Locking pressurizing hole of internal fixed frame

A technique of pressurizing holes and fixing frames, which is applied in the directions of internal fixators, fixators, internal bone synthesis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

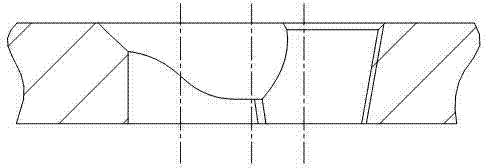

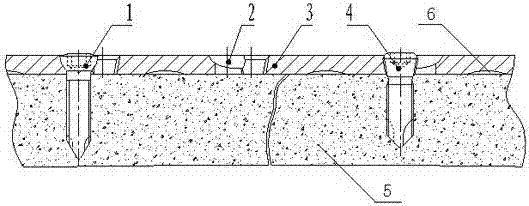

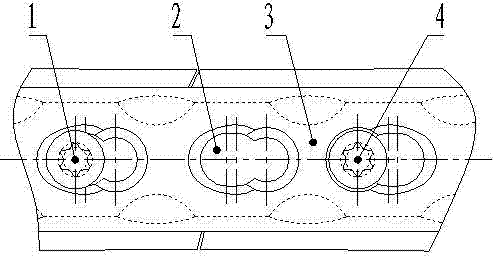

[0012] Embodiment 1, a kind of internal fixation frame locking pressure hole, refer to figure 1 , figure 2 , image 3 As shown, the hole is partially overlapped by a locking hole and a pressure hole. The locking hole is a tapered threaded through hole, and the pressure hole is an unthreaded through hole with an arc-shaped pressure slope. The locking pressure hole 2 Evenly distributed on the internal fixator 3 with a 0.3mm-0.5mm gap 6 with the bone; through the locking pressure hole slot, the locking screw 4 and the end of the pressure bone screw 1 enter the bone 5, locking the pressure hole 2, locking screw 4. The pressurized bone screw 1, the internal fixator 3 and the bone 5 constitute a non-contact fixed frame system.

[0013] During use, by locking the pressure hole, the end of the locking screw uses the locking screw to fix the internal fixator on the fracture site, and the pressure screw 1 pressurizes the fracture end, and the internal fixator is kept in contact with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com