Pick and Place Devices for Test Handlers

A technology for testing sorters and pick-and-place devices, used in semiconductor/solid-state device testing/measurement, sorting, electrical components, etc. Ensuring design freedom, reducing production costs, and easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

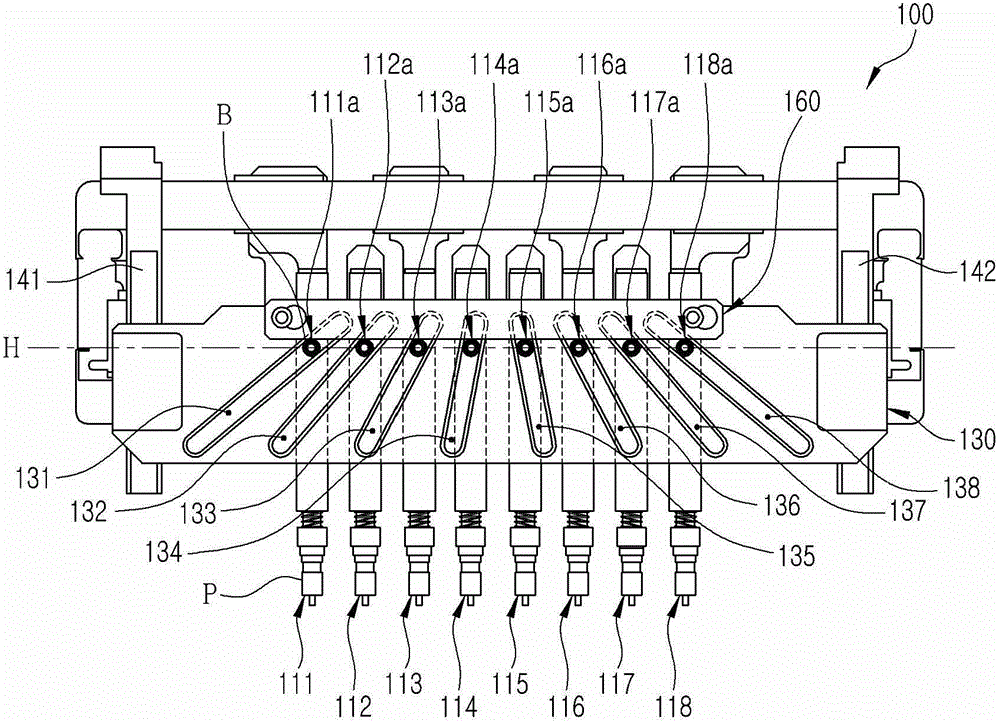

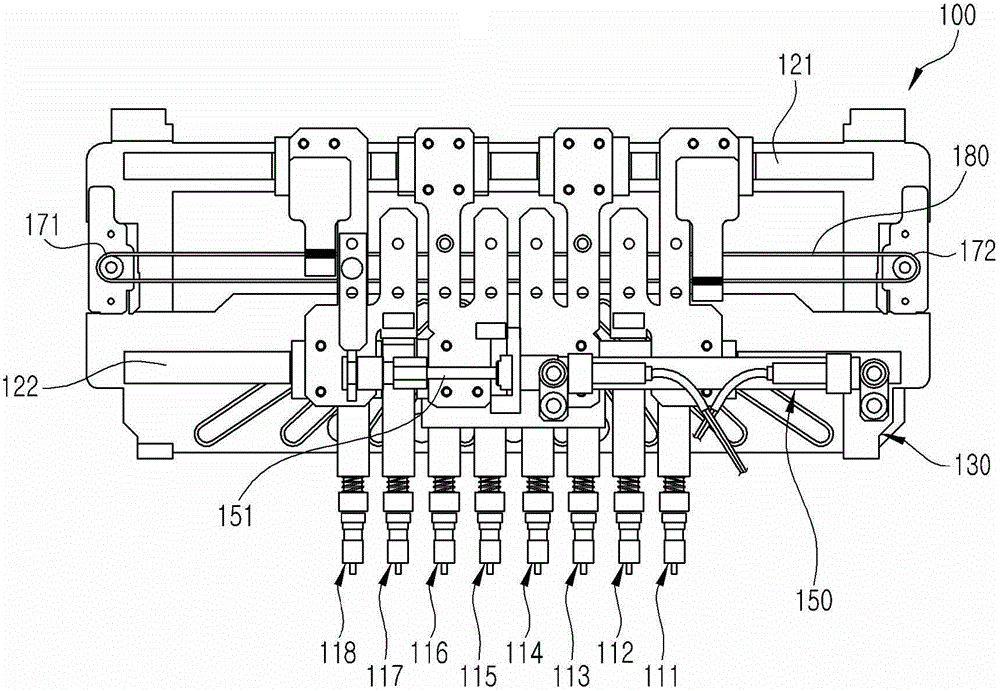

[0042] figure 1 and figure 2 It is a front view and a rear view of a pick-and-place device 100 for a test handler (hereinafter simply referred to as "pick-and-place device") according to the first embodiment of the present invention.

[0043] like figure 1 and figure 2 As shown, the pick-and-place device 100 includes eight picker modules 111 to 118 , a pair of first guide rails 121 , 122 , a cam plate 130 , a pair of second guide rails 141 , 142 , a cylinder 150 , a stopper 160 and the like.

[0044] The eight picker modules 111 to 118 are respectively movable horizontally and each have at least one picker P for gripping a semiconductor component. Reference, figure 1 and figure 2 Restricted by the front view and the rear view, it is only shown that there is only one picker P on one picker module 111 / 112... / 118, but according to the implementation needs, multiple The picker P is unquestionable, in fact, in this embodiment, it is also assumed that one picker module 111 / ...

no. 2 example

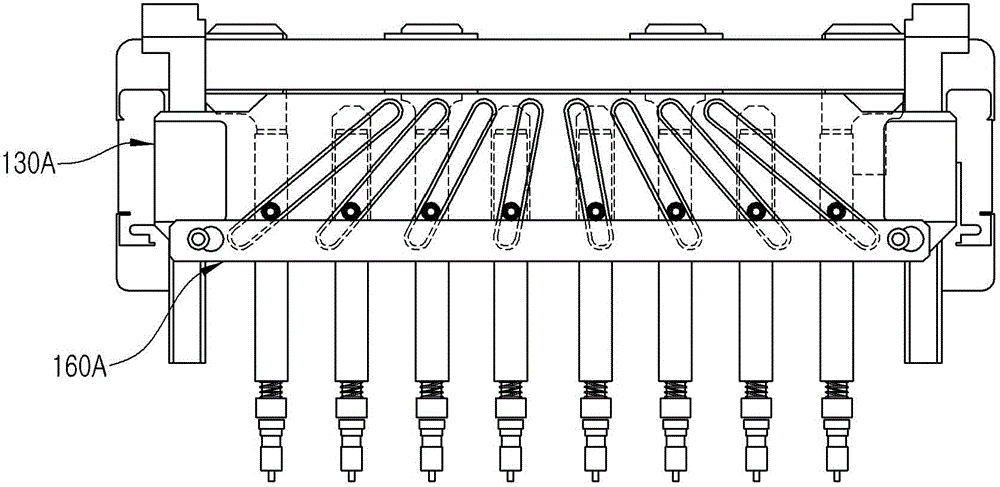

[0065] Figure 8a and Figure 8b The cam plate 830 and the stop member 860 applied to the pick-and-place device of the second embodiment of the present invention are respectively shown.

[0066] like Figure 8a As shown, the cam plate 830 of this embodiment has a plurality of incomplete first open cam grooves 831a to 838a with open upper sides, and has a Figure 8b The reinforcing rib R of the limiting part 860. In addition, a step is formed on the surface of the cam plate 830 on which the stopper 860 is installed, so that the stopper 860 can be properly installed.

[0067] and, if Figure 8b As shown, the limiting member 860 of this embodiment has a plurality of second open cam grooves 861 a to 868 a with open lower sides.

[0068] That is, the first open cam grooves 831a / ... / 838a and the second open cam grooves 861a / ... / 868a are opened toward the facing sides, respectively, so that as Figure 9 As shown, when the stop member 860 is set, the first open cam groove 831a / ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com