Rubber air spring for high-speed railway

A rubber air spring and rubber technology, which is applied in the direction of gas shock absorbers, etc., can solve the problems of fatigue resistance performance and large impact, and achieve the effects of small internal friction, good anti-noise effect and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

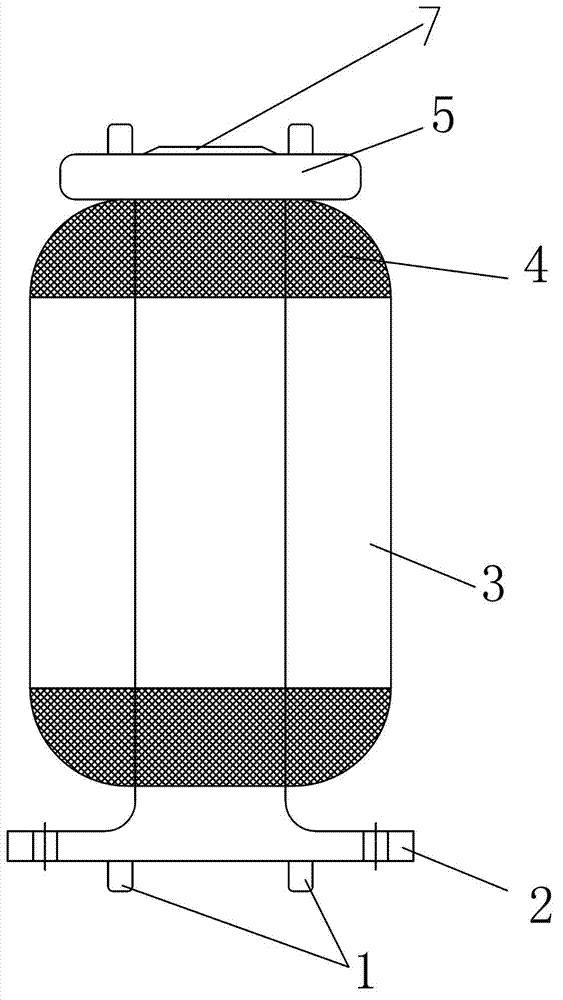

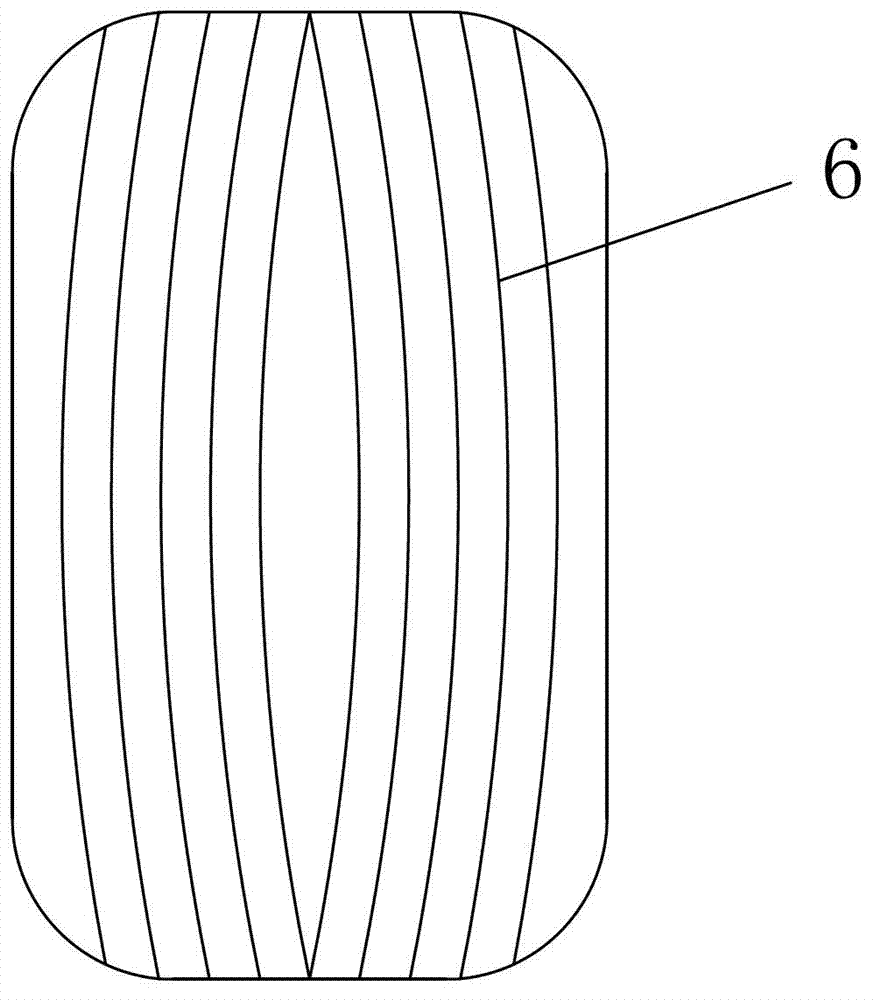

[0014] Such as figure 1 , figure 2 Among them, including positioning pin 1, support seat 2, rubber capsule 3, rubber surface 4, cover plate 5, orifice 7.

[0015] Such as figure 1 As shown, the present invention is a rubber air spring for high-speed rail, comprising a support seat 2, a rubber capsule 3, a rubber surface 4, a cover plate 5, and an orifice 7. The bottom of the rubber capsule 3 is fixed with a support seat 2, and the cover plate 5 is fixed on the rubber The top of the capsule 3 is provided with rubber ribs 6 on the surface of the inner wall of the rubber capsule 3 . The lower surface of the support base 2 and the upper surface of the cover plate 5 are provided with screw steel pipe positioning pins 1 respectively, and the positioning pins 1 make the rubber air spring effectively connected to the mechanical force point, ensuring that the spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com