Underground repetitive shock irritation device and shock irritation method for oil and gas well drilling

A technology for oil and gas drilling and drilling tools, which is applied to the field of repeated shock-initiating devices for oil and gas drilling downholes, can solve the problems of restricted deep application, limited distance, etc., and achieve the effects of easy to realize shock initiation, prolonging service life, and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

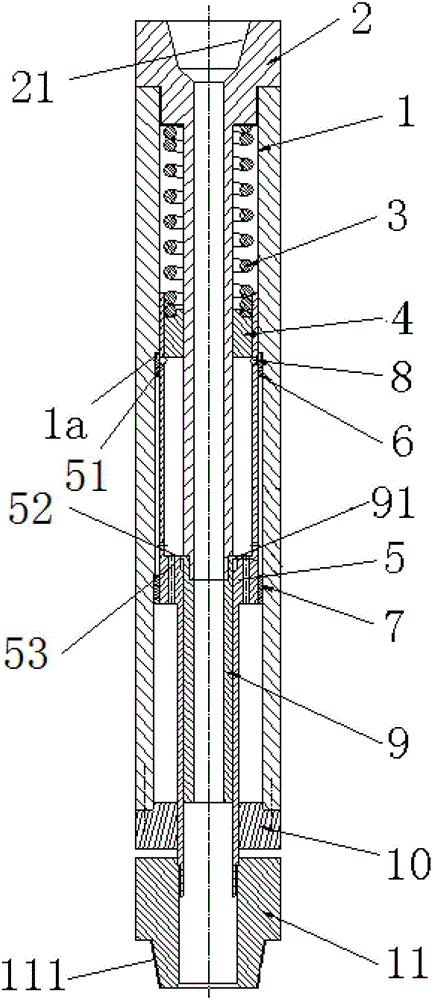

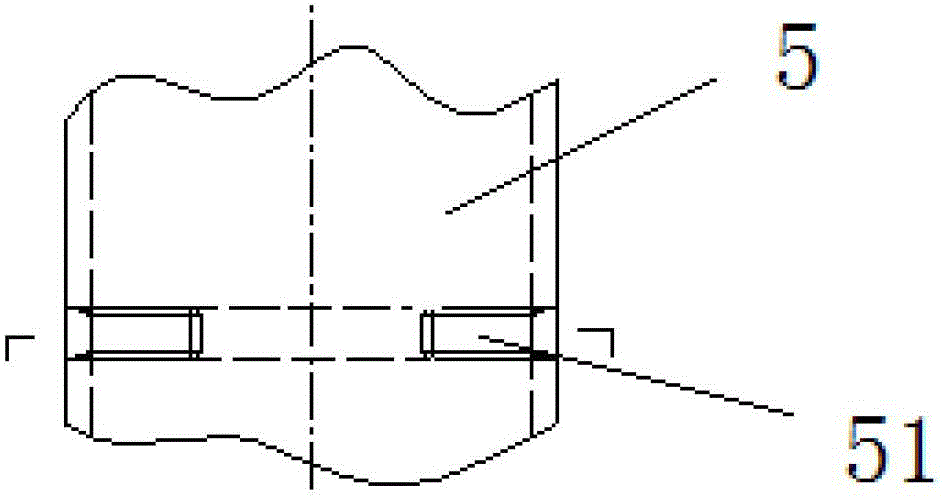

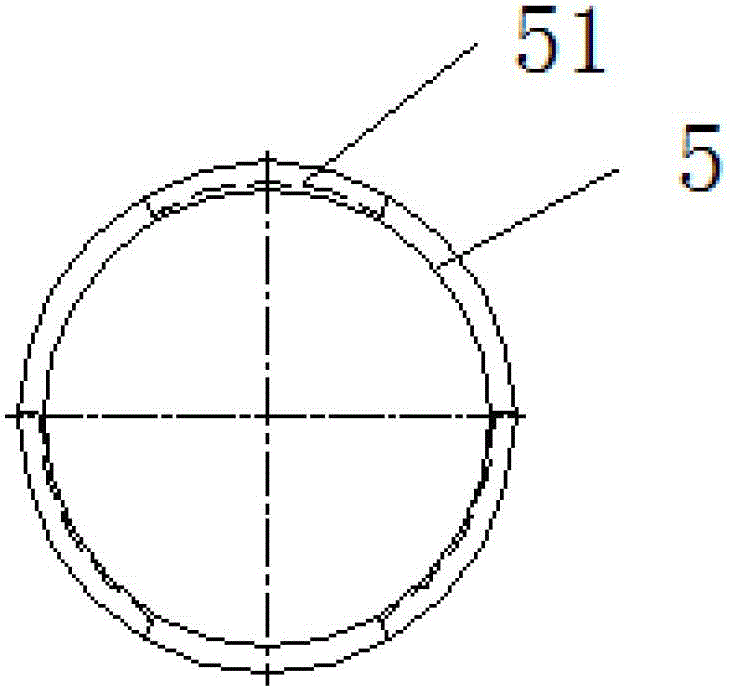

[0022] Such as figure 1 As shown, the device of the present invention includes an outer cylinder 1, and an upper joint 2 with a central hole is inserted in the outer cylinder 1. The central hole at the top of the upper joint 2 is provided with an internal thread 21 connected with the upper drilling tool, and the upper joint 2 passes through the Threaded on the upper mouth of the outer cylinder 1. A spring 3 is sheathed between the middle part of the upper joint 2 and the outer cylinder 1 , an impact hammer 4 is connected to the bottom of the spring 3 , and a sleeve 5 is slidably sandwiched between the impact hammer 4 and the outer cylinder 1 . The middle part of the inner wall of the outer cylinder 1 has a shoulder 1a with an enlarged inner diameter, and a thrust ring 6 is slidably arranged on the inner wall of the outer cylinder 1 below the shoulder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com