Patents

Literature

49results about How to "Good anti-noise effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

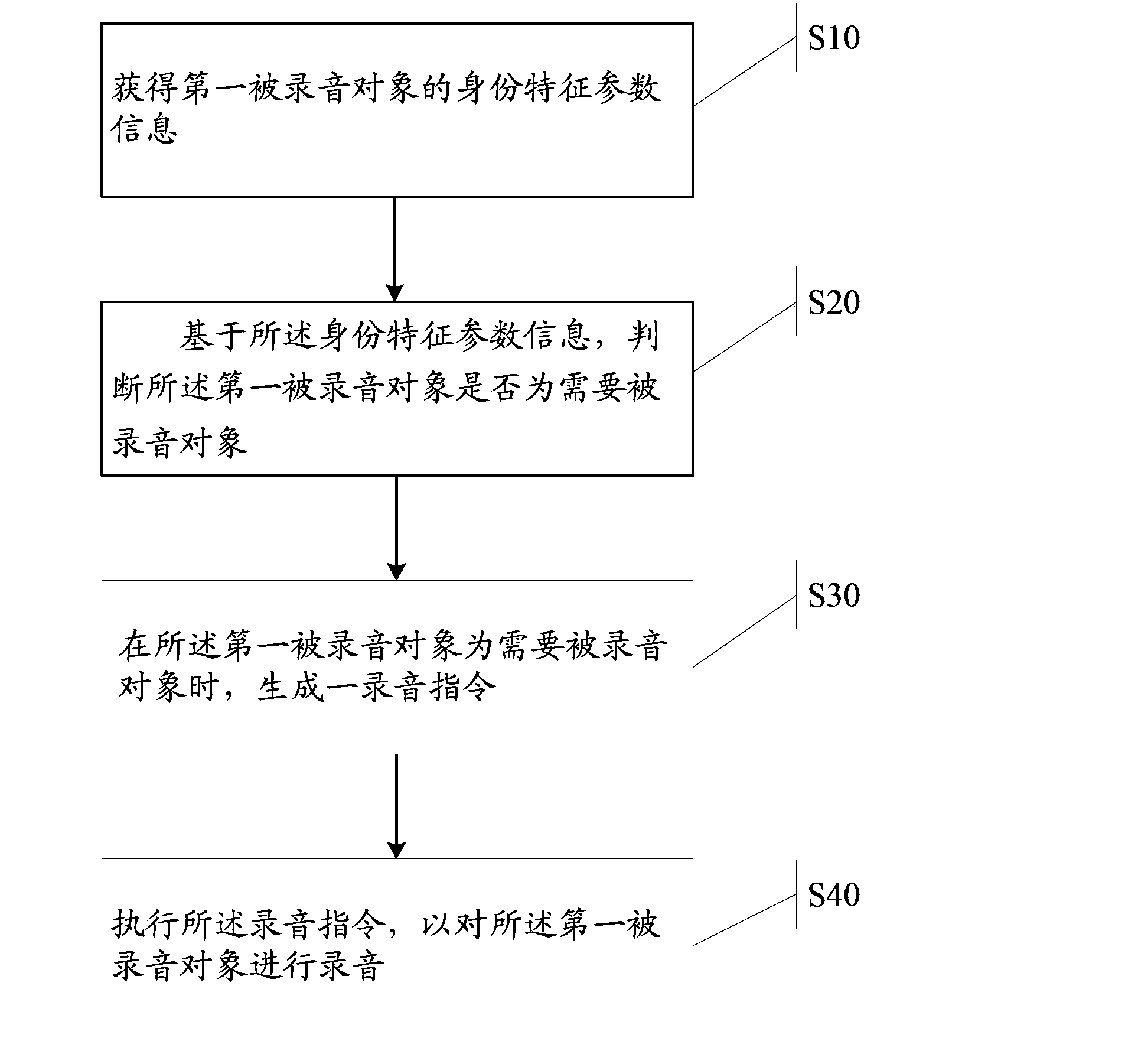

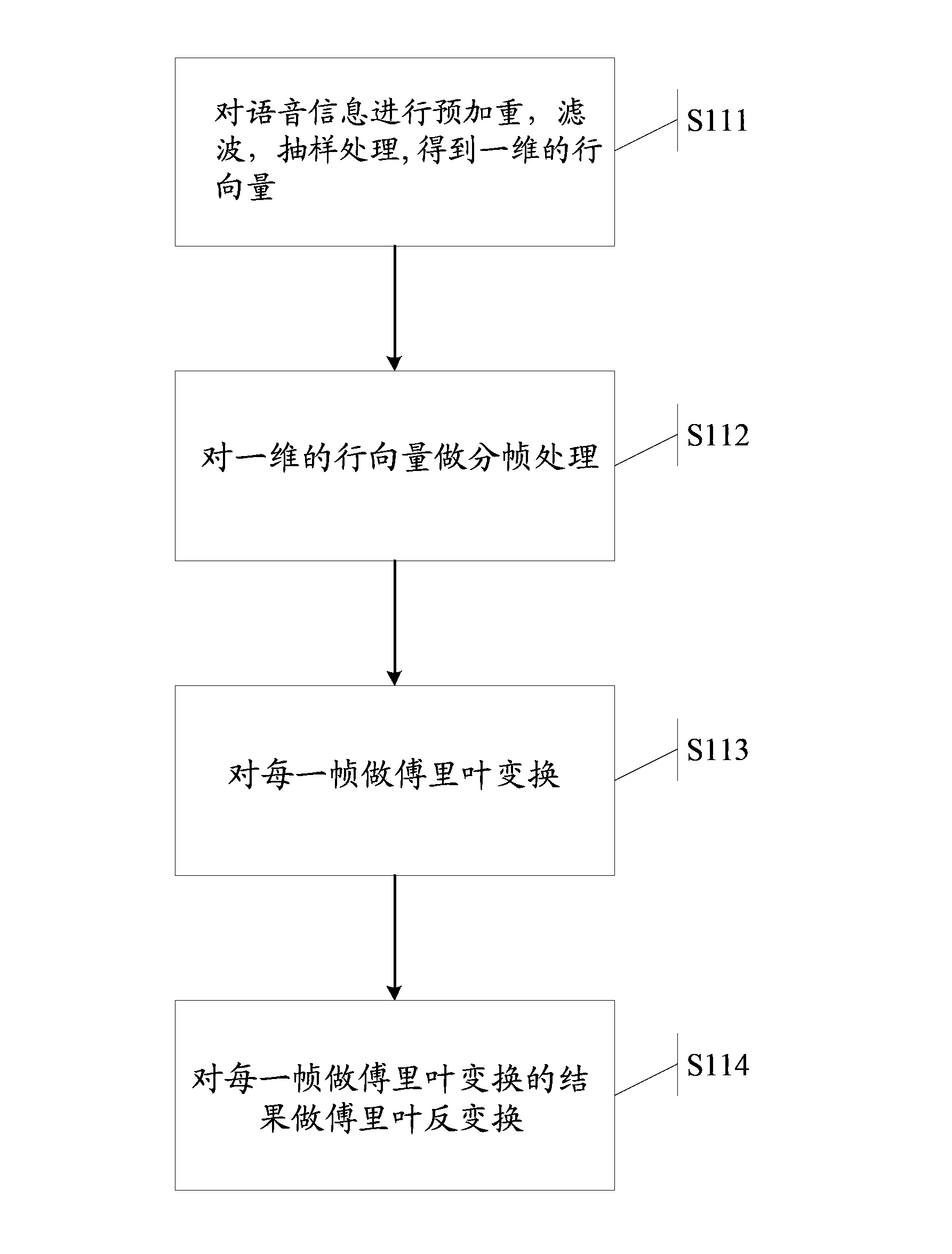

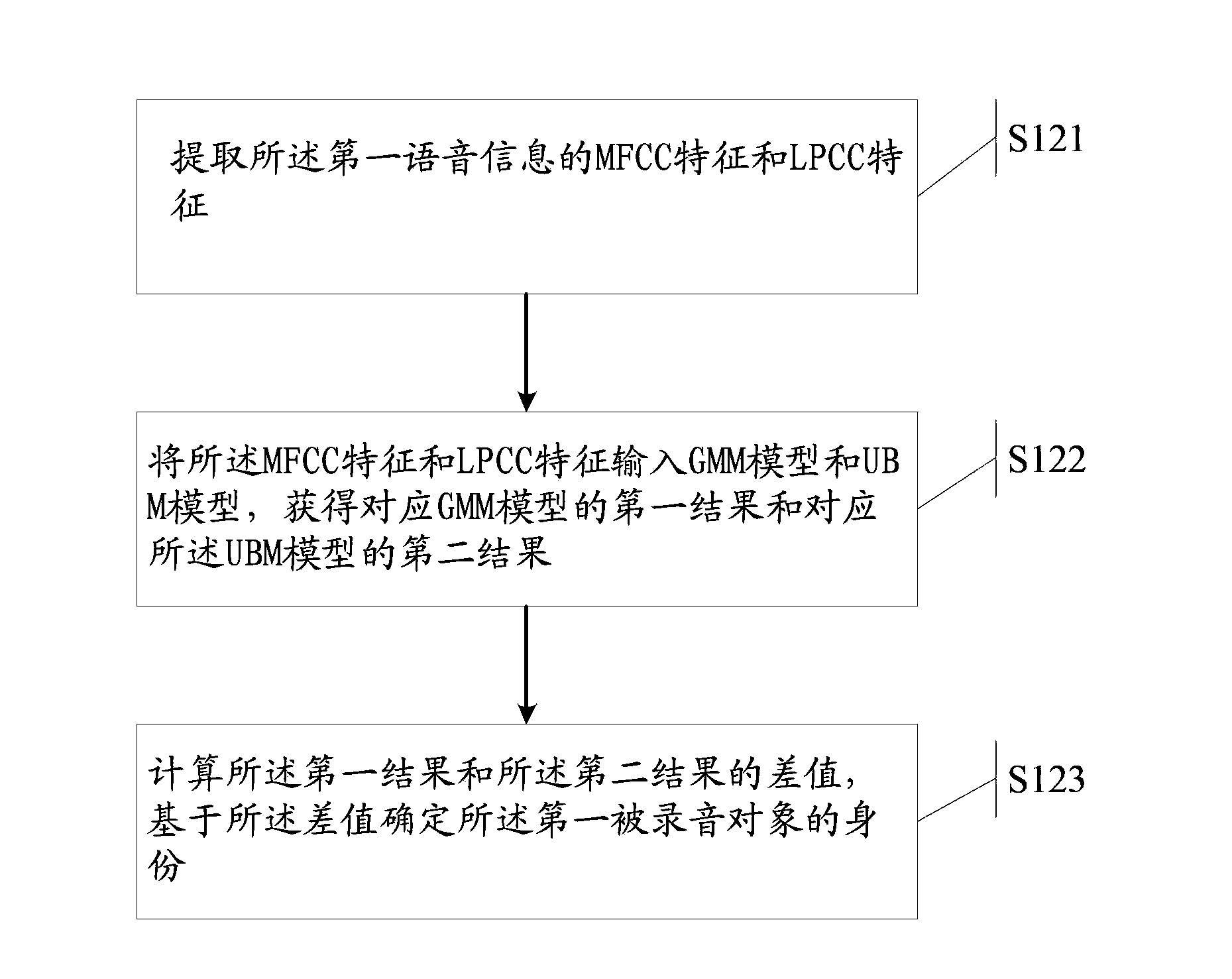

Automatic recording method and device

ActiveCN103391347ARealization of recordingSolve technical problems that cannot recordAutomatic call-answering/message-recording/conversation-recordingRecord information storageFunctional moduleComputer science

The invention discloses an automatic recording method and device. The automatic recording method and device are used for solving the technical problem that important content can be missed and not recorded in the prior art. The automatic recording method includes the following steps that identity characteristic parameter information of a first recorded object is obtained, whether the first recorded object is the object needing recording or not is judged based on the identity characteristic parameter information. When the first recorded object is the object needing recording, a recording instruction is generated. The recording instruction is executed and a module with the recording function is turned on to record the first recorded object.

Owner:ZTE CORP

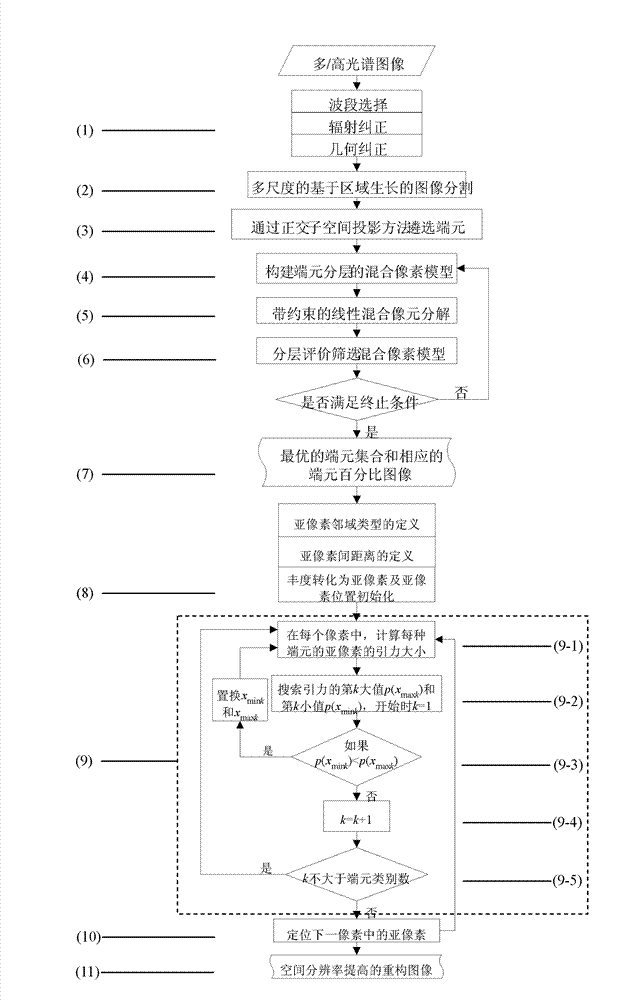

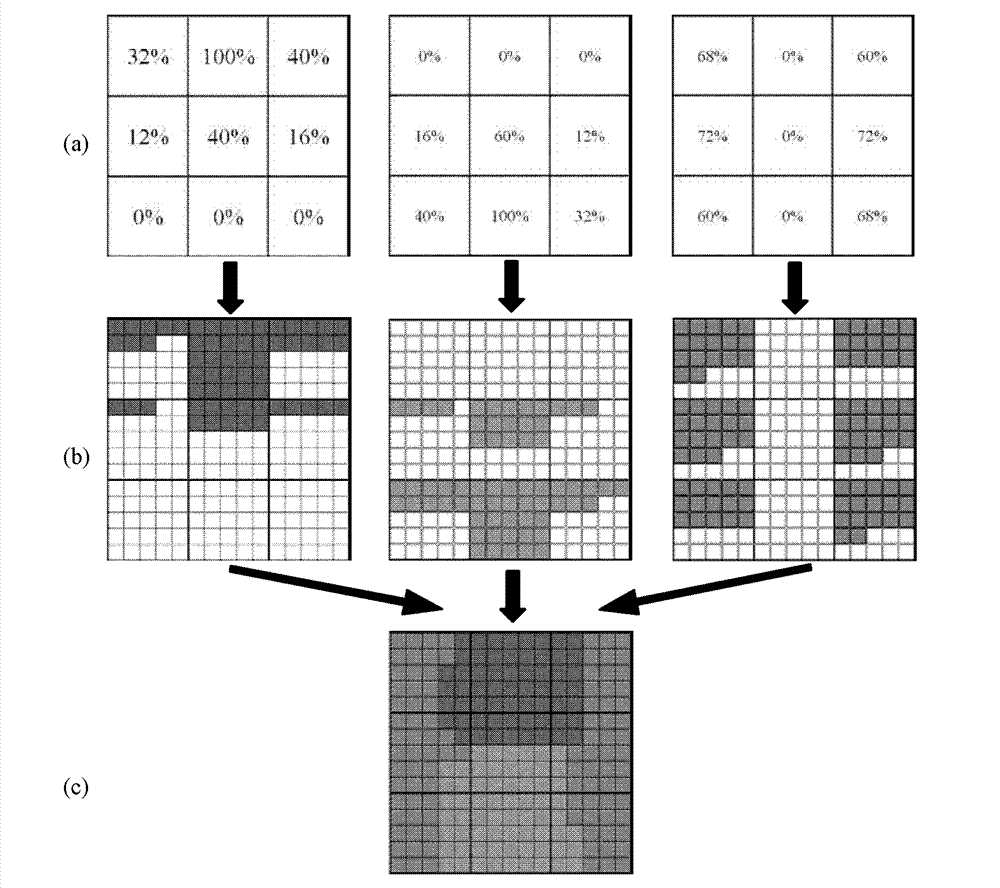

Remote sensing image resolution improving and processing method based on image segmentation and gravity model

InactiveCN102789631AResolution preservationImprove spatial resolutionImage enhancementDecompositionImage resolution

The invention relates to a remote sensing image resolution improving and processing method based on image segmentation and a gravity model. The method comprises the steps of preprocessing an image; performing multi-scale image segmentation of the image; selecting end members to be selected by using a orthogonal subspace projection method; constructing mixed pixel models with layered end members; obtaining the percentage values of the end members in various mixed pixels by using a mixed pixel decomposition method; selecting the mixed pixel models layer by layer; obtaining an optimum mixed pixel decomposition image; converting mixed pixel decomposition images of the end members into sub-pixel images; adjusting positions of sub-pixels and ensuring the total gravitational force among all the sub-pixels to be maximum; adjusting sub-pixels in all pixels repeatedly until all pixels in the images are processed and the processing is finished; and after the processing, obtaining sub-pixel images of which the spatial resolution is improved. Compared with the prior art, the method has the advantages of being simple in method, independent from high spatial resolution, good in anti-noise performance and capable of saving plenty of time.

Owner:张学

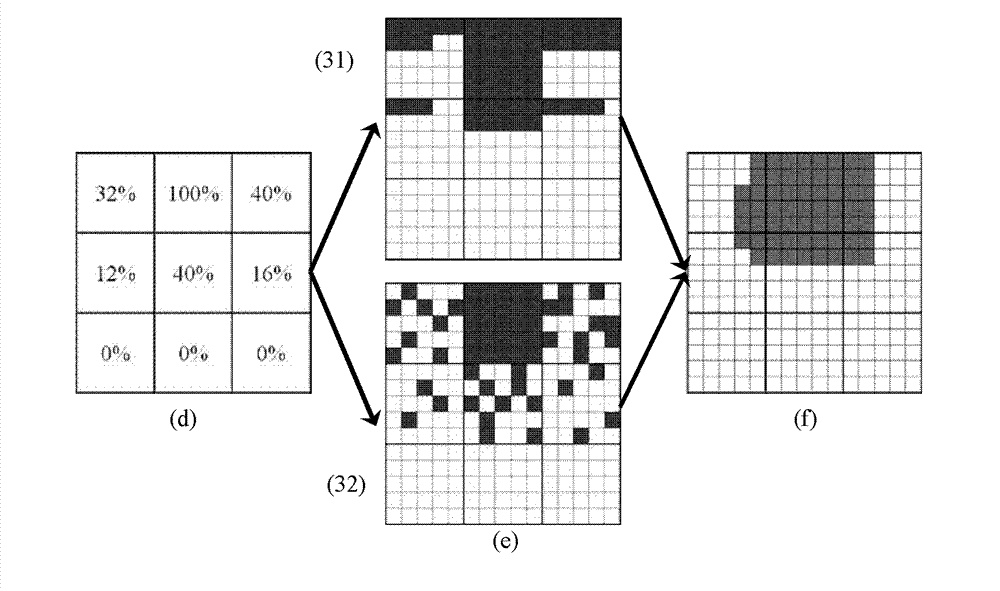

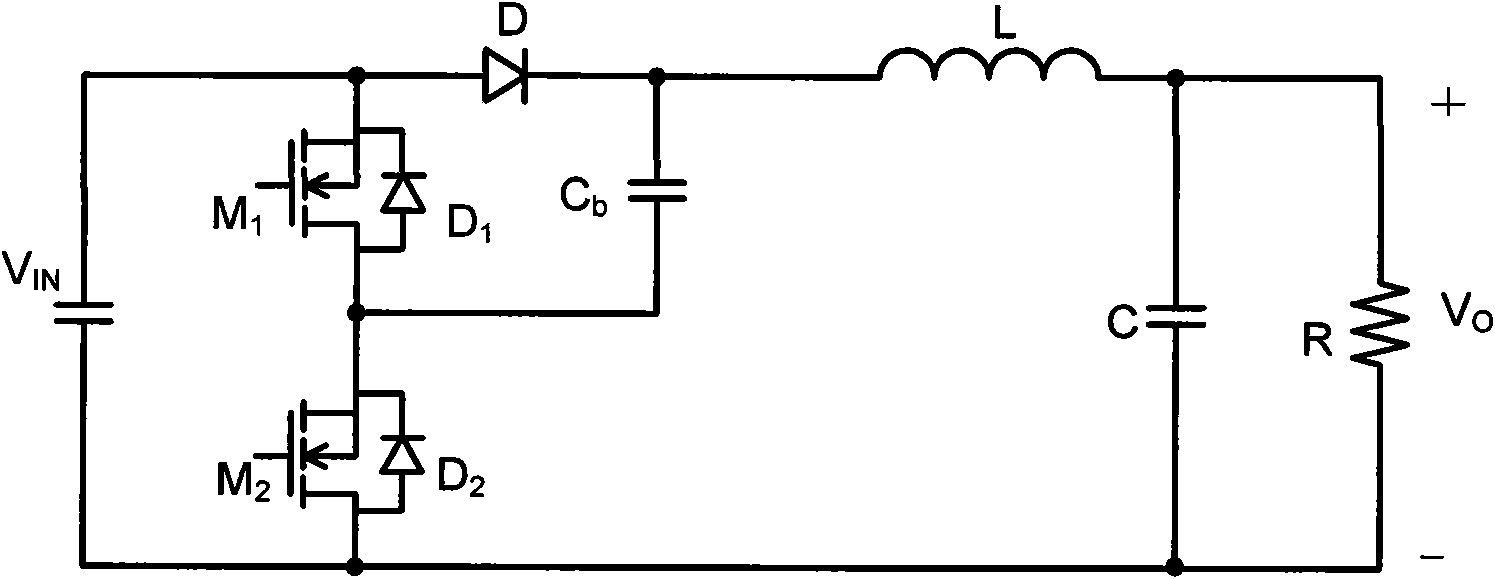

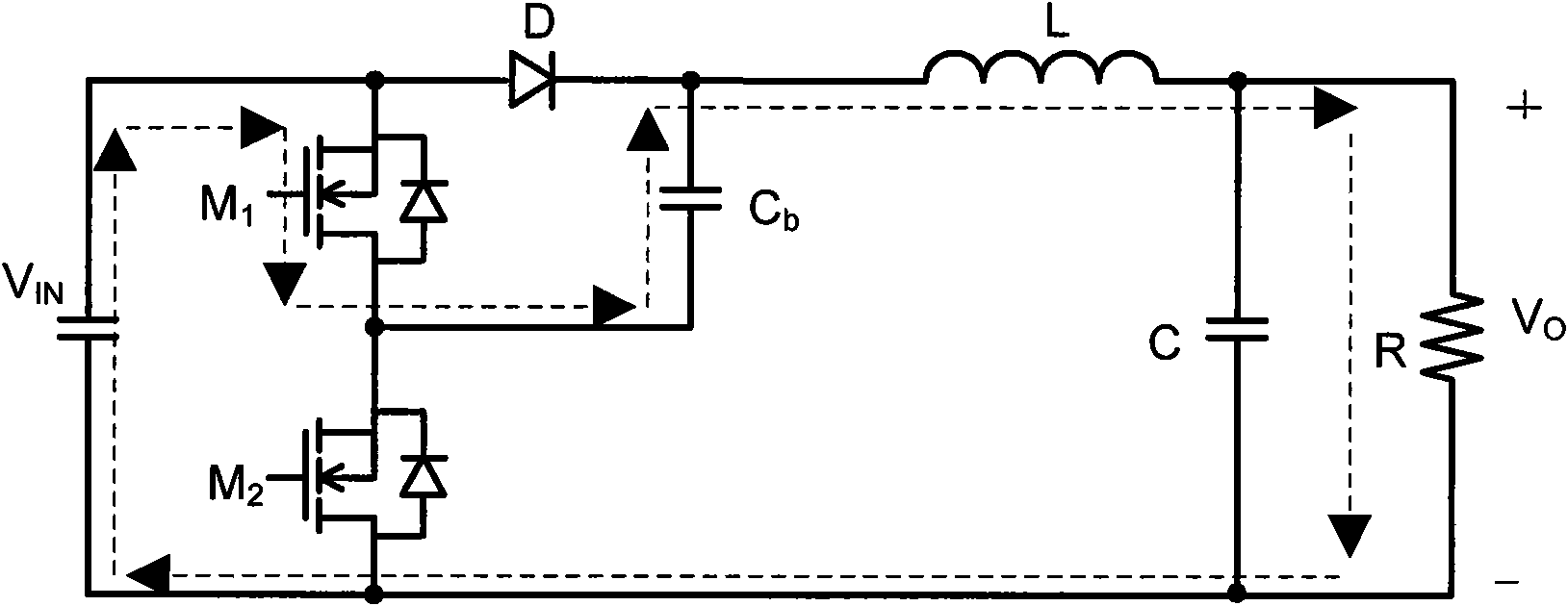

DC convertor

ActiveCN101640478ASmall rippleGood noise immunityApparatus without intermediate ac conversionVoltage rangeInductor

The invention provides a DC convertor, which comprises an input part, a first switch element, a second switch element, a first capacitor, a second capacitor, an inductor and a third switch element, wherein the first end of the input part is connected with the first end of the first switch element and the first end of the third switch element, the second end of the first element is connected with the first end of the second switch element and the first end of the first capacitor, the second end of the third switch element is connected with the second end of the first capacitor and the first end of the inductor, the second end of the inductor is connected with the first end of the second capacitor, and the second end of the second capacitor, the second end of the second switch element and the second end of the input part are grounded. The DC convertor has properties of small output-voltage ripple, good noise resistance and rapid loading response, the output voltage can be increased or decreased, namely, the range of the output voltage is wider, and the input and the output can be effectively cut off when required.

Owner:CHENGDU MONOLITHIC POWER SYST

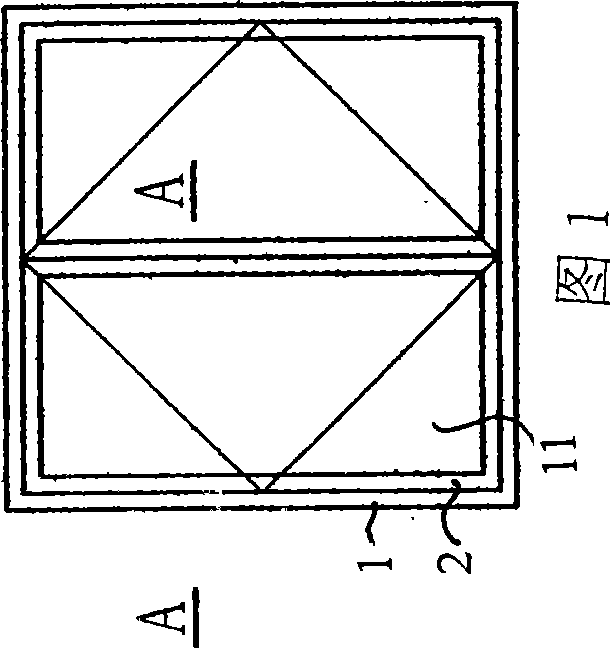

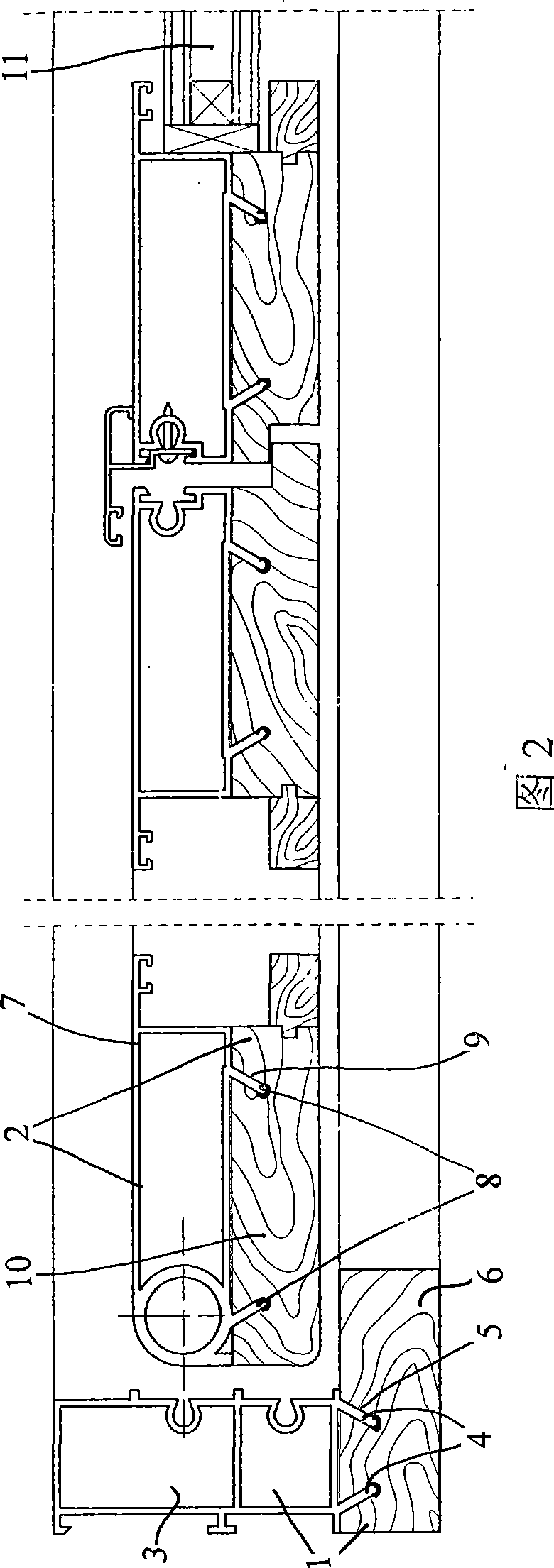

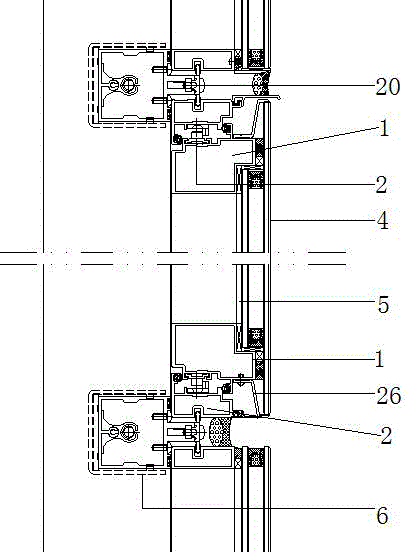

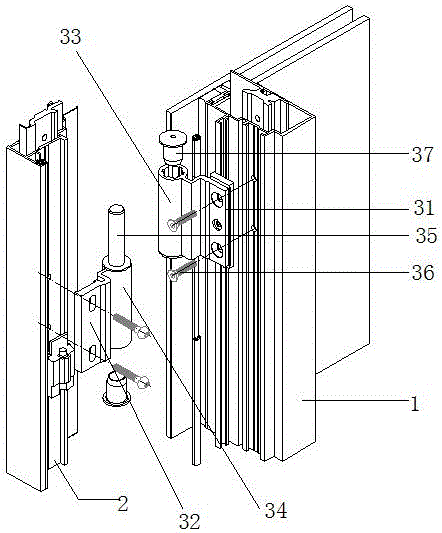

Assembling aluminium-wood energy saving door and window

InactiveCN101387178ASmooth meshingEasy to assembleHingesWing arrangementsEngineeringMechanical engineering

The invention provides an assembled aluminum wood energy-saving door and window, which is provided with an outer frame and a sash frame, and is characterized in that the outer frame is provided with an aluminum sash layer, aluminum sash connecting strip components which are integrated into a whole with the aluminum sash layer and arranged in the shape of inverted V and / or V, solid wooden frame connecting groove components which are matched with the aluminum sash connecting strip components and arranged in the shape of the V and / or the inverted V, and a solid wooden frame layer which is assembled into a whole with the aluminum sash layer through the solid wooden frame connecting groove components and the aluminum sash connecting strip components; the sash frame comprises an aluminum sash frame layer, aluminum sash frame connecting strip components which are integrated into a whole with the aluminum sash frame layer and arranged in the shape of the inverted V and / or the V, solid wooden sash frame connecting groove components which are matched with the aluminum sash frame connecting strip components and arranged in the shape of the V and / or the inverted V, and a solid wooden sash frame layer which is assembled into a whole with the aluminum sash frame layer through the solid wooden sash frame connecting groove components and the aluminum sash frame connecting strip components. The assembled aluminum wood energy-saving door and window is heat-insulated, heat-preserved, vibration-absorbed and noiseproof.

Owner:詹庆富

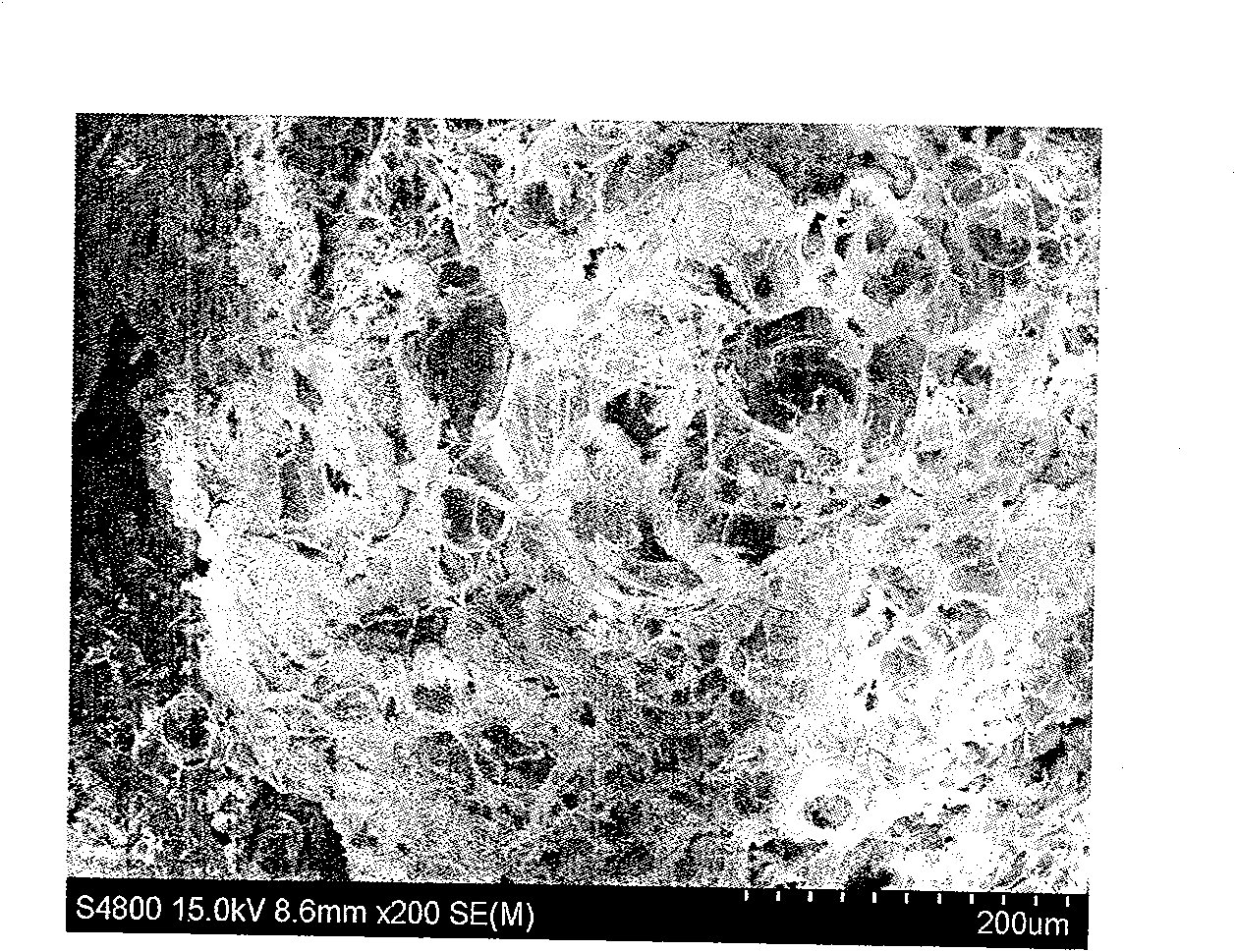

Magnesium-base porous compound material and method of producing the same

A magnesium-based porous composite material is characterized in that the magnesium-based porous composite material is a metal-based composite material which floating beads with cavities are distributed in the magnesium alloy matrix; the chemical components of the floating bead comprises that SiO<2> which is more than or equal to 53 percent and less than or equal to 33 percent, Al<2>O<3> which is more than or equal to 30 percent and less than or equal to 36 percent, Fe<2>O which is more than or equal to 0 percent and less than or equal to 33 percent, CaO which is more than or equal to 1.5 percent and less than or equal to 3.6 percent and MgO which is more than or equal to 0.5 percent and less than or equal to 4 percent; the weight of the floating bead is 0.3 to 0.4 g / cm3 and the size is 200 to 400 um; the volume percent of the composite material which is occupied by the floating bead is 20 percent to 50 percent; the magnesium matrix component content is that Al which is more than or equal to 7wt percent and less than or equal to 10 wt percent, Zn which is more than or equal to 0.8wt percent and less than or equal to 2wt percent, Ti which is more than or equal to 1wt percent and less than or equal to 2wt percent, Zr which is more than or equal to 0 percent and less than or equal to 0.5wt percent, Sr which is more than or equal to 0 percent and less than or equal to o.5wt percent, Sn which is more than or equal to 0 percent and less than or equal to 1wt percent, Si which is more than or equal to 0 percent and less than or equal to 0.2wt percent, Be which is more than or equal to 0.1wt percent and less than or equal to 0.3wt percent and the rest is magnesium. The magnesium-based micrometer pore composite material of the invention contains inorganic non-metal phase with thin pore and the density of the phase is very small.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

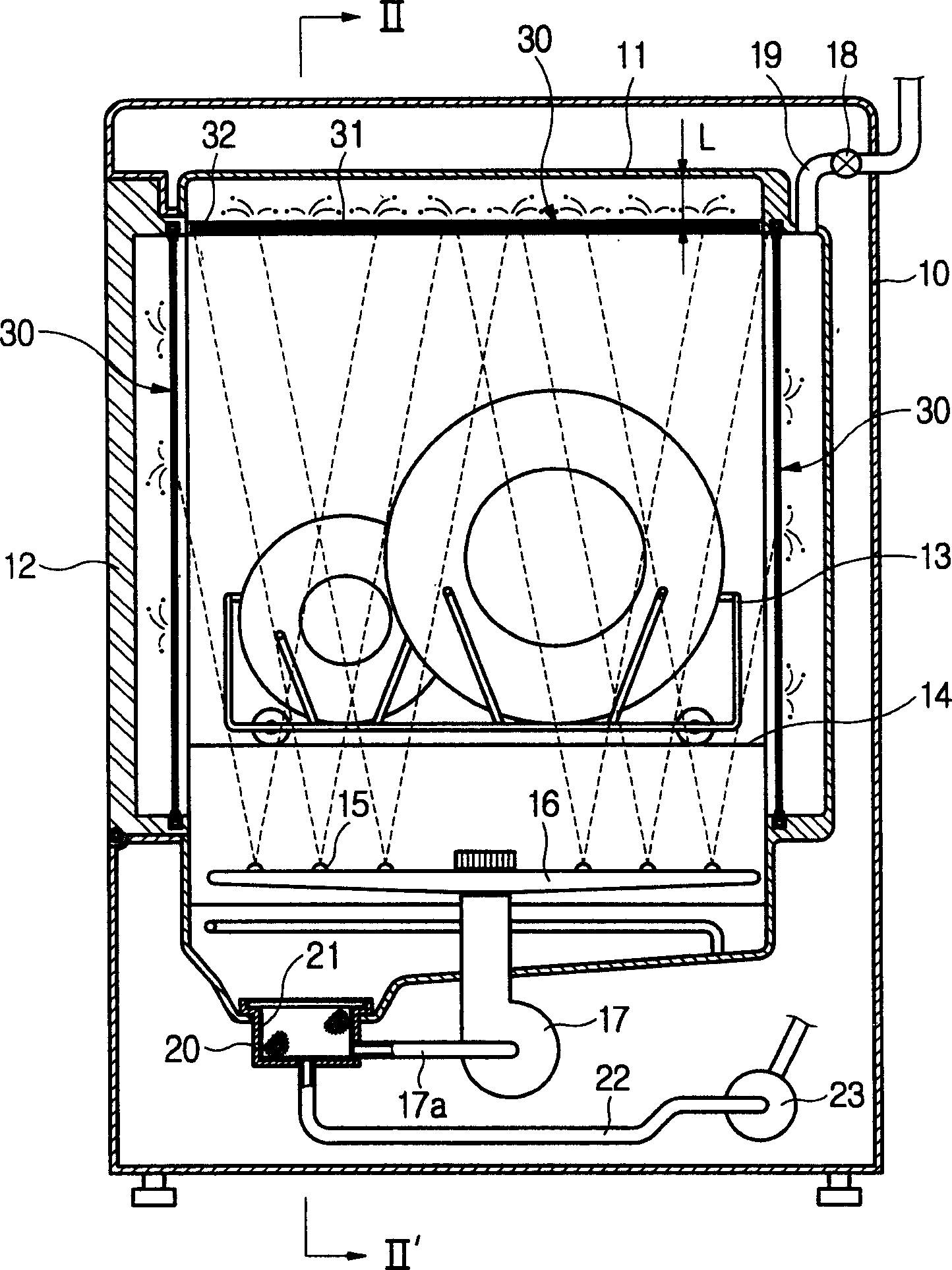

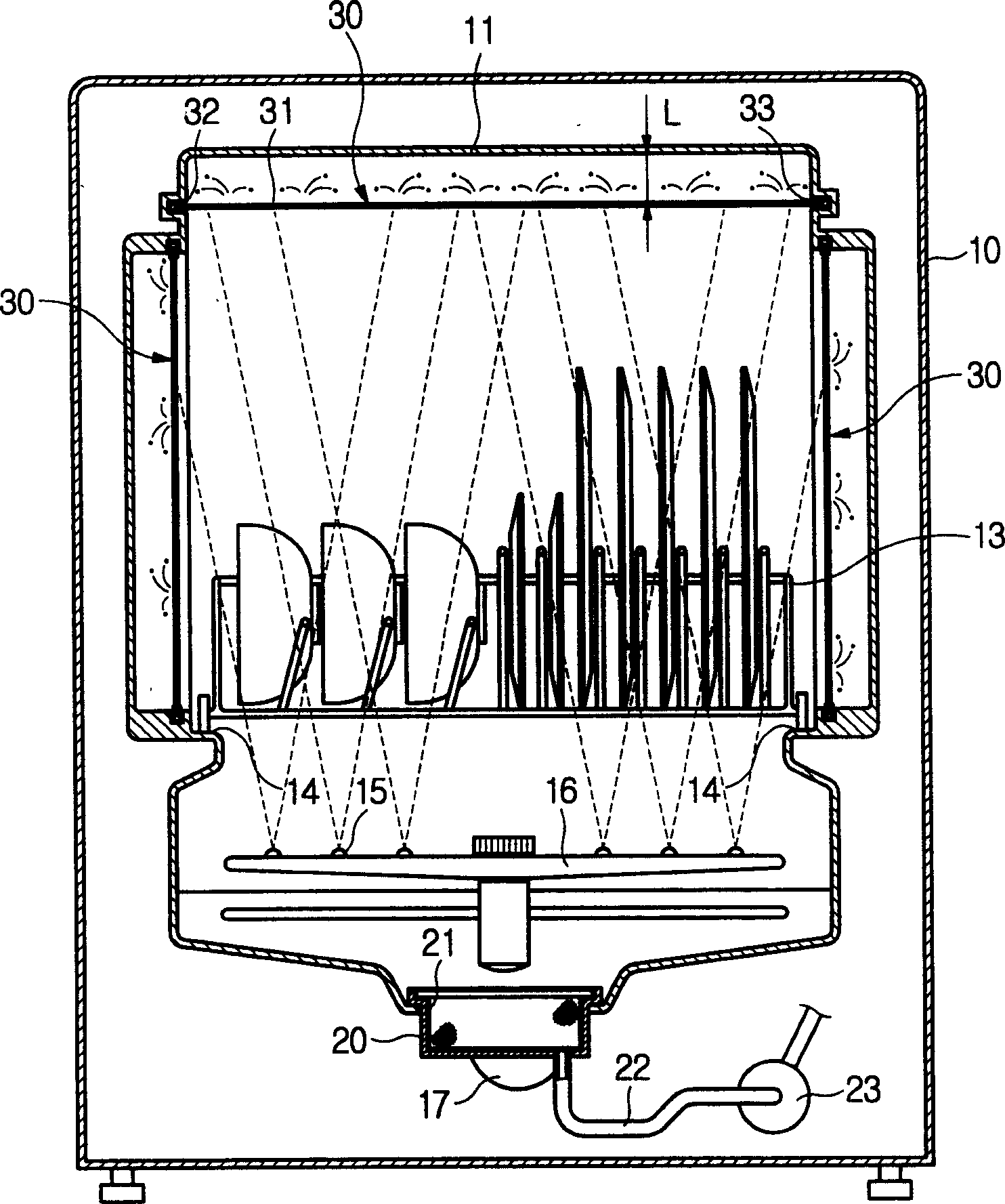

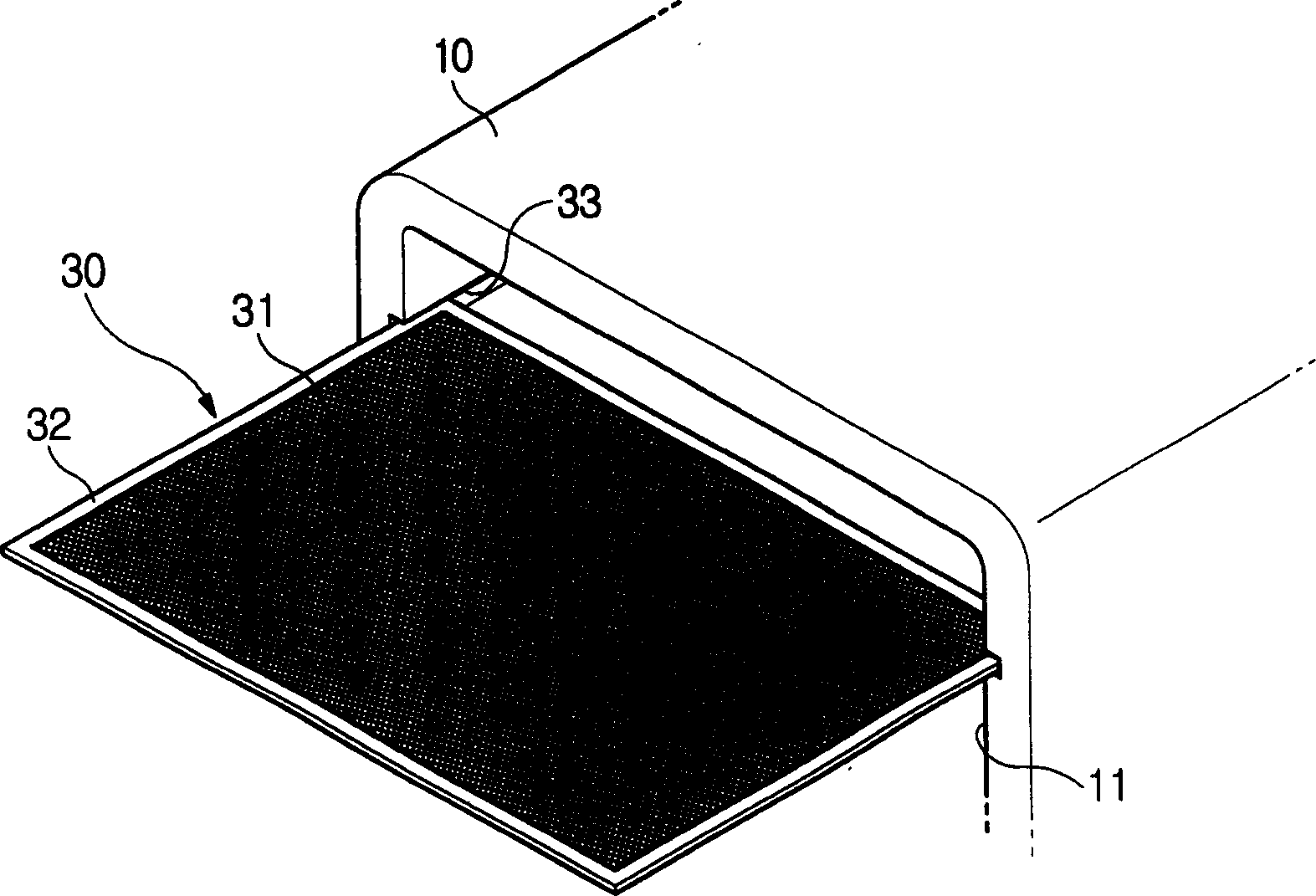

Dish washing machine

InactiveCN1493248AReduce manufacturing costGood anti-noise effectTableware washing/rinsing machine detailsWash waterSpray nozzle

A dishwasher that is provided with an improved soundproofing structure to reduce the manufacturing cost of the dishwasher and accomplish an improved soundproofing effect in comparison with conventional dishwashers. The disclosed dishwasher includes a washing tub provided in a cabinet. A basket is provided in the washing tub to hold dishes therein. A washing pump pressurizes wash water contained in the washing tub. An injection nozzle sprays wash water supplied from the washing pump. A soundproofing unit with a net structure is installed in the washing tub in such a way as to be spaced apart from the inner surface of the washing tub, thus dispersing wash water sprayed from the injection nozzle while reducing pressure of the wash water.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for reducing electrical power noise in high-speed ADC application

InactiveCN101335524AEliminate noise sourcesGood anti-noise effectAnalogue-digital convertersPhysical parameters compensation/preventionPower noiseData acquisition

The invention relates to an ADC (Analog to Digital Converter), in particular to a method for reducing power noise in the application of a high speed ADC. The method comprises main steps of: A. decoupling to the power; B. grounding item; C. independent power. By adopting the method of the invention, noise sources in the ADC power and surrounding circuits can be eliminated and the noise-proof performance in a data collecting design can be substantially improved.

Owner:SHANGHAI MINHANG HIGH SCHOOL +1

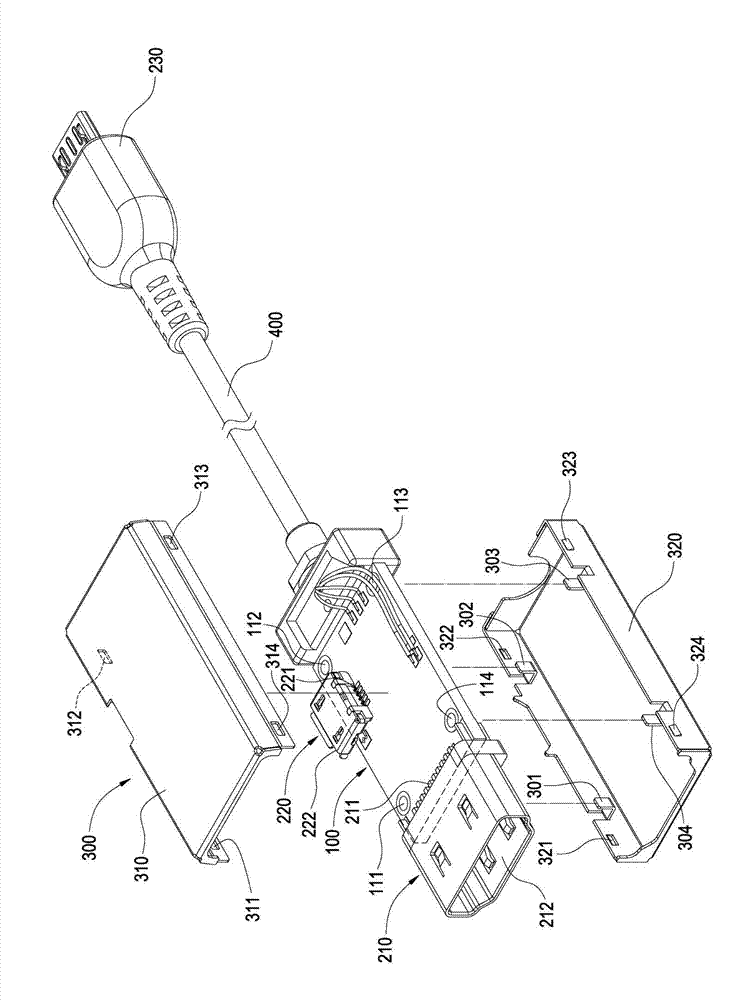

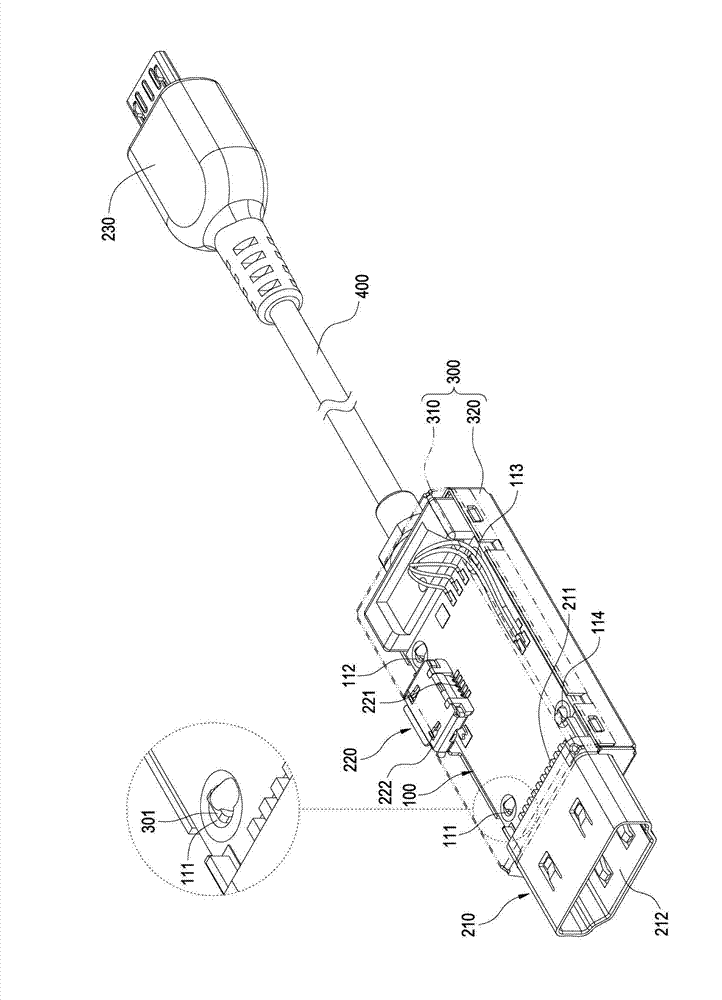

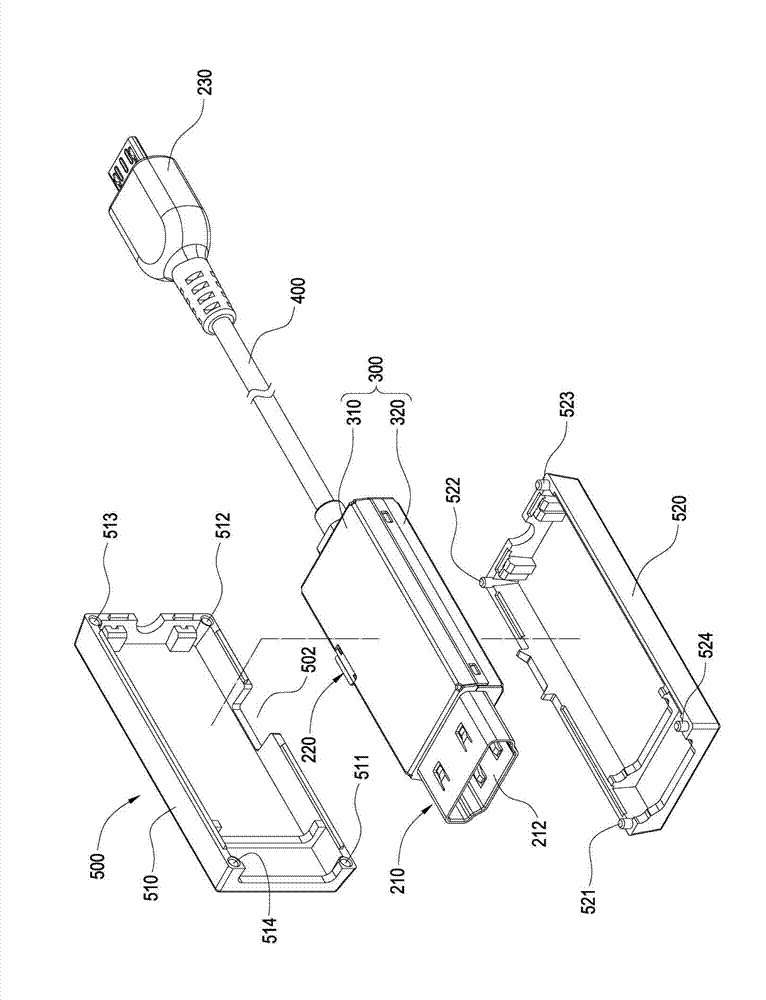

Adapting connector

InactiveCN103247929ALow costIncrease ground areaCoupling protective earth/shielding arrangementsEngineeringElectrical and Electronics engineering

An adapting connector comprises a circuit board, at least one first connector and a metal shell. The circuit board comprises an adapting circuit, each first connector comprises a plurality of weld legs, and the weld legs are welded on the circuit board and are electrically connected with the adapting circuit. The metal shell covers on the circuit board, shades the weld legs and the adapting circuit, and comprises at least one positioning pin that is welded on the circuit board.

Owner:泗阳万旭电子元件有限公司

Corrosion resistant magnesium alloy and compound material containing corrosion resistant magnesium alloy and preparation method thereof

The invention relates to a corrosion-resistant magnesium alloy. The compositions in weight percentage of the alloy are 0.5 to 9 percent of tin, 0.05 to 5 percent of plumbum, less than or equal to 2 percent of strontium, less than or equal to 0.2 percent of stibium, less than or equal to 0.2 percent of tellurium and the balance being magnesium. The invention relates to a porous composite material containing the corrosion-resistant magnesium alloy, which is a metal base composite material containing inorganic nonmetal phase mixed particles. The corrosion-resistant magnesium alloy only uses common tin and plumbum or general elements such as tin, plumbum, cerium and so on, avoids using rare and noble elements, and has simple manufacturing and preparation technologies, low cost and good corrosion resistance and plasticity. The corrosion-resistant magnesium base porous composite material consists of the corrosion-resistant magnesium alloy and corrosion-resistant inorganic porous materials with low density. The composite material not only has corrosion resistance but also has good damping performance, can be widely used for corrosion-resistant vibration-absorbing components and parts on high speed machines such as automobiles and so on, and has good vibration absorption effect, sound insulation effect and noise control effect.

Owner:CHANGSHU NANJING NORMAL UNIV DEV RES INST

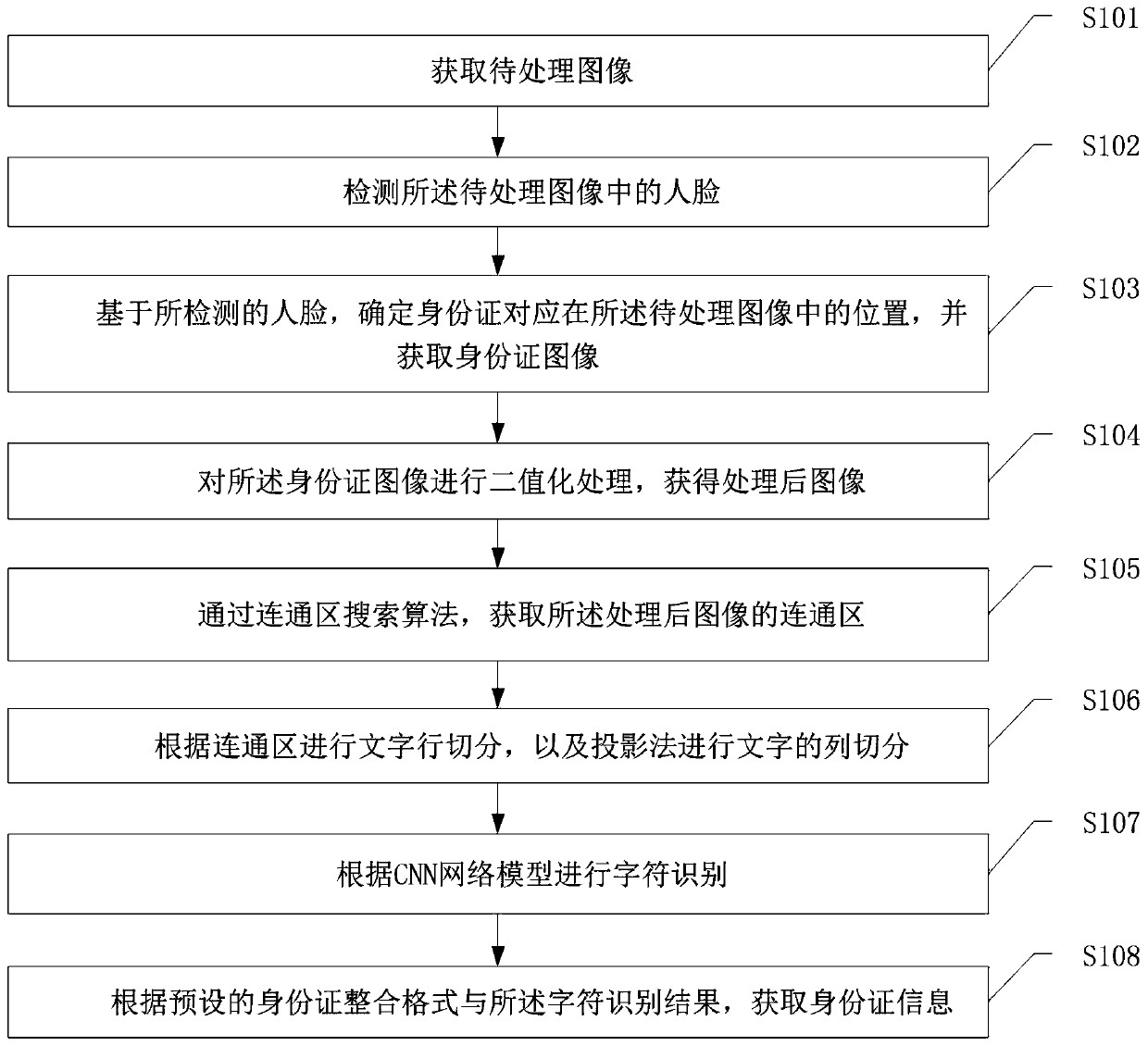

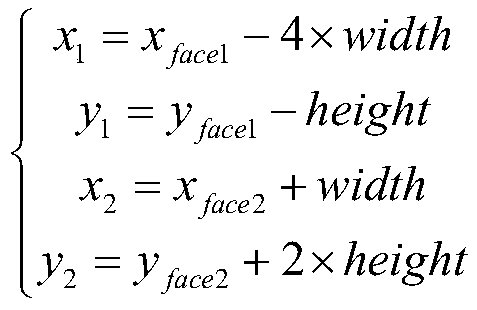

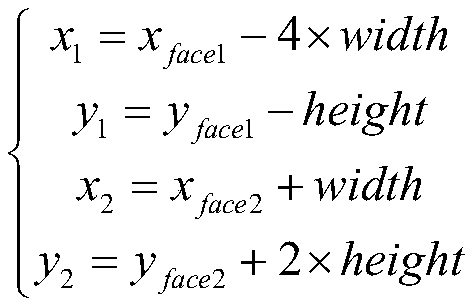

Identity card information extraction method and device and computer storage medium

ActiveCN110443184AQuickly identify and locateEfficient acquisitionCharacter recognitionCharacter recognitionNetwork model

The invention provides an identity card information extraction method. The method comprises the steps of obtaining a to-be-processed image; detecting a human face in the to-be-processed image; determining the position of an identity card in the to-be-processed image based on the detected face, and obtaining an identity card image; performing binarization processing on the identity card image to obtain a processed image; obtaining a connected region of the processed image through a connected region search algorithm; carrying out character row segmentation according to the communication area, and carrying out character column segmentation according to a projection method; performing character recognition according to the CNN network model; and acquiring identity card information according toa preset identity card integration format and the character recognition result. In addition, the invention further discloses an identity card information extraction device and a computer storage medium.

Owner:SHANGHAI MARITIME UNIVERSITY

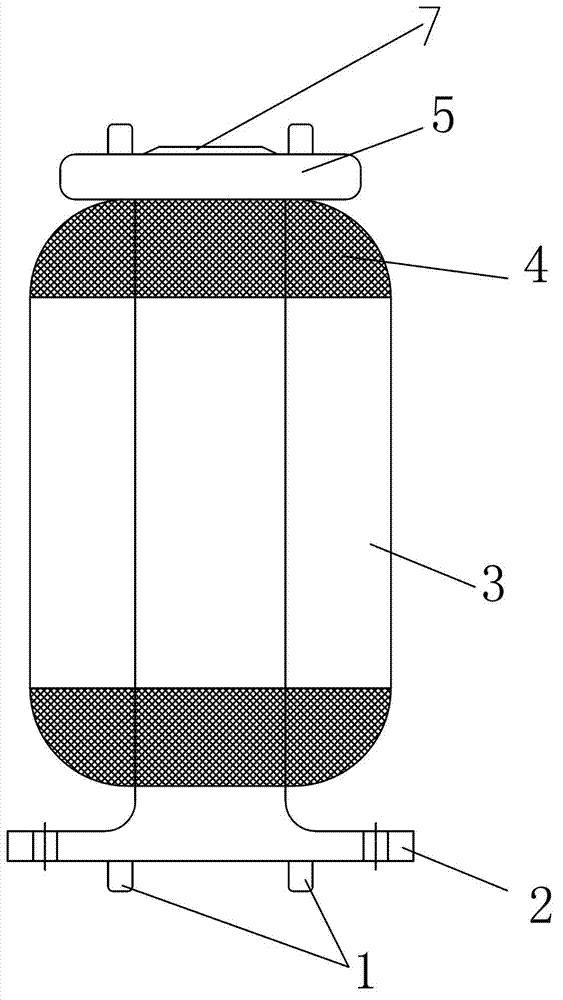

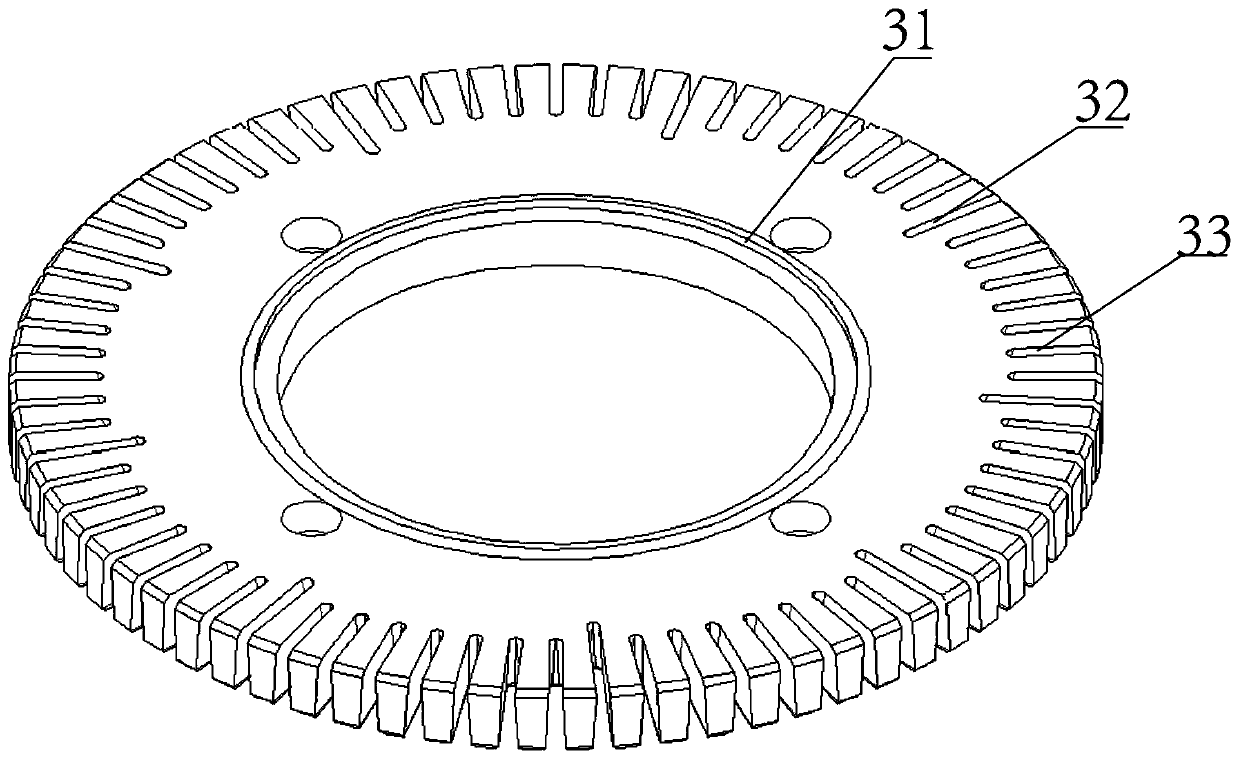

Rubber air spring for high-speed railway

InactiveCN102829120AImprove fatigue resistanceExtended service lifeGas based dampersAir springEngineering

The invention relates to damping and buffering equipment for a high-speed railway, in particular to a rubber air spring for a high-speed railway, comprising a supporting seat, a rubber capsule, a rubber surface, a cover plate and a throttling hole. The rubber air spring is characterized by comprising the supporting seat, the rubber capsule, the rubber surface, the cover plate and the throttling hole, wherein the bottom of the rubber capsule is fixedly provided with the supporting seat; the cover plate is fixed on the top of the rubber capsule; the surface of the inner wall of the rubber capsule is provided with a rubber ribbed band; the lower surface of the supporting seat and the upper surface of the cover plate are respectively provided with a screw steel pipe locating pin; and the throttling hole is arranged in the upper part of the rubber capsule. Due to the adoption of the ribbed band arranged on the surface of the inner wall of the capsule of the rubber air spring provided by the invention, the fatigue resistance of the spring is effectively enhanced, and the service life of the spring is prolonged; and due to the adoption of the throttling hole arranged in the spring, vibration in the spring using process can be attenuated, the spring is enabled to keep lower and approximately equal vibration frequency, and meanwhile, the service life of the spring is prolonged.

Owner:WUXI ZHONGJIE VIBRATION ISOLATORS

Anti-noise sheath for headphone cables

InactiveCN102977538ACaused by noiseGood anti-noise effectEarpiece/earphone attachmentsChemistryPolypropylene

An anti-noise sheath for headphone cables is processed from the following components by mass: 50%-60% of hydrogenated styrene-butadiene block copolymer, 10%-13% of polypropylene, 15%-20% of a filler, 5%-20% of lubricant, 1%-5% of a coloring agent, and 0.1%-0.3% of a stabilizer. The hydrogenated styrene-butadiene block copolymer, with a chemical formula of (C8H8-C4H6)x, is a hot melt-type rubber. The filler is calcium carbonate with a chemical formula of CaCO3. The lubricant is white mineral oil. The stabilizer is zinc stearate with a chemical formula of C8H16O4. The coloring agent is carbon powder. The anti-noise sheath for headphone cables of the present invention can prevent noise and has good anti-noise performance after being assembled in the cable, due to the use of the specific component composition and ratio.

Owner:HUBEI YINGTONG ELECTRONICS +1

Anti-noise heat-resistant ABS resin composition and preparation method thereof

The invention relates to an anti-noise heat-resistant ABS resin composition and a preparation method thereof. The composition includes the following raw materials, by weight: 100 parts of acrylonitrile-butadiene-styrene (ABS) resin, 5-20 parts of a heat-resistant agent, 5-20 parts of an anti-noise master batch, 0.5-1.0 part of a photo-stabilizer, and 0.5-1.5 parts of other processing additives. The preparation method includes the steps of: stirring the raw materials in a high-speed mixer to fully mix the raw materials, feeding the mixture into a double-screw extruder through a metering device to melt and composite the raw materials through transportation, shear and mixing by means of screw rods, and performing extrusion, bar drawing, cooling and granule cutting to prepare the anti-noise heat-resistant ABS resin composition. The preparation method is simple. The anti-noise heat-resistant ABS resin composition is excellent in anti-noise effect and mechanical performance, and is very suitable for being used in the field of automobile interior.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

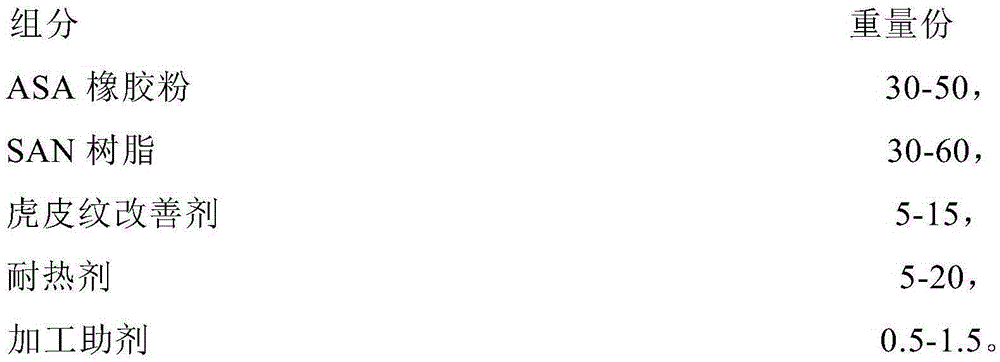

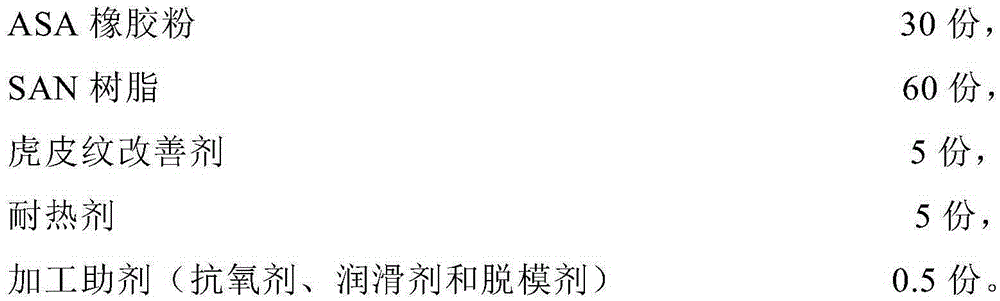

Heat-resistant ASA resin composition with tiger wrinkle defect eliminated and preparation method thereof

The invention relates to a heat-resistant ASA resin composition with tiger wrinkle defect eliminated and a preparation method thereof. The heat-resistant ASA resin composition is prepared from following raw materials, by weight: 30-50 parts of ASA rubber powder, 30-60 parts of SAN resin, 5-15 parts of a tiger wrinkle defect eliminating agent, 5-20 parts of a heat-resistant agent and 0.5-1.5 parts of a processing aid. The preparation method comprises the following steps: stirring and fully mixing the raw materials in a high-speed mixing machine, feeding the mixture into a double-screw extruder through a metering device to melt and composite the mixture through transportation, shear and mixing by means of screw rods, and performing extrusion, bar drawing, cooling and granule cutting to prepare the heat-resistant ASA resin composition. The method is easy to carry out. The tiger wrinkle defect on a workpiece during an injection molding process can be completely avoided by means of the ASA resin composition. The resin composition also is excellent in anti-impact, heat-resistant and such comprehensive performance, and is very suitable for being used as automobile exteriors, such as automobile gratings, columns, empennage decorative plates and the like.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Magnesium-base porous compound material and method of producing the same

A magnesium-based porous composite material is characterized in that the magnesium-based porous composite material is a metal-based composite material which floating beads with cavities are distributed in the magnesium alloy matrix; the chemical components of the floating bead comprises that SiO<2> which is more than or equal to 53 percent and less than or equal to 33 percent, Al<2>O<3> which is more than or equal to 30 percent and less than or equal to 36 percent, Fe<2>O which is more than or equal to 0 percent and less than or equal to 33 percent, CaO which is more than or equal to 1.5 percent and less than or equal to 3.6 percent and MgO which is more than or equal to 0.5 percent and less than or equal to 4 percent; the weight of the floating bead is 0.3 to 0.4 g / cm3 and the size is 200 to 400 um; the volume percent of the composite material which is occupied by the floating bead is 20 percent to 50 percent; the magnesium matrix component content is that Al which is more than or equal to 7wt percent and less than or equal to 10 wt percent, Zn which is more than or equal to 0.8wt percent and less than or equal to 2wt percent, Ti which is more than or equal to 1wt percent and less than or equal to 2wt percent, Zr which is more than or equal to 0 percent and less than or equal to 0.5wt percent, Sr which is more than or equal to 0 percent and less than or equal to o.5wt percent, Sn which is more than or equal to 0 percent and less than or equal to 1wt percent, Si which is more than or equal to 0 percent and less than or equal to 0.2wt percent, Be which is more than or equal to 0.1wt percent and less than or equal to 0.3wt percent and the rest is magnesium. The magnesium-based micrometer pore composite material of the invention contains inorganic non-metal phase with thin pore and the density of the phase is very small.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

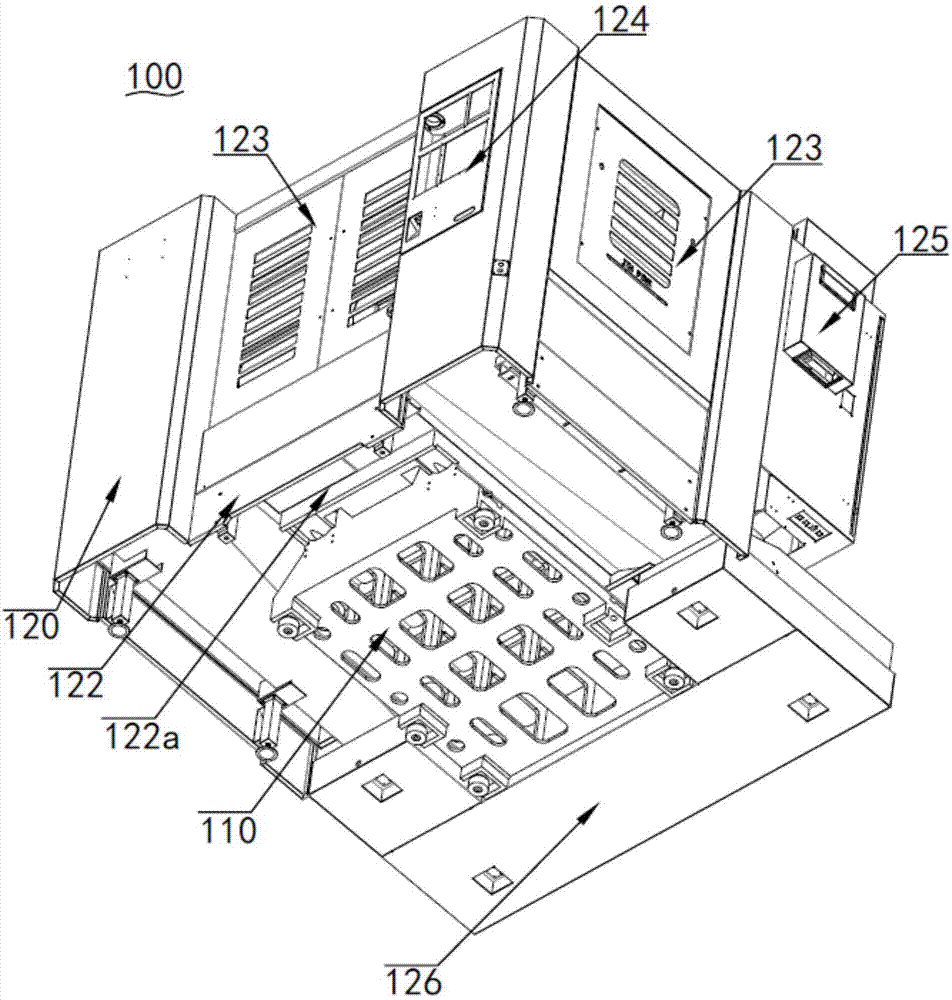

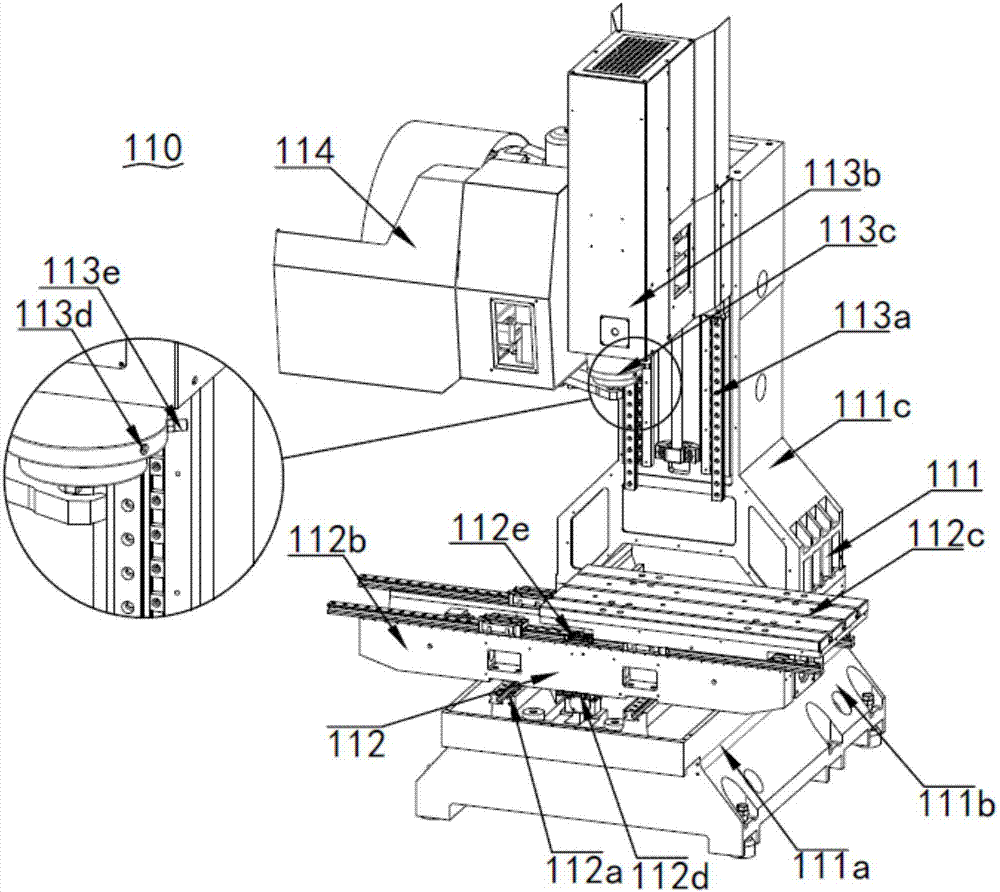

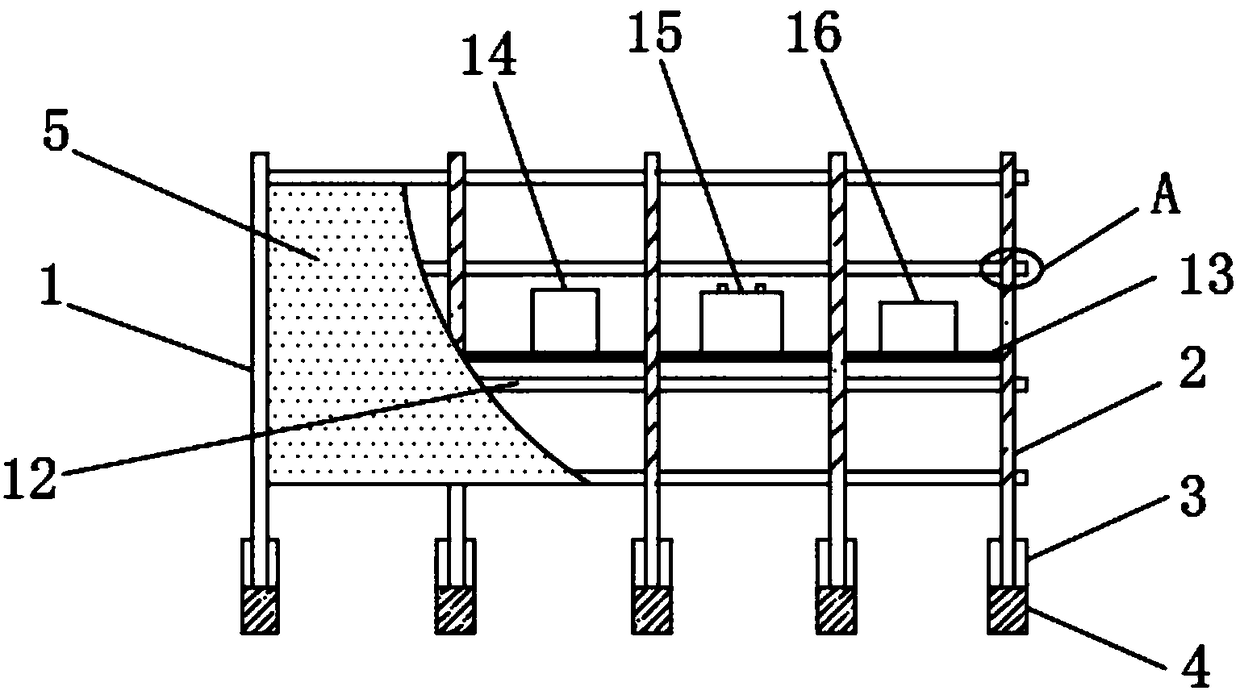

Low-noise vertical machining center

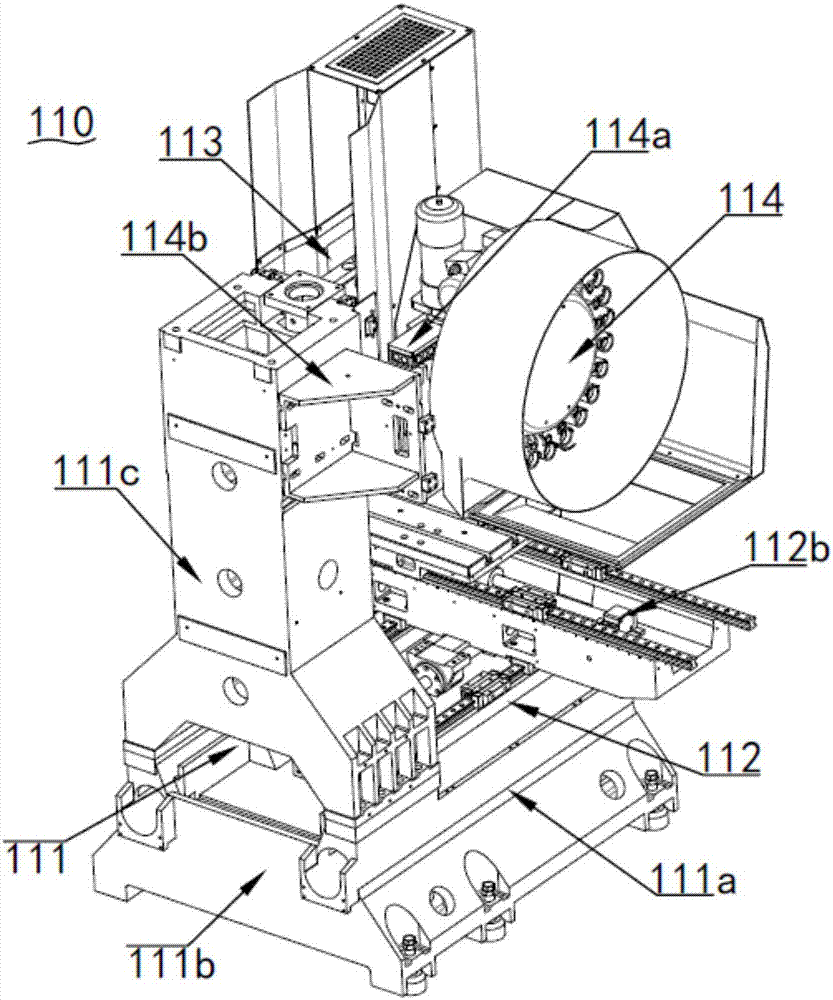

PendingCN107127632AImprove work efficiencyGood protectionMaintainance and safety accessoriesPhysicsEngineering

The invention relates to the technical field of machining centers, in particular to a low-noise vertical machining center. The low-noise vertical machining center comprises a main machine and a protective frame. The outer side of the main machine is covered by the protective frame. The main machine comprises a machine frame, a workbench, a machining portion and a tool rest, wherein the workbench, the machining portion and the tool rest are installed on the machine frame. The machining portion is hung above the workbench in a lifting mode. The tool rest is located on one side of the machining portion. The inner wall of the protective frame is provided with an acoustic panel. The tool rest is provided with a silencer. The position, provided with the workbench, of the machine frame is provided with a damping belt. Noise produced by the machining portion in the machining process is isolated through the acoustic panel, the noise is effectively reduced when a tool of the tool rest is replaced through the silencer, vibration of the workbench is relieved through the damping belt in the machining process of the machining portion, a protection effect can be effectively achieved, and meanwhile noise brought by machining can be effectively reduced.

Owner:DONGGUAN JIR FINE MACHINERY

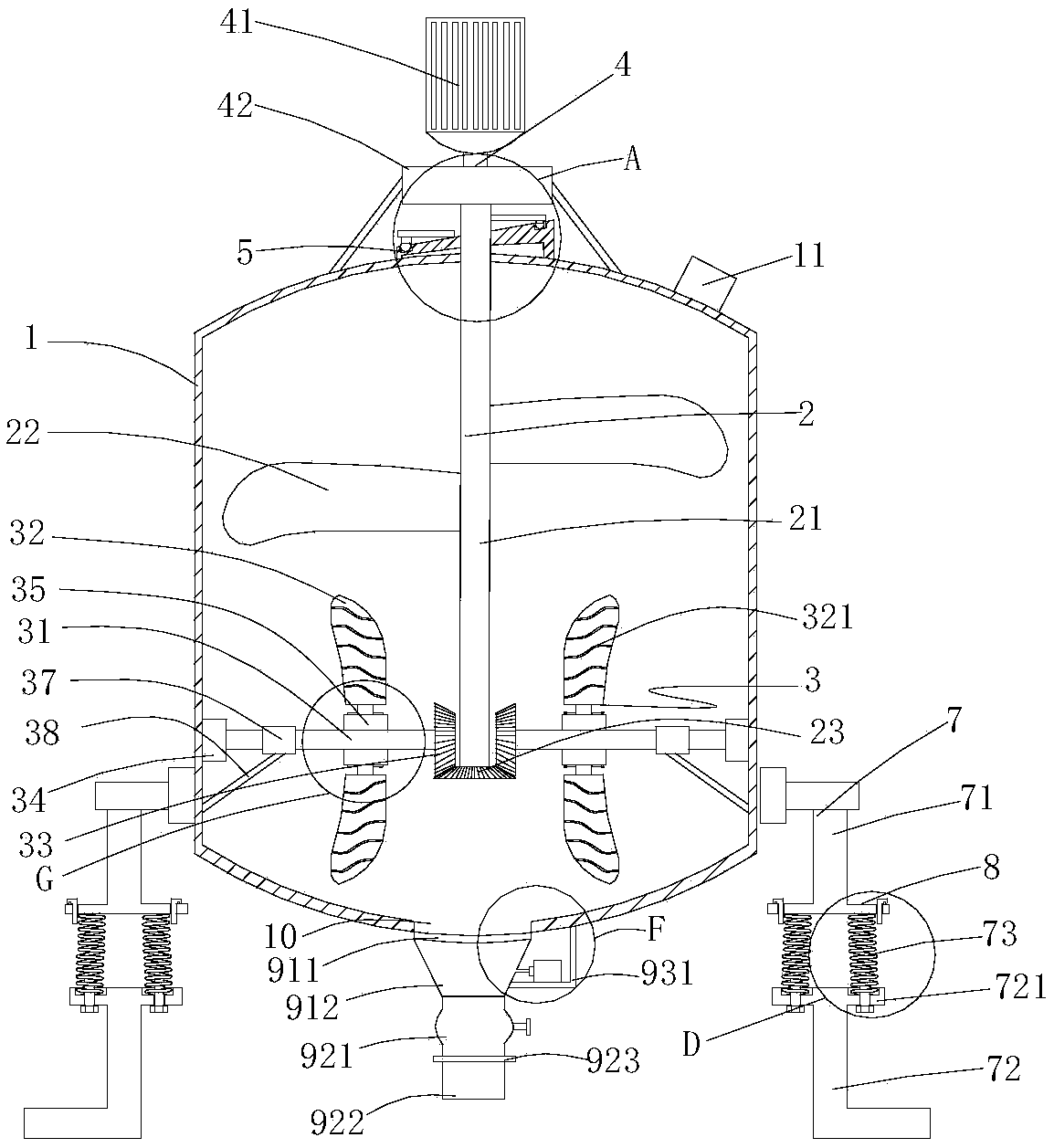

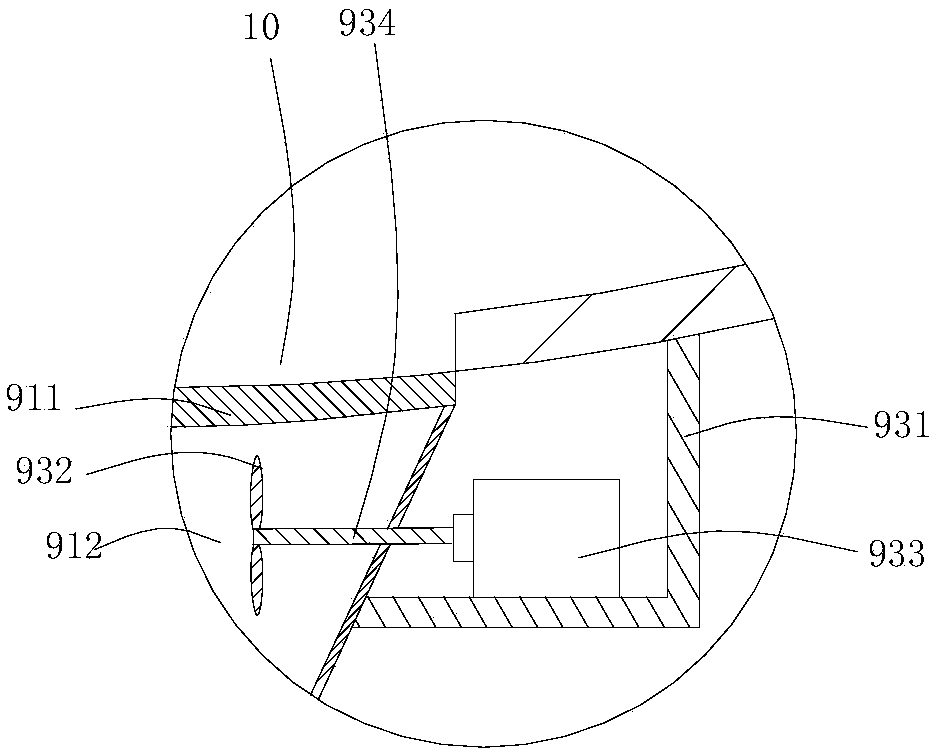

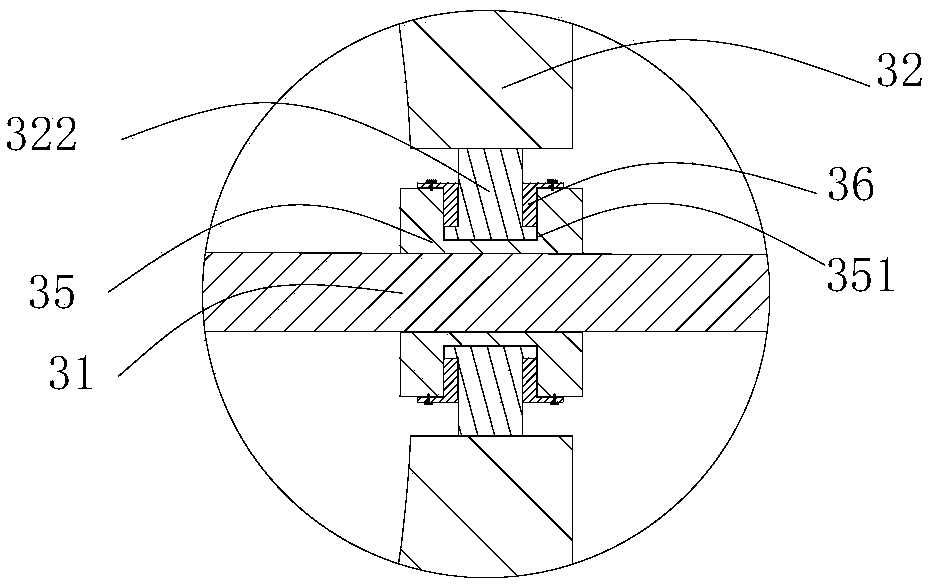

Stirring device for producing plastic

The invention discloses a stirring device for producing plastic. The stirring device comprises a barrel body provided with a discharging opening at the bottom, a first stirring part for transversely stirring, a second stirring part for longitudinally stirring, a driving mechanism for driving the first stirring part and the second stirring part at the same time, a plurality of supporting parts arranged at two sides of the barrel body, and a discharging mechanism arranged at the bottom of the barrel body, wherein the discharging mechanism comprises a material guide room, a closing door connectedwith the material guide room, a flow adjusting device for adjusting a discharging speed of raw materials from the material guide room, and a rotating part for driving the raw materials in the material guide room to rotate. According to the stirring device for producing the plastic, the discharging speed can be improved through the discharging mechanism and the working efficiency is improved; thefirst stirring part and the second stirring part are arranged so that the stirring efficiency of the raw materials is high, the mixing uniformity is high and conditions that the raw materials are precipitated at the bottom of the barrel body and the like are also reduced; one driving mechanism is utilized, so that the stirring device has the advantages of simple equipment structure, low fault rate, low energy consumption and low cost.

Owner:江苏洋口港建设发展集团有限公司

Cleaning method for silencer

InactiveCN105316692AEfficient removalGuaranteed uptimeCleaning using liquidsCooking & bakingMoisture

The invention provides a cleaning method for a silencer. The produced as-cast silencer is cleaned through ultrasonic wave with the temperature being 55-65 DEG C for 45-120 seconds, the silencer is cleaned for three times, and an alkaline detergent is added to ultrasonic water; rinsing is conducted through pure water; the silencer is rinsed through water with an alkaline rust remover added therein for 45-120 second and for twice; rust removal treatment is connected with the alkaline rust remover for 45-120 seconds; cleaning is conducted through pure water; air drying is conducted; and baking is conducted. According to the cleaning method for the silencer, a combined chemical and physical method is adopted, the alkaline detergent is combined with the ultrasound, and residual acid on the surface of the silencer can be effectively removed; then the water with the alkaline rust remover added therein is used for rinsing, it is further ensured that acid liquor is completely removed. Moisture in the technological process of the whole process is evaporated through air drying and baking, the surface of the silencer is ensured to be clean, the silencer is made to work well, and the noise defending effect is better.

Owner:佛山市南海新奥电器有限公司

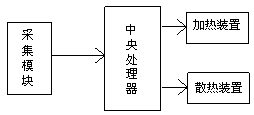

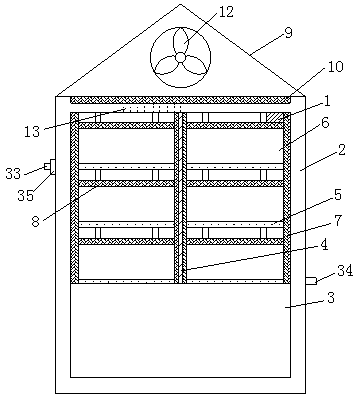

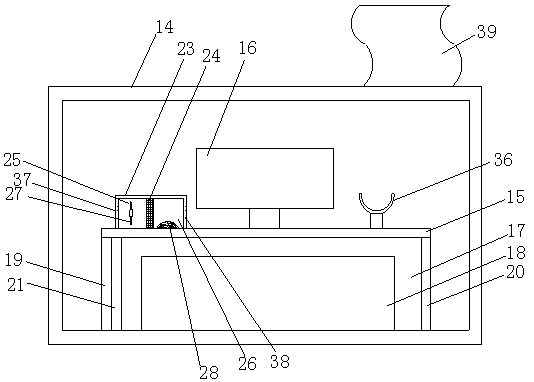

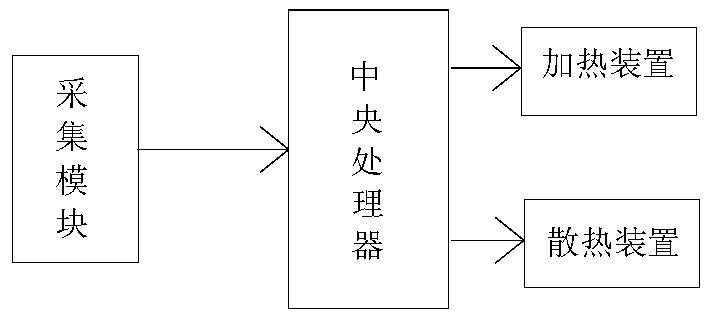

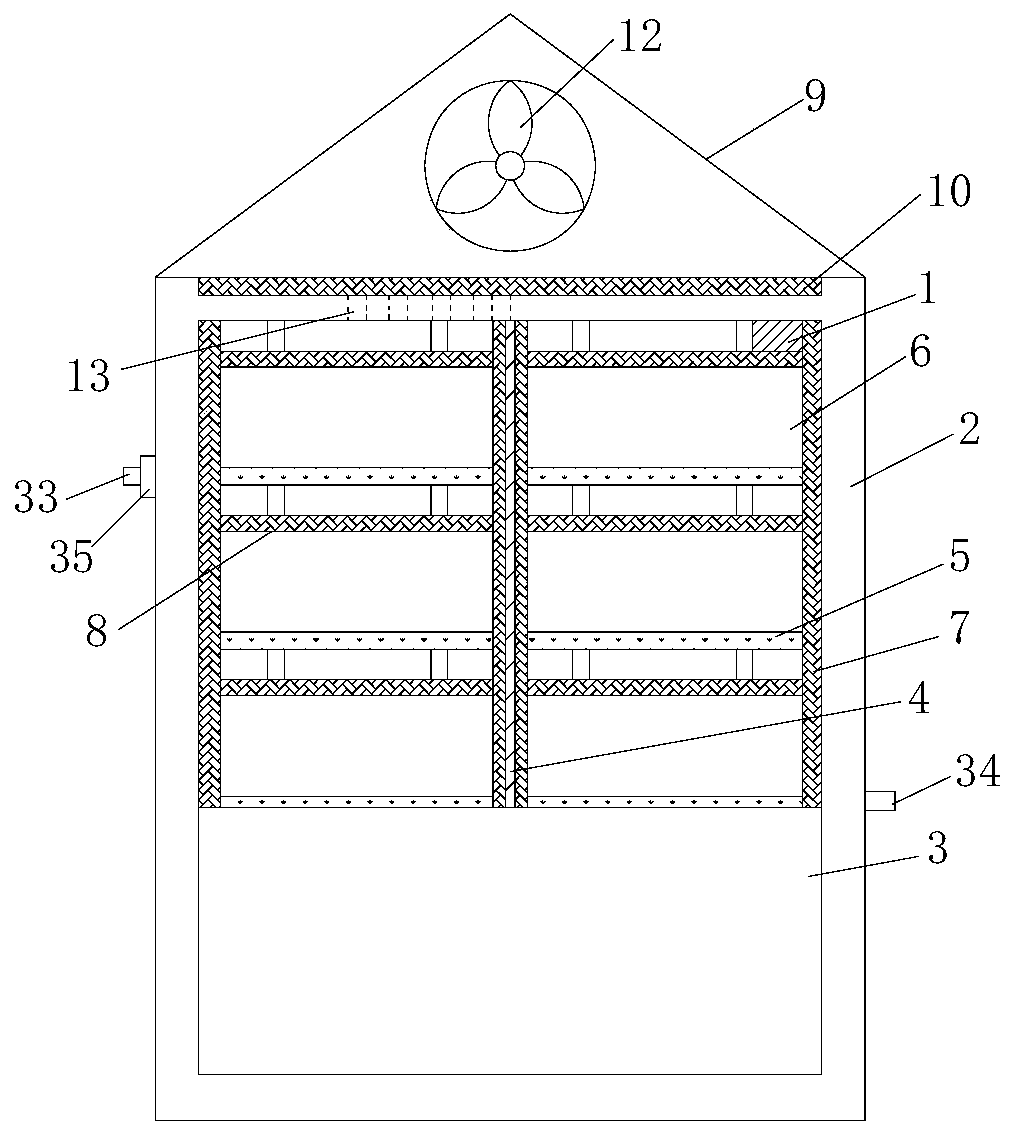

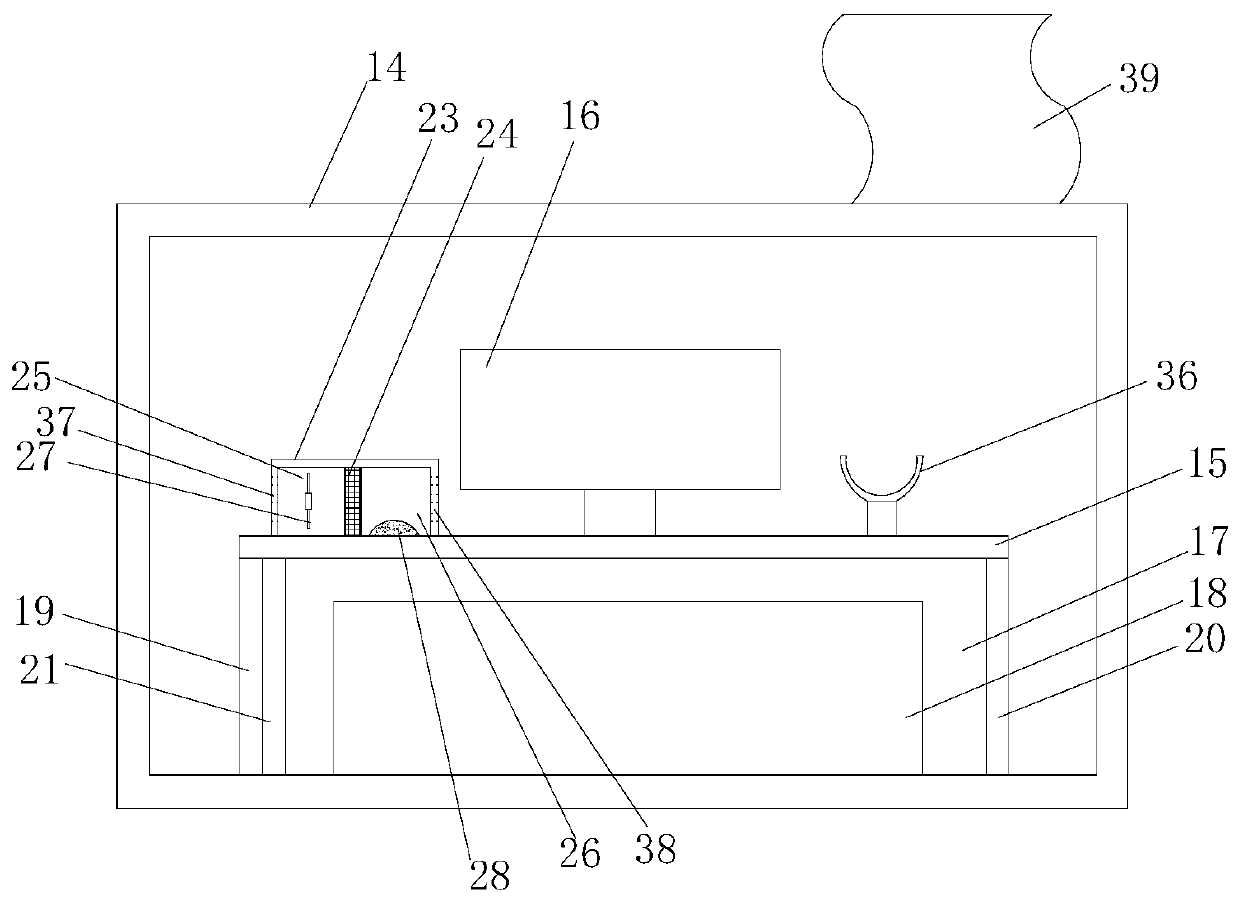

Intelligent environment control system for improving equipment operation environment

InactiveCN107734922AGuaranteed uptimeQuality assuranceWallsLighting and heating apparatusIntelligent environmentControl system

The invention discloses an intelligent environment control system for improving an equipment operation environment. The intelligent environment control system relates to the technical field of environment control systems, and is mainly composed of an acquisition module, a regulation and control system and a monitoring terminal. The intelligent environment control system not only has good heat dissipation and dehumidification effects on a cabinet body, but also provides a good monitoring environment for a monitoring room.

Owner:安徽瀚和智能科技有限公司

Green lightweight tensile bamboo reinforced concrete precast block

The invention discloses a green lightweight tensile bamboo reinforced concrete precast block. Raw materials of the concrete precast block comprise bamboo sheet fibers, jute fibers, kraft paper, broken stones, recycled concrete, fly ash, perlite and phosphate cement. The green lightweight tensile bamboo reinforced concrete precast block produced in the invention has the advantages of light weight, large tensile strength, great reduction of the self-weight and the cracking probability of walls built by using the concrete precast block and the cracking probability of pavement bricks, good heat insulation property and good noise prevention performance. Materials used in the invention are more environmentally-friendly and economical than traditional brick materials, so the demand for clay is reduced, and the fertile land is protected. Waste concrete is reused, so resources are reasonably used.

Owner:FUJIAN AGRI & FORESTRY UNIV

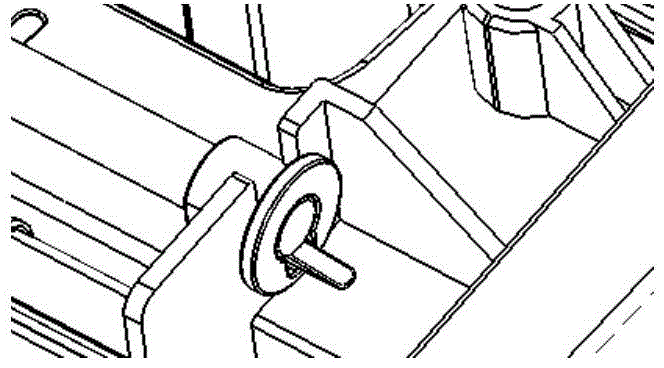

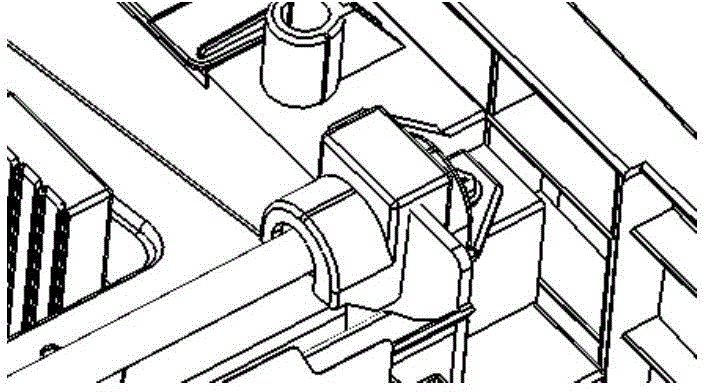

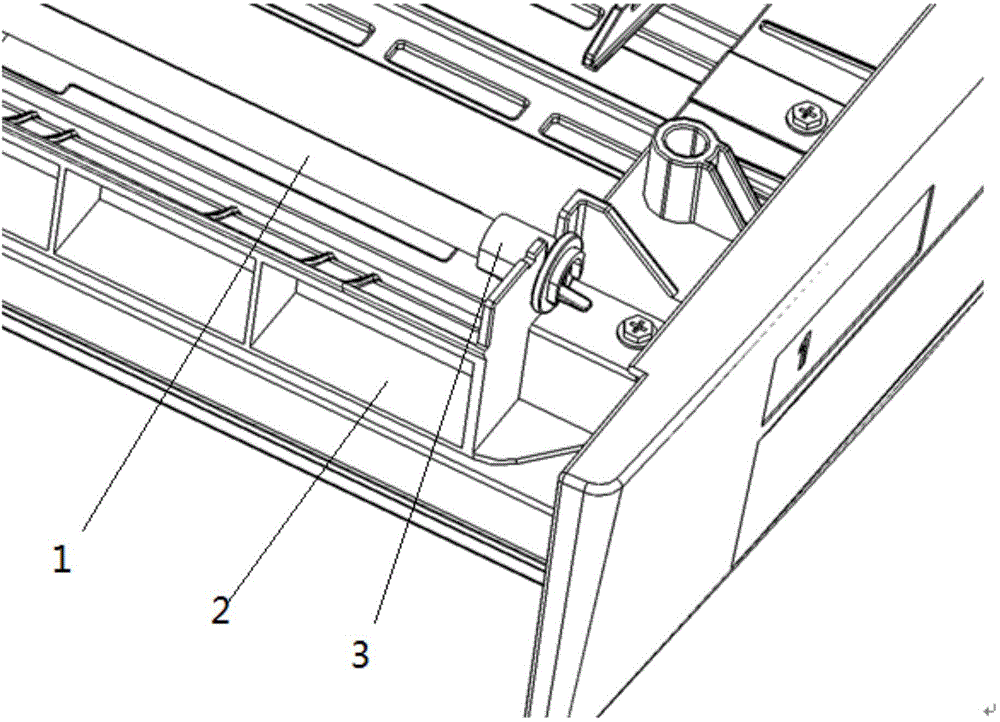

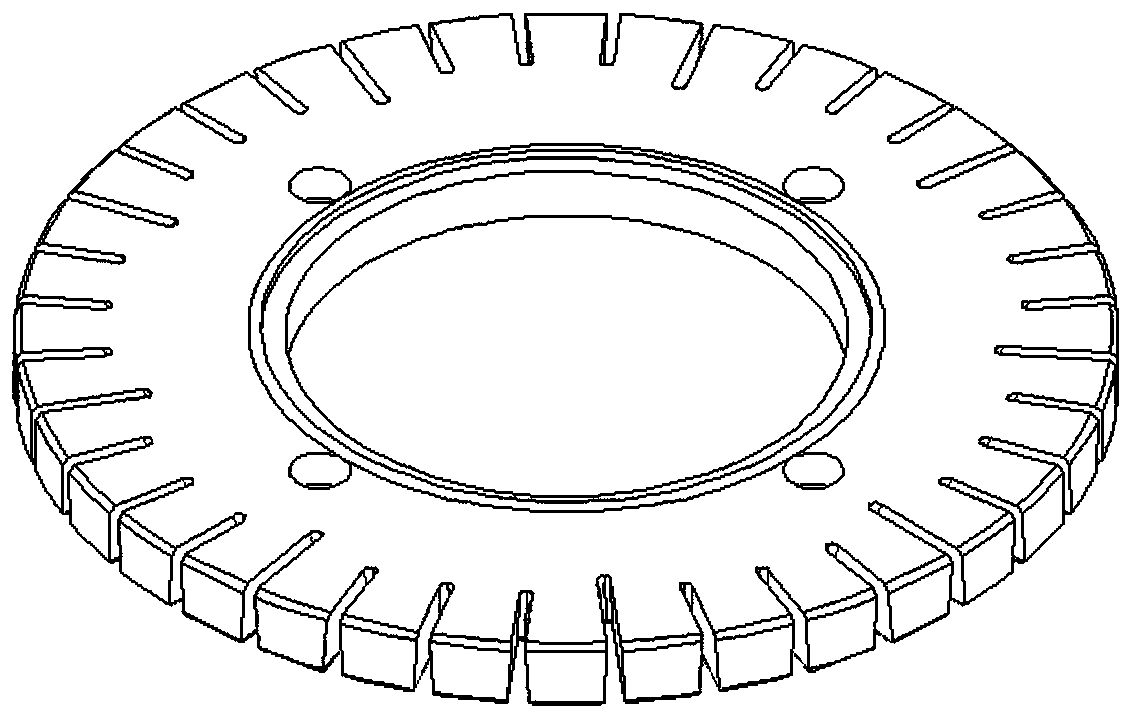

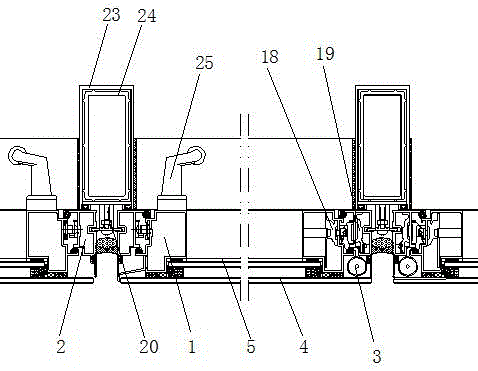

Ink powder prevention bearing mechanism of paper box of image forming device

ActiveCN103982555AImprove experienceGood anti-noise effectElectrographic process apparatusBearing unit rigid supportEngineeringMechanical engineering

The invention relates to a paper box of an image forming device, in particular relates to an ink powder prevention bearing mechanism of the paper box of the image forming device, and belongs to the technical field of image forming devices. The ink powder prevention bearing mechanism of then image forming device is characterized by comprising a paper conveying shaft (1) and an ink powder prevention bearing (3), wherein the ink powder prevention bearing (3) comprises a main bearing (3b); the outer end face of the main bearing (3b) is connected with a baffle (3d); a cambered cap (3a) inwards extending along the axial direction is arranged on the upper half part of the inner end face of the main bearing (3b); a convex rib (3a1) is arranged on the inner side of the cambered cap (3a) along the axial direction and is in contact with the paper conveying shaft (1); the outer end face of the baffle (3d) is connected with a dustproof cap (3c). The ink powder prevention bearing mechanism can prevent noise generated by a fact that ink powder enters a space between a shaft and a bearing; meanwhile, the number of parts is reduced, mounting is simplified, and the machine cost is lowered.

Owner:FUJI XEROX SHANGHAI

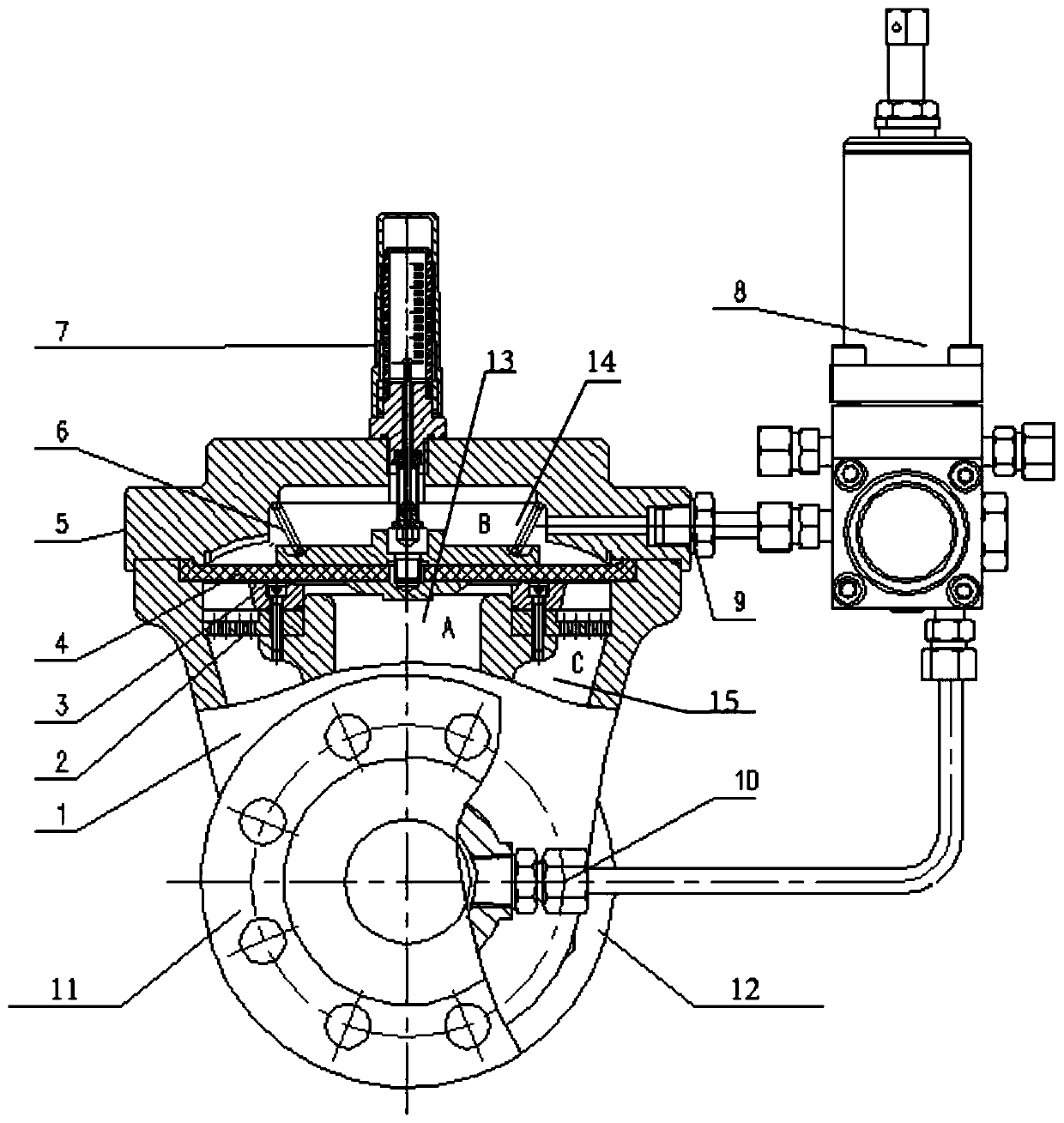

Radial flow type gas pressure regulator

PendingCN110307357ARealize shuntProne to noiseDiaphragm valvesOperating means/releasing devices for valvesNoise controlEngineering

A radial flow type gas pressure regulator is characterized by comprising a shell and a pressure regulating component; the top of the shell is provided with a valve cover, and a closed cavity is formedin the pressure regulator; the internal cavity of the shell is divided into a gas inlet cavity, a regulating cavity and a gas outlet cavity through the pressure regulation component; the shell is provided with a gas inlet and a gas outlet; the gas inlet extends into the gas inlet cavity, and the regulating cavity communicates with the gas outlet cavity; the gas outlet cavity communicates with thegas outlet; the pressure regulating component comprises a closing spring, an elastic membrane and a valve seat from top to bottom in sequence, and the elastic membrane is in tight contact with the valve seat; and the top of the elastic membrane is provided with the regulating cavity, and the bottom of the elastic membrane is provided with the gas inlet cavity. According to the radial flow type gas pressure regulator provided by the invention, the elastic membrane is used as an open-close part, and the radial type flow gas pressure regulator has the advantages of less movable components, the simple structure, convenient maintenance, good noise control effect, high practicability, safety and reliability and the like.

Owner:天津新科成套仪表有限公司

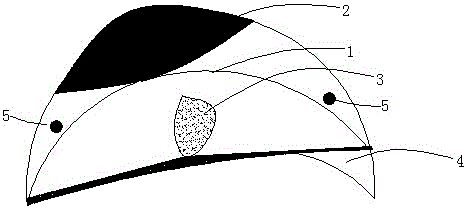

Intelligent anti-impact safety helmet

InactiveCN106235489AImprove impact resistanceWill not harmHatsHeadwear capsEngineeringElectrical and Electronics engineering

The invention discloses an intelligent anti-impact safety helmet and belongs to the field of safety supplies. The purpose is to solve the problems that the safety performance and anti-noise performance of an existing safety helmet are not good enough. The intelligent anti-impact safety helmet comprises a safety helmet body and a buffering device located at the top of the safety helmet body. Anti-noise devices are arranged on the inner sides of the two sides of the safety helmet body respectively, and provided with buckles. Clamping grooves or clamping hooks are formed in / arranged on the inner wall or the outer wall of the safety helmet body. The buckles on the anti-noise devices are matched with the clamping grooves or the clamping hooks on the safety helmet body to fix the anti-noise devices, cuboid grooves are formed in the inner walls of the anti-noise devices, the inner walls of the grooves are covered with layers of sponge, a neck-protecting device is arranged on the rear side of the safety helmet body, safety warning lights are arranged on the outer wall of the safety helmet body, and a solar panel is arranged on the outer wall of the safety helmet body and used for supplying power to the safety warning lights.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

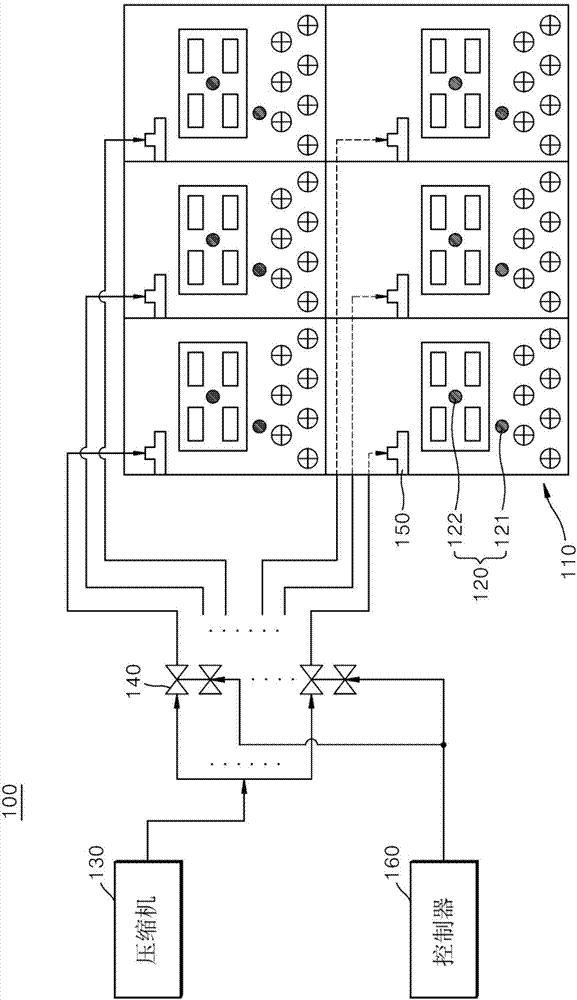

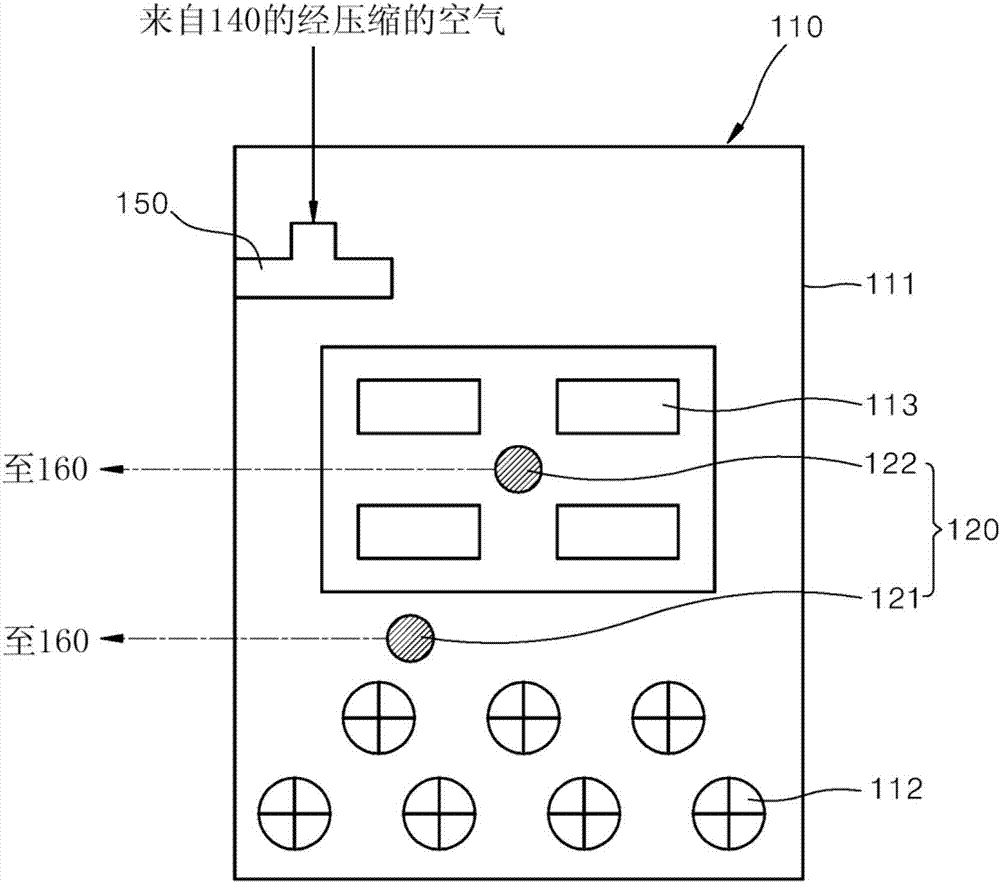

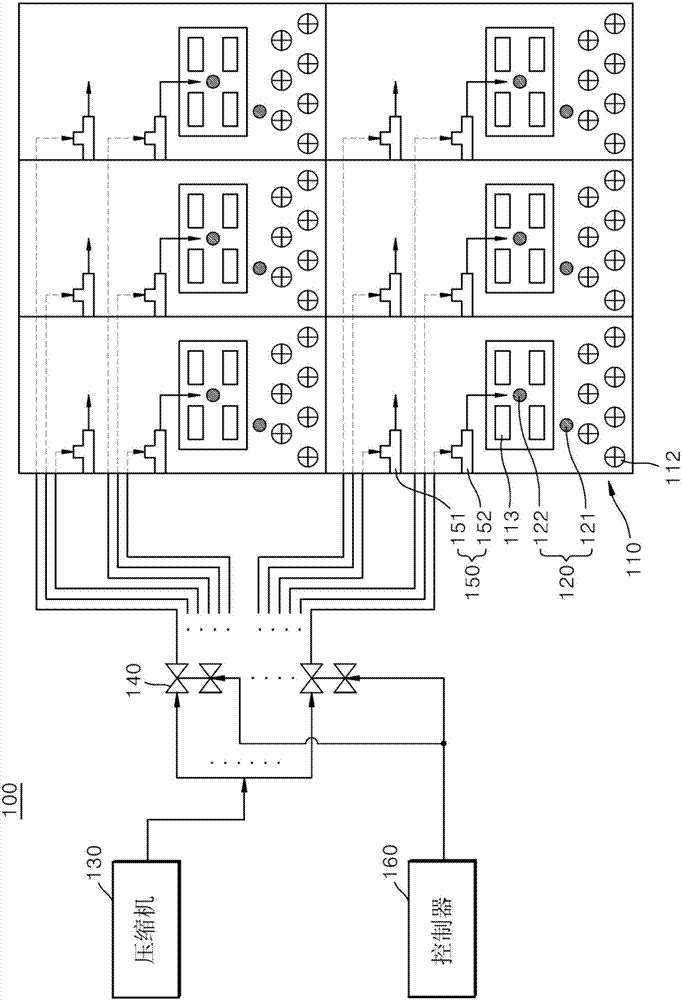

Cooling system for two-dimensional array power converters

ActiveCN107092281ASave installation spaceReduce replacement costsTemperatue controlCompression machinesElectrical and Electronics engineeringCompressed air

Disclosed herein is a cooling system for two-dimensional array power converters. The cooling system includes: a plurality of power converters 110 arranged in two-dimension; a compressor 130 configured to generate compressed air; vortex tubes 150 each installed in the respective power converters, the vortex tubes configured to generate low-temperature air based on compressed air from the compressor; valves 140 installed between the compressor and the vortex tubes; temperature sensors 120 each installed in the respective power converters to measure temperature inside the power converters; and a controller 160 configured to determine whether to supply the low-temperature air into the power converters by using the vortex tubes, based on the temperature measured by the temperature sensors, and to control the valves depending on a result of the determination.

Owner:LSIS CO LTD

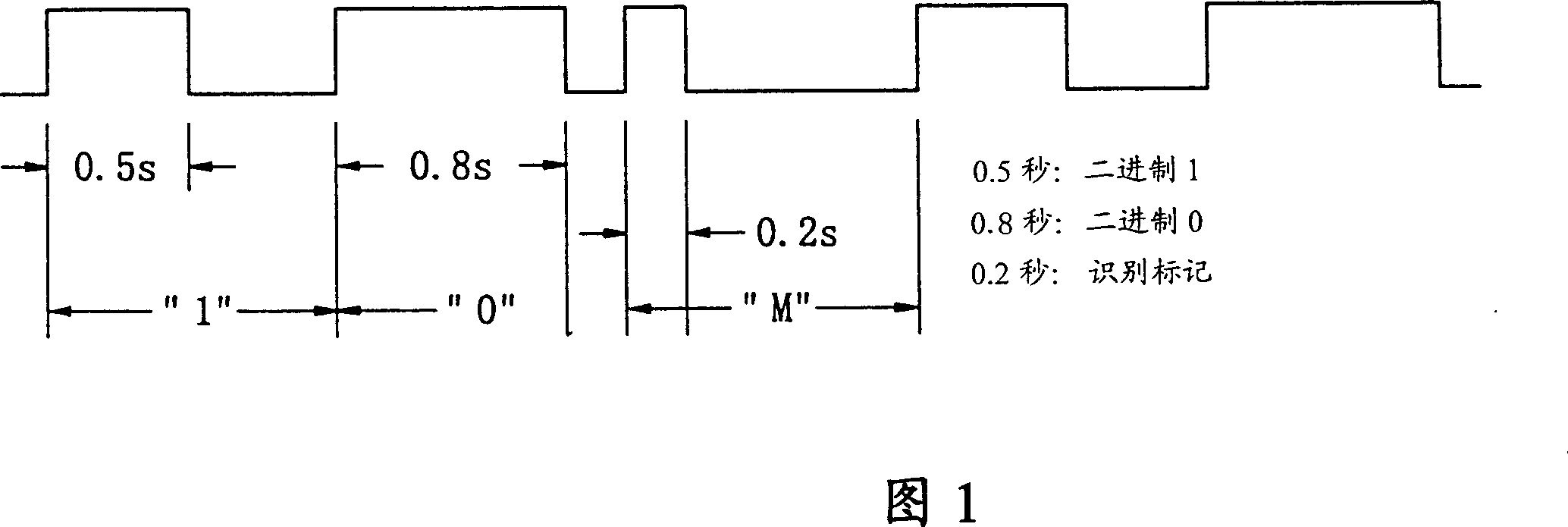

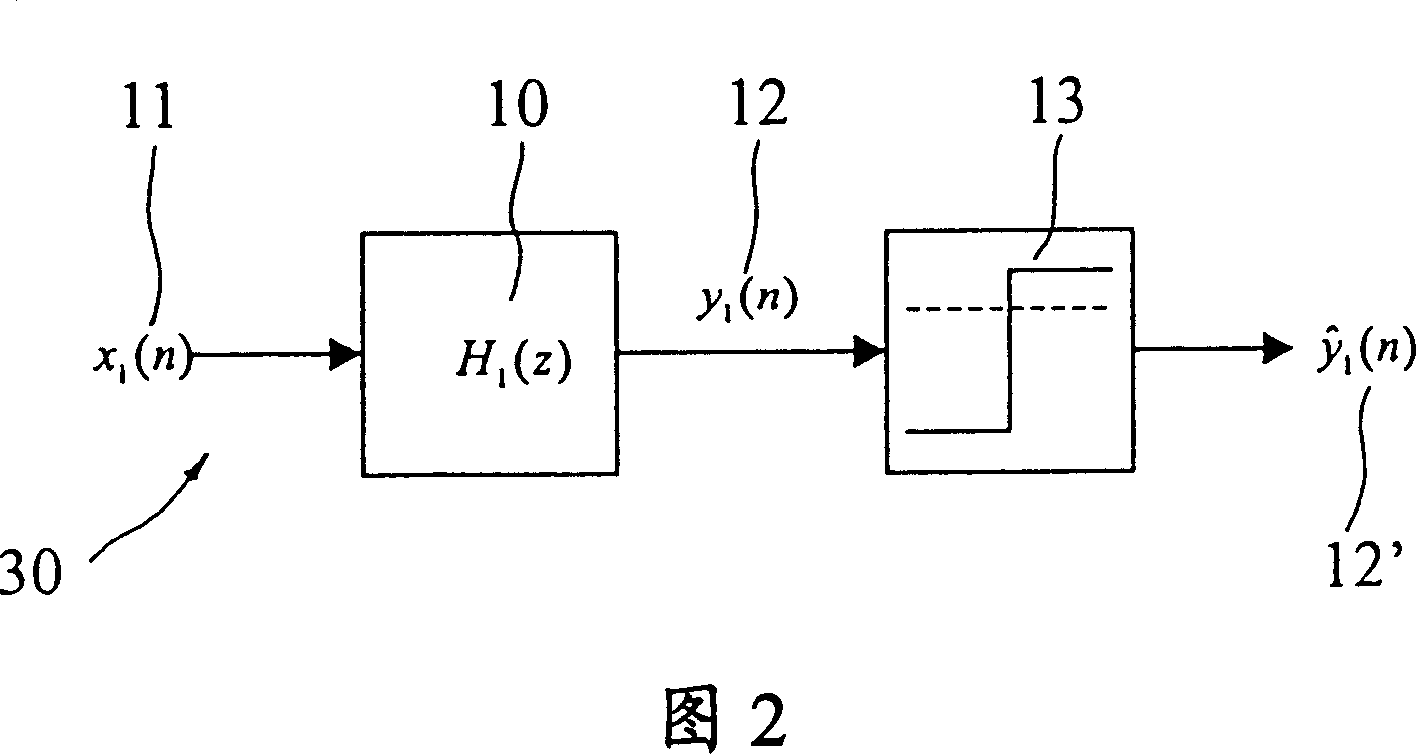

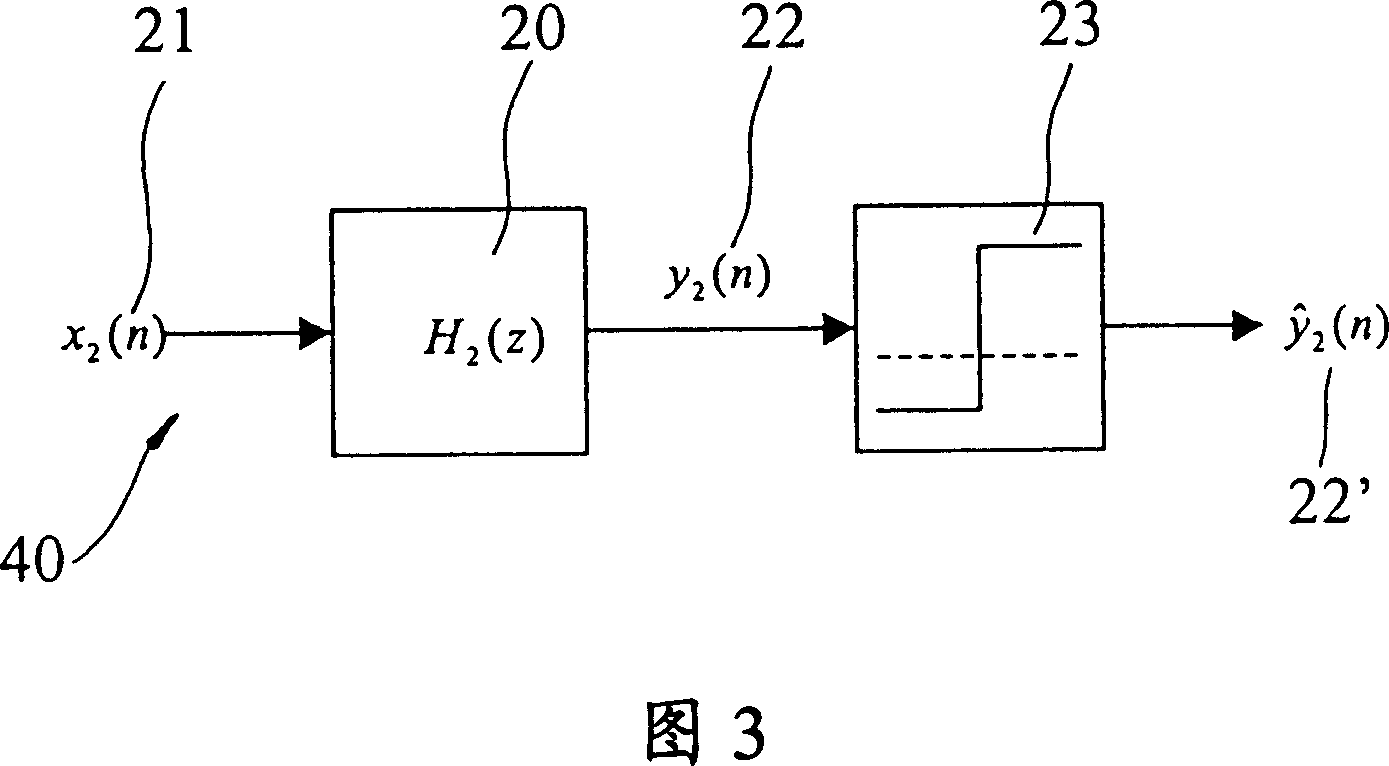

Non-linear digital filtering method for handling binary noise

The invention refers to a nonlinear digital filter method to process dual noise, especially adopting firmware to design a 'nonlinear digital filter', producing filter effect on the noise of low-frequency radio-controlled timepieces, and having efficacies of overcoming the persecution of pulse-type dual noise, saving extra hardware cost, and preventing the parts from aging and being influenced by environmental factor.

Owner:HIGHER WAY ELECTRONICS

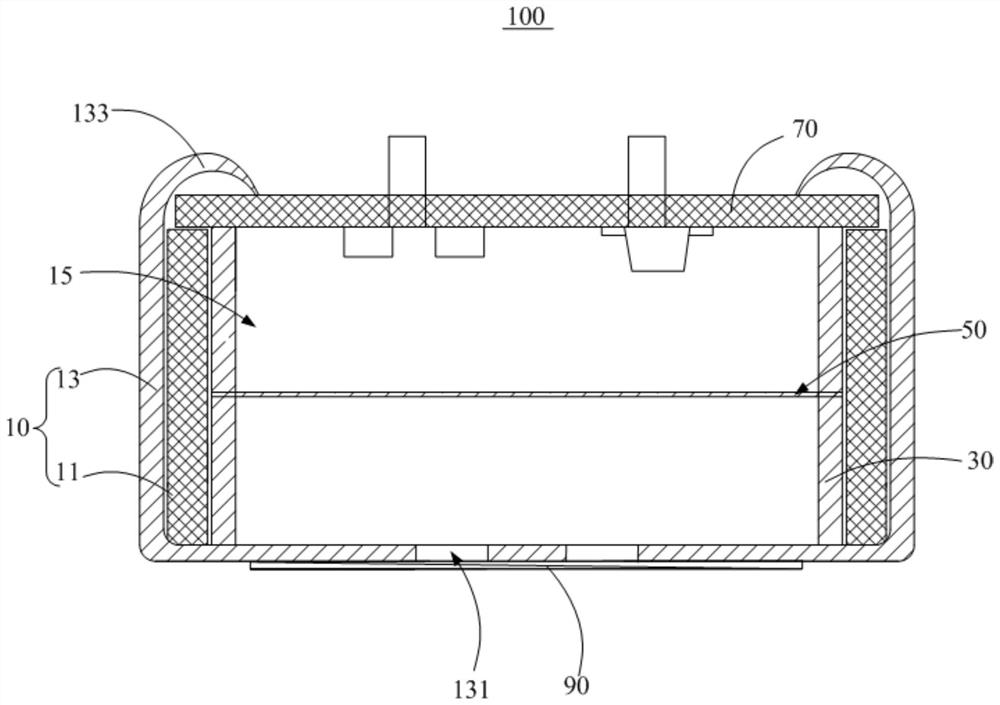

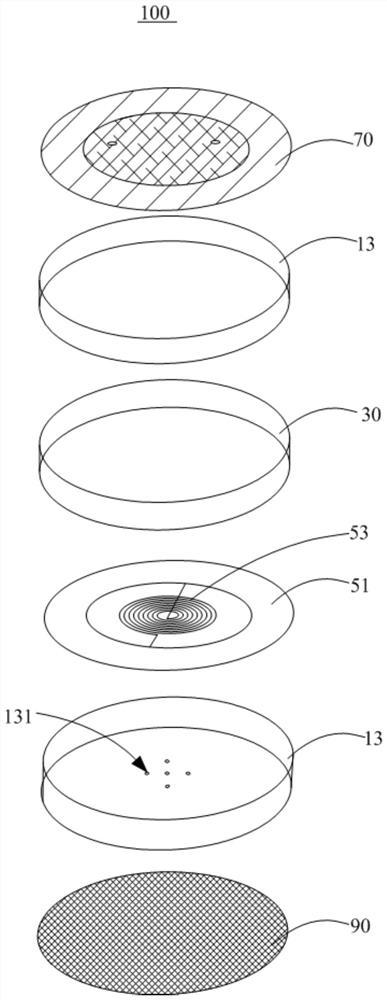

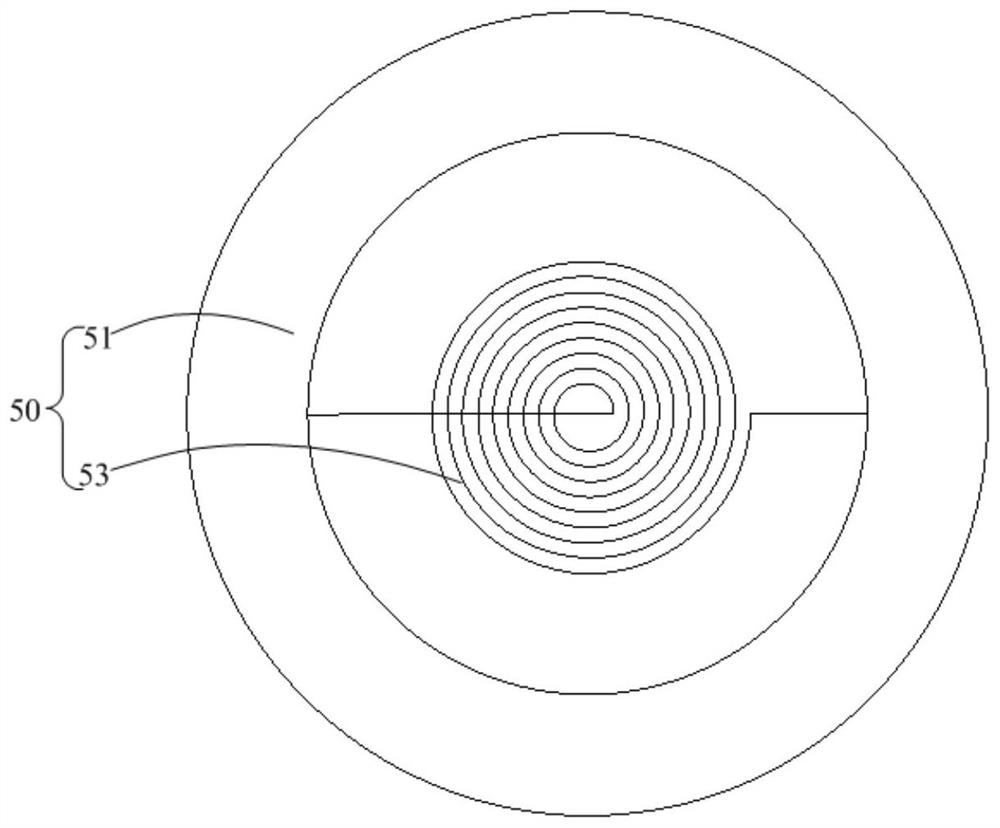

Microphone and electronic equipment

ActiveCN112954557ASimple structureEasy to produceMicrophonesMouthpiece/earpiece sanitary/hygienic devicesElectrical connectionEngineering

The invention discloses a microphone and electronic equipment. The microphone comprises a shell, wherein an accommodating cavity is formed in the shell, and the shell is further provided with a sound hole communicated with the accommodating cavity; a circuit board which is arranged at one end, far away from the sound hole, of the accommodating cavity; an annular magnet which is accommodated in the accommodating cavity and is fixedly connected with the cavity wall of the accommodating cavity; and a vibration assembly which is connected with the annular magnet and electrically connected with the circuit board, wherein at least part of the vibration assembly is located on the inner side of an annular space defined by the annular magnet, the vibration assembly is arranged towards the sound hole, and audio frequency can penetrate through the sound hole to enter the containing cavity, and the vibration assembly is driven to vibrate in the accommodating cavity, so that the vibration assembly cuts magnetic induction lines to generate current signals. The technical scheme of the invention aims to improve the acoustic performance and prolong the service life of the microphone.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

An intelligent environment control system for improving the operating environment of equipment

InactiveCN107734922BGuaranteed uptimeQuality assuranceLighting and heating apparatusWallsIntelligent environmentControl system

The invention discloses an intelligent environment control system for improving an equipment operation environment. The intelligent environment control system relates to the technical field of environment control systems, and is mainly composed of an acquisition module, a regulation and control system and a monitoring terminal. The intelligent environment control system not only has good heat dissipation and dehumidification effects on a cabinet body, but also provides a good monitoring environment for a monitoring room.

Owner:安徽瀚和智能科技有限公司

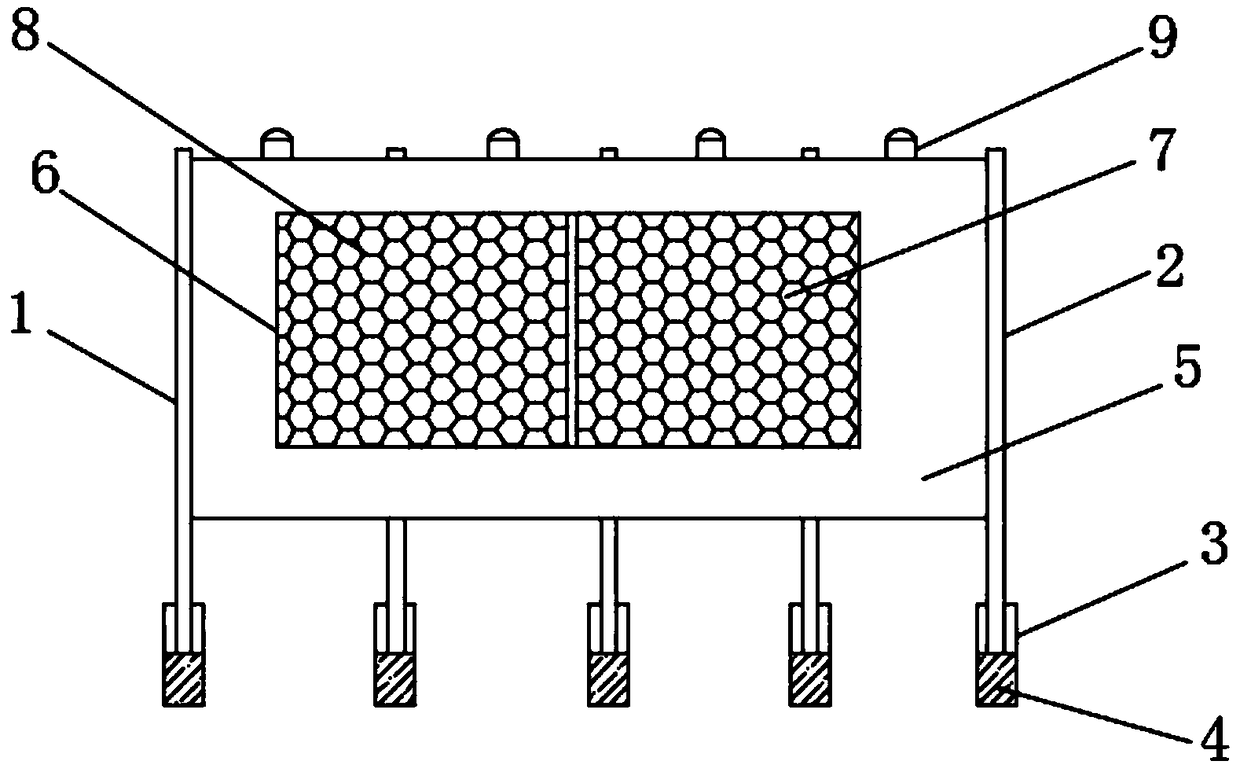

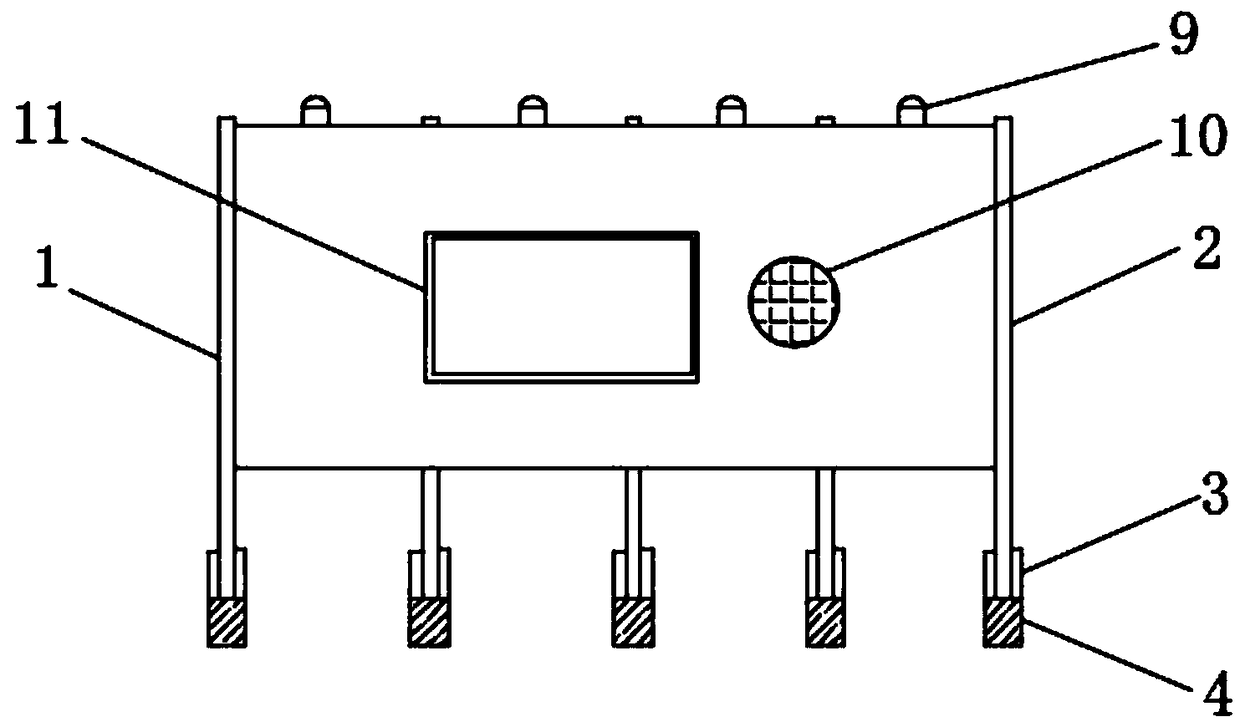

Anti-noise fence for building engineering construction

InactiveCN108824960AInterfere with daily lifeEasy to observePhotovoltaic supportsBatteries circuit arrangementsArchitectural engineeringPhotovoltaics

The invention discloses an anti-noise fence for building engineering construction. The anti-noise fence comprises a first support column, and a second support column is arranged on one side of the first support column. A base is fixedly mounted on the outer surface of the bottom end of the second support column, and a counterweight block is arranged at the bottom of the base. A panel is disposed between the first support column and the second support column, and a solar panel is fixedly mounted on the front surface of the front end of the panel. The solar panel is provided with a first photovoltaic module and a second photovoltaic module, wherein the first photovoltaic module is located on one side of the second photovoltaic module. Warning lights are uniformly distributed on the outer surface of the upper end of the panel, a display screen is fixedly mounted on the outer surface of the rear end of the panel, and a through hole is formed in one side of the display screen. The anti-noise fence for the building engineering construction can detect the intensity of noise, avoids excessive noise to interfere with the daily life of citizens and can fully use solar energy for power generation, and the overall stability is high.

Owner:HEFEI JINGMEI GRAPHIC TECH CO LTD

Heat resistant magnesium alloy and composite material containing heat resistant magnesium alloy and its preparation method

The invention provides a heat-resistant magnesium alloy, and the compositions in mass percentage of the alloy are: more than or equal to 3 percent and less than or equal to 7 percent of Al, more than or equal to 0.5 percent and less than or equal to 7 percent of Zn more than or equal to 0.5 percent and less than or equal to 2 percent of Ti, more than or equal to 1 percent and less than or equal to 6 percent of Sn, more than or equal to 0.01 percent and less than or equal to 0.1 percent of La, more than or equal to 0.5 percent and less than or equal to 4 percent of Si and more than or equal to 0.05 percent and less than or equal to 0.6 percent of Zr and the balance being manganese. The heat-resistant magnesium alloy uses only such normal non-precious rare elements as Al, Zn, Ti, Sn, La, Si and Zr, has low cost and keeps good heat-resistant property without adding the elements; and the plastic deformation rate of the alloy is 0.2 to 0.35 percent at the temperature of 250 DEG C and under the stress of 30Mpa, and the alloy can be widely applied in the working environment of high temperature. The heat-resistant magnesium-based porous composite material consists of heat-resistant magnesium alloy and a minimum-density heat-resistant inorganic porous material, has heat-resistant function and good damping property below the temperature of 250 DEG C, can be widely applied to the heat-resistant vibration-absorption parts and components of rapid machinery like an automobile, and has the advantages of good vibration-absorption, sound insulation and voice confusion. The composite material is simple in preparation process and low in production cost.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

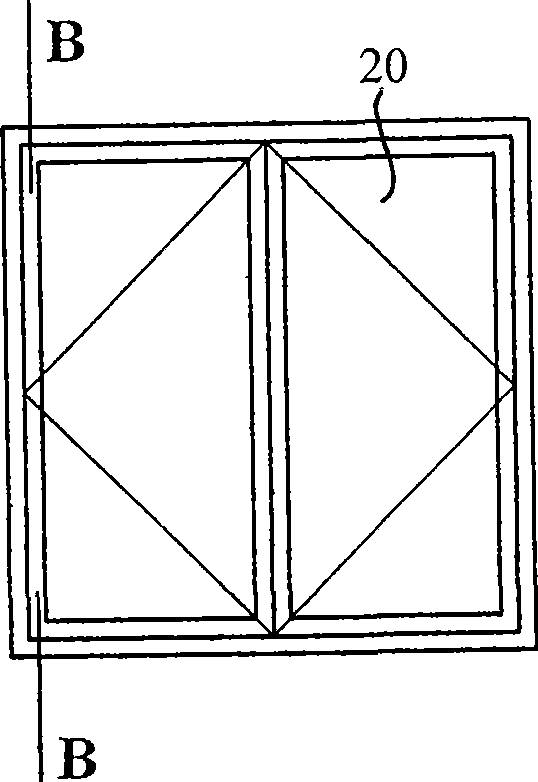

A hidden-type outward casement window of a glass curtain wall

ActiveCN106121449ASimple and fast operationIncrease lighting and ventilation areaWindow/door framesConstruction fastening devicesMating connectionEngineering

The invention provides a hidden-type outward casement window of a glass curtain wall. The outward casement window comprises an upper end portion connecting part, a lower end portion connecting part, a left side connecting structure, a right side connecting structure and a hollow glass body. A handle is connected to the inner side of the left side connecting structure; the left side connecting structure is in mating connection with a left window frame; the right side connecting structure is connected with a moving mechanism and is in mating connection with a right window frame; the moving mechanism is movably connected between the right side connecting structure and the right window frame; the left window frame and the right window frame are fixedly connected with an aluminum alloy stand pillar. The outward casement window has the advantages of simple structure, great installation stability, large horizontal opening angle and large day lighting and ventilation area. With the hidden-type design, the aluminum alloy section bar is hidden, so that the overall penetration and appearance of a glass curtain wall are improved; the casement window is high in safety and stability.

Owner:江苏晶天建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com