Touch structure, manufacturing method thereof and display device

A production method and touch technology, applied in the direction of instruments, electrical digital data processing, electrical components, etc., can solve the problems of poor mechanical reliability of flexible panels, large-scale production, loss of touch function, and accelerated products, so as to improve quality and Use performance, prevent touch failure, reduce the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following description of the embodiments refers to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "top", "bottom", etc., are only for reference to the attached drawings. direction. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

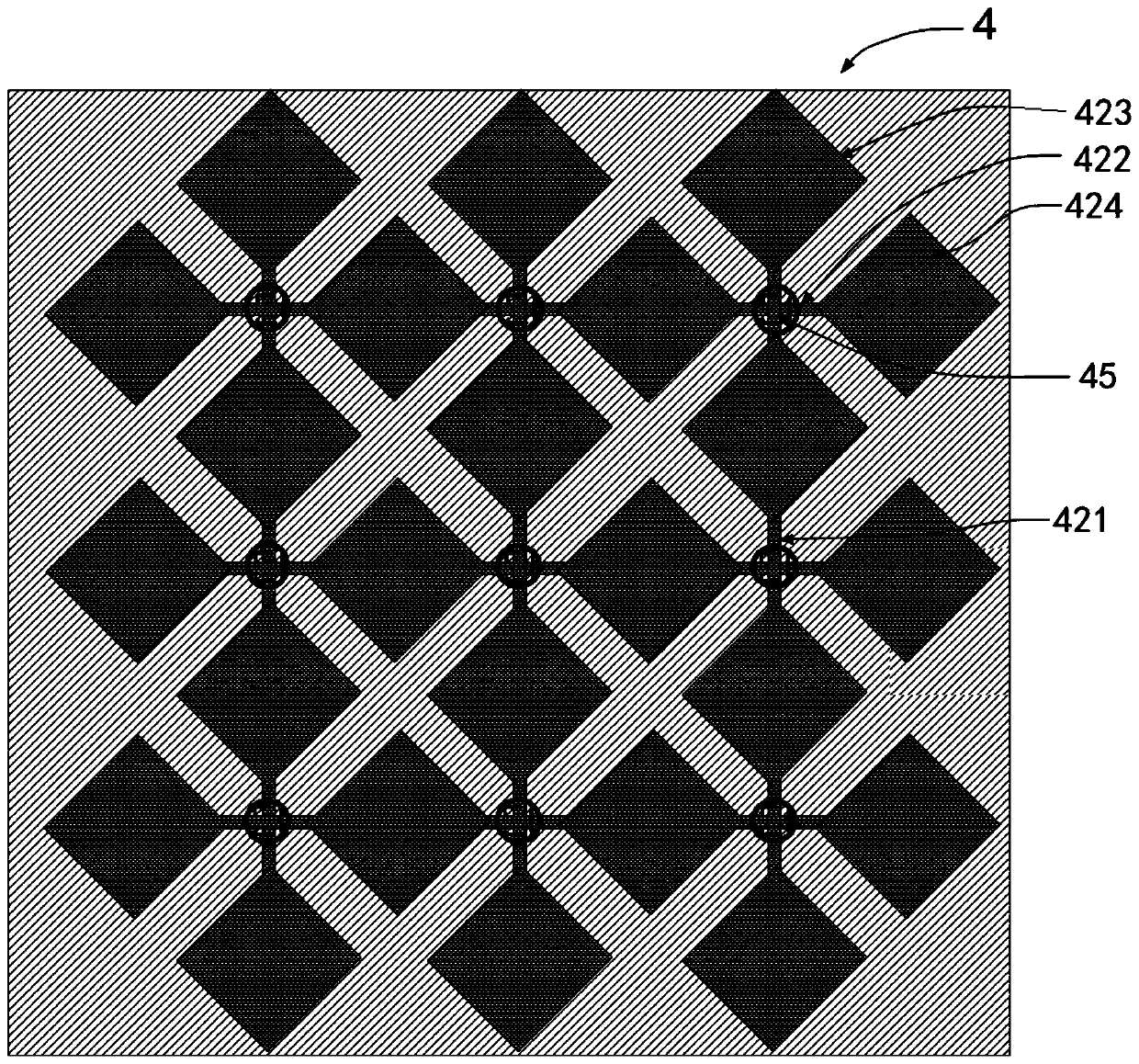

[0036] Such as Figure 6 As shown, in one embodiment, the touch structure 4 of the present invention includes an insulating layer 41 , a metal grid 42 , an insulating filling layer 43 and a protective layer 44 .

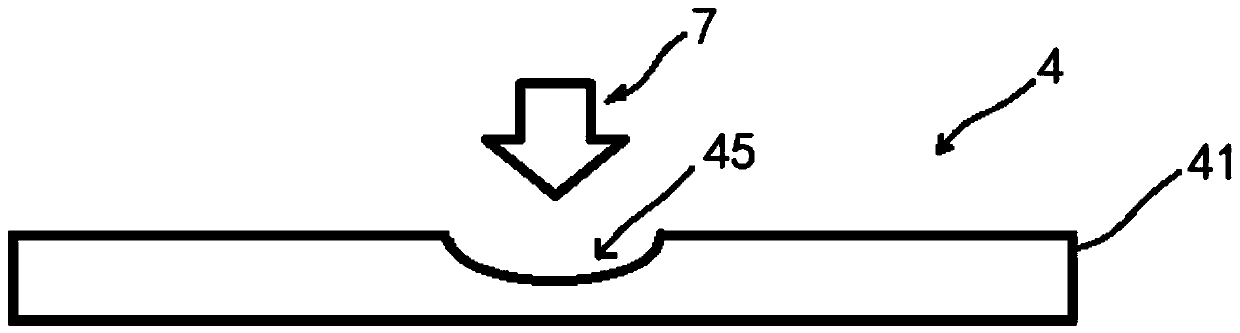

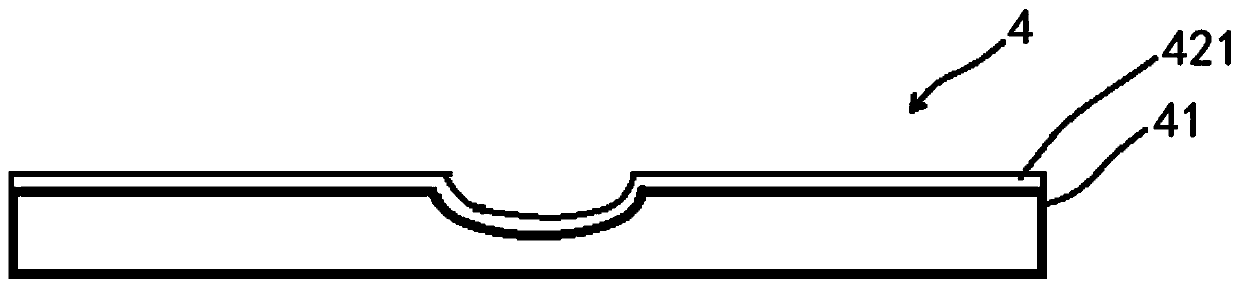

[0037] Such as figure 2 As shown, one side of the insulating layer 41 has several grooves 45 , and only one of the grooves 45 is shown in the figure to clearly show the enlarged structure of the groove 45 . In this embodiment, the insulating layer 41 is a flexible inorg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com