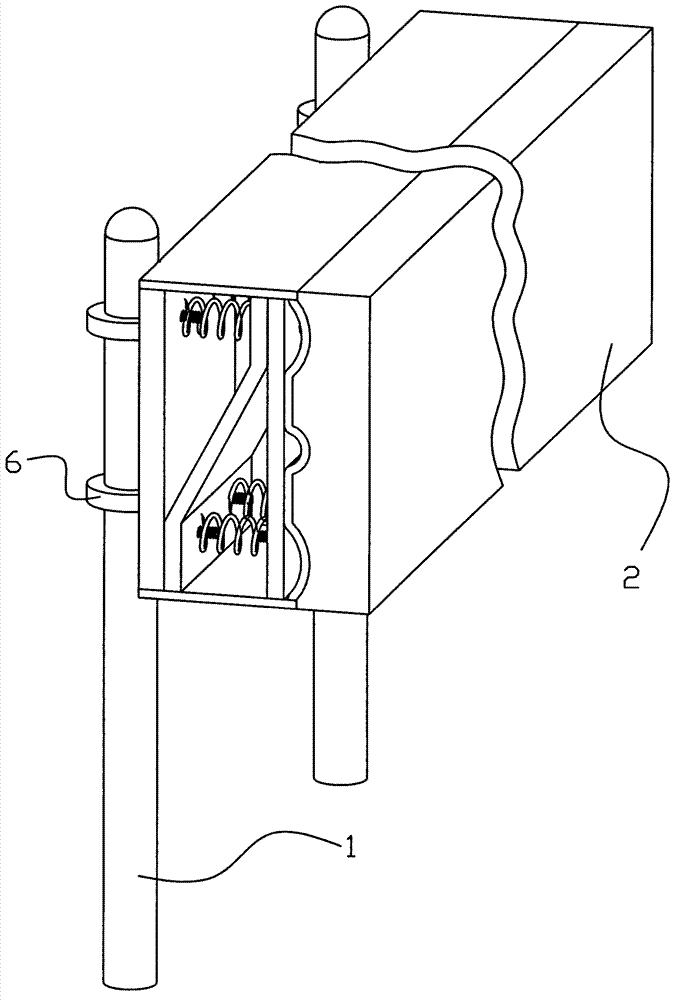

[0025] Embodiment one: Figure 1 to Figure 4 The highway buffer guardrail shown includes a guardrail post 1 and a guardrail body 2, the guardrail body 2 is installed on the guardrail post 1, and the guardrail body 2 includes a guard plate 3 made of elastic plastic, a corrugated steel plate 4, N Two elastic component units that are repeatedly arranged side by side, the guard plate 3 is closely attached to the corrugated steel plate 4, and the guard plate 3 and the corrugated steel plate 4 of this embodiment are pressed against the corrugated steel plate 4 by one-time injection molding. Plate 4 on. The corrugated steel plate 4 is vertically attached to one side of the N elastic components and fixed together with bolts, and the other side of the N elastic components is fixed on the guardrail column 1 through the connecting buckle 6, and can be fixed on the guardrail column when necessary. The guardrail body 2 is installed on both sides of 1, and an upper cover plate and a lower ...

Embodiment 2

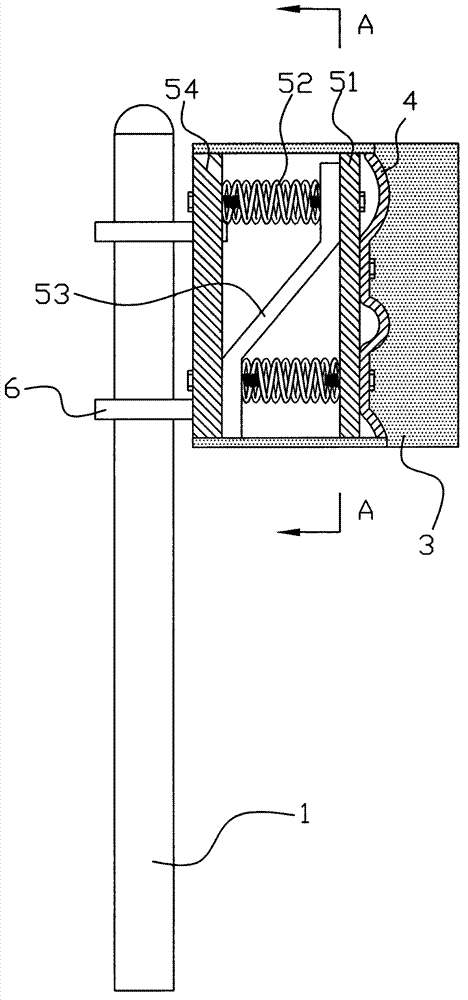

[0026] Example 2: Figure 5 and Figure 7 As shown in the highway buffer guardrail, the elastic assembly unit includes a first fixed plate 51, a spring steel plate 53 approximately in the shape of "Z", a second spring steel plate 56 approximately in the shape of "Z", and a third steel plate approximately in the shape of "Z". Spring steel plate 57, the second fixed plate 54, described second fixed plate and guardrail post 1 are fixed together, and described protective plate 3 is attached on the corrugated steel plate 4, and described corrugated steel plate 4 is connected with the first by fixing piece The fixed plate 51 is fixed together, and the spring steel plate 53 and the second spring steel plate 56 are vertically supported between the first fixed plate and the second fixed plate, and the upper parts of the spring steel plate 53 and the second spring steel plate 56 are The first fixed plate is fixed, and the spring steel plate 53 and the top of the second spring steel pla...

Embodiment 3

[0027] Embodiment three: Figure 8 and Figure 9As shown in the highway buffer guardrail, the elastic assembly unit is composed of two sets of components arranged side by side. The structure of the first set of components: includes a first fixed plate 51, a spring steel plate 53 approximately in the shape of "Z", and a spring steel plate in the shape of "Z". "The second spring steel plate 56, the third spring steel plate 57 in the shape of "Z", the second fixed plate 54, the second fixed plate is fixed with the guardrail column 1, and the guard plate 3 is attached to the wave-shaped On the steel plate 4, the corrugated steel plate 4 is fixed together with the first fixed plate 51 through a fixing member, and the spring steel plate 53 and the second spring steel plate 56 are vertically supported between the first fixed plate and the second fixed plate In between, the upper parts of the spring steel plate 53 and the second spring steel plate 56 are fixed to the first fixed plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com