Actuator including mechanism for converting rotary motion to linear motion

A linear motion, actuator technology, applied in non-rotational vibration suppression, shock absorbers, mechanical equipment, etc., to achieve the effect of less complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

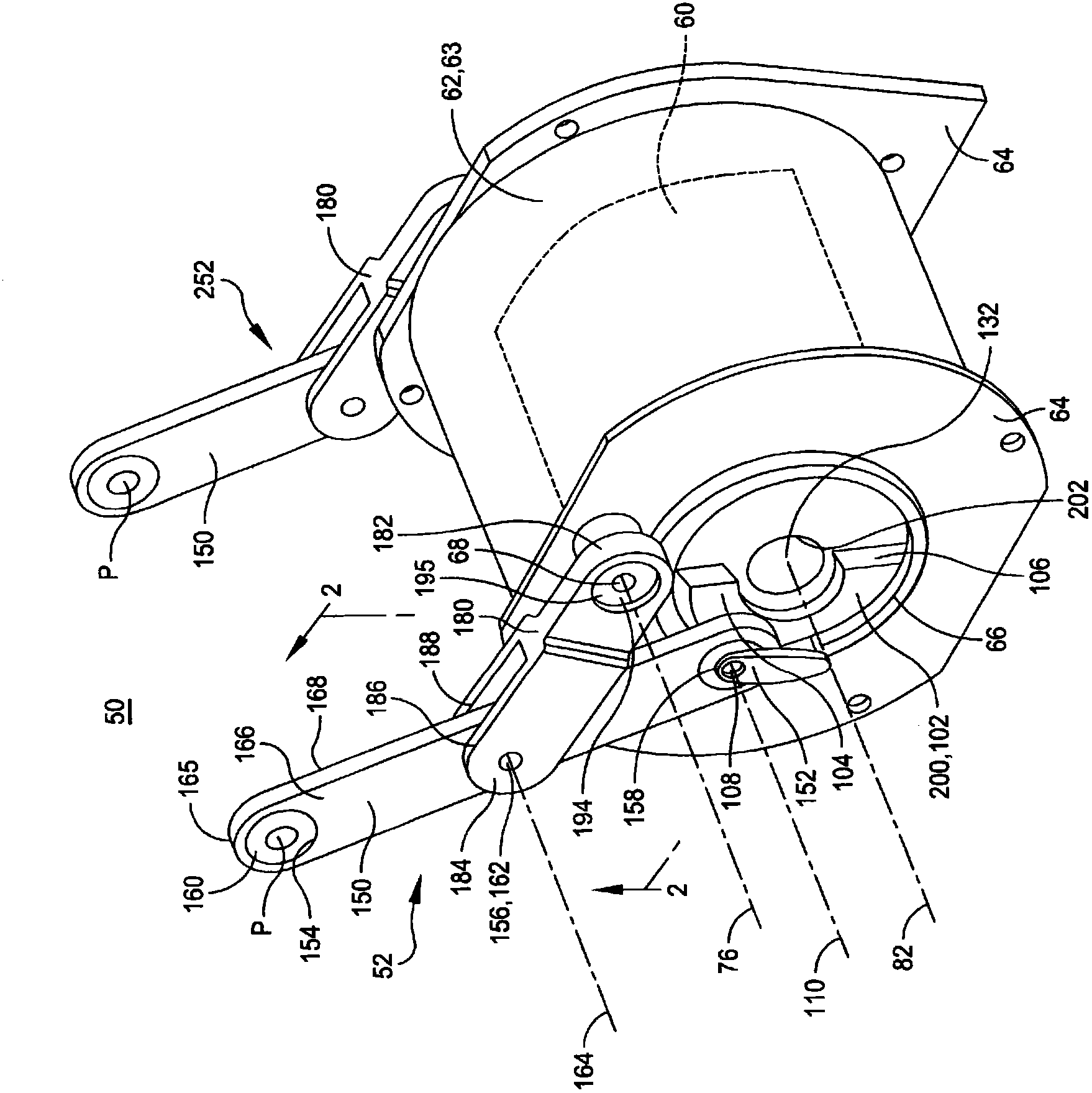

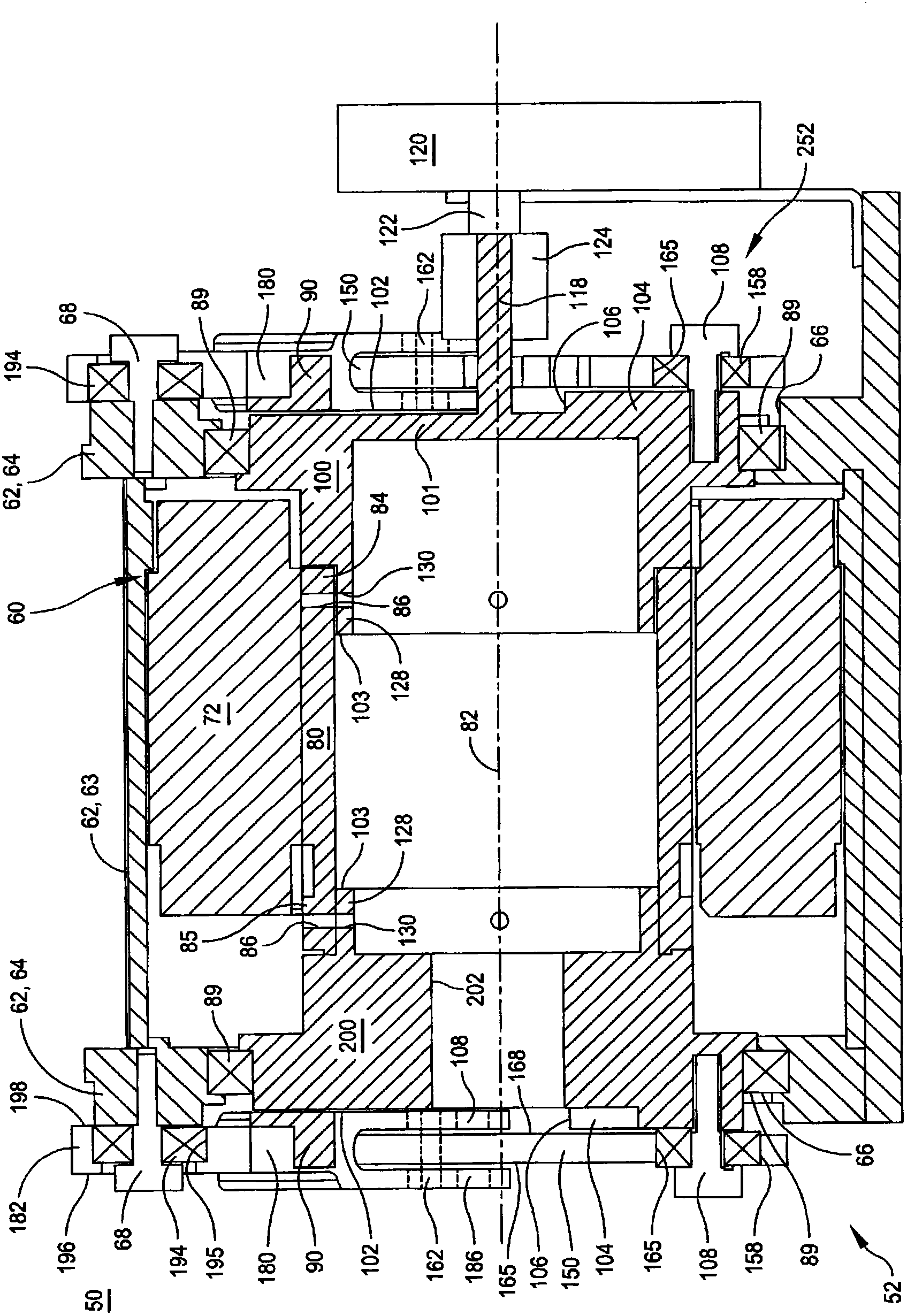

[0031] As will be described in more detail below, an actuator comprising a rotary drive combined with a linkage having specific mechanical characteristics provides conversion of rotary to linear motion in a manner well suited to applications where Maximize linear travel range in limited space.

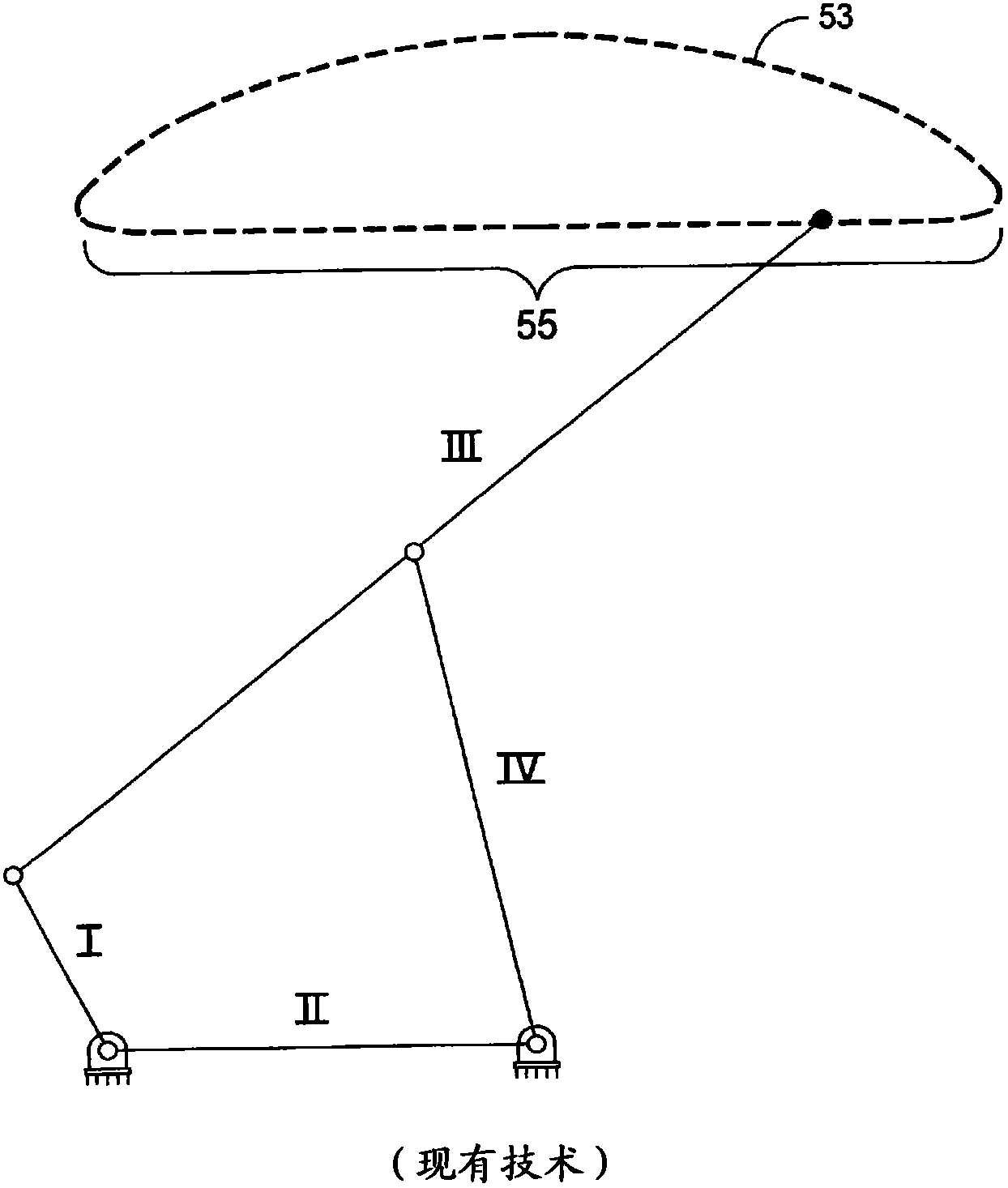

[0032] figure 1 , figure 2 , Figure 4 and Figure 6 An actuator having this desired feature in the form of a rotary motor and a four bar linkage is shown. exist Figure 16 An alternative implementation of the actuator is shown in . Figure 5 , Figure 7 and Figure 8 The mechanical characteristics of the actuator are illustrated, including the ratio of the displacement at a predetermined point on the link to the angular displacement of the rotary motor, and a constant force at a predetermined point for both angular displacements, and a constant torque for the rotary motor The output is the displacement of the predetermined point in the linear portion of the motion of the link 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com