Rebound apparatus calibrating device and using method thereof

A technology for verification devices and rebound hammers, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve the problems that the verification of rebound hammers is not universal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

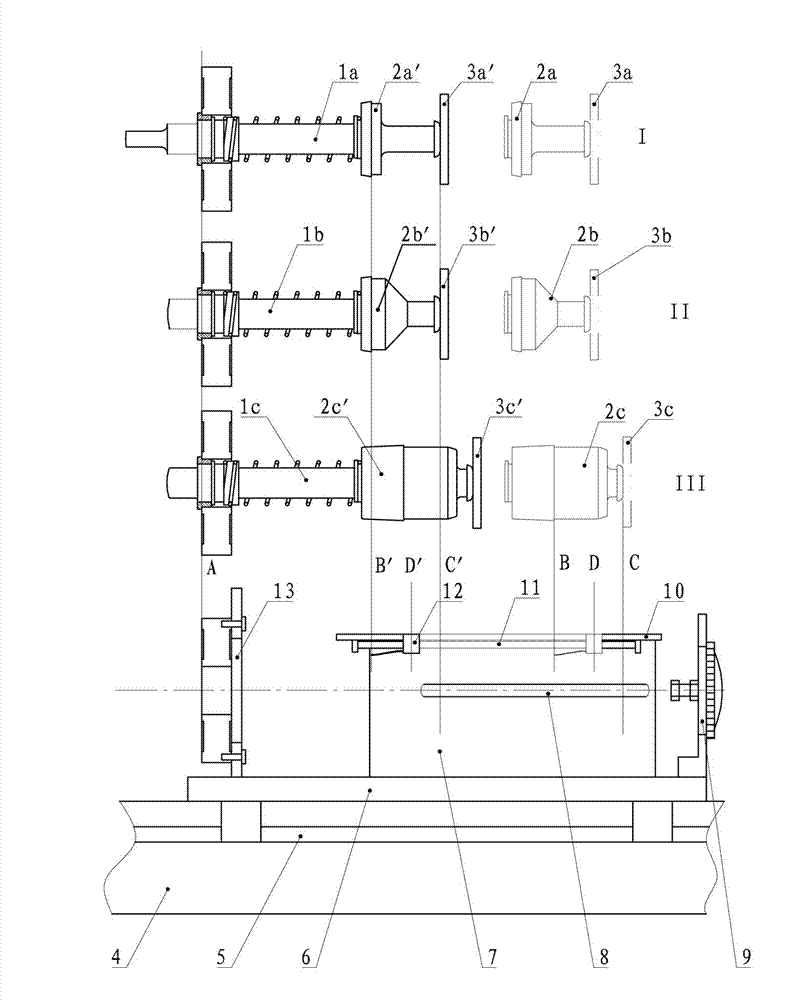

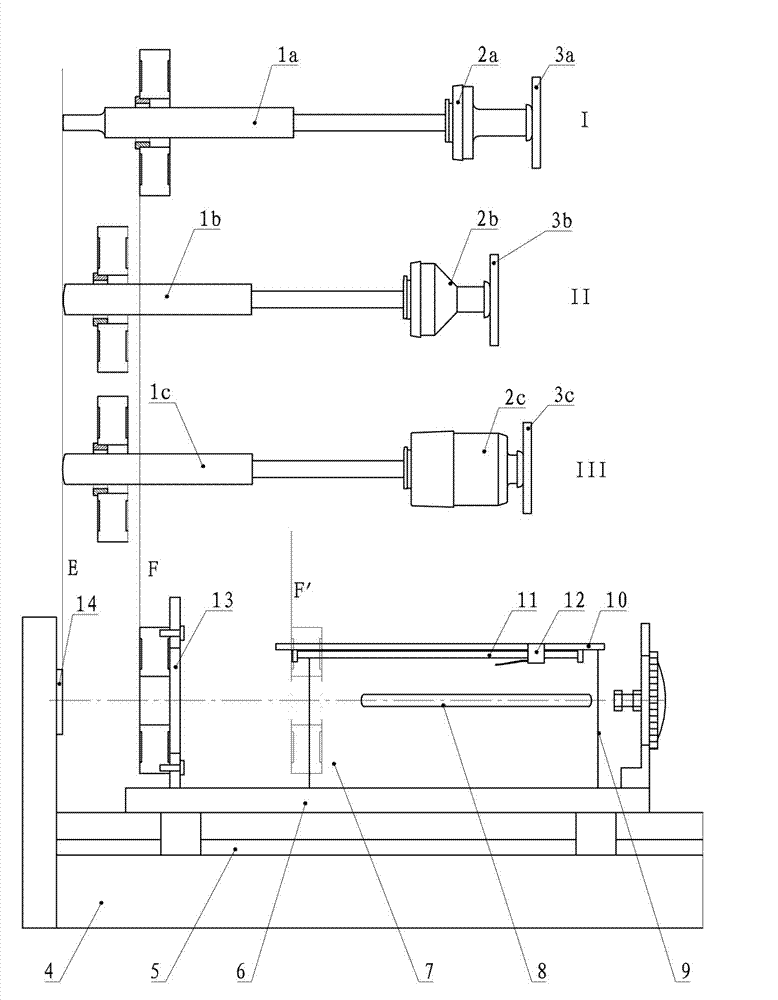

[0019] Example 1: This example is a hammer verification device compatible with the hammer verification of L20 hammer I, L75 hammer II and M225 hammer III. Its structure is as figure 1 , 2-1 , 2-2, 2-3, and 3.

[0020] The differences of the main components of the three types of rebound hammers:

[0021] The length of the extension spring seat from the top of the ejection rod: M225 and L75 are the same, and L20 is 20mm longer than M225 and L75 (there is a 20mm extension at the front end);

[0022] The extension spring seat has the same length;

[0023] Working length (free length) of extension spring: both are 61.5mm, that is, when the extension spring is in a free state, the length from the front end of the spring hammer to the fixed end of the extension spring seat is the same;

[0024] Tensile length of tension spring: both are 75mm;

[0025] Flange thickness: the same;

[0026] The diameter of the step of the pointer of the bounce hammer is the same;

[0027] The pos...

example 2

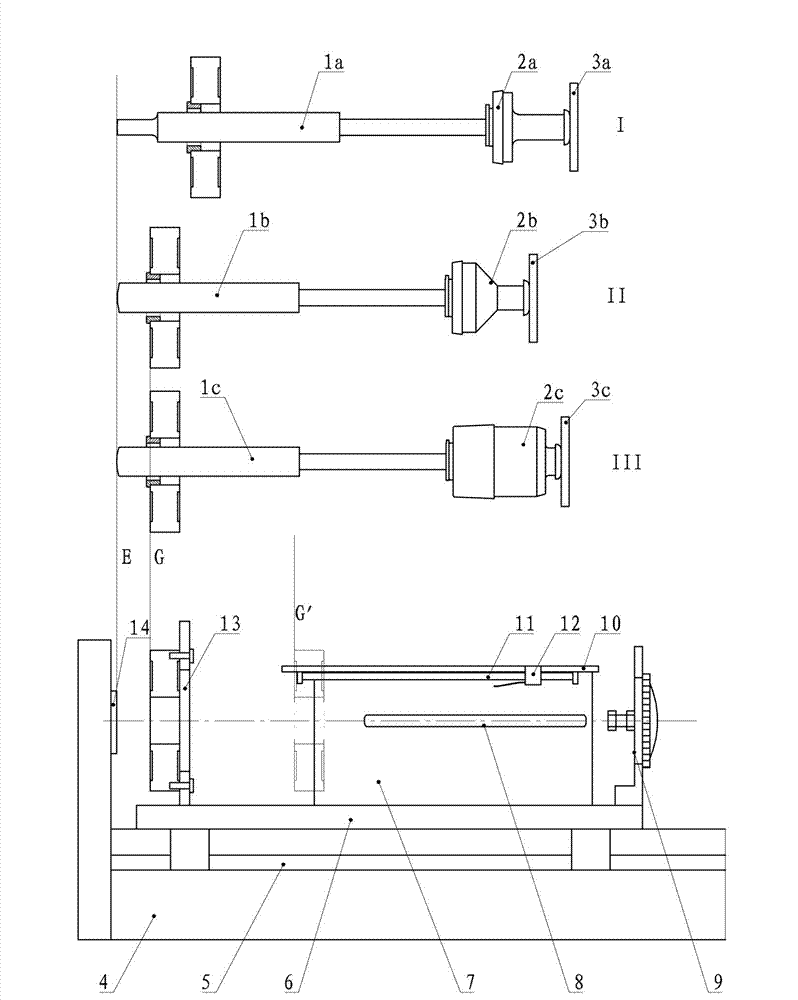

[0041] Example 2: This example is a hammer verification device compatible with the verification of two types of hammers, such as the M225 hammer and the H550 hammer.

[0042] The difference between the main components of the two types of rebound hammers:

[0043] The length of the top of the ejection rod protruding from the spring seat: H550 type is 1mm longer than M225 type;

[0044] The extension spring seat has the same length;

[0045] Extension spring working length (free length): M225 type is 61.5mm, H550 type is 86mm;

[0046] Tensile length of tension spring: 75mm for M225 type and 100mm for H550 type;

[0047] Flange thickness: the same;

[0048] The diameter of the step of the pointer of the bounce hammer is the same;

[0049] The position of the pointer step plane from the front face of the hammer: the H550 type is 8mm behind the M225 type;

[0050] The total length of the bullet hammer (front and rear end faces): H550 type is 7.5mm longer than M225 type;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com