Patents

Literature

39results about How to "Eliminate noise sources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

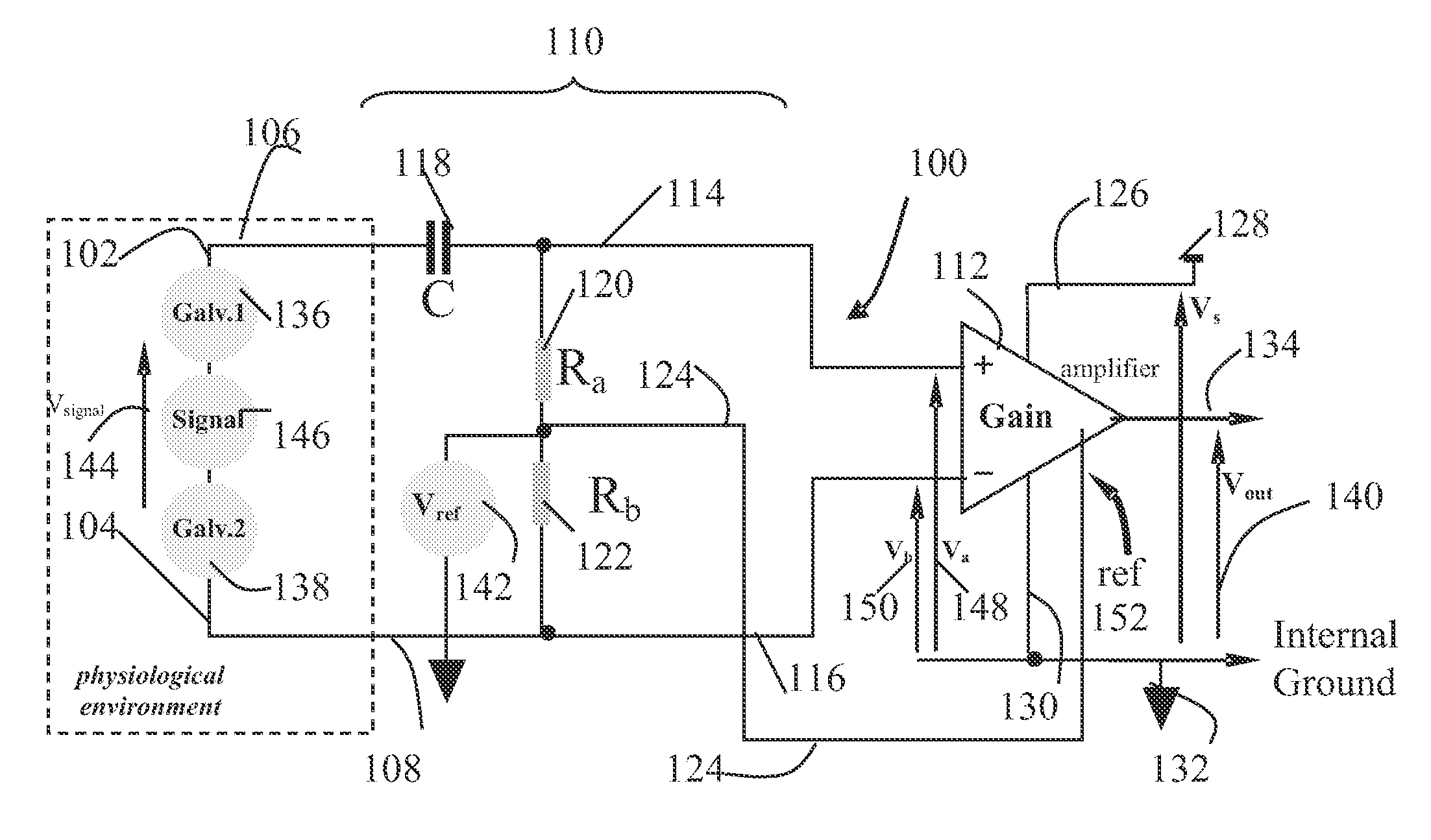

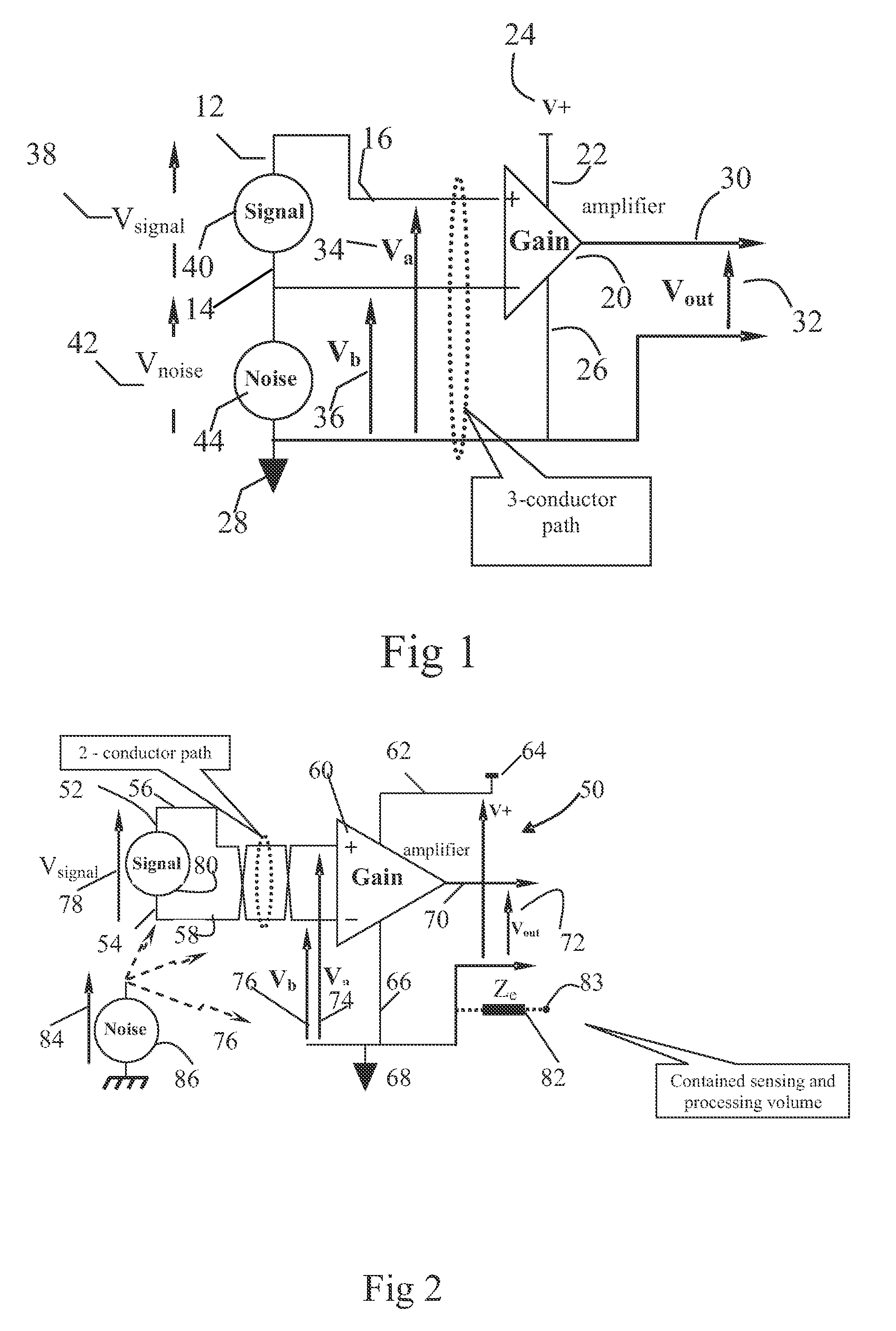

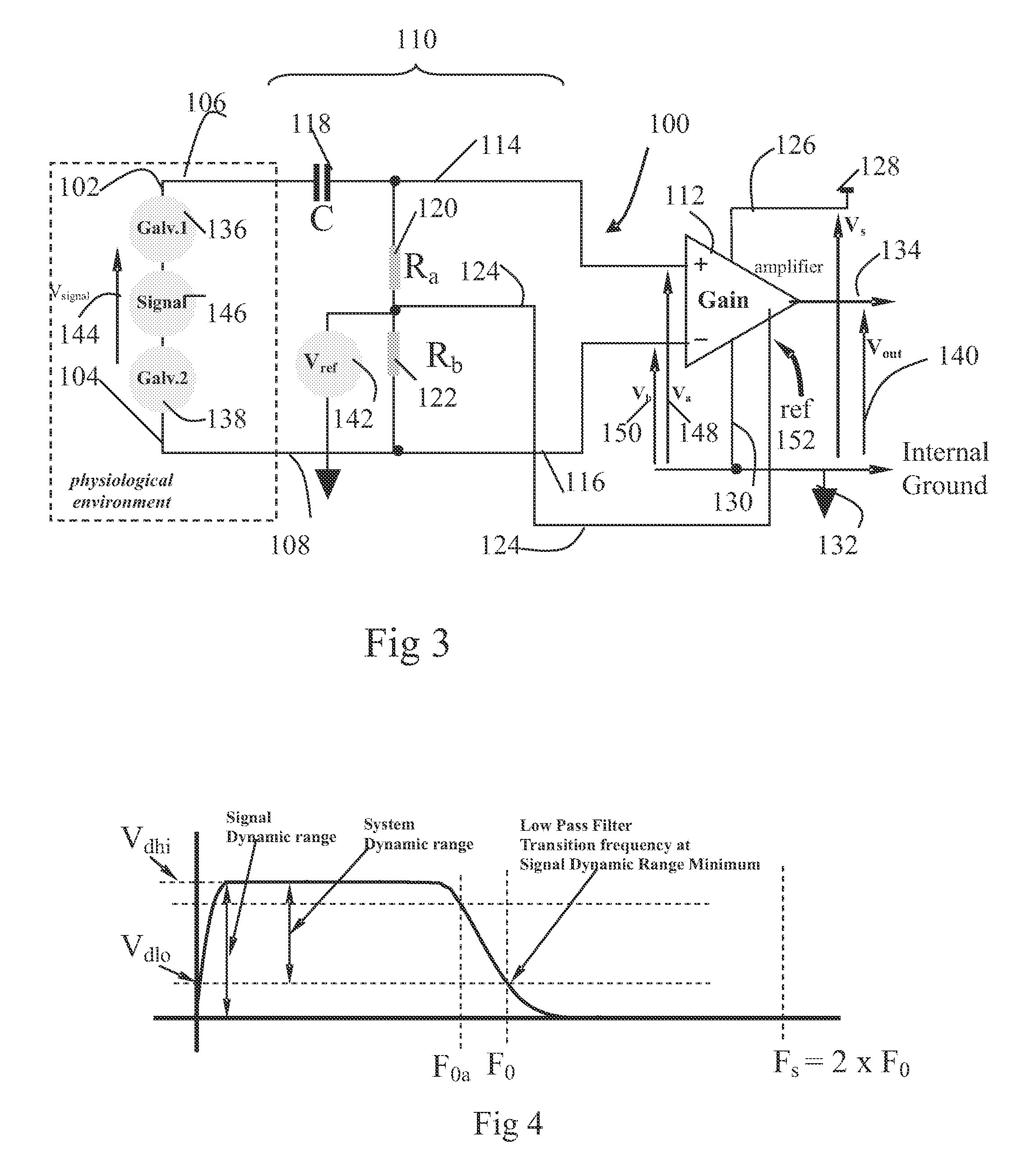

Signal sensing in an implanted apparatus with an internal reference

InactiveUS20080146894A1Avoid pick upElimination of DC and very low frequency noiseHeart stimulatorsDiagnostic recording/measuringVoltage referenceSignal correlation

An apparatus for sensing biological signals from an animal. The implanted apparatus includes at least one implantable electrode pair that is connected to a twisted pair of insulated conductors. The electrode pair is disposed at a first set of locations to sense biological signals. The twisted pair of insulated conductors is connected to an instrumentation amplifier via a passive network of filters. The amplifier amplifies the filtered biological signal from the electrode pair to provide an amplified differential signal. The amplifier has an internal voltage reference. Additionally, an energy source powers the apparatus without being connected to mains or an isolation transformer of medical equipment. A signal analysis module analyzes amplified differential signals to obtain at least one physiological parameter. The apparatus may also comprise a signal presentation module to display amplified signals and physiological parameters associated with the signal.

Owner:KENERGY INC

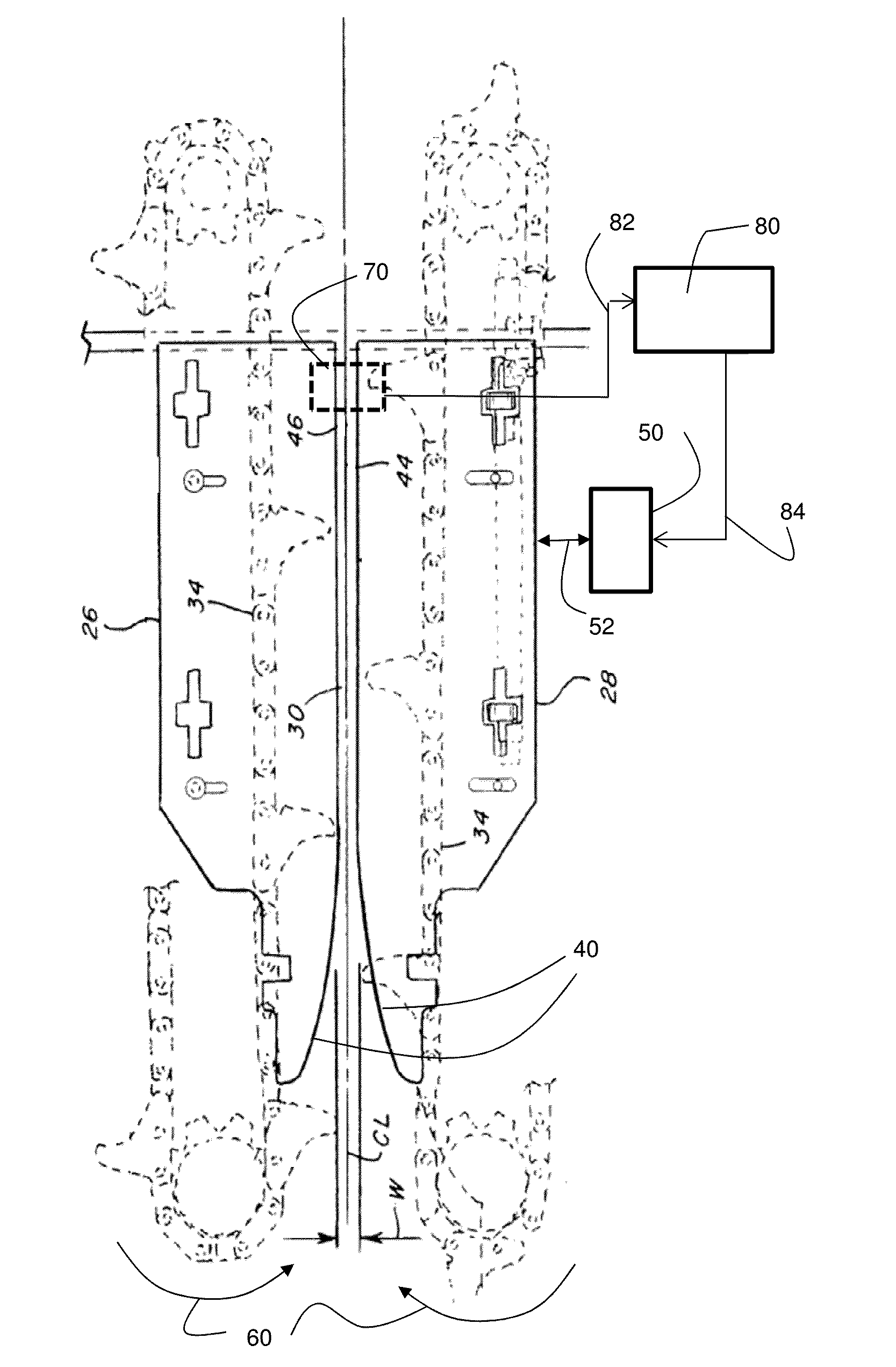

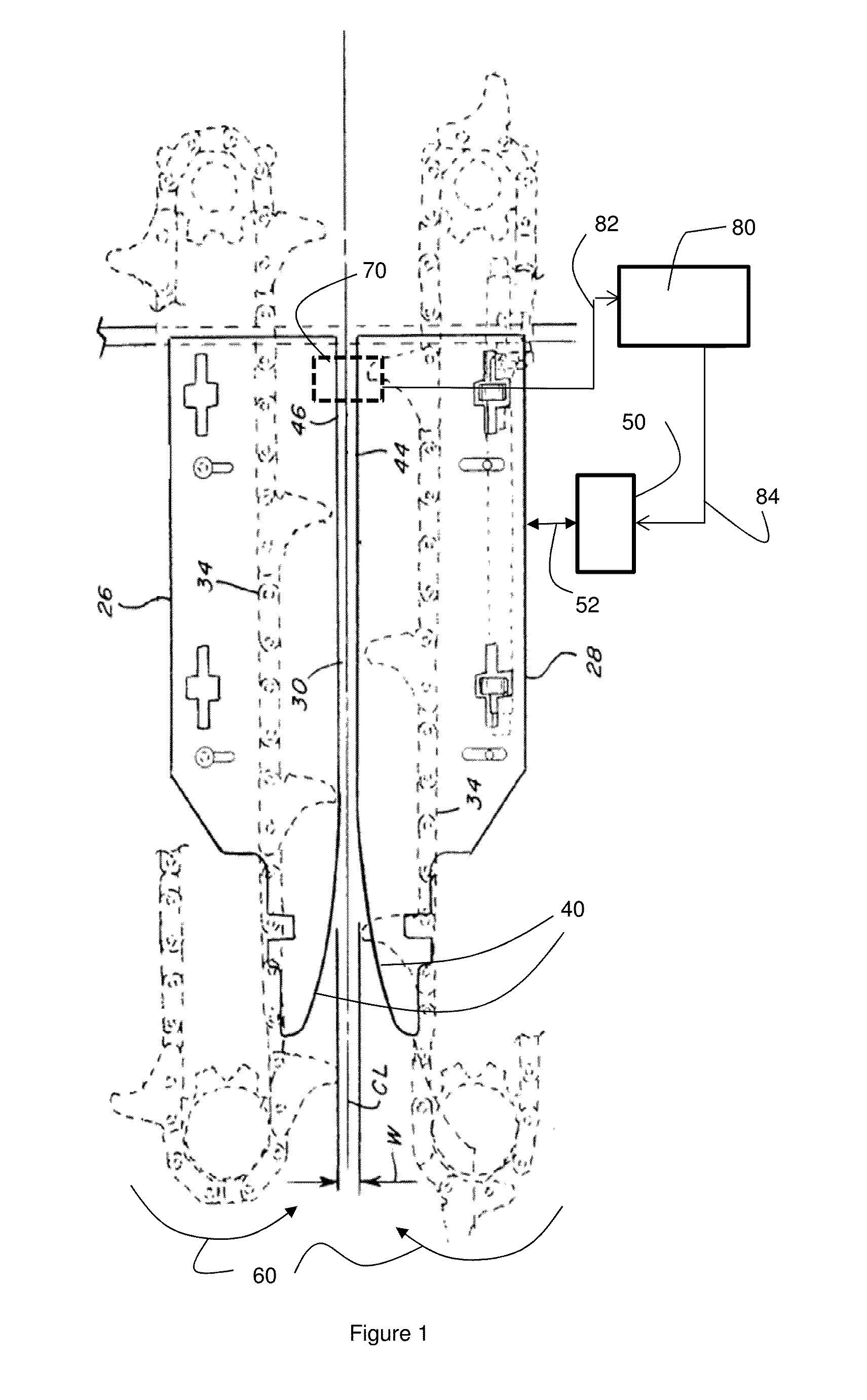

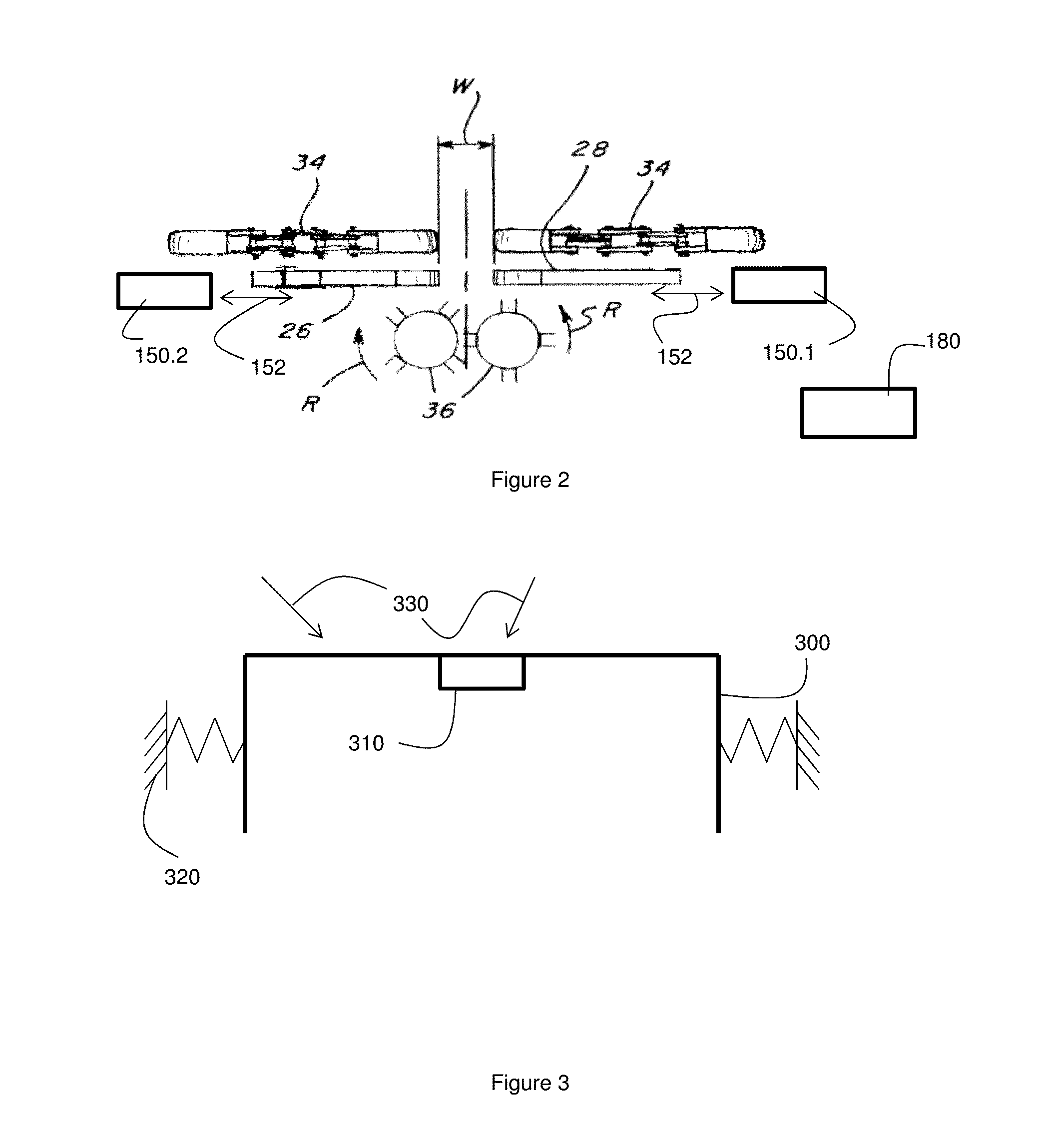

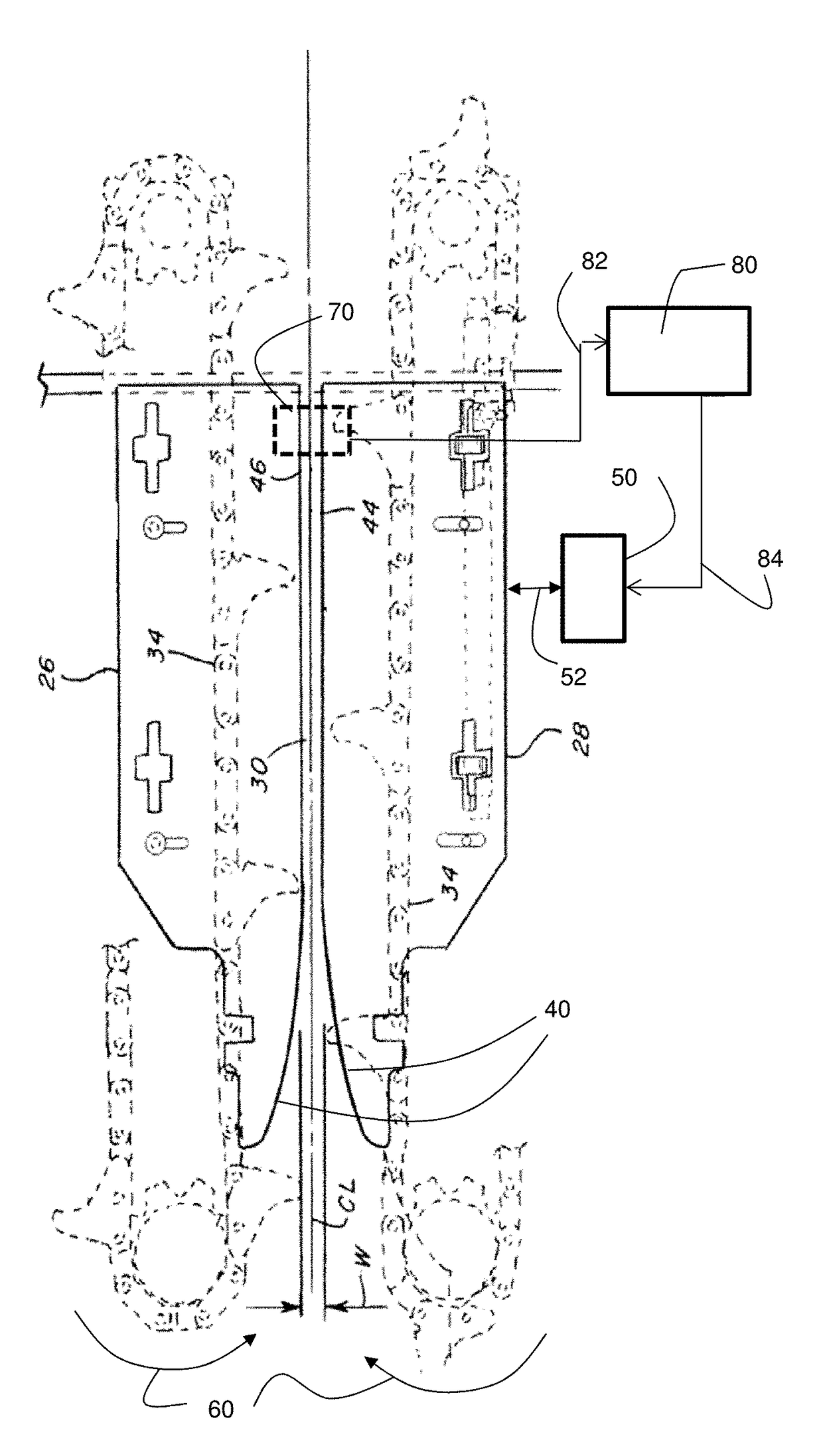

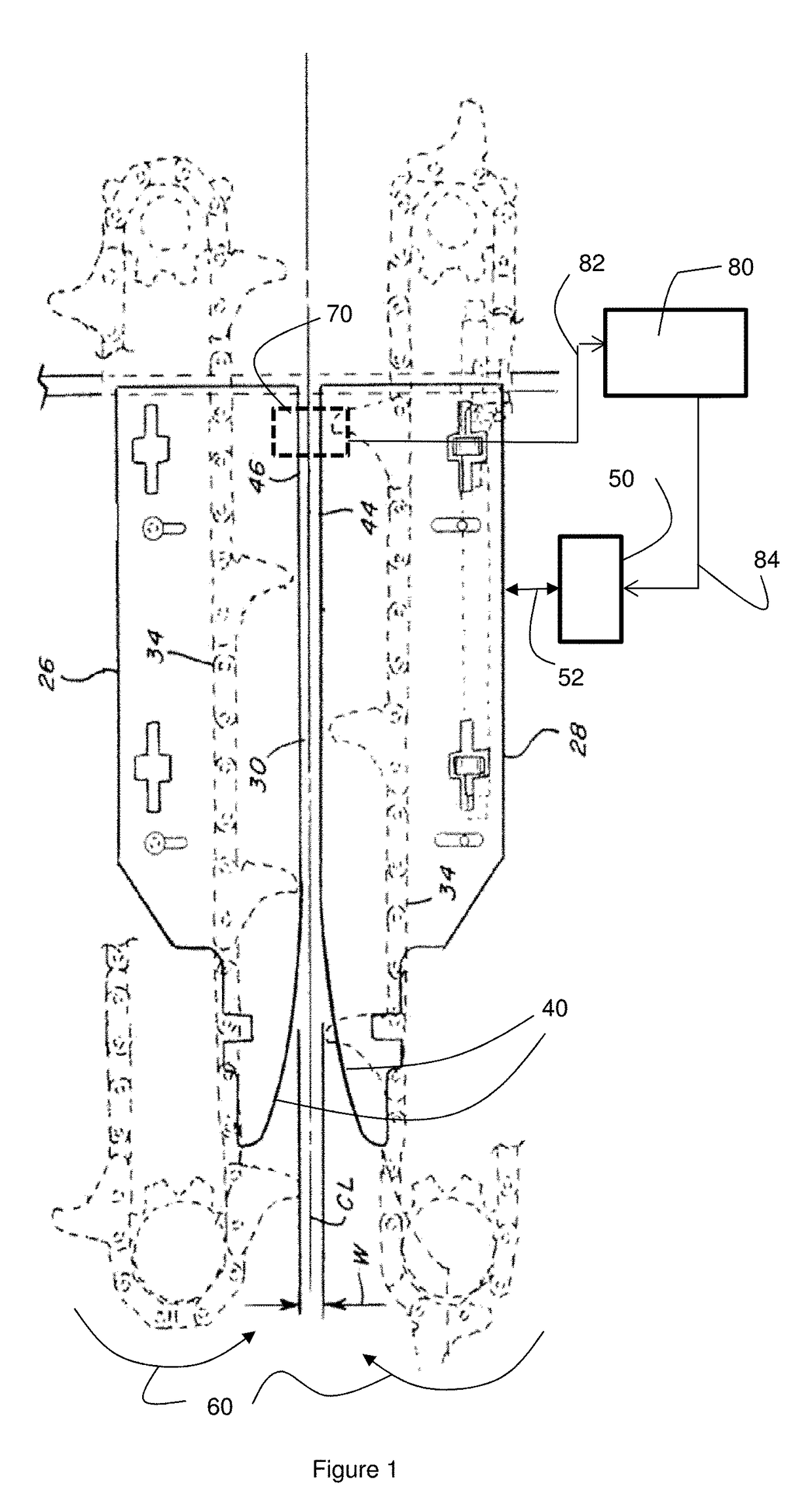

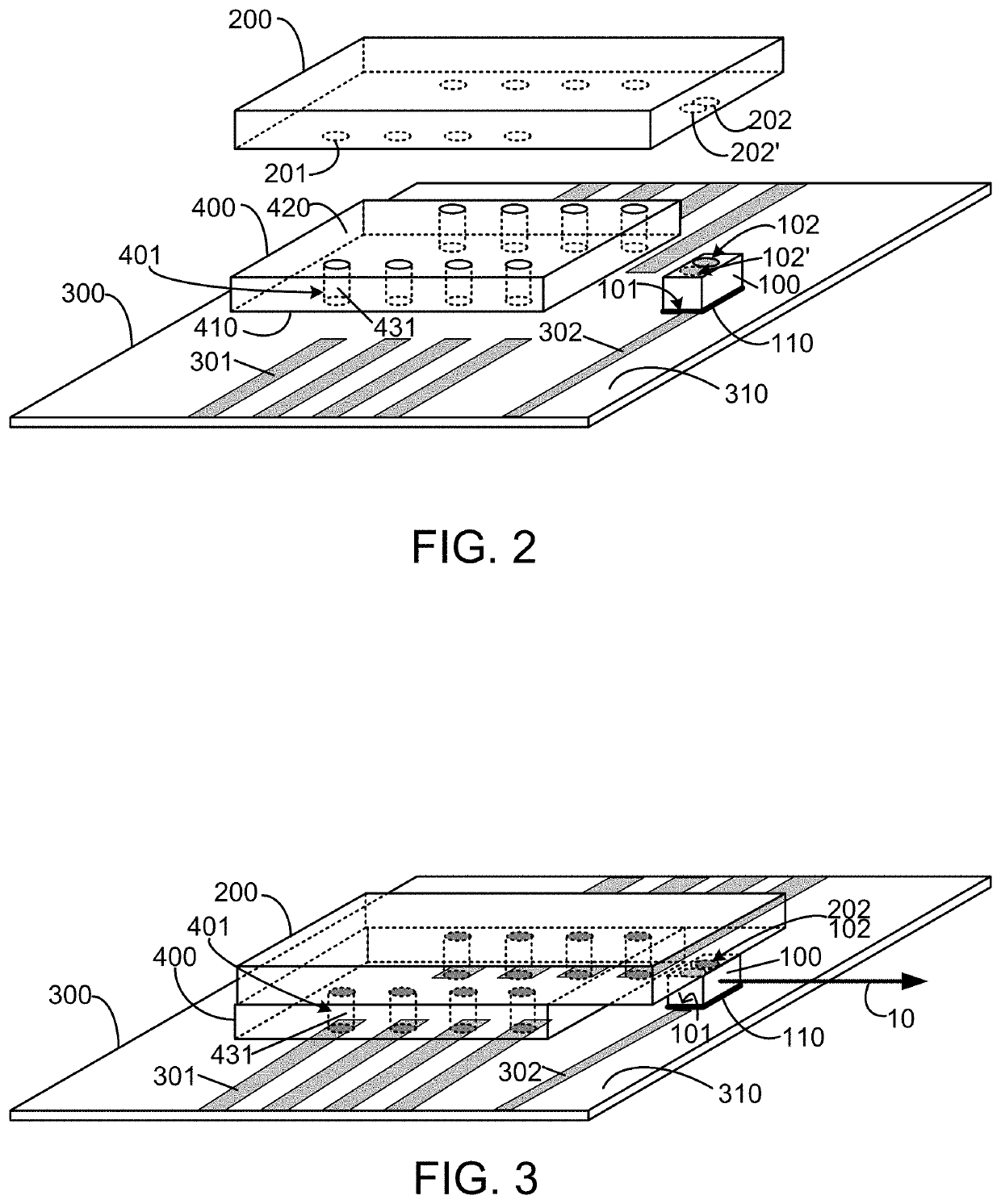

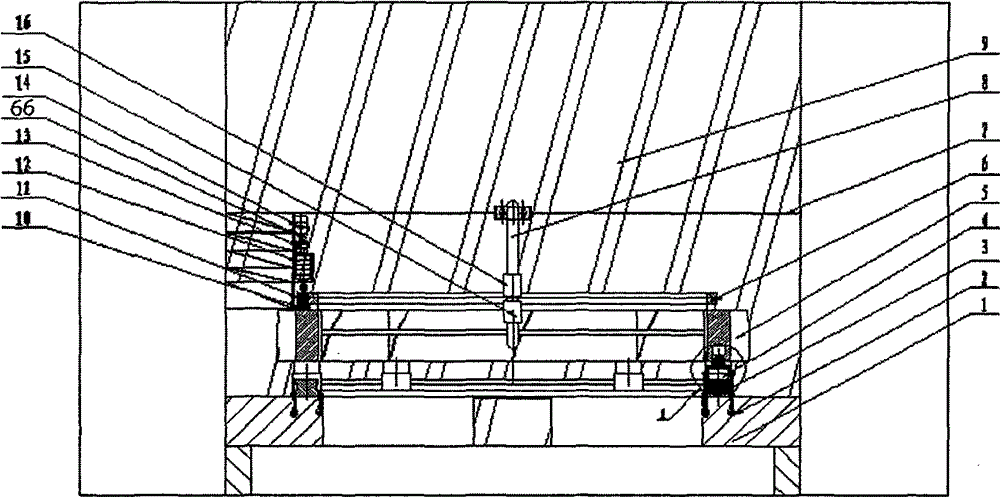

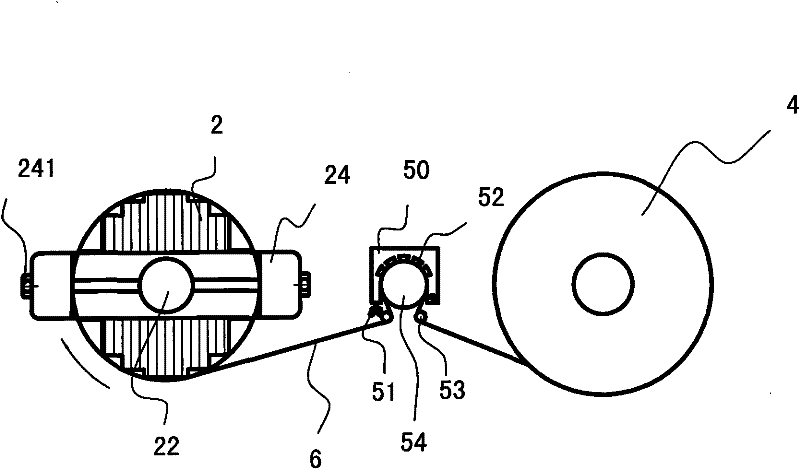

Corn Header Including Kernel Sensor for a Combine Harvester

ActiveUS20160113199A1Reduce decreaseEliminate noise sourcesMowersPicking devicesControl signalActuator

A corn header includes a plurality of harvesting units to separate corn ears from corn stalks. Each harvesting unit has a deck plate assembly, and an actuator assembly to adjust a width of a stalk receiving channel by adjusting a position of at least a deck plate of the deck plate assembly. A kernel sensor can generate a signal representative of the presence of kernels detached from the ears during the separation of the corn ears from the corn stalks by the harvesting units and a control unit to receive the signal from the kernel sensor and generate an actuator control signal for controlling the actuator assemblies of the plurality of harvesting units, thereby controlling the width of the stalk receiving channels of the harvesting units.

Owner:BLUE LEAF I P INC

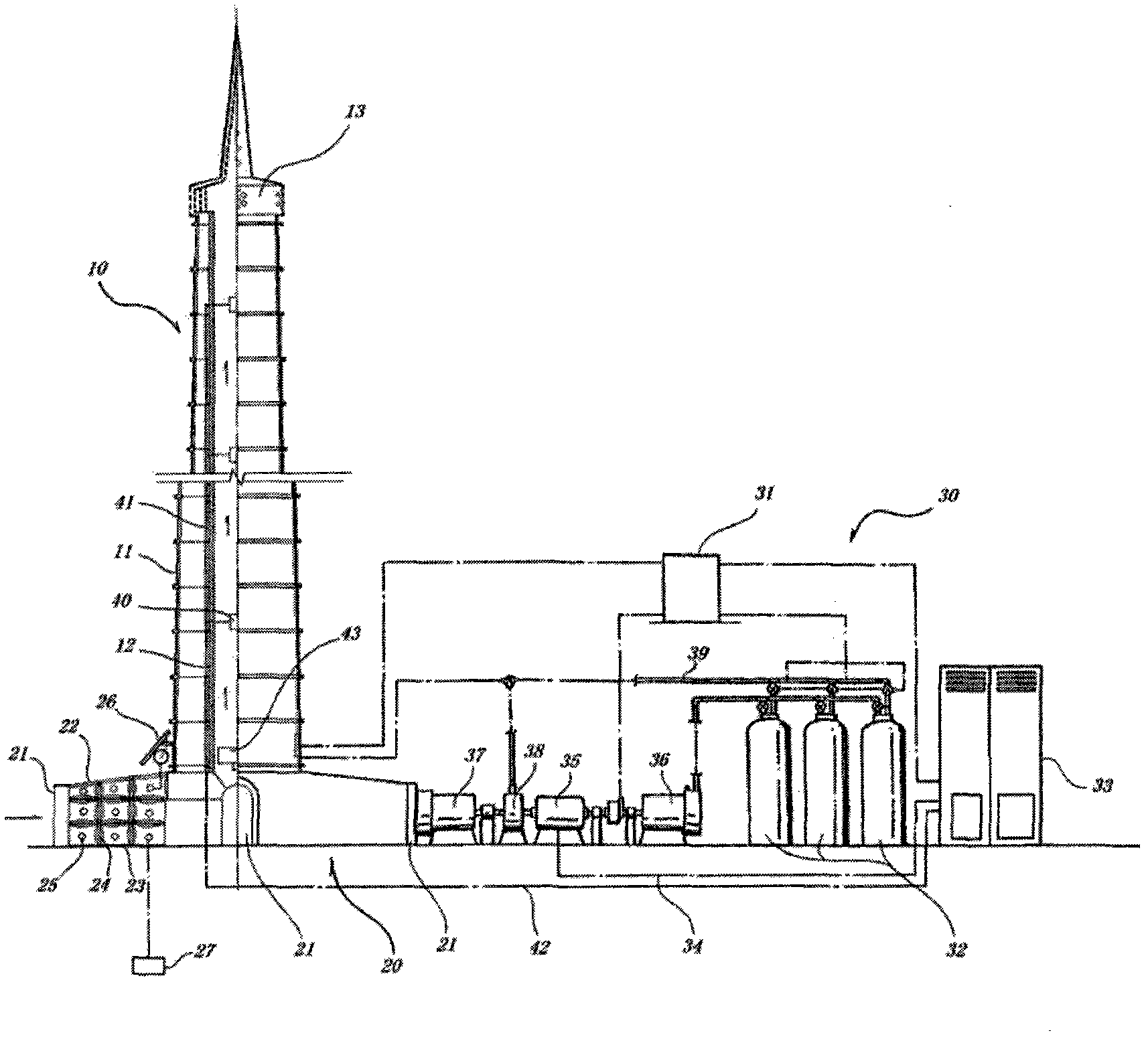

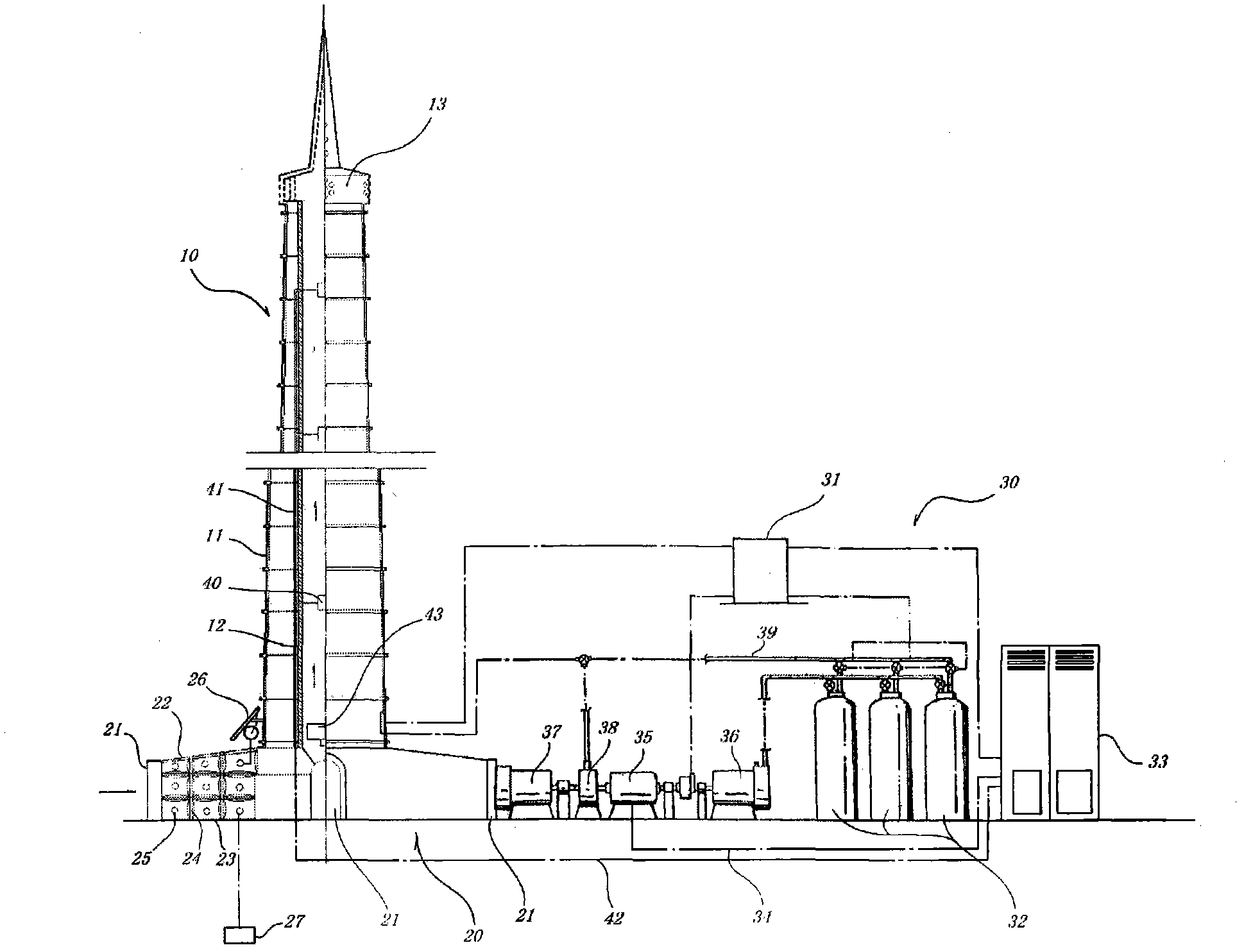

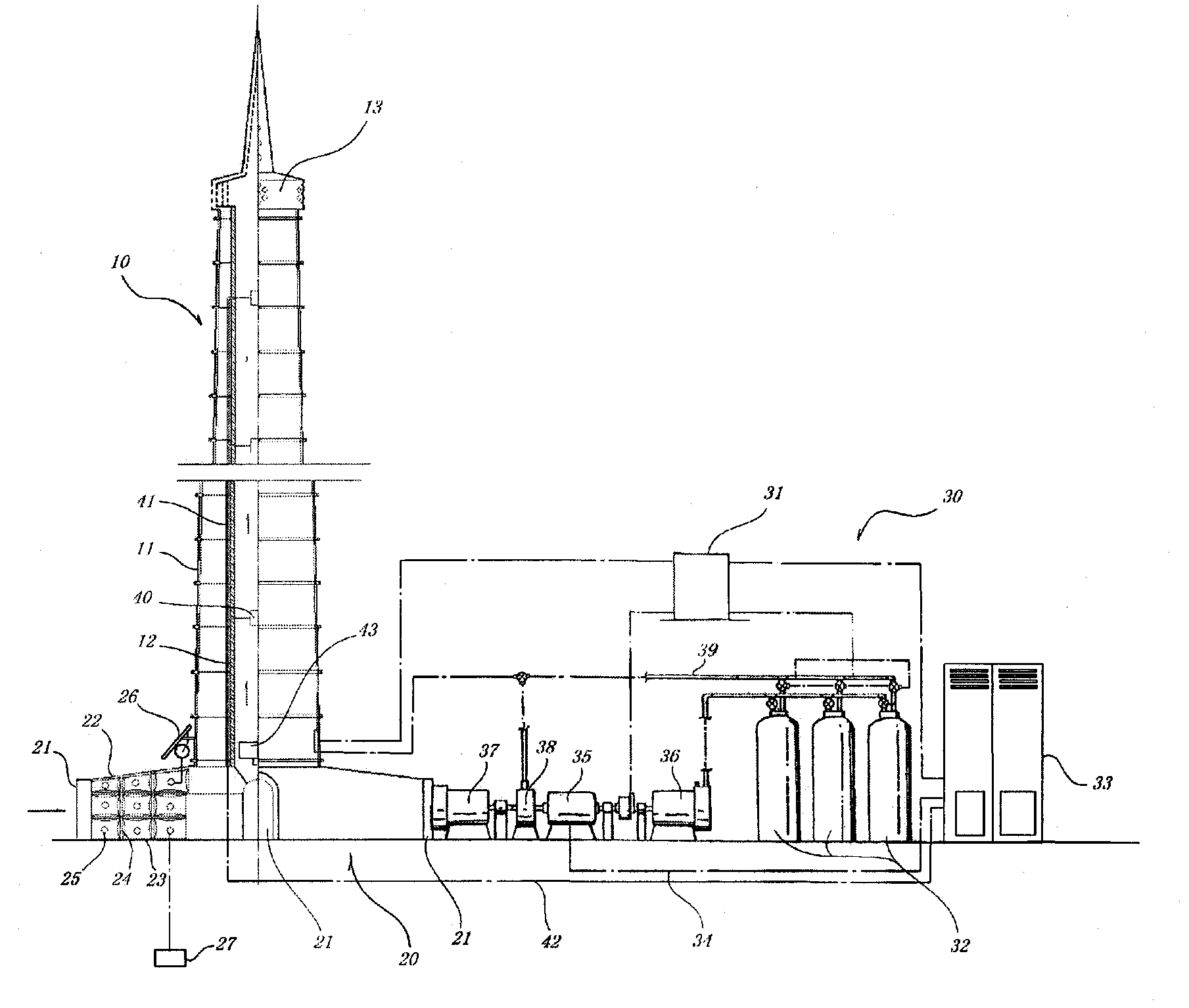

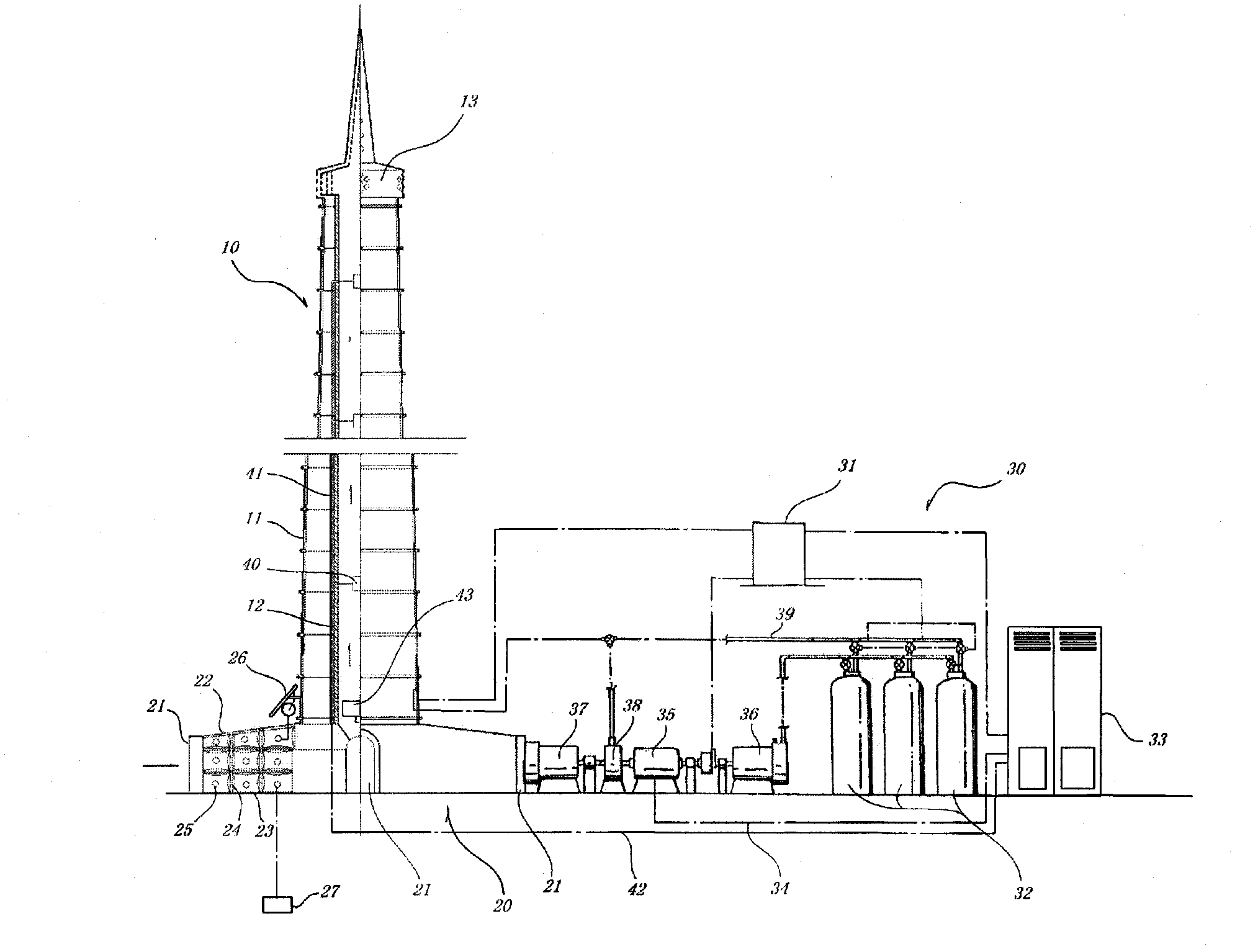

Natural energy storage power generation method and power generation system thereof

InactiveCN102996359AEfficient SupplementEnough temperatureGas turbine plantsEmission reduction for energy storageElectricityPower grid

Owner:周登荣 +1

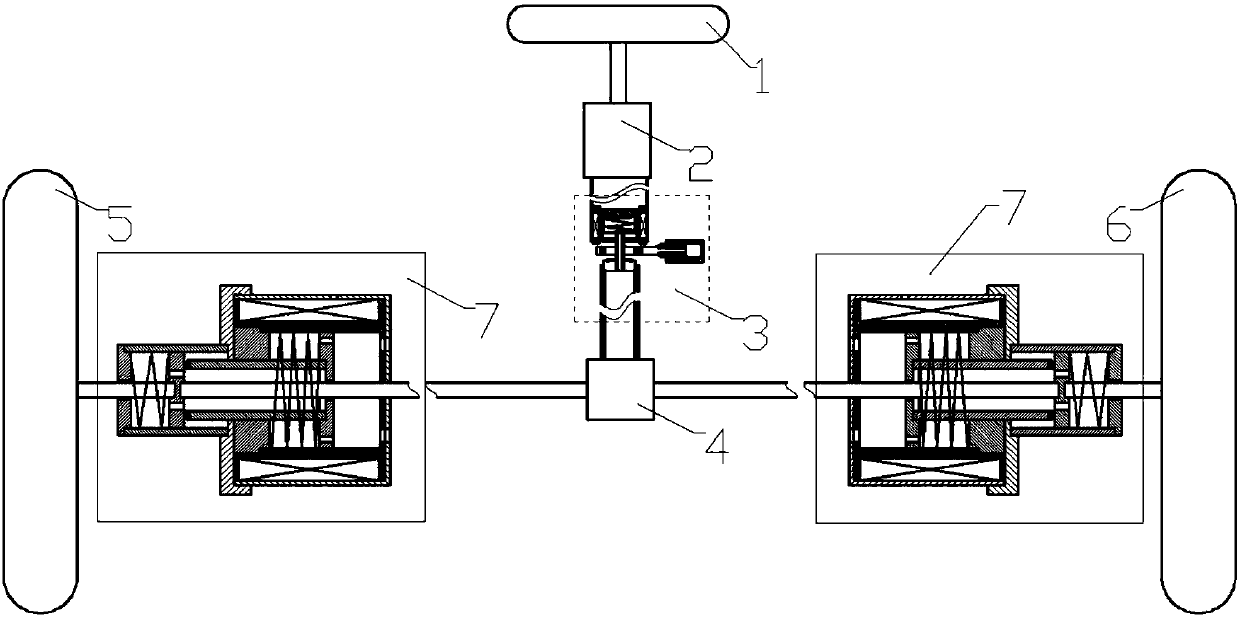

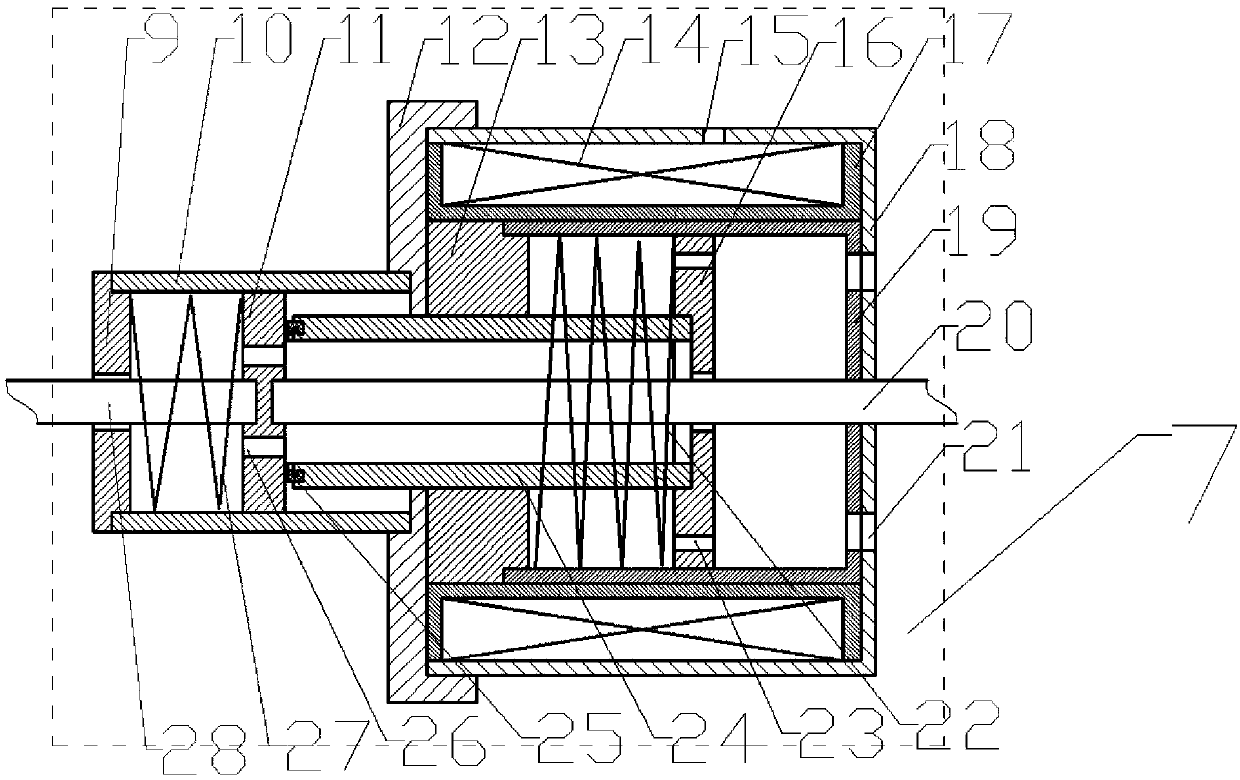

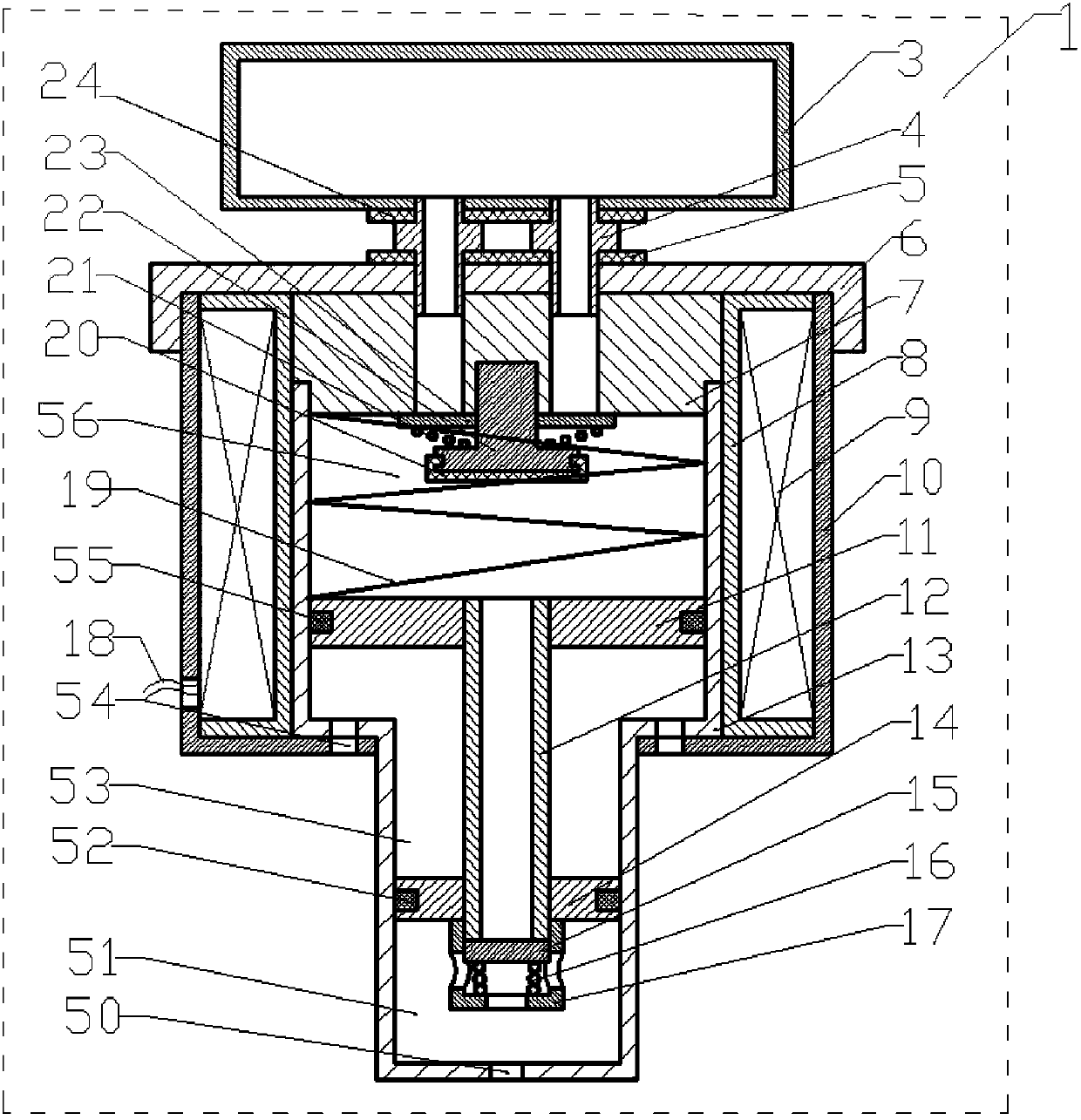

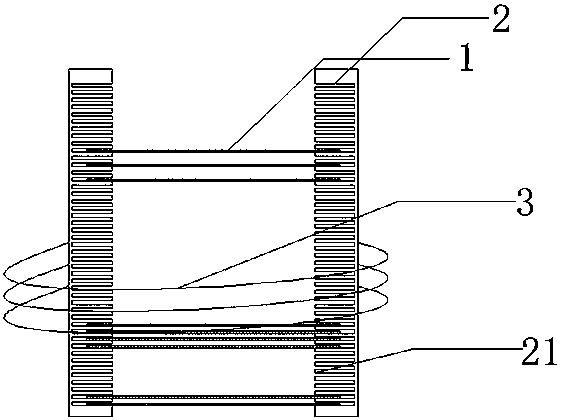

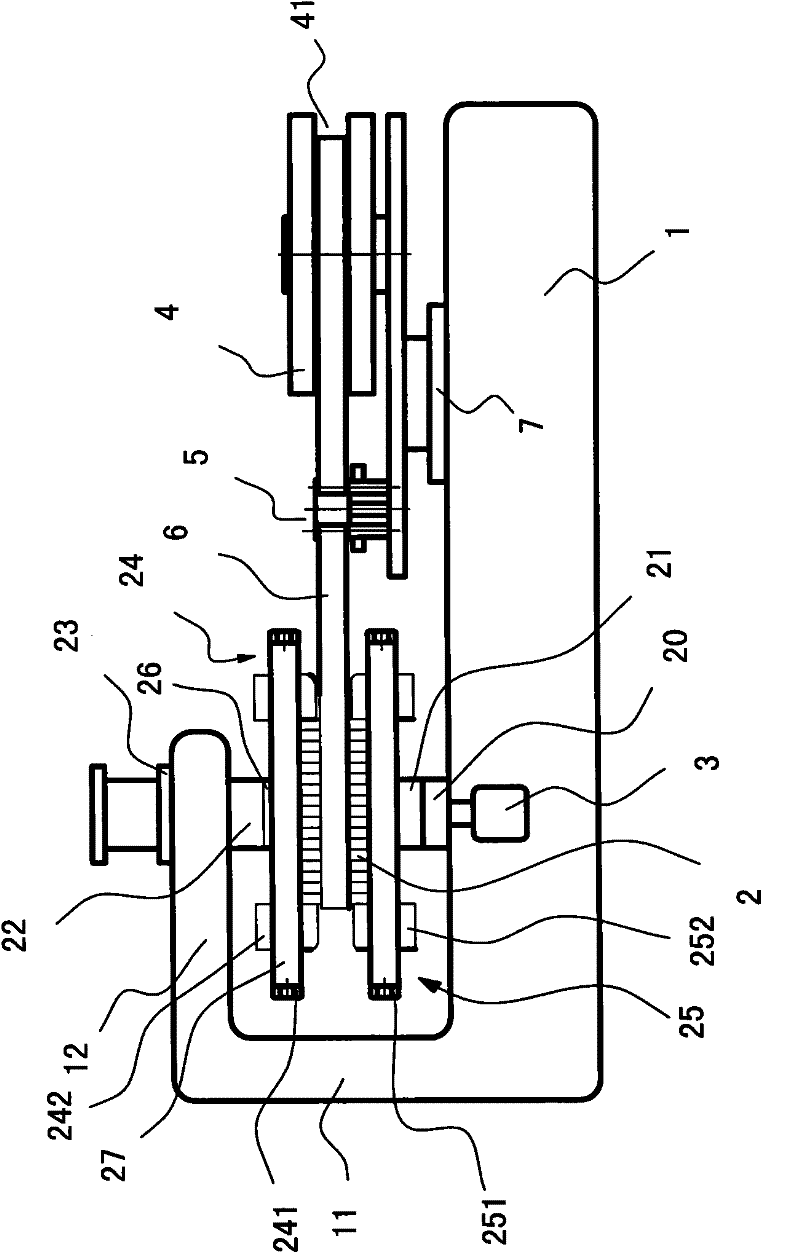

Full decoupling steering-by-wire system

ActiveCN107672669ASolve the noise problemEliminate noise sourcesMechanical steeringElectrical steeringFailure rateSteering wheel

The invention discloses a full decoupling steering-by-wire system. The full decoupling steering-by-wire system is used for solving the problems that a motor in a traditional EPS is large in noise, andthe function of steering full decoupling needed by an intelligent automobile cannot be achieved; mechanical connection between a steering wheel and a steering wheel is omitted in parts of steering-by-wire systems, and consequently, efficacy-losing steering cannot be completed when the systems are powered off and lose efficacy; when the parts of the steering-by-wire systems adopts motors as steering-by-wire power sources, the noise is large, and the response speed is low; and when the parts of the steering-by-wire systems adopts liquid or gas as a steering medium, leakage occurs, the failure rate is increased, and maintenance is difficult. According to the full decoupling steering-by-wire system, electromagnetic force is adopted to drive a steering rod to move, so that an automobile completes a steering action rapidly and precisely; and the full decoupling steering-by-wire system can achieve full decoupling of a driver and the steering system, has the efficacy-losing protection function, and is free from constraints of the motors, the liquid and the gas, simple in structure and high in integration level.

Owner:JILIN UNIV

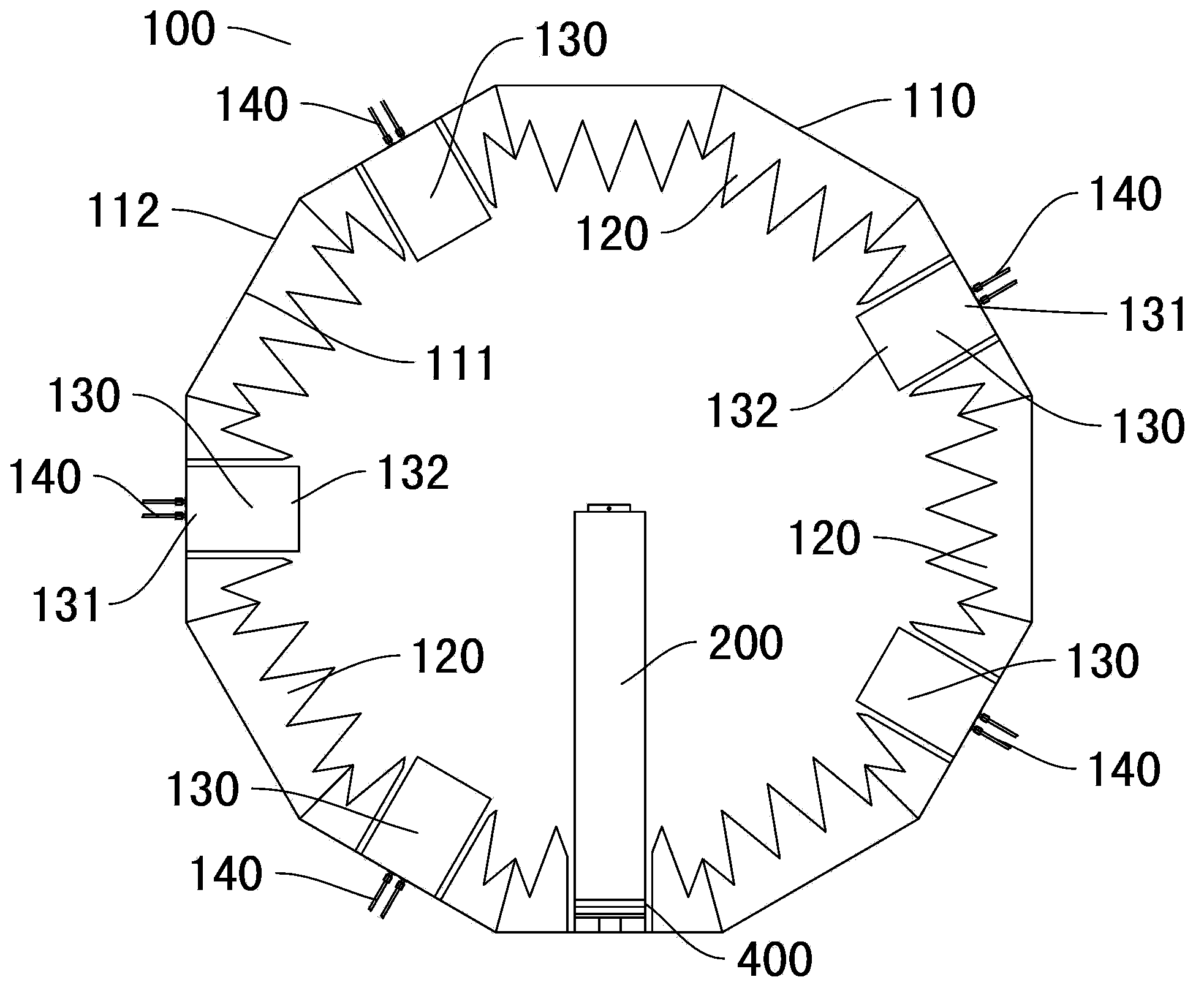

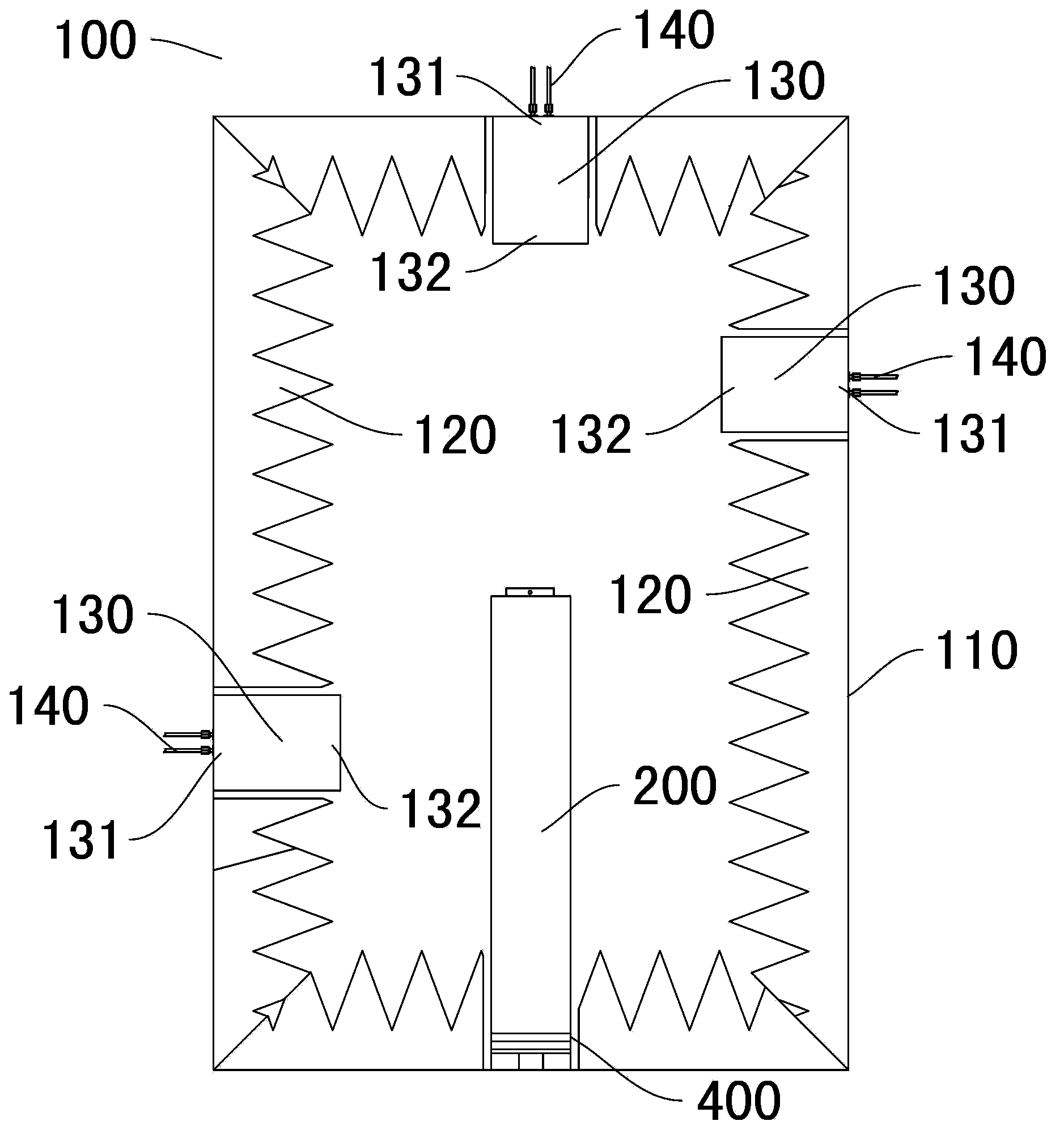

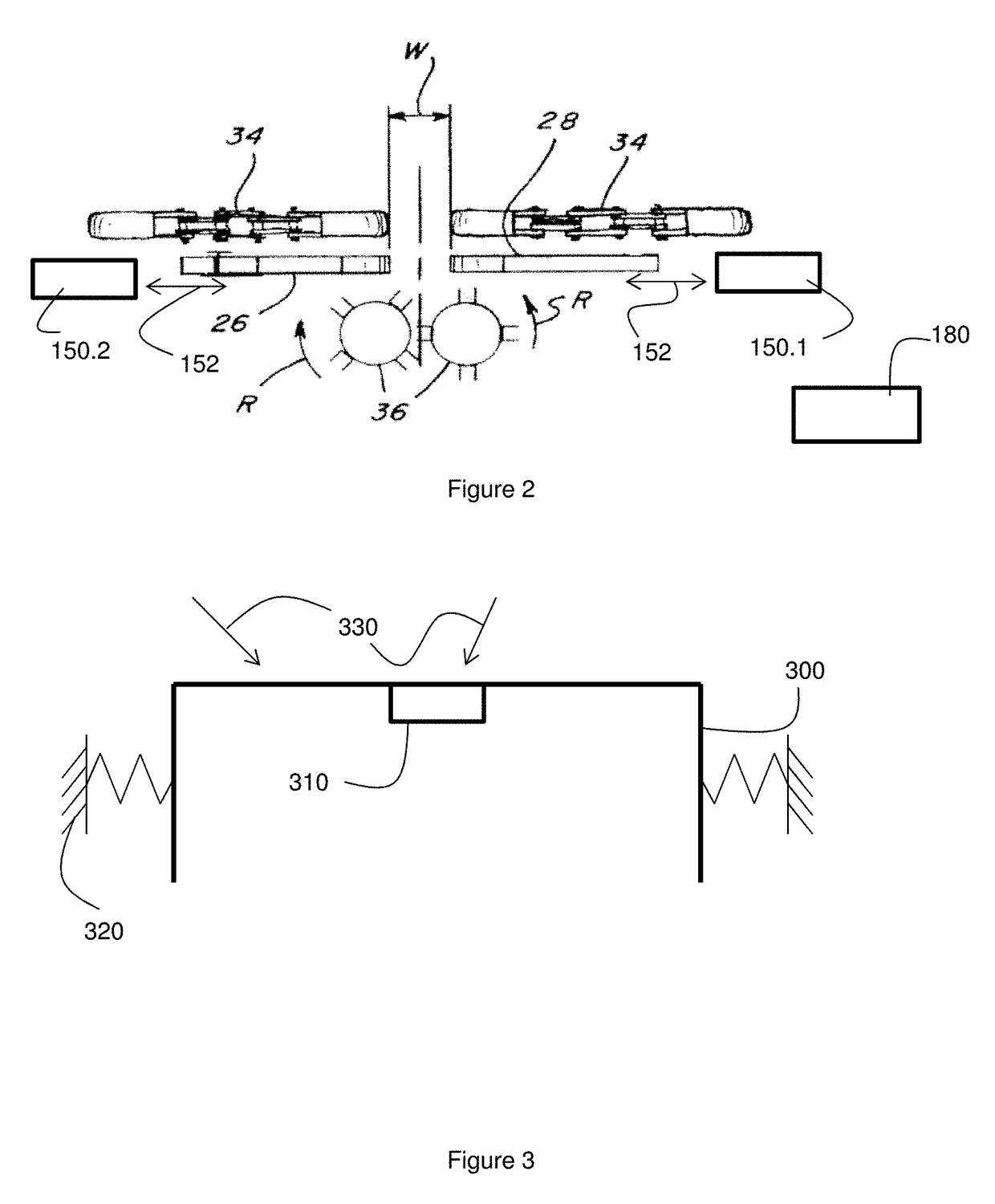

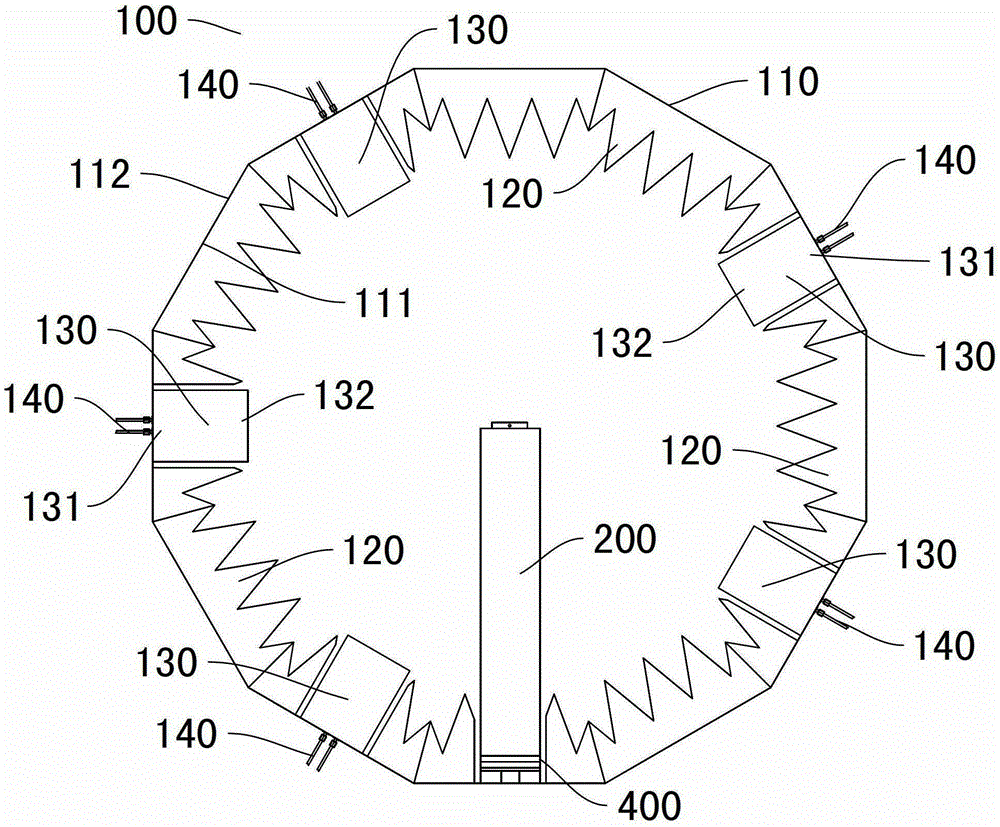

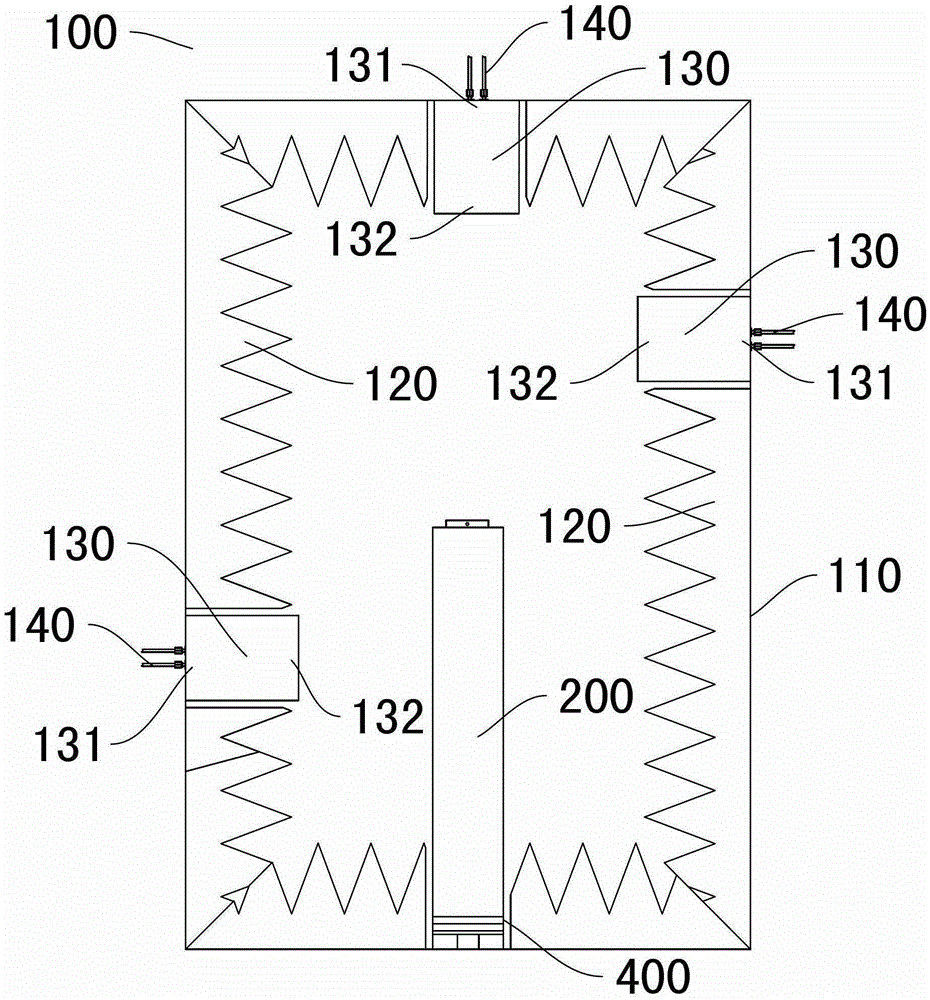

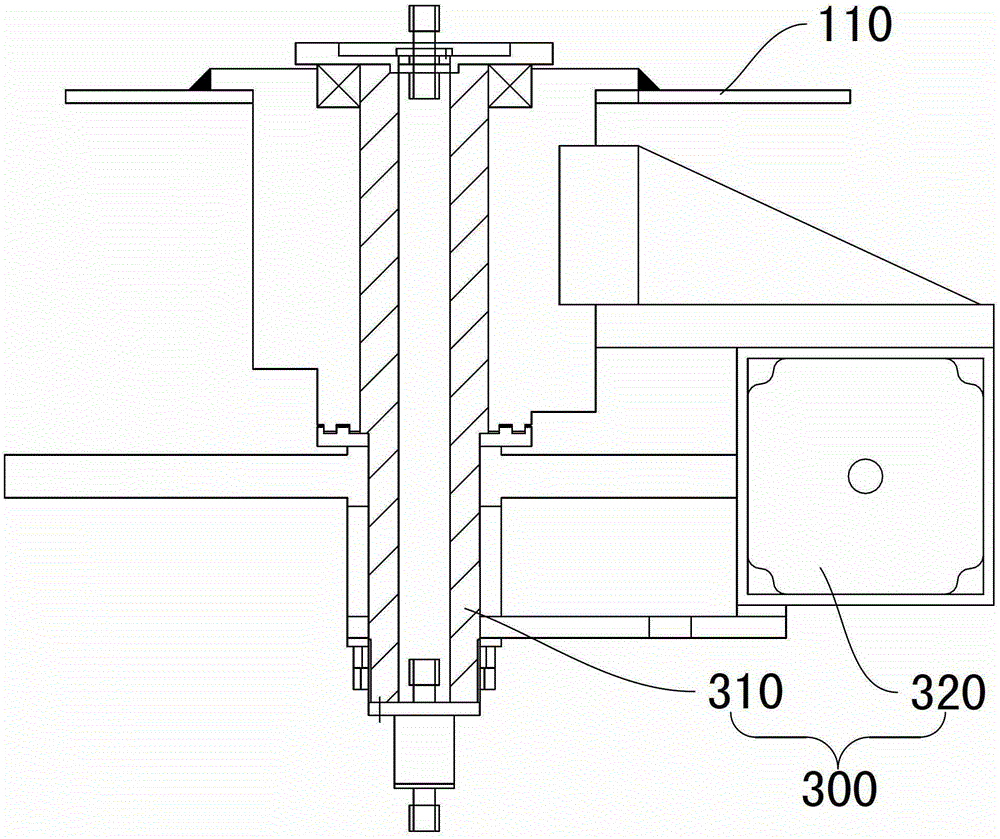

Darkroom

ActiveCN103812585AReduce manufacturing costEliminate errorsElectrical testingTransmission monitoringDark roomElectrical and Electronics engineering

The invention discloses a darkroom. The darkroom comprises a shielding box, a wave-absorbing material layer and a plurality of measuring antennas, wherein the wave-absorbing material layer is arranged on an inner wall of the shielding box; and the measuring antennas are arranged on the inner wall of the shielding box and are suitable for being connected with a cable outside the shielding box. The darkroom has the advantages of being low in manufacturing cost and small in occupied space and improving wireless communication measurement accuracy and consistency.

Owner:GENERAL TEST SYST

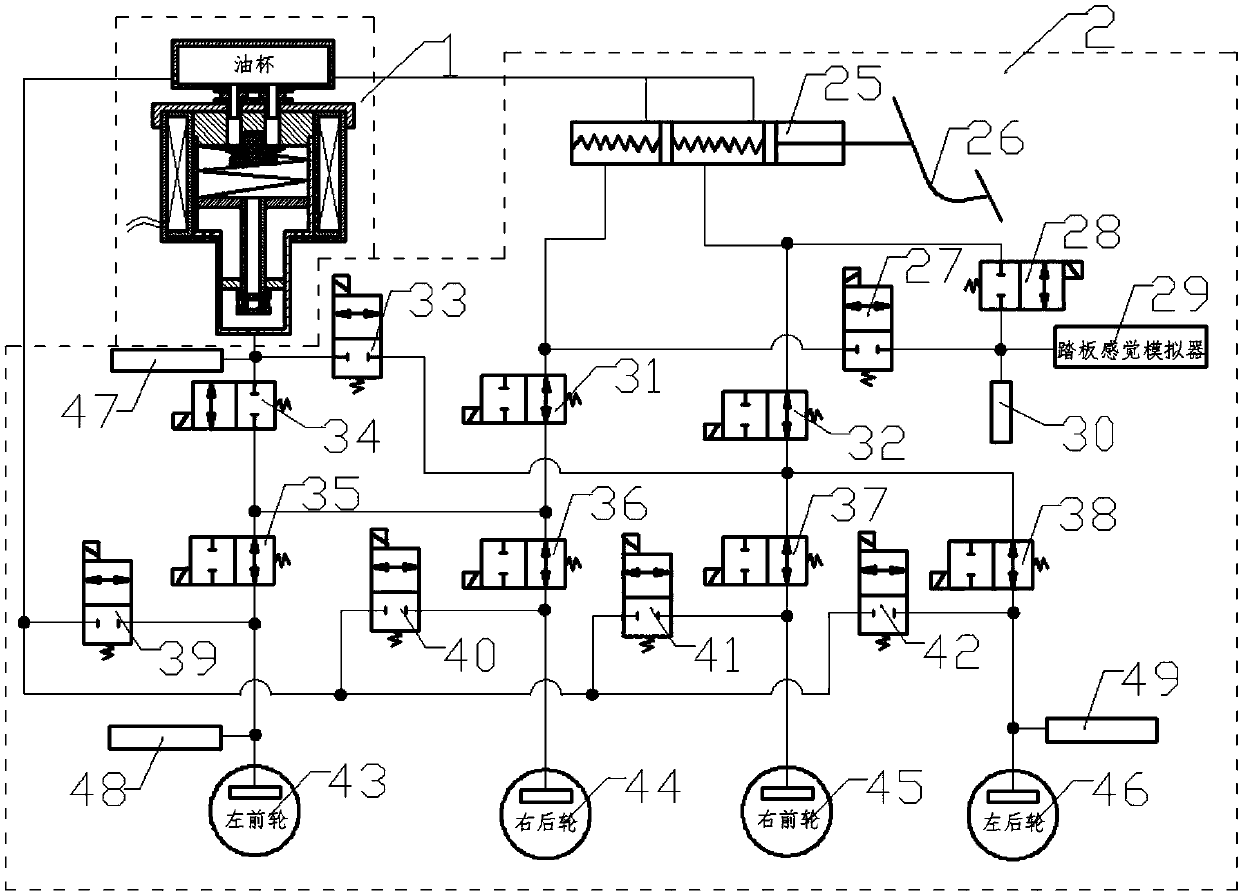

Drive-by-wire hydraulic brake system using liquid high pressure source generator

InactiveCN107697050AEliminate dependenciesCompact structureBraking action transmissionBrake-by-wireInternal pressureDrive by wire

The invention discloses a drive-by-wire hydraulic braking system using a liquid high pressure source generator, and belongs to the technical field of vehicle drive-by-wire brake. The problems that a power assisting form of an existing brake system mostly depends on the vacuum degree of an engine, so that the existing brake system cannot be applied to an electric vehicle; when parts of drive-by-wire brake systems adopt a motor to assist power and brake a main cylinder or an auxiliary main cylinder directly, noise is large, and the responding speed is low; when the parts of drive-by-wire brake systems adopt the motor to drive a pump to supply liquid to a high pressure energy accumulator, damage to the braking system by pulsation with internal pressure is large, and the life of the high pressure energy accumulator is limited, so that frequent replacing is required are solved. The drive-by-wire hydraulic brake system is a mechanical device which uses electromagnetic force to drive a pistonto move and continuously produce the high pressure brake fluid, so that the drive-by-wire brake system is free from shackle of a vacuum power booster, the motor, the pump and the high pressure energyaccumulator, the structure is simpler, the integration degree is higher, and meanwhile the drive-by-wire brake system has the functions of fast active pressure buildup, accurate pressure adjusting, low vibration noise, failure protection, full decoupling of pedal force and the like.

Owner:JILIN UNIV

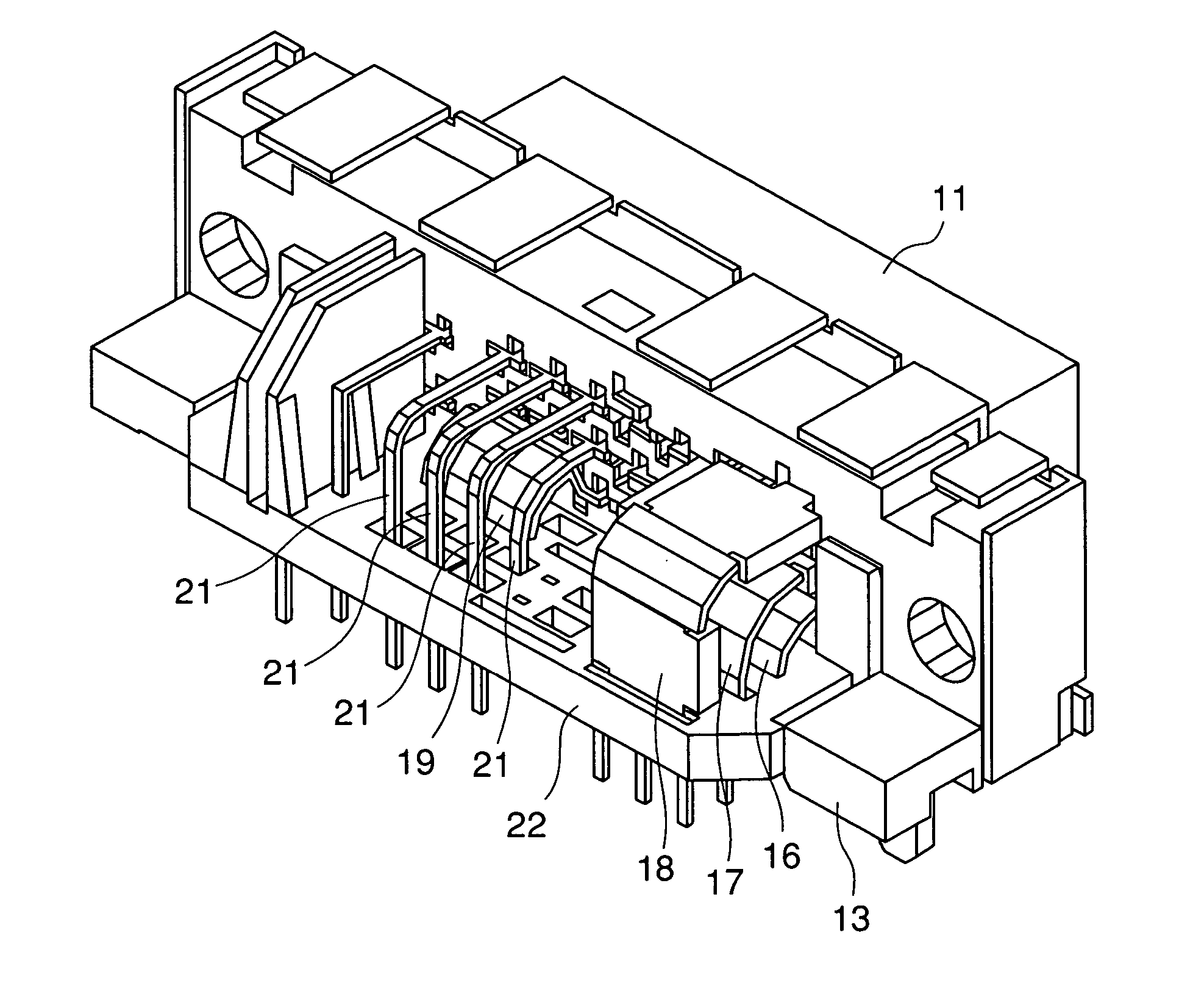

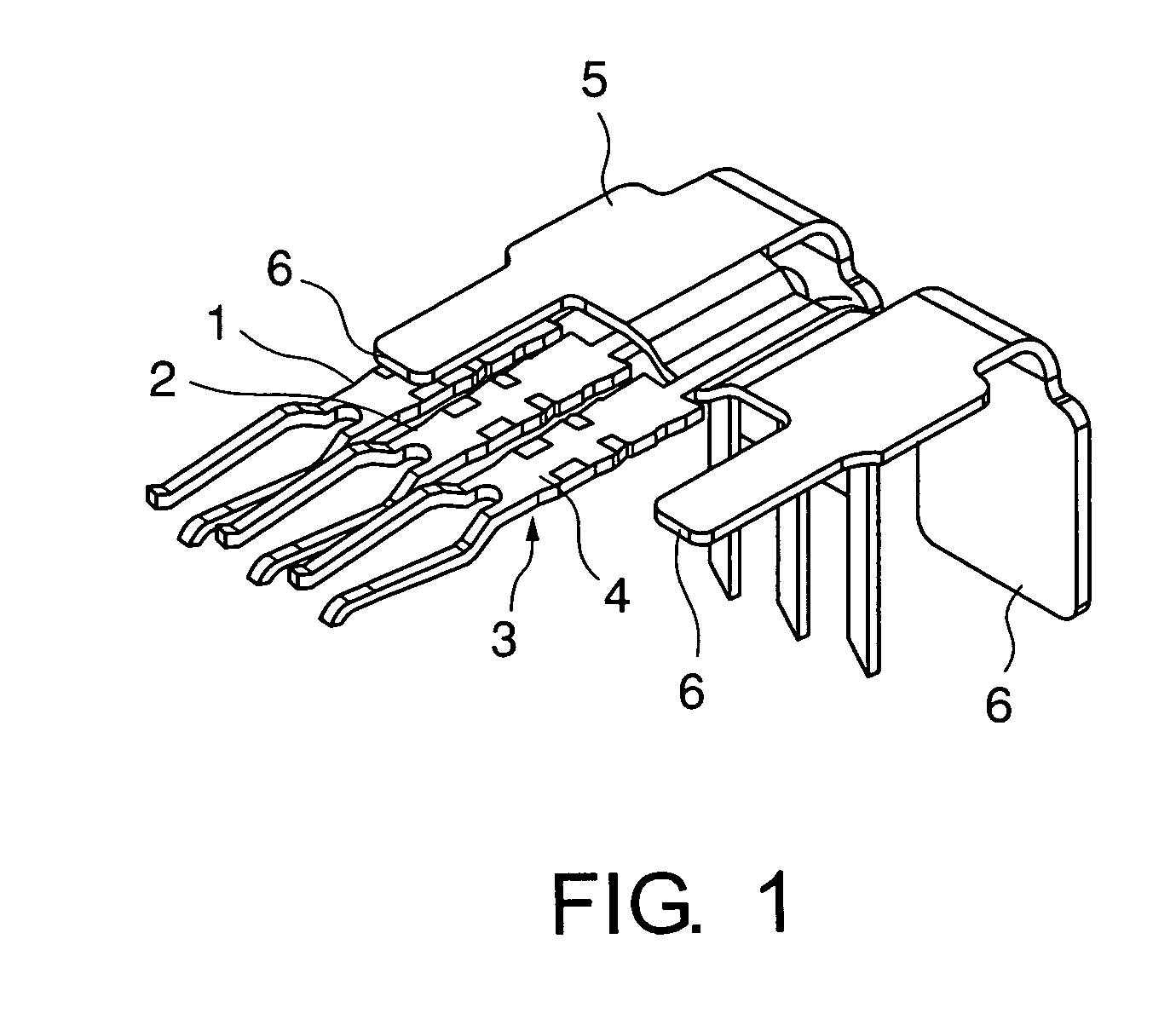

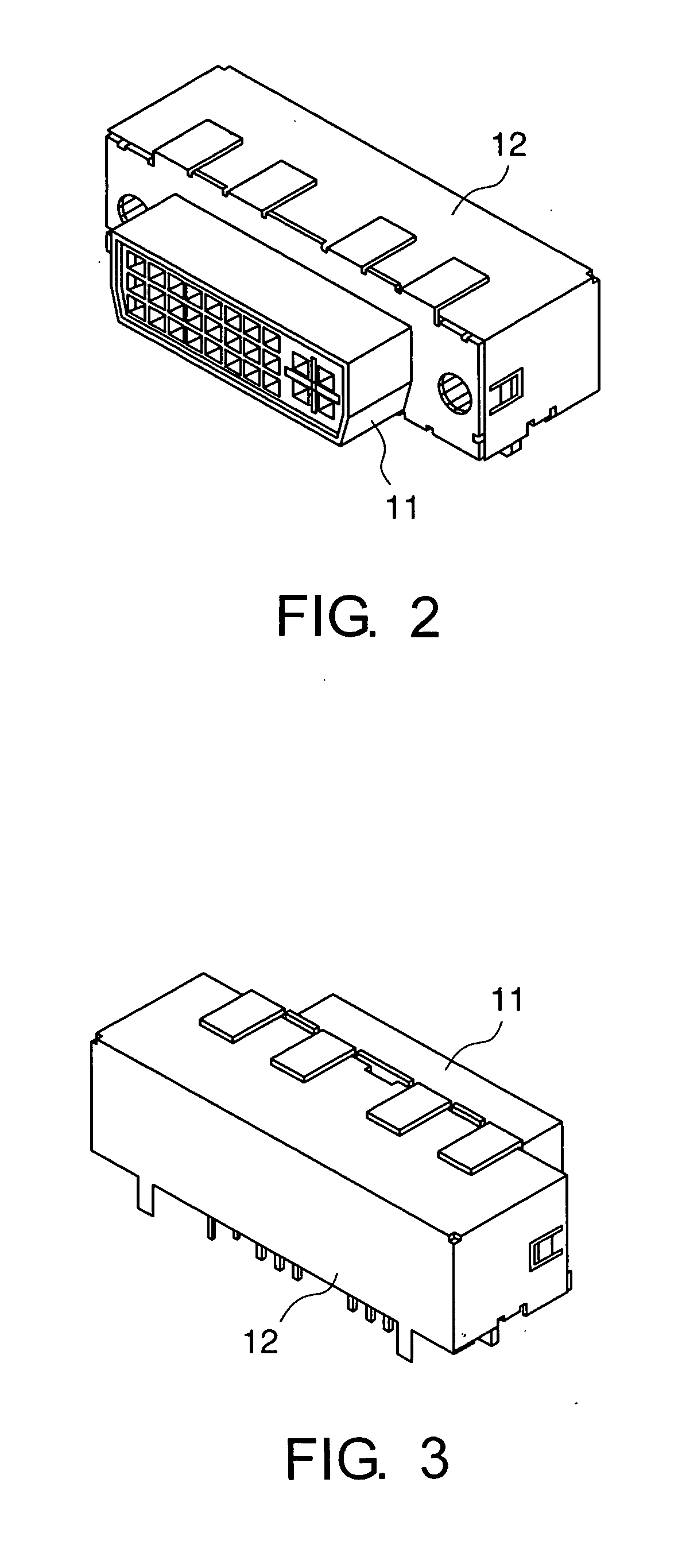

Connector having an excellent transmission characteristic and an excellent EMI suppression characteristic

InactiveUS20050032425A1Improve featuresEliminate noise sourcesCoupling for high frequencyTwo-part coupling devicesMechanical engineeringEngineering

In a connector including signal and shield contacts which are conductive, a housing holds the signal and the shield contacts. The shield contact has a holding portion held by the housing. In the shield contact, a contacting portion extends from the holding portion and adapted to be contacted with a mating object. A shielding portion extends from the holding portion to cover a portion of the signal contact. A terminal portion extends from the shielding portion and adapted to be connecting with ground.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

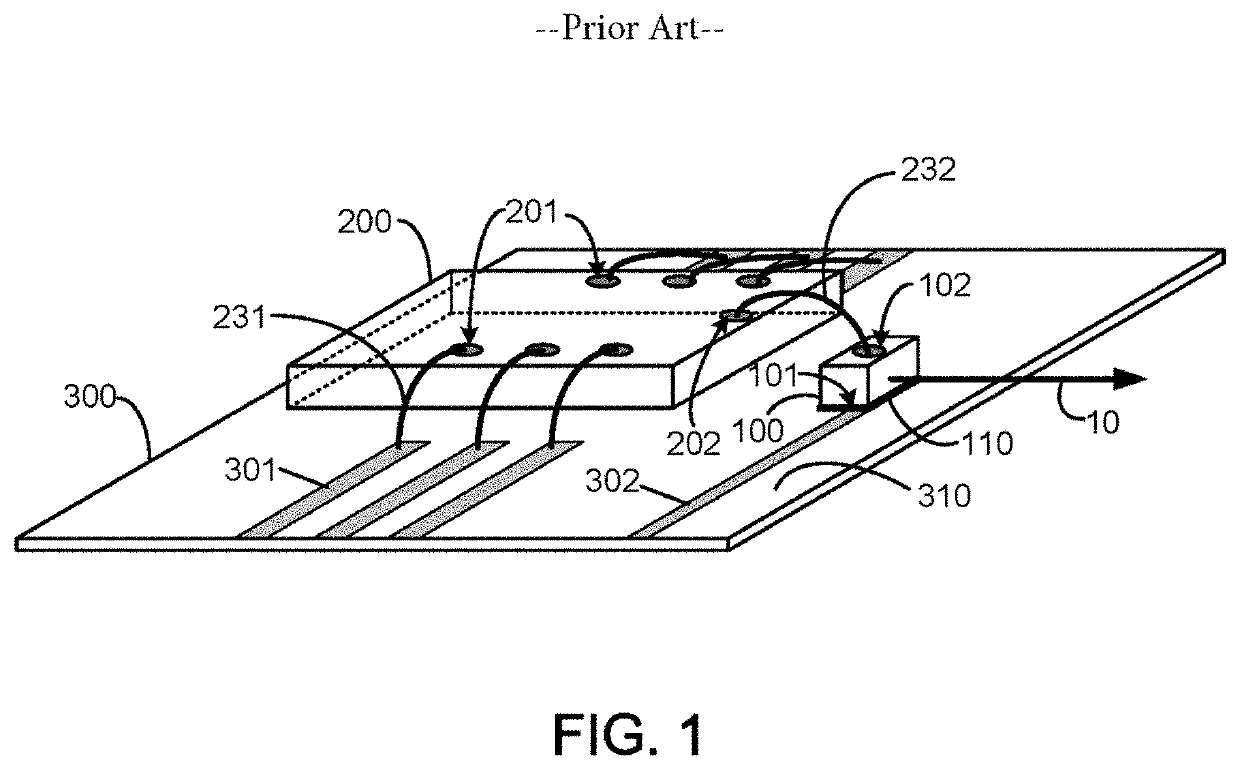

Corn header including a kernel sensor and a control unit for controlling desk plates of the corn header

A corn header includes a plurality of harvesting units to separate corn ears from corn stalks. Each harvesting unit has a deck plate assembly, and an actuator assembly to adjust a width of a stalk receiving channel by adjusting a position of at least a deck plate of the deck plate assembly. A kernel sensor can generate a signal representative of the presence of kernels detached from the ears during the separation of the corn ears from the corn stalks by the harvesting units and a control unit to receive the signal from the kernel sensor and generate an actuator control signal for controlling the actuator assemblies of the plurality of harvesting units, thereby controlling the width of the stalk receiving channels of the harvesting units.

Owner:BLUE LEAF I P INC

Method for reducing electrical power noise in high-speed ADC application

InactiveCN101335524AEliminate noise sourcesGood anti-noise effectAnalogue-digital convertersPhysical parameters compensation/preventionPower noiseData acquisition

The invention relates to an ADC (Analog to Digital Converter), in particular to a method for reducing power noise in the application of a high speed ADC. The method comprises main steps of: A. decoupling to the power; B. grounding item; C. independent power. By adopting the method of the invention, noise sources in the ADC power and surrounding circuits can be eliminated and the noise-proof performance in a data collecting design can be substantially improved.

Owner:SHANGHAI MINHANG HIGH SCHOOL +1

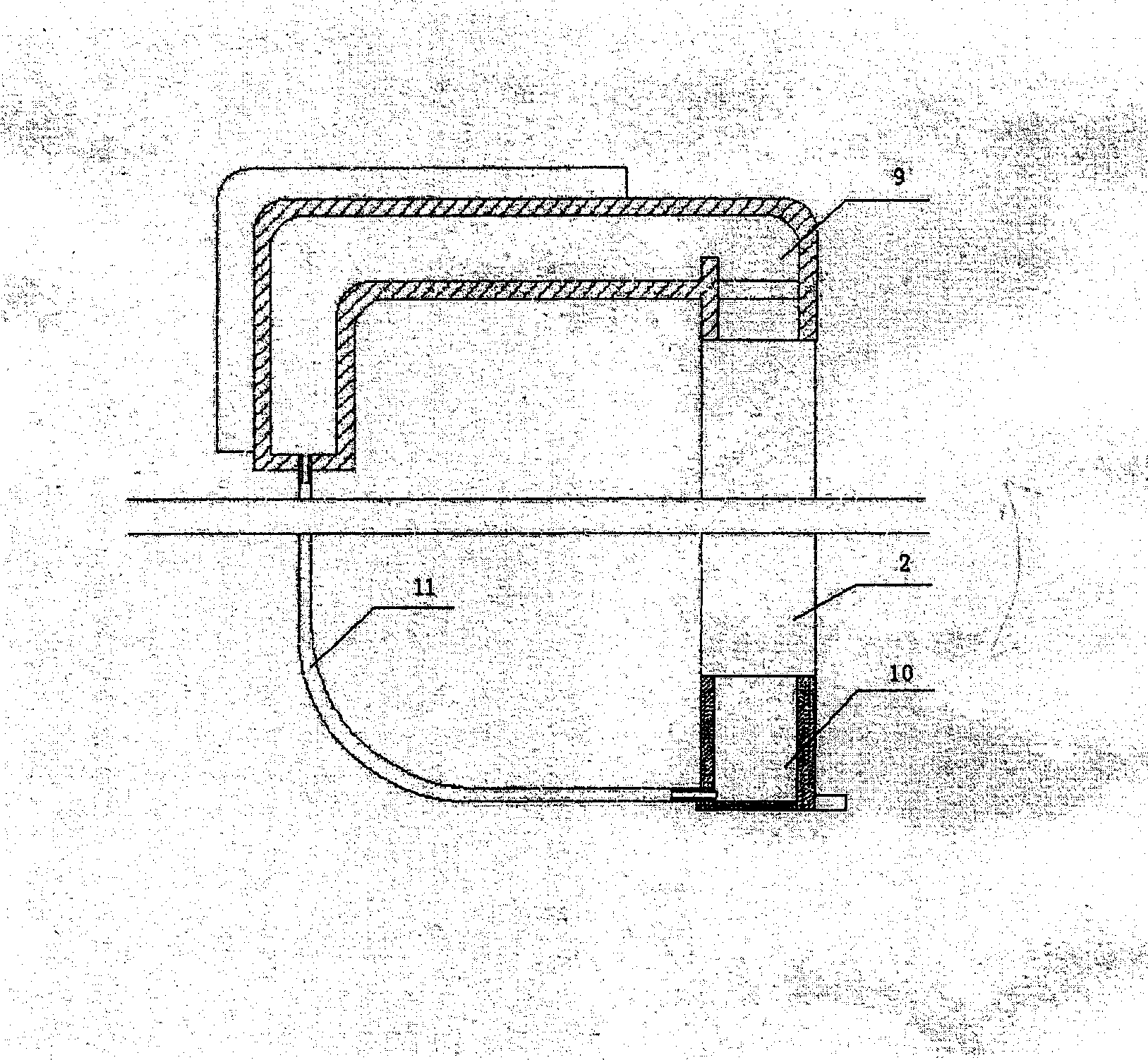

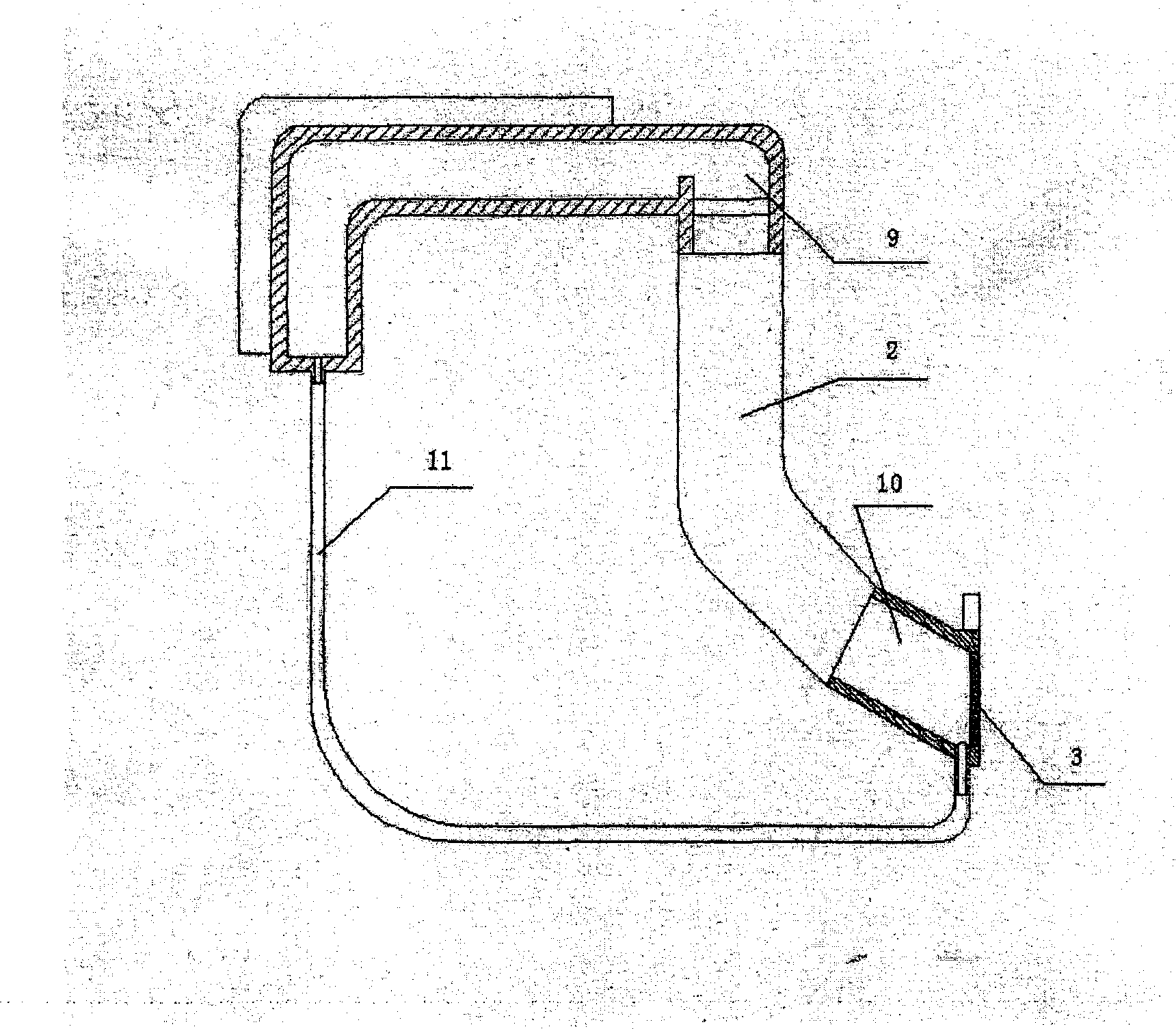

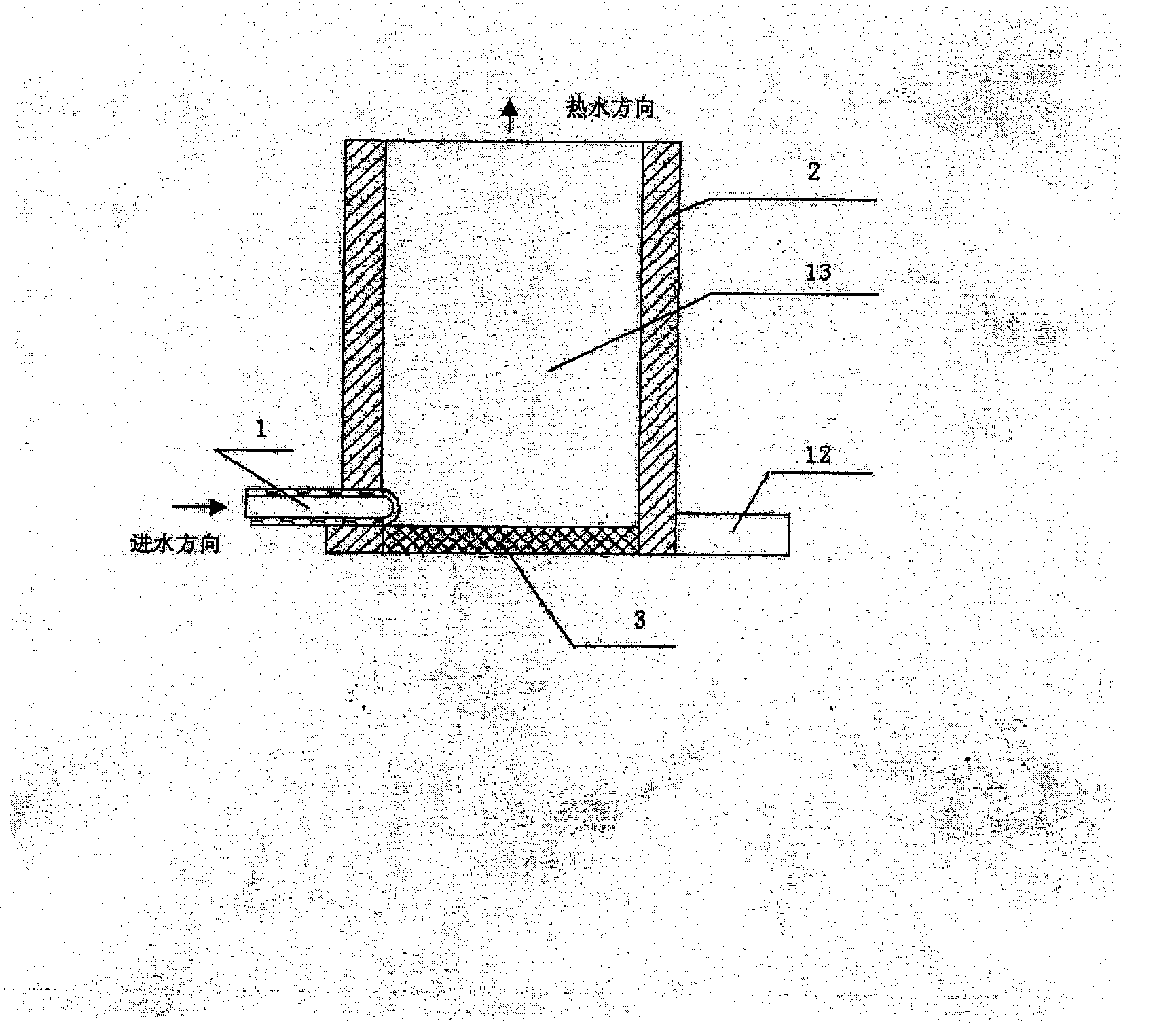

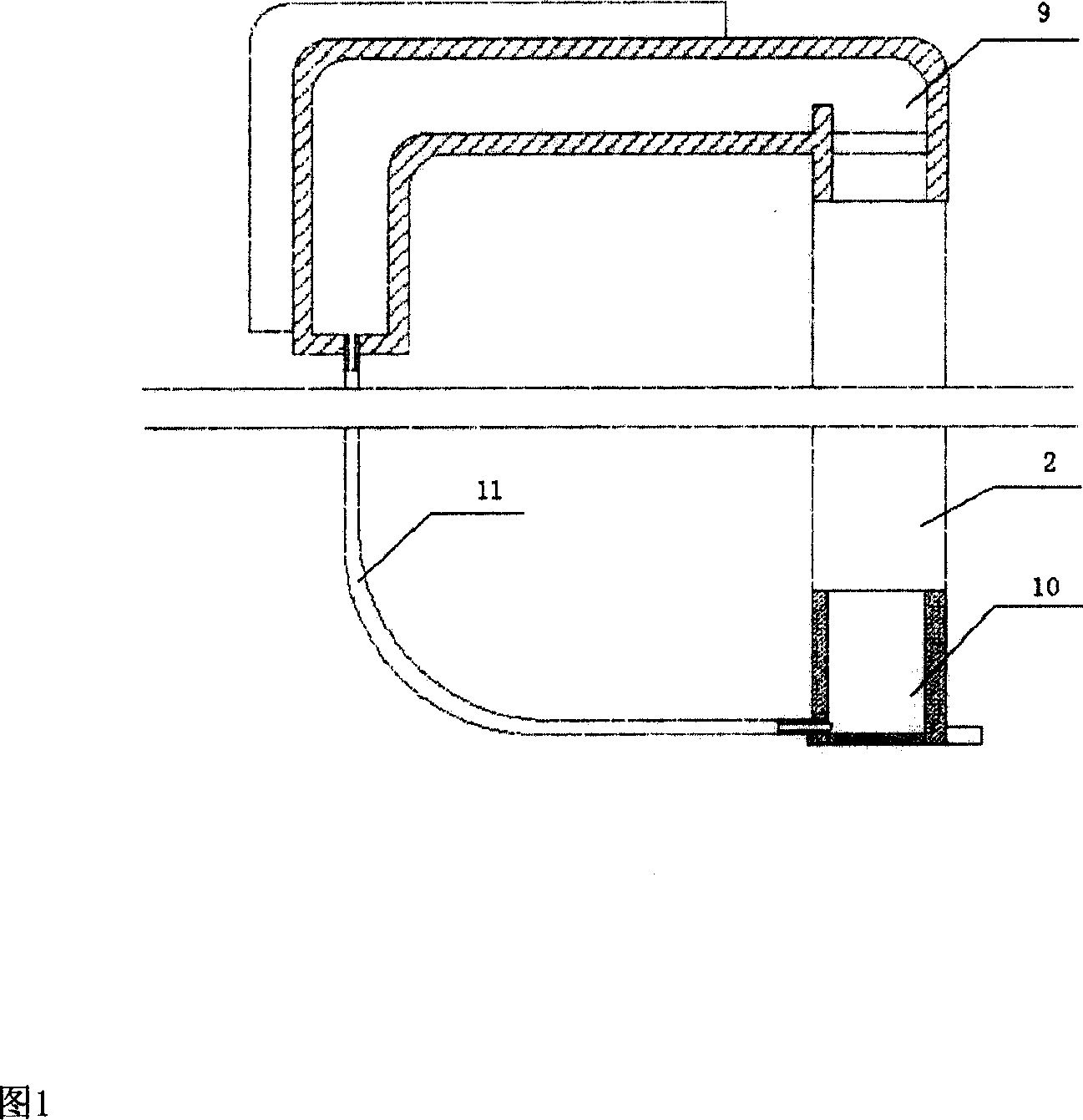

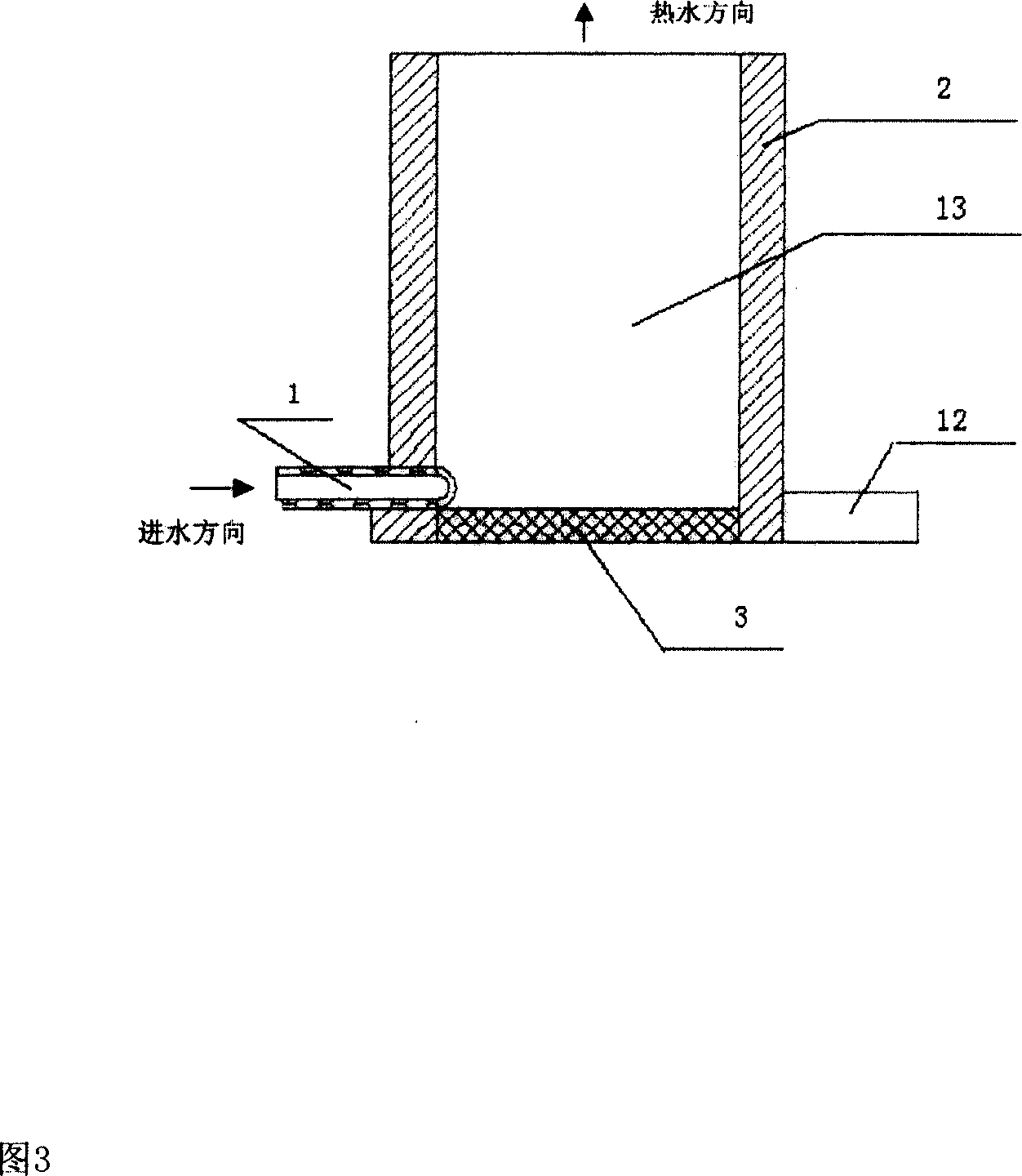

Unpowered self-loop computer liquid cooling system

InactiveCN1632718AReduce consumptionEliminate noise sourcesDigital data processing detailsSemiconductor/solid-state device detailsHeat flowLiquid cooling system

This invention discloses a powerless self-recycling computer liquid cooling system, which comprises heat collector and dissipation device. The heat collector is set with heat collection pad and water-in pipe with its direction at an angle with heat flow varying from zero to ninety degrees. Its heat water exit mouth is of a widening shape and its flow area is larger than the water-in flow area. And the dissipation device has deposit chamber, water barrier pad. The heat collector and dissipation device are connected through heat water pipe and cool water pipe.

Owner:DALIAN UNIV

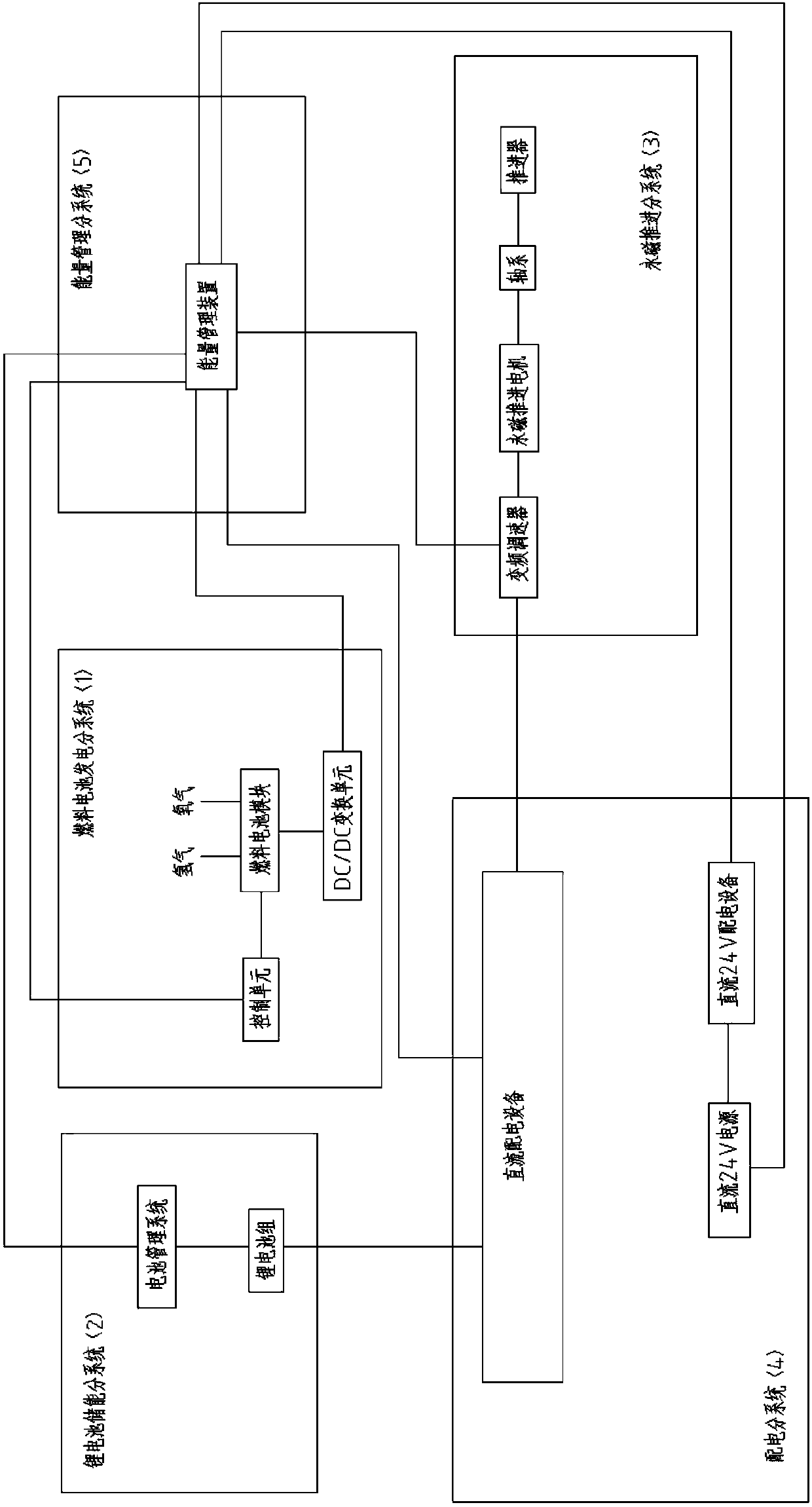

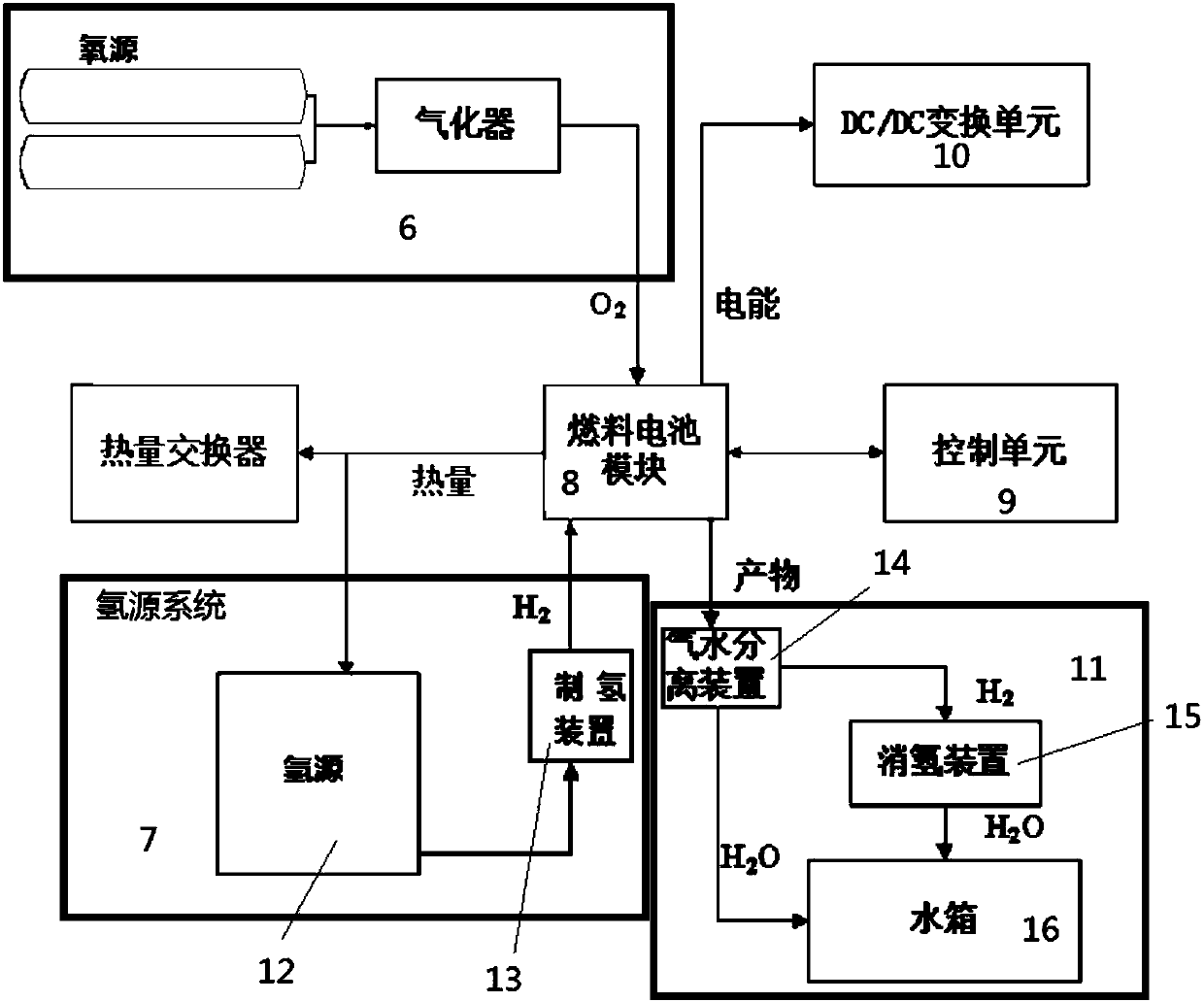

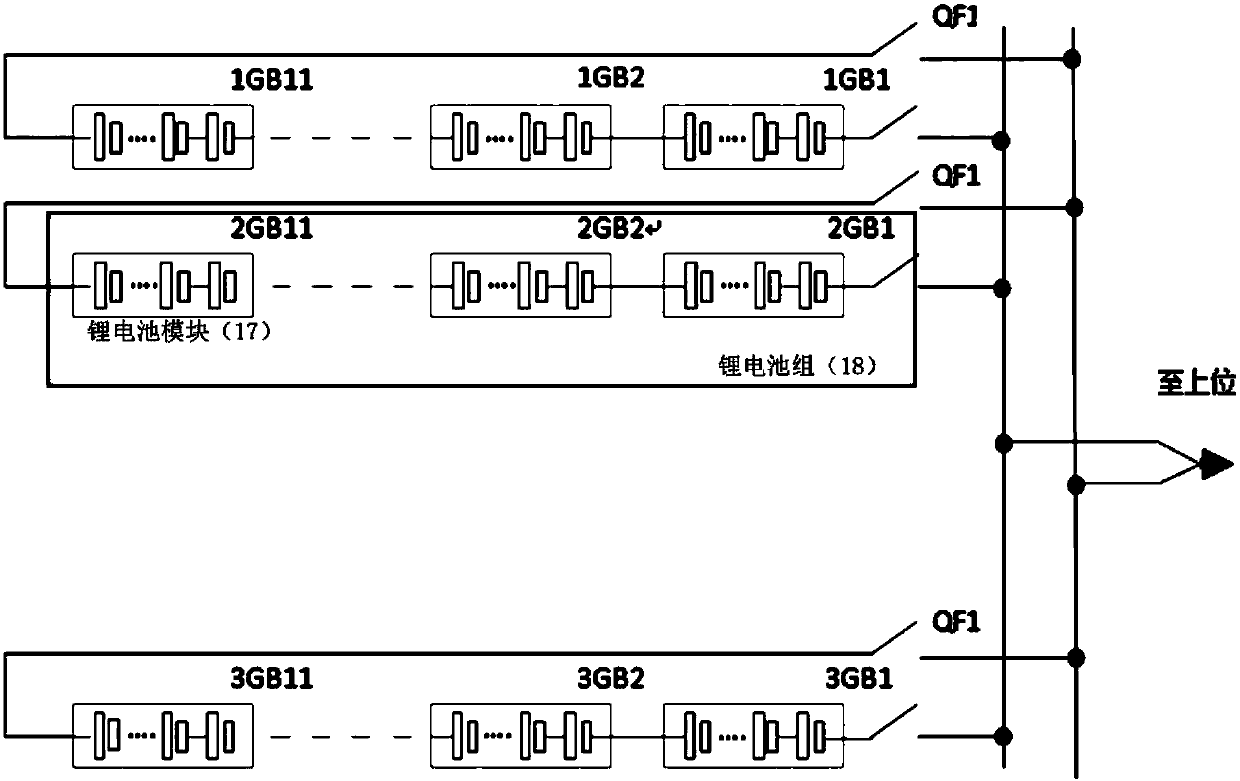

Comprehensive ship power system

InactiveCN107800128AImprove power densityEliminate noise sourcesDc network circuit arrangementsBatteries circuit arrangementsElectric power systemEngineering

The invention discloses a comprehensive ship power system including a fuel battery power generation subsystem, a lithium battery energy storage subsystem, a permanent magnet propulsion subsystem, a power distribution subsystem and an energy management subsystem, wherein the fuel battery power generation subsystem adopts a fuel battery pack as a main generator set, the lithium battery energy storage subsystem is configured to carry out energy buffering, and the lithium battery energy storage subsystem is composed of a lithium titanate battery units in series-parallel connection. The fuel battery pack converts chemical energy into direct-current electric energy, and provides electric energy for a propelling motor and a whole-boat auxiliary machine. The electric energy generated by the fuel battery power generation subsystem is transmitted to the lithium battery energy storage subsystem, the permanent magnet propulsion subsystem, auxiliary machines, weapons, detectors, and daily power consumption and other electric equipment. Energy monitoring and dispatching are realized through the energy management subsystem. The applicability of the system is improved, the high utilization of energy is achieved, and the acoustic concealing performance is improved.

Owner:CHINA SHIP DEV & DESIGN CENT

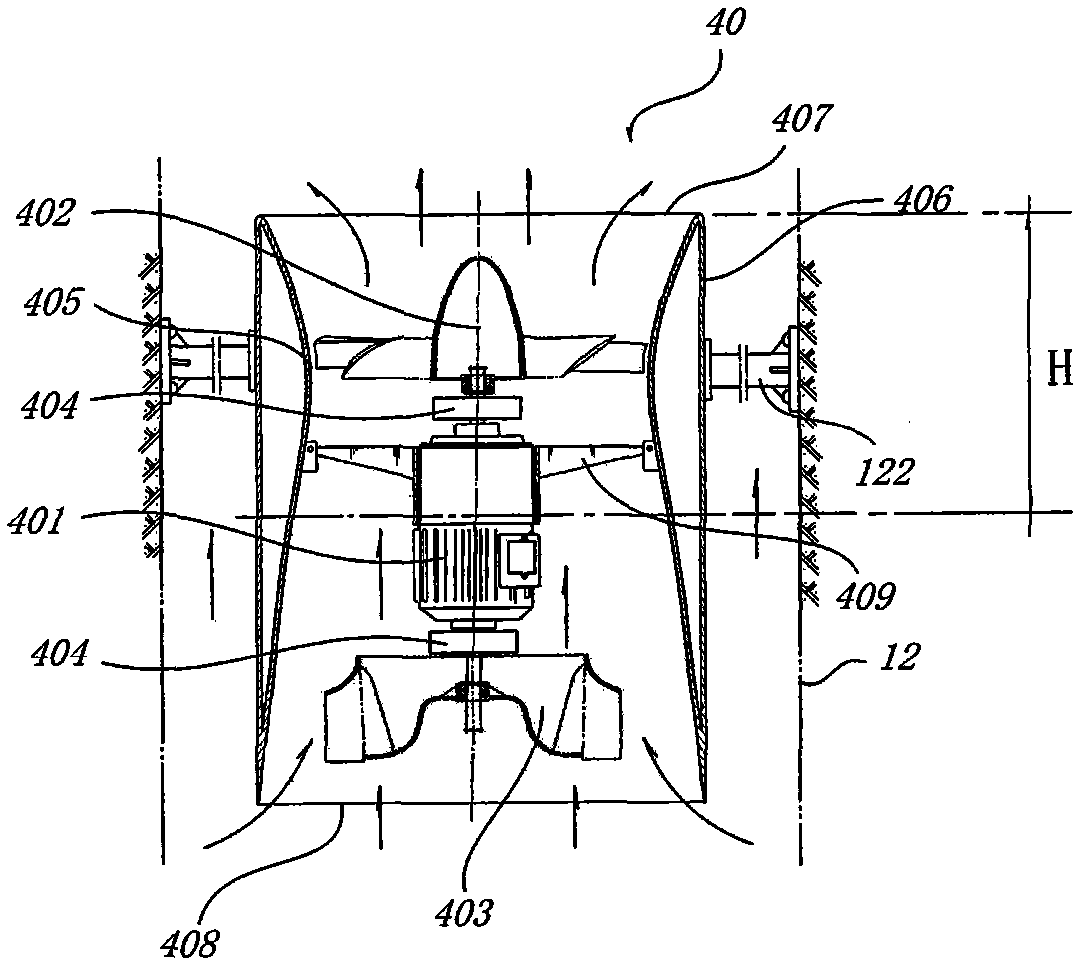

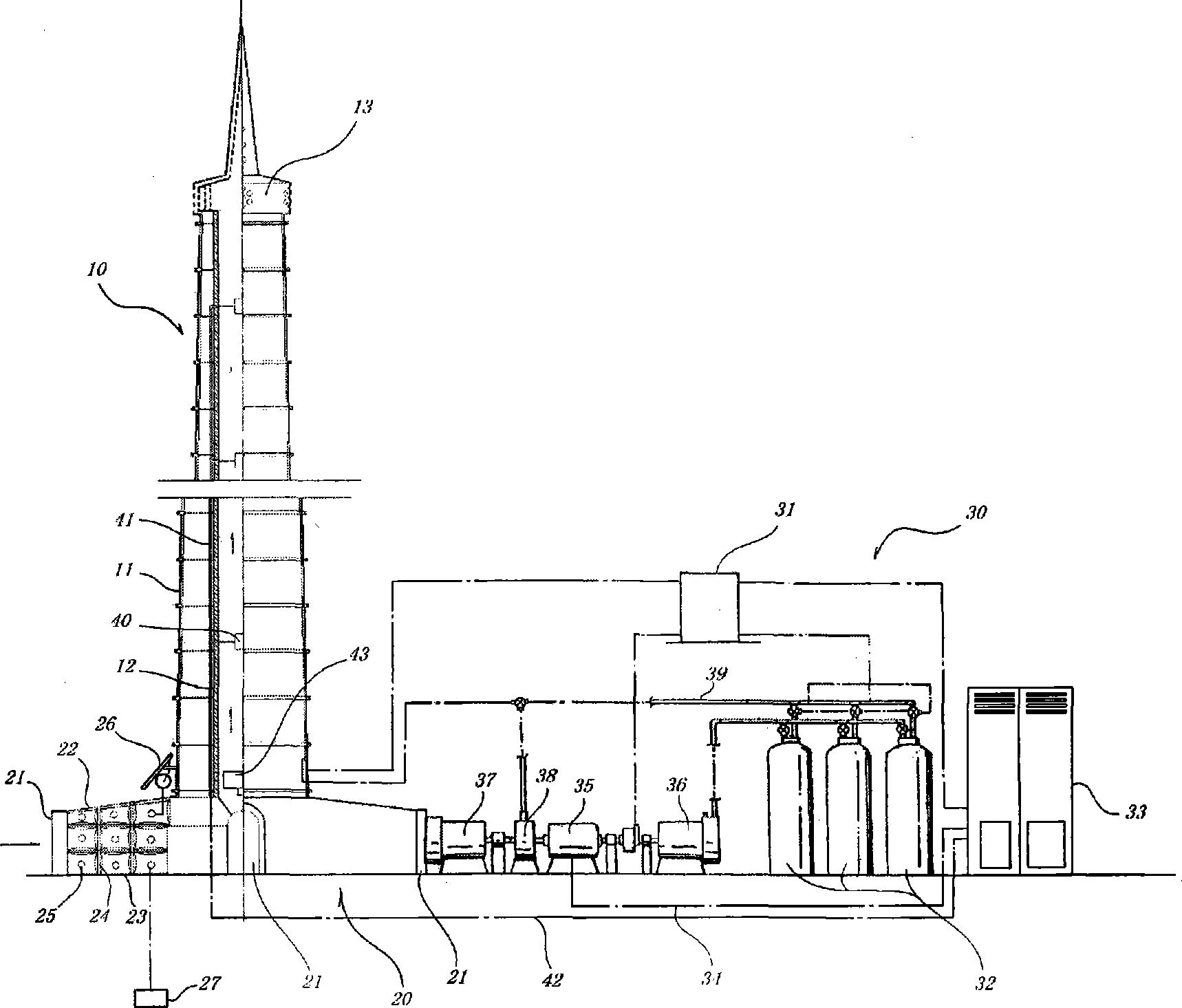

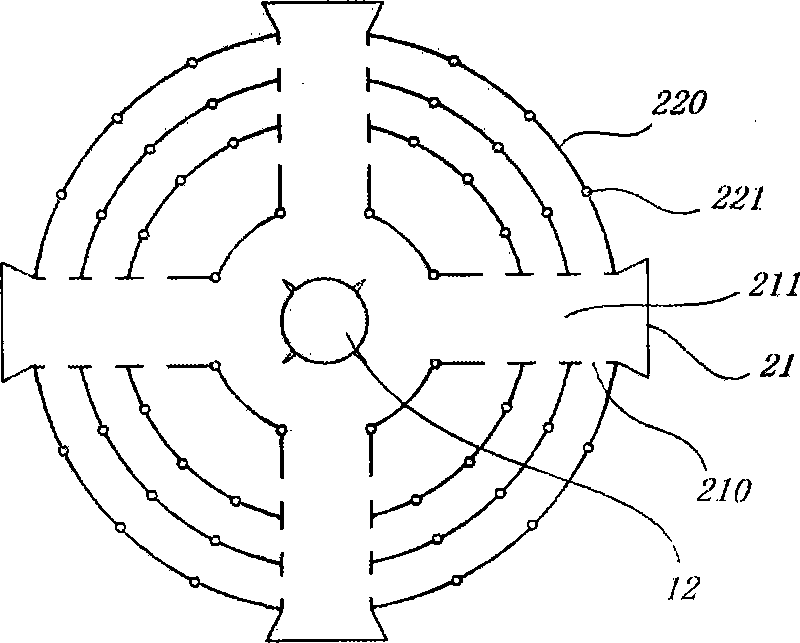

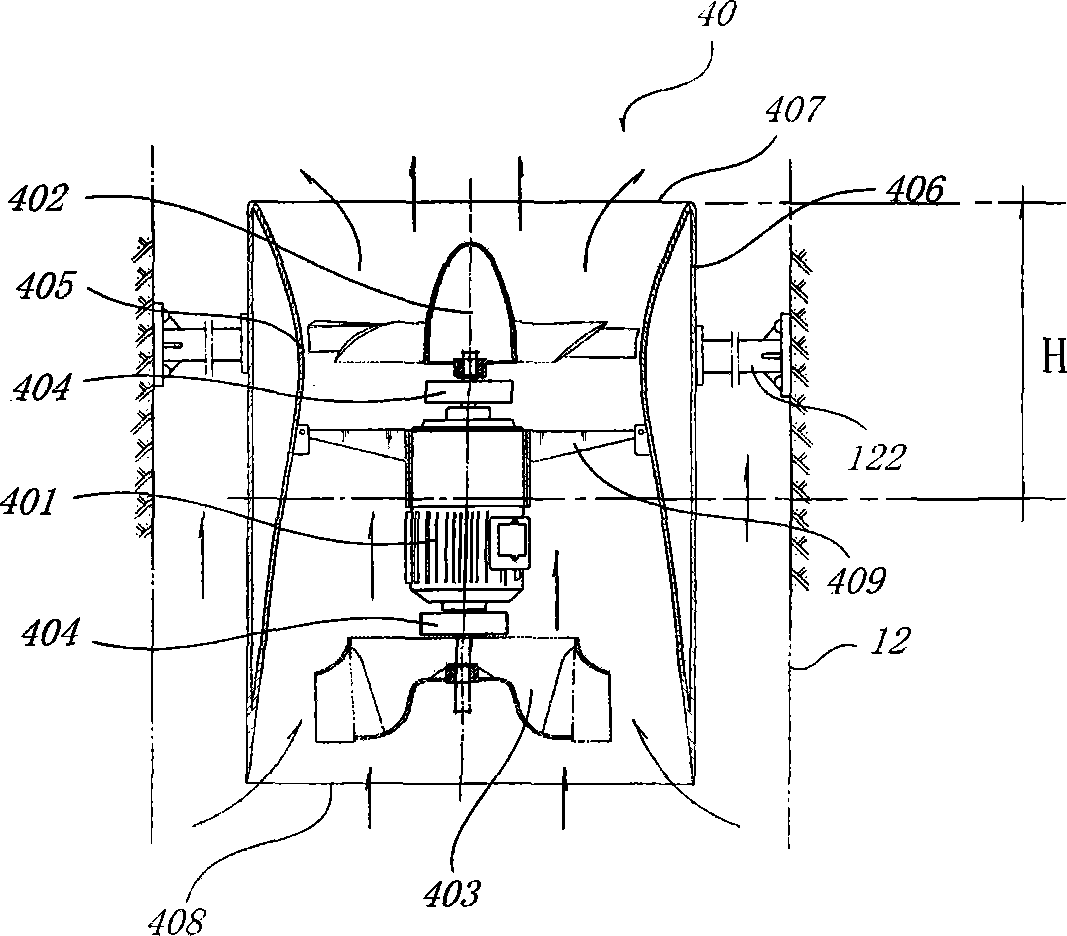

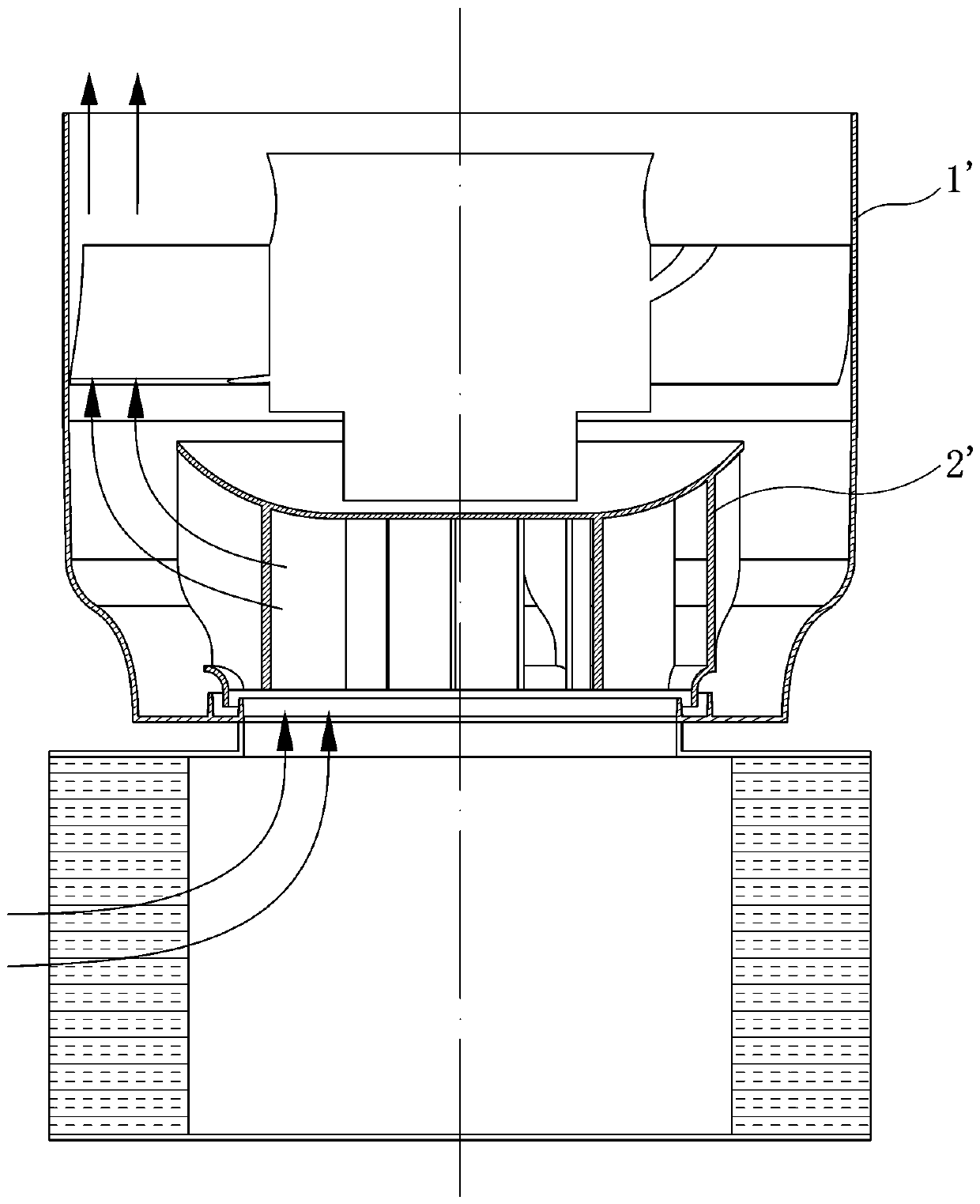

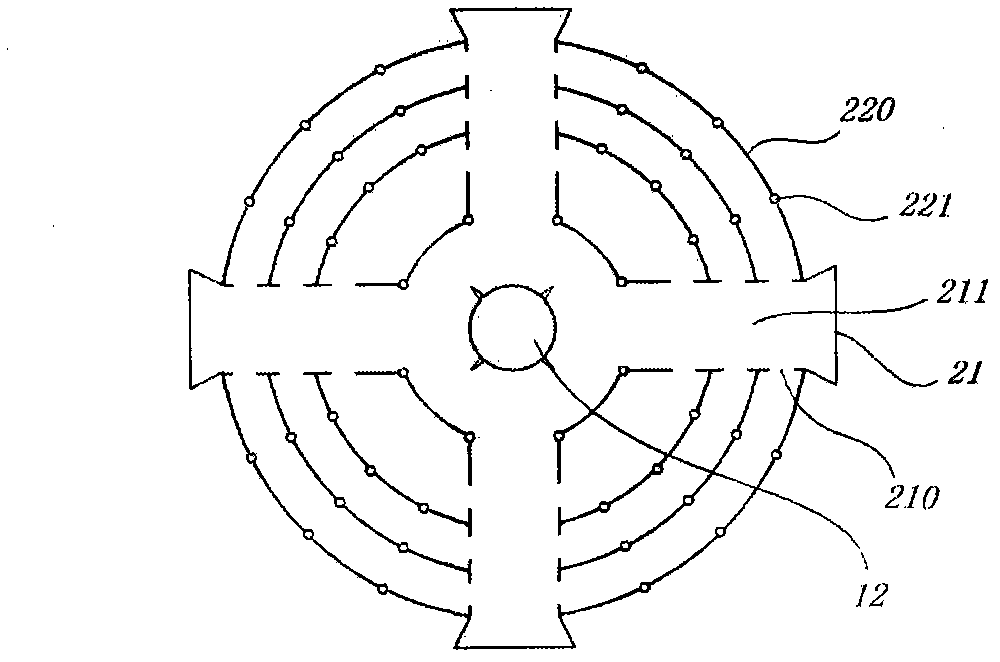

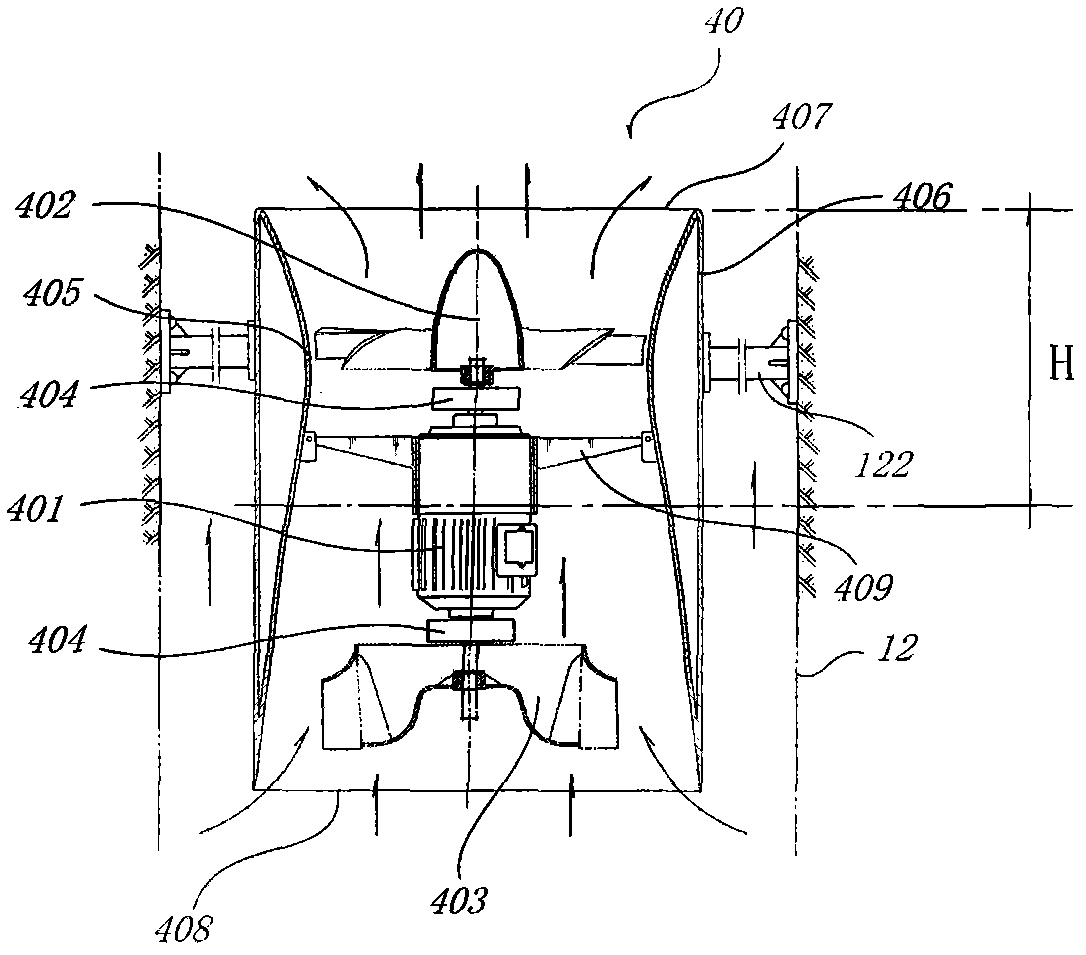

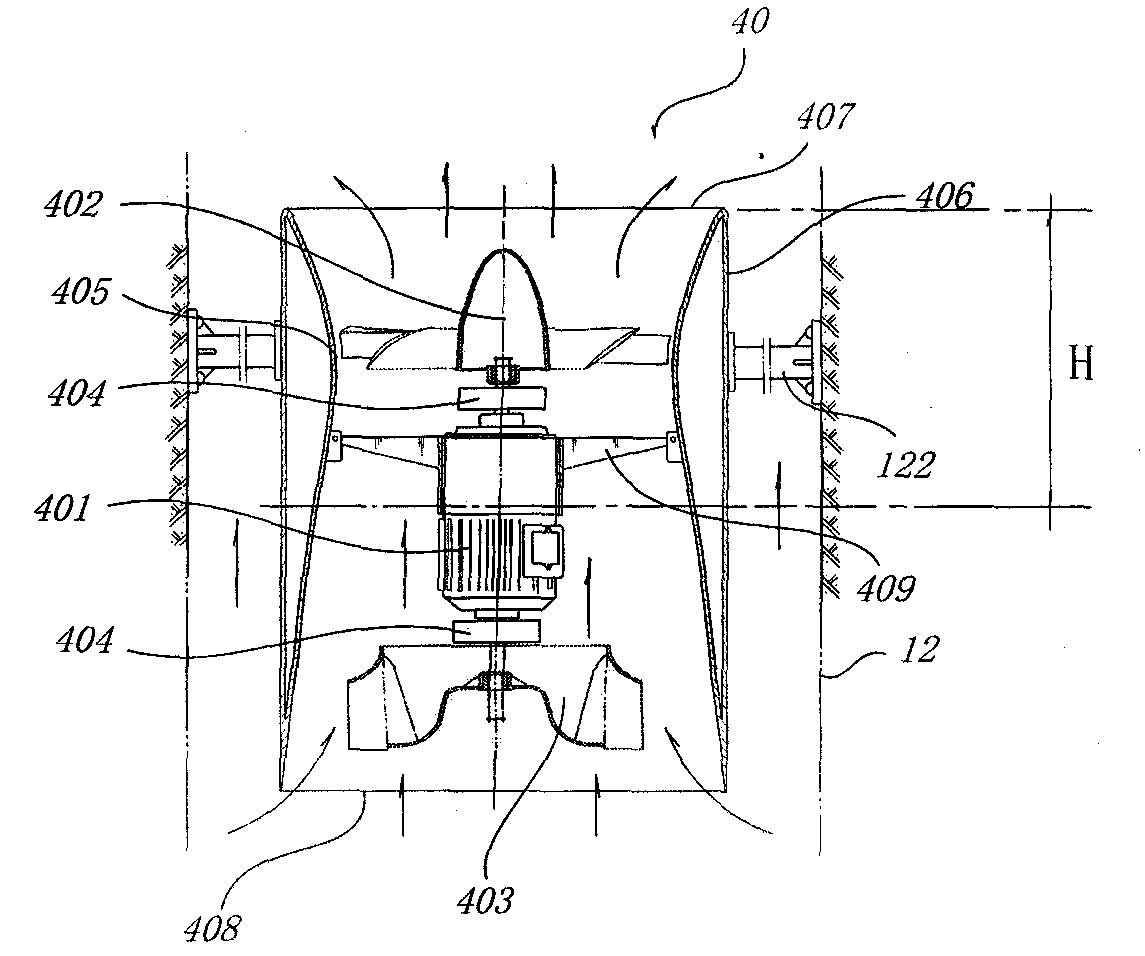

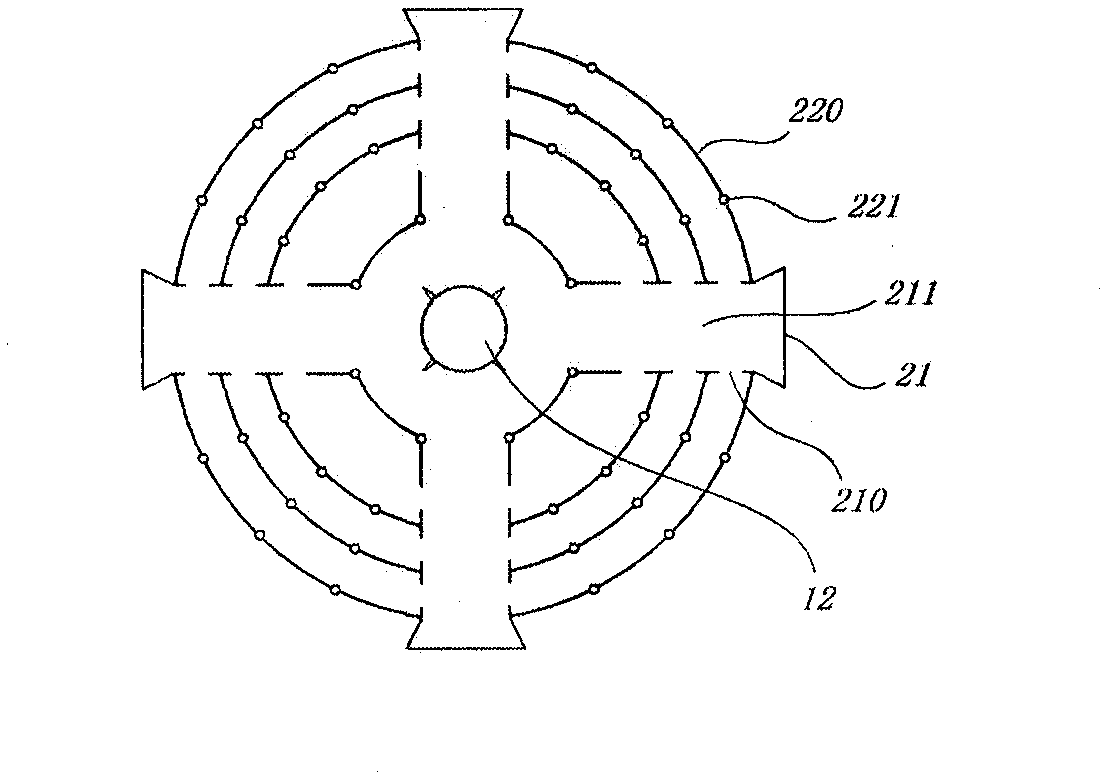

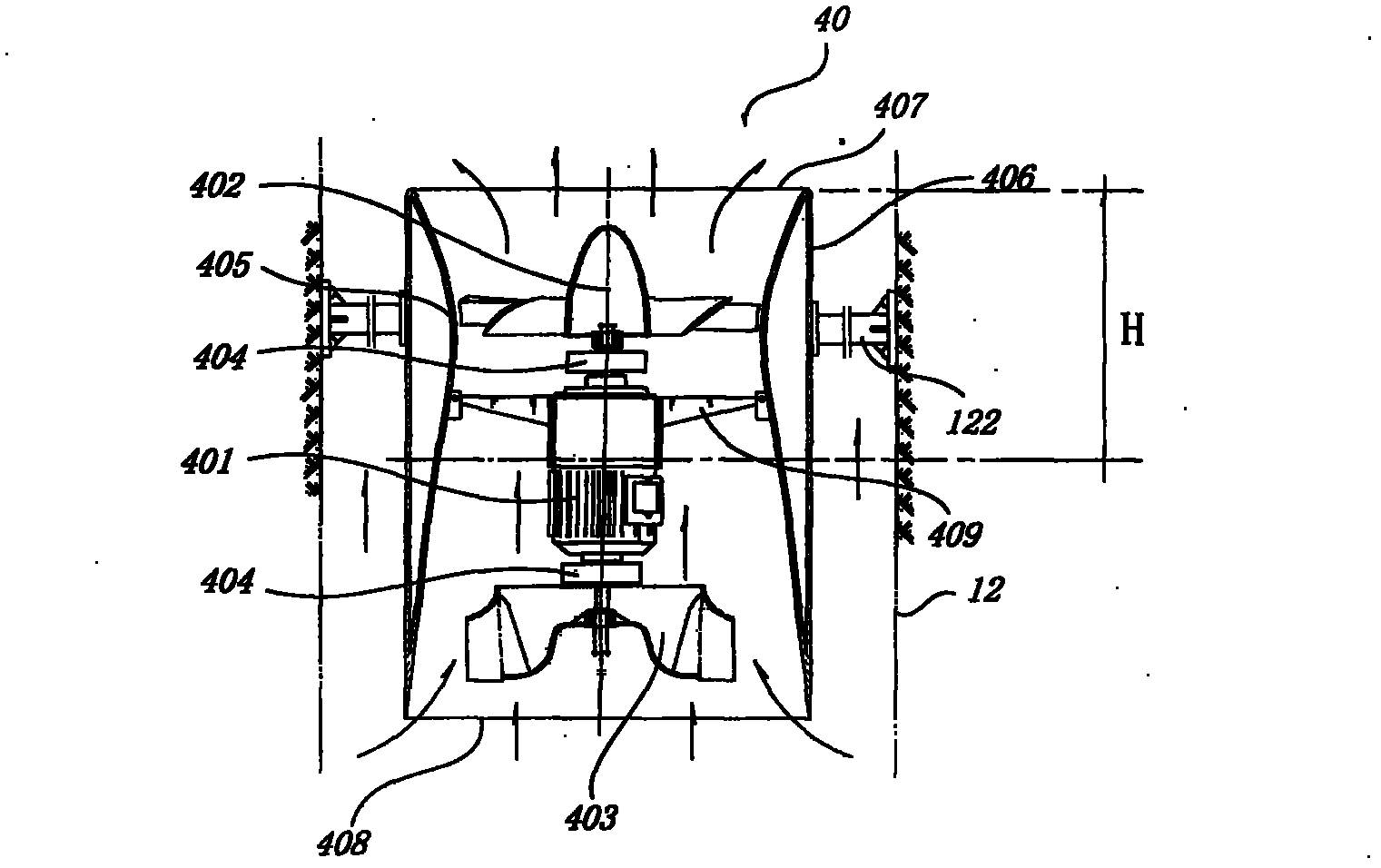

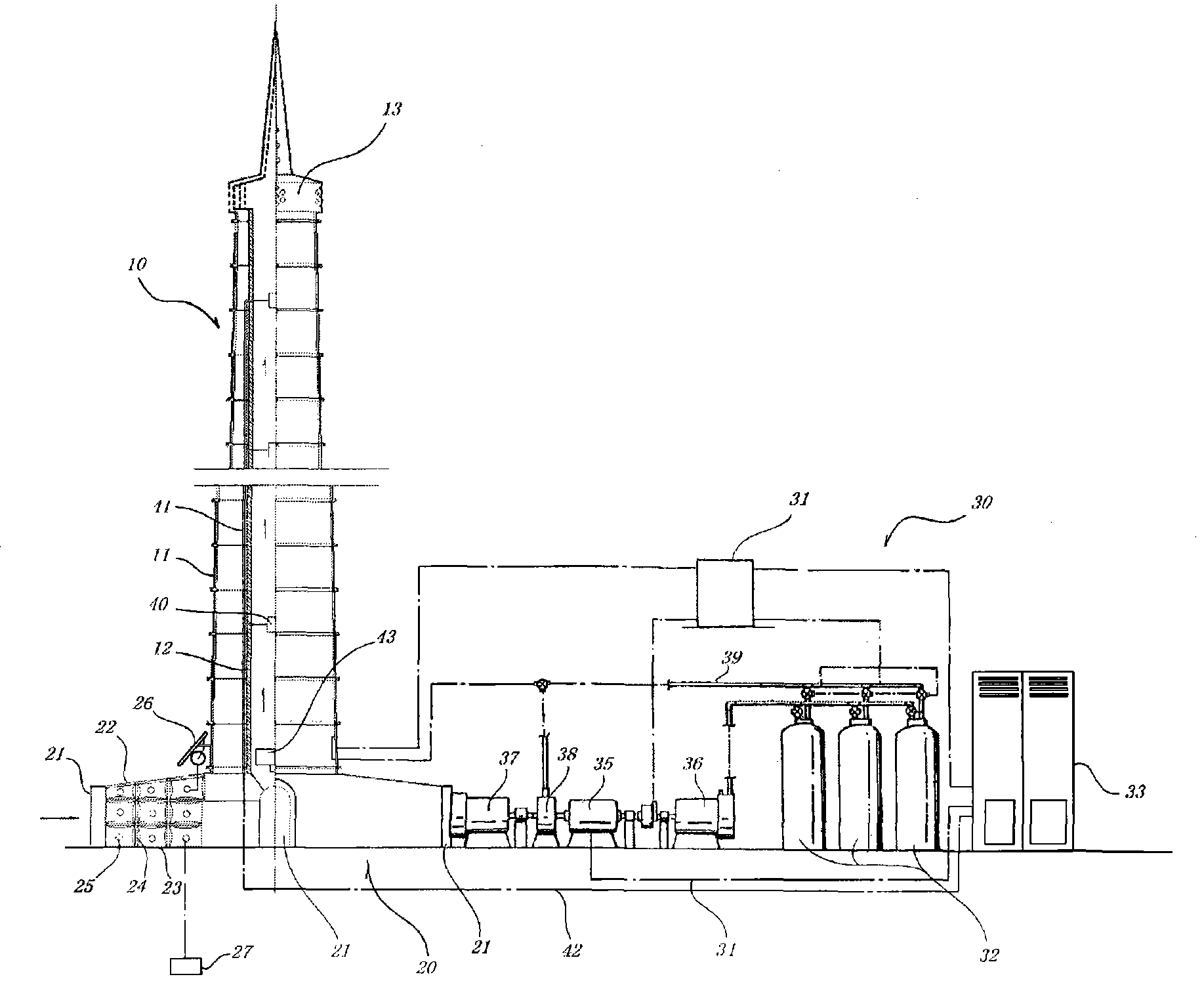

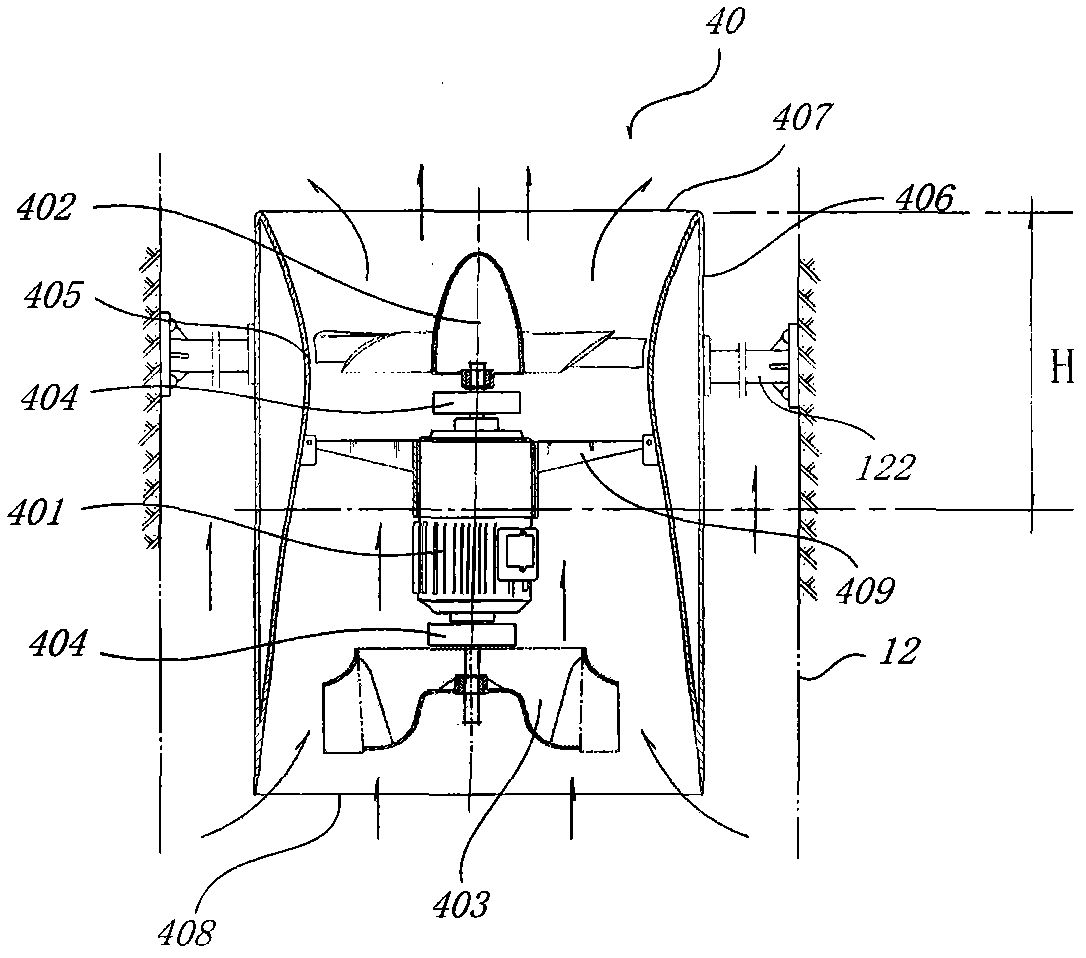

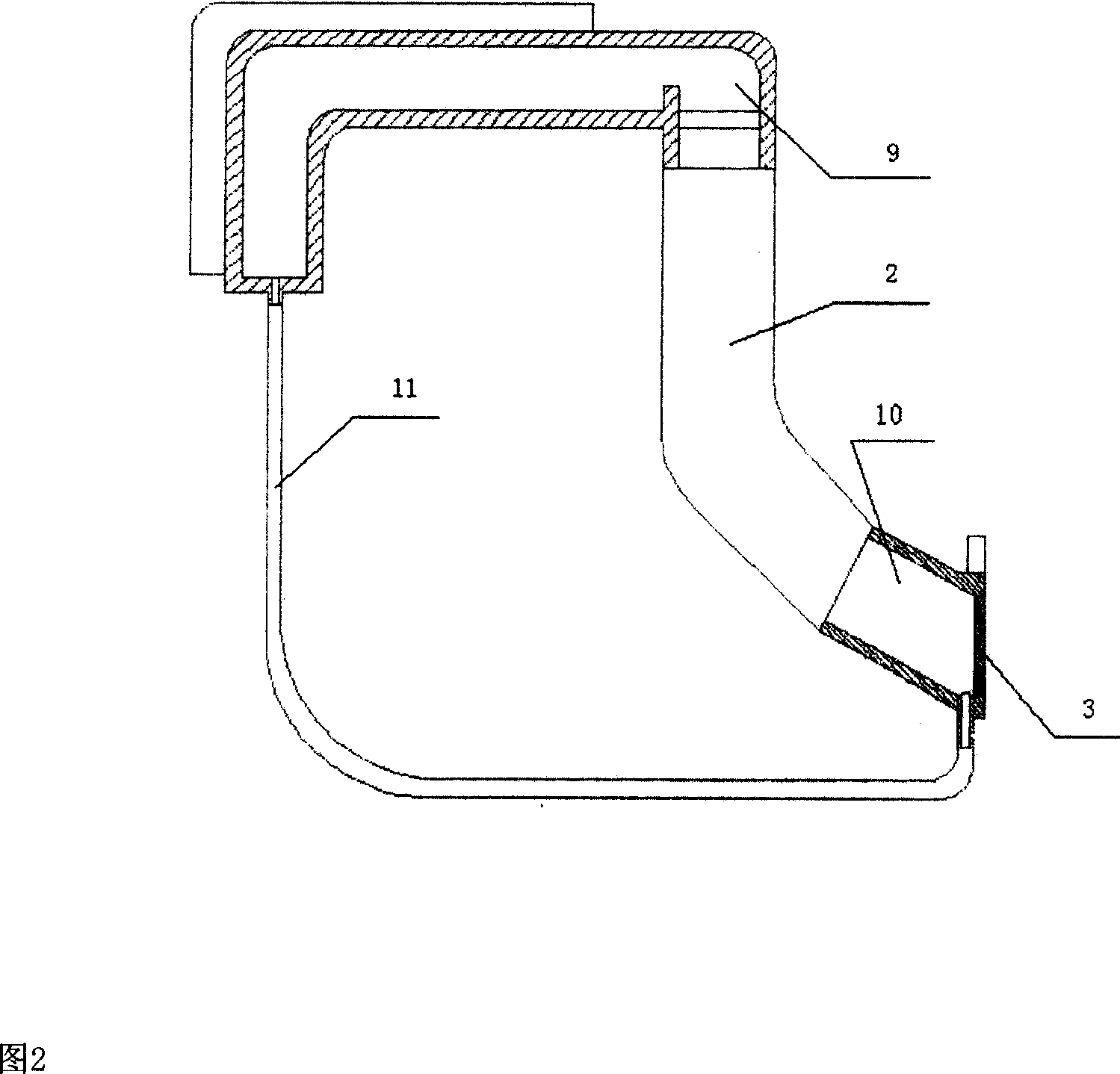

Wind driven generation device of comprehensive energy air channel well power generation station

ActiveCN102996358BEnough temperatureIncrease pressureFrom solar energyMachines/enginesImpellerWind driven

A wind driven generation device of a comprehensive energy air channel well power generation station comprises an air channel well, a power generator and an impeller. The air channel well is perpendicular to the ground and with a plurality of air feeding channels arranged on the base portion. A solar preheating chamber surrounds the periphery of the base portion, and more than one wind driven generator is arranged in the air channel well and comprises a reducing duct device with a diameter shrinkage portion. The power generator is arranged in the duct device. The impeller used for driving the generator to rotate is arranged at the position of the smallest diameter of the diameter shrinkage portion in the duct device and is connected onto a rotor shaft of the power generator. The rotor shaft penetrates through the power generator, and the penetrating end is connected with an air injection turbine which is located in the air feeding direction of the duct device relative to the impeller. Therefore, the wind driven generation device effectively improves air flow acting efficiency.

Owner:周登荣 +1

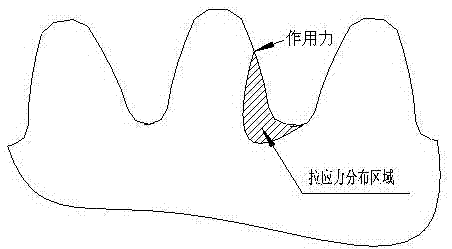

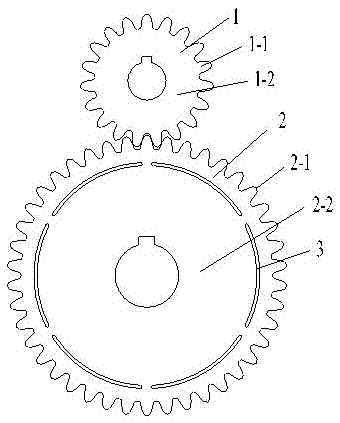

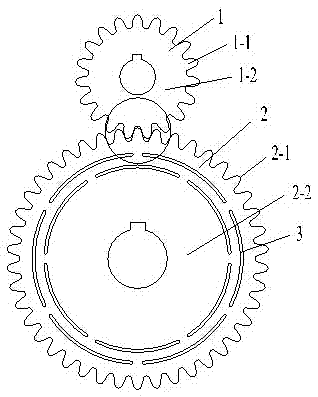

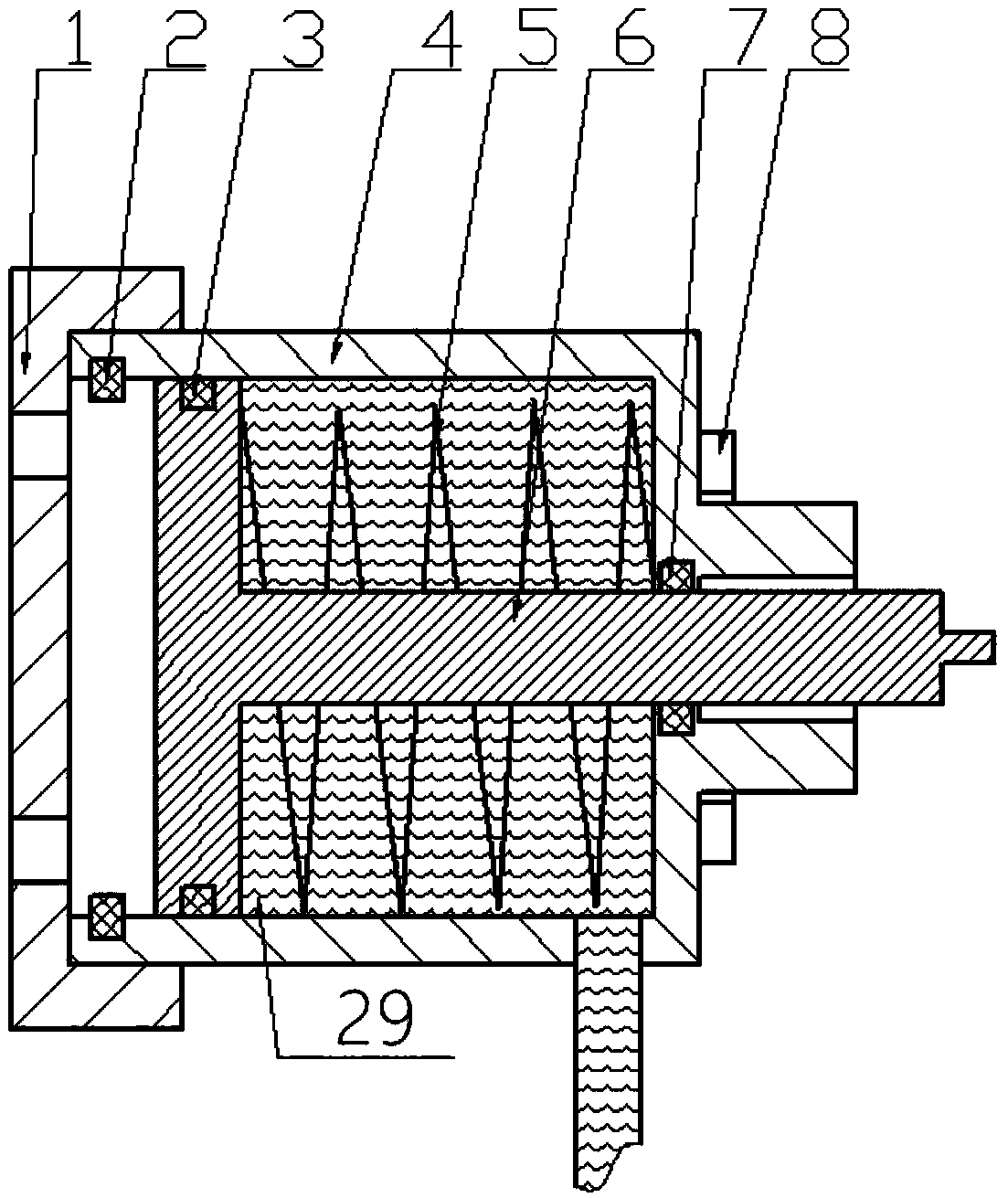

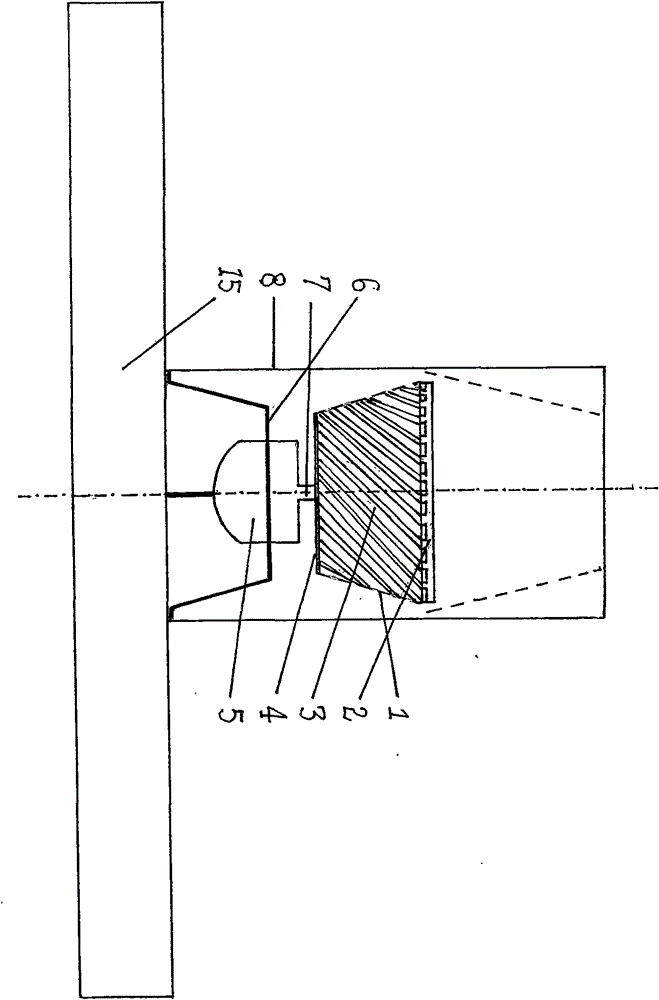

Zero-backlash low-noise transmission gear

InactiveCN105443724AEliminate noise sourcesHigh precisionPortable liftingGearing elementsAutomotive engineeringGear tooth

The invention discloses a zero-backlash low-noise transmission gear. The zero-backlash low-noise transmission gear comprises a driving gear and a driven gear, wherein the driving gear comprises a driving gear body and driving gear teeth; the driving gear teeth are uniformly distributed on the circumferential edge of the driving gear body; the driven gear comprises a driven gear body and driven gear teeth; the driven gear teeth are uniformly distributed on the circumferential edge of the driven gear body; the driven gear teeth are meshed with the driving gear teeth; axle holes are respectively formed in the centers of the driving gear body and the driven gear body; the end face, close to the root parts of the driven gear teeth, of the driven gear body is provided with a ring arc-shaped groove; the ring arc-shaped groove consists at least two segmented arc-shaped grooves which are distributed along the circumference, equal in diameter and concentric; the segmented arc-shaped grooves are through grooves arranged along the axial direction of the gear. The zero-backlash low-noise transmission gear disclosed by the invention has the advantages of reducing the contact pressure stress of the tooth surfaces at the meshed position, reducing concentration of bending pull stress of the root parts of the gear teeth and improving the transmission precision.

Owner:HUNAN TONGSHENG JINGCHUAN TECH CO LTD

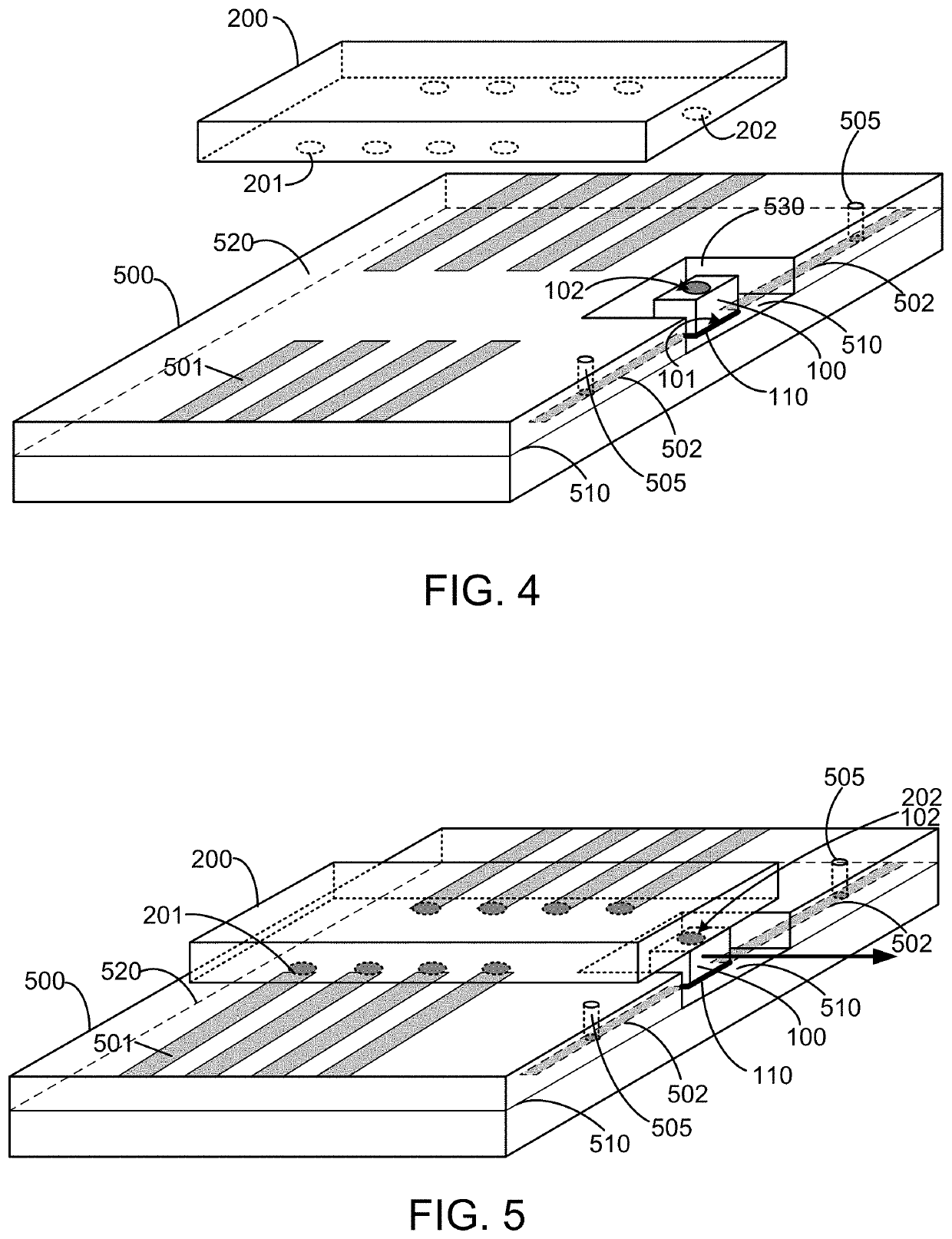

Packaging of a directly modulated laser chip in photonics module

ActiveUS20200194969A1High bandwidthEliminate noise sourcesLaser detailsCoupling light guidesThermoelectric coolingElectrical conductor

A package structure of a directly modulated laser in a photonics module includes a thermoelectric cooler including multiple conductor traces formed in a cool surface. The package structure further includes a directly modulated laser (DML) chip having a first electrode being attached with the cool surface and a second electrode at a distance away from the cool surface. Additionally, the package structure includes an interposer having a plurality of through-holes formed between a first surface to a second surface. The first surface is mounted to the cool surface such that each through-hole is aligned with one of the multiple conductor traces and the second surface being leveled with the second electrode. Moreover, the package structure includes a driver disposed on the second surface of the interposer with at least a galvanically coupled output port coupled directly to the second electrode of the DML chip.

Owner:MARVELL ASIA PTE LTD

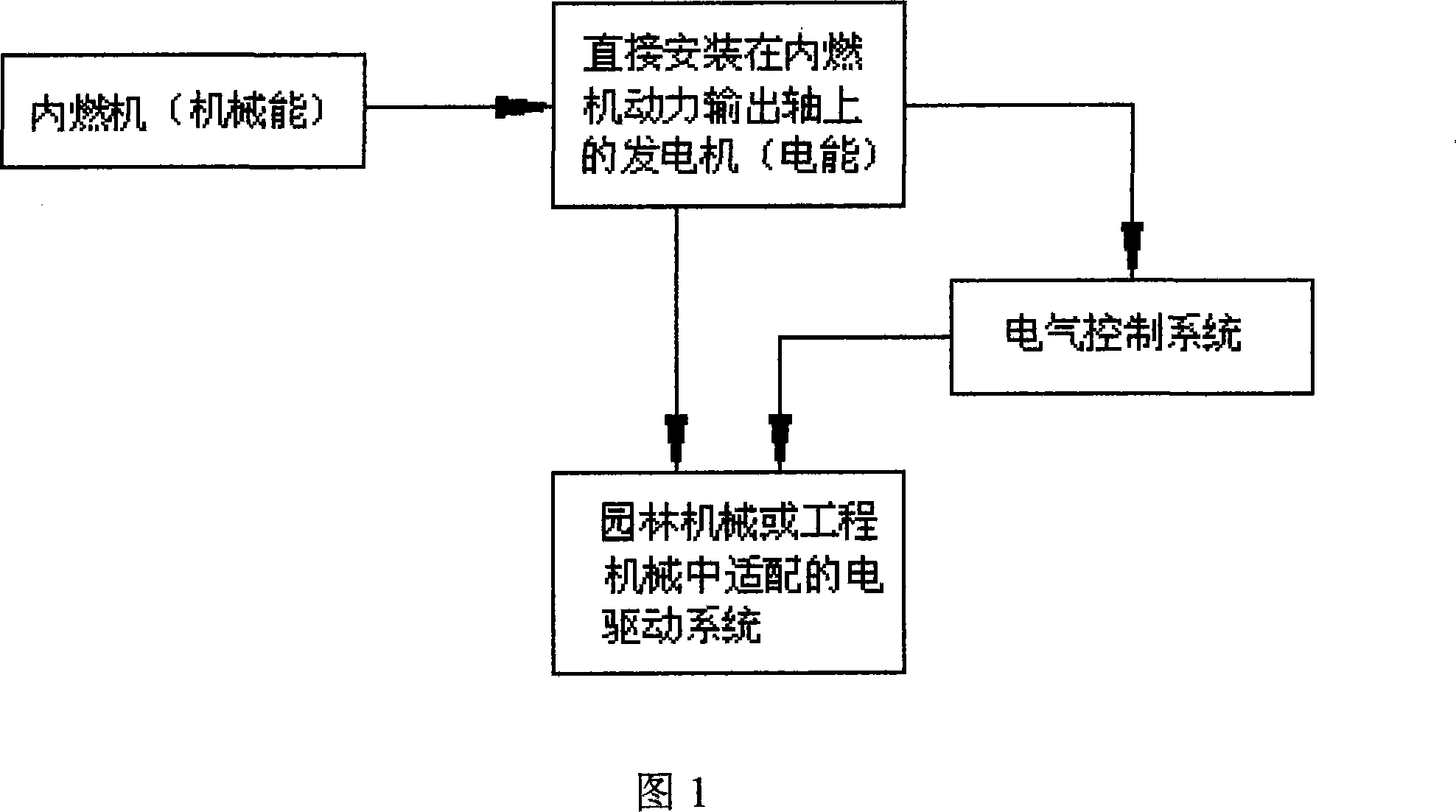

Gardening machinery or engineer machinery electric drive system

InactiveCN101169068AEliminate noise sourcesCompact and simplified structureMachines/enginesMechanical energyPrice ratio

The invention discloses an electric drive system for garden machine or engineering machine. The invention enables an internal combustion engine to transform a part of mechanical energy into electrical energy by directly arranging an electricity generator and a corresponding electrical control system on the power outputting shaft of an internal combustion engine, and then uses the electricity generator as the energy source of all the adapted electric drive system on the garden machine or the engineering machine. The invention aims at dispensing and simplifying the mechanical transmission mechanism, uses electric system to replace parts of mechanical system, achieves the goal of simplifying and compacting the whole structure, eliminates the noise source produced by the mechanical control mechanism, improves the work efficiency and the performance price ratio of the whole machine.

Owner:卓本与

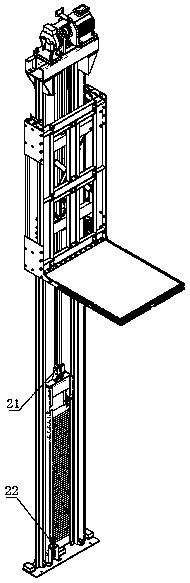

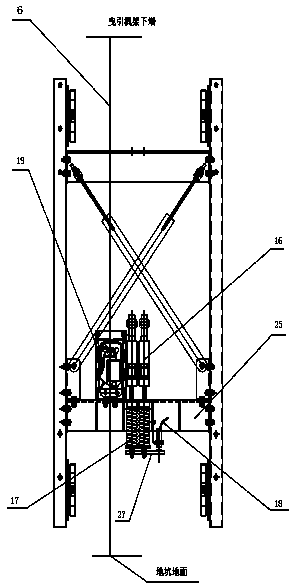

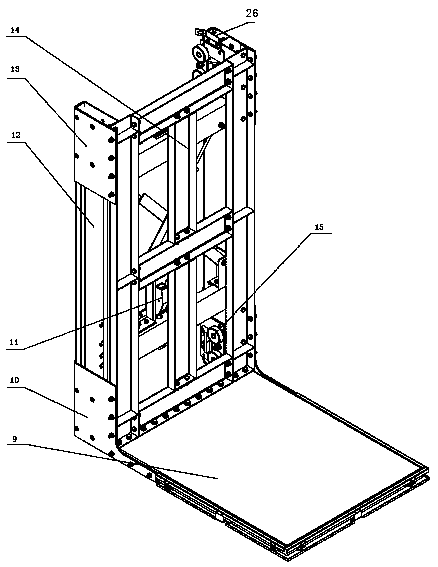

Steel belt traction type household platform

PendingCN110282524AEliminate noise sourcesUniform force operationElevatorsBuilding liftsLow noiseElastic component

The invention discloses a steel belt traction type household platform. The platform capable of lifting up and down along a platform operating guide rail is arranged in a household building hoistway and comprises a platform bottom plate, a platform frame, a platform left column and a platform right column; a traction machine is connected with a bracket via a damping piece; the bracket is connected with the platform operating guide rail and the top end of a counter-weight operating guide rail through a support plate; idler wheel guide shoes of the platform operating guide rail are fixedly mounted on the two inner sides of the platform left column and the platform right column; elastic components for absorbing vibration are arranged on a steel belt of the traction machine and at the front end of a head joint piece of the platform; and the traction machine drives the platform to run in the hoistway with low noise. The steel belt traction type household platform has the following advantages: two-side car walls, a front car wall and a car top are not arranged, and a platform frame decorative plate and the platform bottom plate are arranged, so that steel belt traction type household platform is of the structure with open space, and connection between a door opener and the car walls is avoided to eliminate a noise source; and a traction wheel rotates, so that the steel belt drives the platform and counter-weight to run, the steel belt is stressed to uniformly run, the operating noise is lowered, and the manufacturing cost is reduced.

Owner:上海爱登堡电梯集团股份有限公司 +1

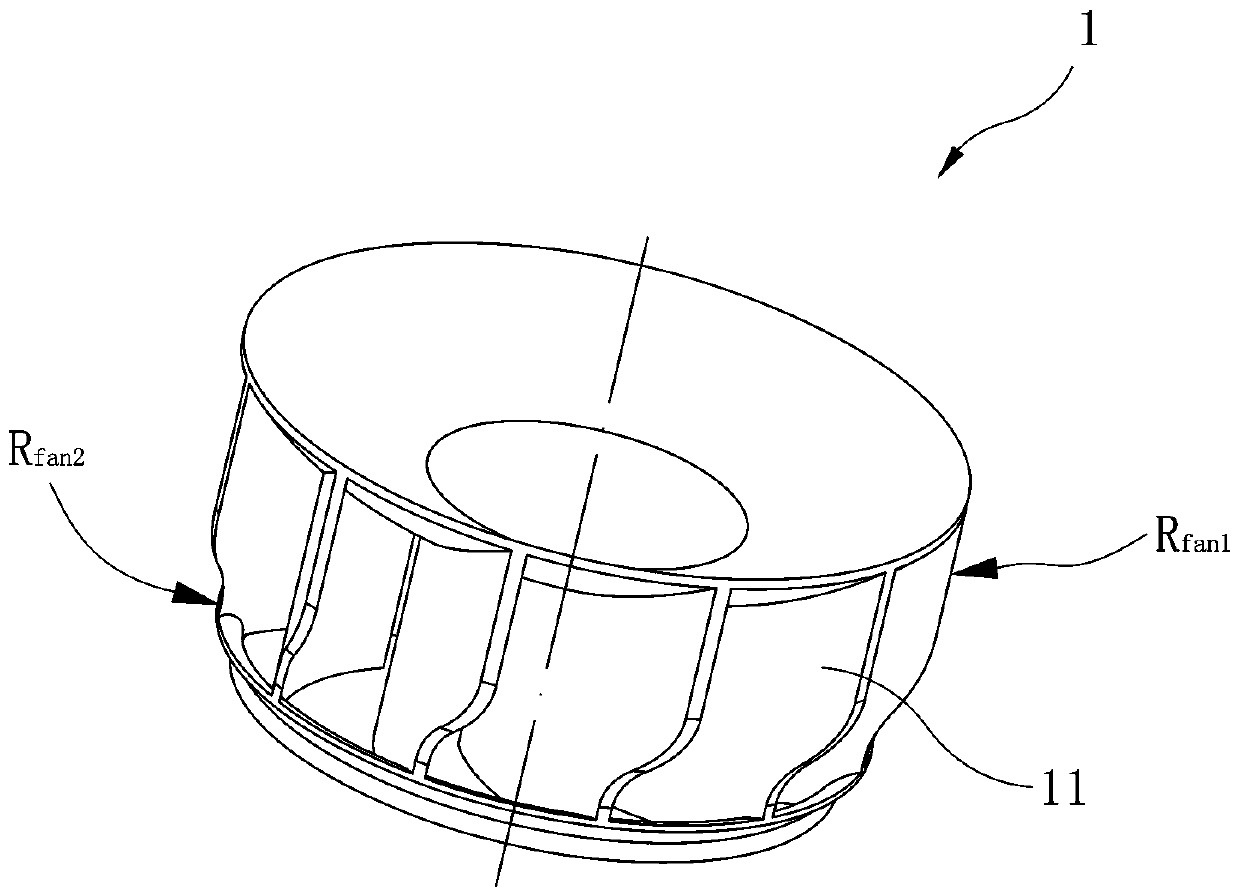

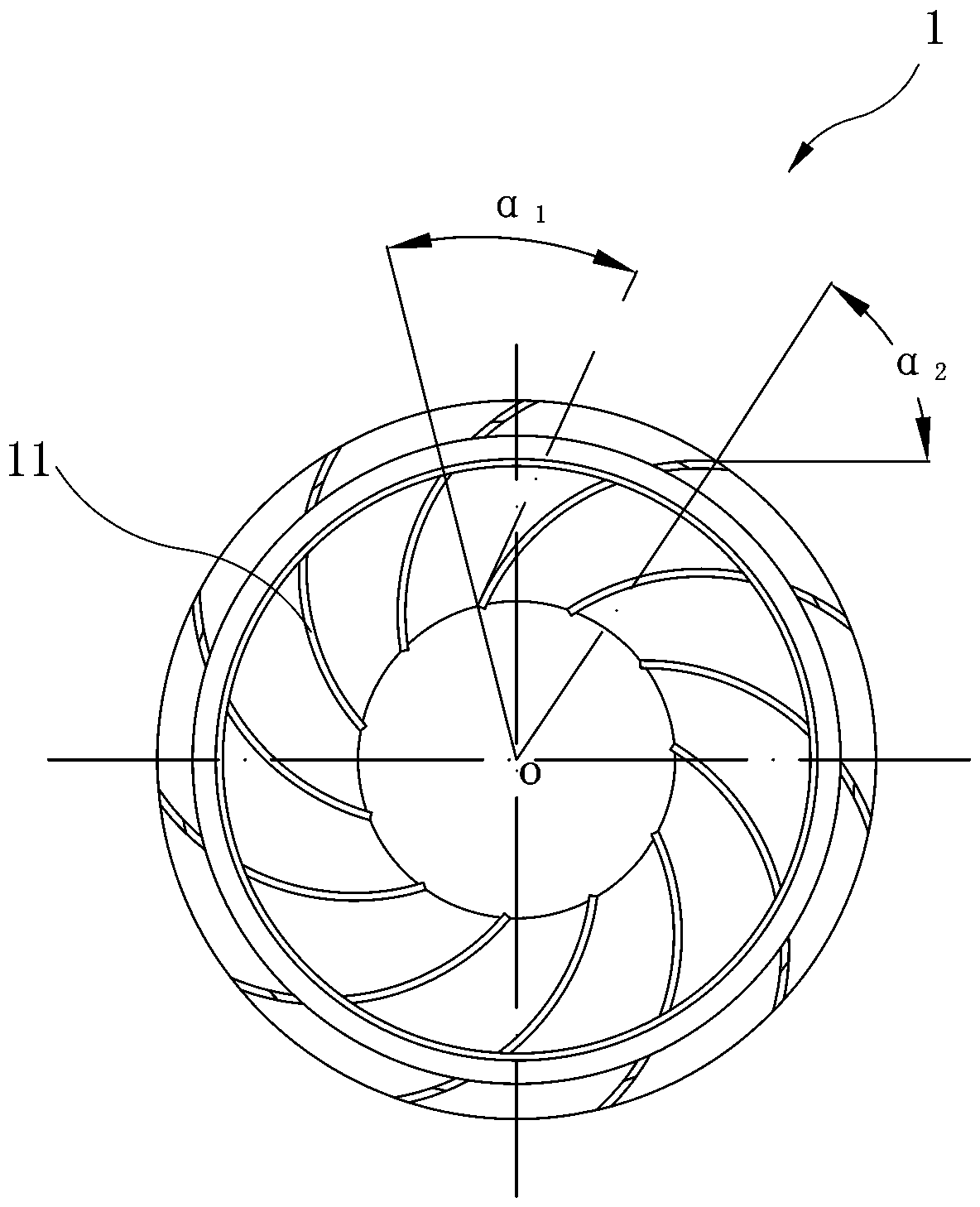

Design method for non-volute centrifugal wind wheel

ActiveCN110206754ASmall self lossEliminate self-lossGeometric CADPump componentsAir volumeEngineering

The invention discloses a design method for a non-volute centrifugal wind wheel. The design method includes outer diameter design of the wind wheel and blade profile design of a wind wheel blade. Dueto the fact that the absolute speed v which is equal to omega*Rfan*cosalpha2 of the blade is reduced by reducing the outer diameter of the blade in a high-speed airflow concentrated area in the centrifugal wind wheel, a self-loss area of high-speed airflow is eliminated, and the purpose of noise reduction is achieved. By means of the design method, the self-loss area of the high-speed airflow of an air way system of the non-volute wind wheel is determined through pneumatics simulation, and two-stage outer diameter type wind wheel design is put forwards in a targeted manner. The second-level outer diameter design of the coefficient epsilon is introduced, the self loss of the high-speed airflow near an air suction opening is eliminated, and the noise can be reduced on the premise that the air volume is not reduced. By means of the design method for the non-volute centrifugal wind wheel, due to mathematical derivation on a pneumatic formula theory, the combination of an air outlet angle alpha 2 and the air inlet angle alpha 1 of the best pneumatic performance is calculated, and the maximum air volume output is achieved in the minimum total pressure loss range.

Owner:XIAMEN VORK HEALTH IND CO LTD

Wind driven generation device of comprehensive energy air channel well power generation station

ActiveCN102996358AEnough temperatureIncrease pressureFrom solar energyMachines/enginesWind drivenImpeller

A wind driven generation device of a comprehensive energy air channel well power generation station comprises an air channel well, a power generator and an impeller. The air channel well is perpendicular to the ground and with a plurality of air feeding channels arranged on the base portion. A solar preheating chamber surrounds the periphery of the base portion, and more than one wind driven generator is arranged in the air channel well and comprises a reducing duct device with a diameter shrinkage portion. The power generator is arranged in the duct device. The impeller used for driving the generator to rotate is arranged at the position of the smallest diameter of the diameter shrinkage portion in the duct device and is connected onto a rotor shaft of the power generator. The rotor shaft penetrates through the power generator, and the penetrating end is connected with an air injection turbine which is located in the air feeding direction of the duct device relative to the impeller. Therefore, the wind driven generation device effectively improves air flow acting efficiency.

Owner:周登荣 +1

Ship and appendage structure thereof

InactiveCN110901827AHigh strengthEliminate cavity permeable structureHull partsMarine engineeringClassical mechanics

The invention belongs to the technical field of ships, and discloses a ship and an appendage structure thereof. The ship appendage structure comprises a framework, a shell and a buoyancy material, theshell is fixed through the framework, and a cavity formed by the shell and the framework is filled with the buoyancy material. According to the ship and the appendage structure thereof, noise generated during advancing can be restrained, and the underwater relative weight can be reduced.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

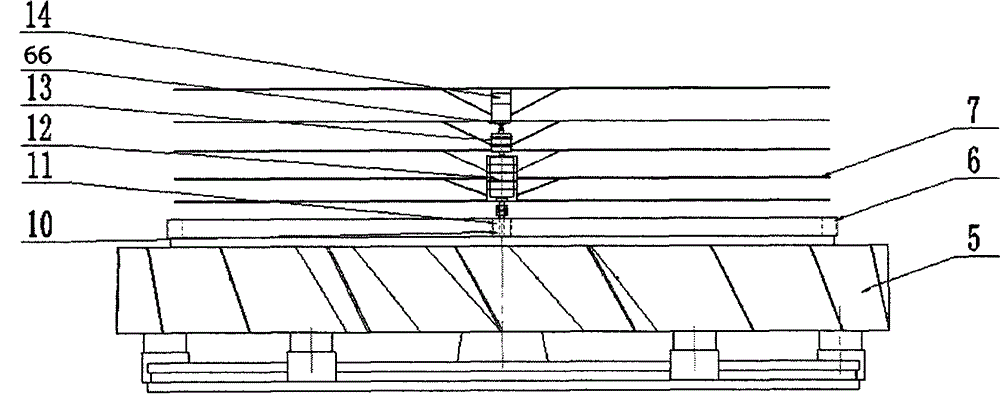

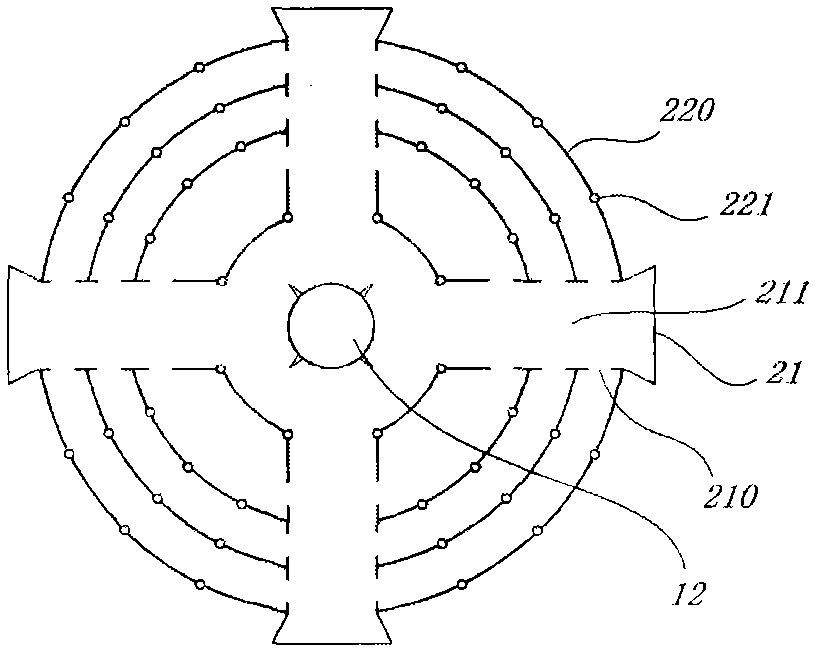

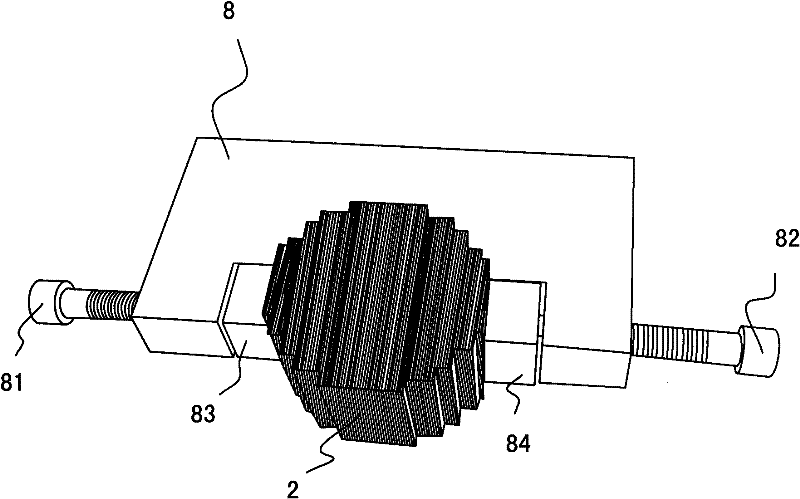

Electricity generating tower turbine turbofan revolving structure

ActiveCN103133244BEnough temperatureUniform power generationMachines/enginesWind motor combinationsImpellerElectricity

The invention relates to an electricity generating tower turbine turbofan revolving structure. The structure comprises a traveling orbit, a turbine turbofan, a revolving gear ring, a shaft component, a fixing support and a motor component. The traveling orbit is placed on a concrete base platform. Bolt sets are evenly distributed at the bottom of the traveling orbit and used for fixing the traveling orbit on the concrete base platform. The turbine turbofan is arranged on the traveling orbit. Five support posts are evenly distributed on the traveling orbit. The revolving gear ring is placed on a top face of the turbine turbofan. The shaft component is connected with the fixing support. A driving component and a braking component are fixed on the fixing support. The whole component is placed in a cylindrical barrel provided with static vanes. The electricity generating tower turbine turbofan revolving structure has the advantages of being simple in turbine turbofan revolving structure, convenient to assemble and disassemble and capable of generating larger electric quantity at the same wind speed compared with existing vanes.

Owner:周登荣 +1

Muffler of comprehensive energy air channel well power generation station

ActiveCN102996204BEnough temperatureIncrease pressureFrom solar energySilencing apparatusInlet channelEngineering

Provided is a muffler of a comprehensive energy air channel well power generation station. The air channel well power generation station comprises an air channel well perpendicular to the ground and with a plurality of air feeding channels arranged on the base portion. A solar preheating chamber surrounds the periphery of the base portion, the air channel well and a bearing frame form an air tower together, and the muffler communicated with the air channel well is arranged at the top end of the air tower. Therefore, the muffler enables air discharge to be smooth without producing air discharge noise and reduces direct impact of the structure at the top end of air tower.

Owner:周登荣 +1

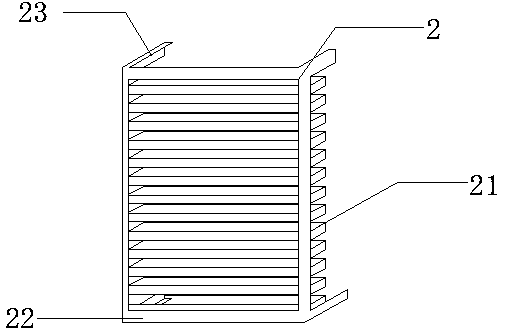

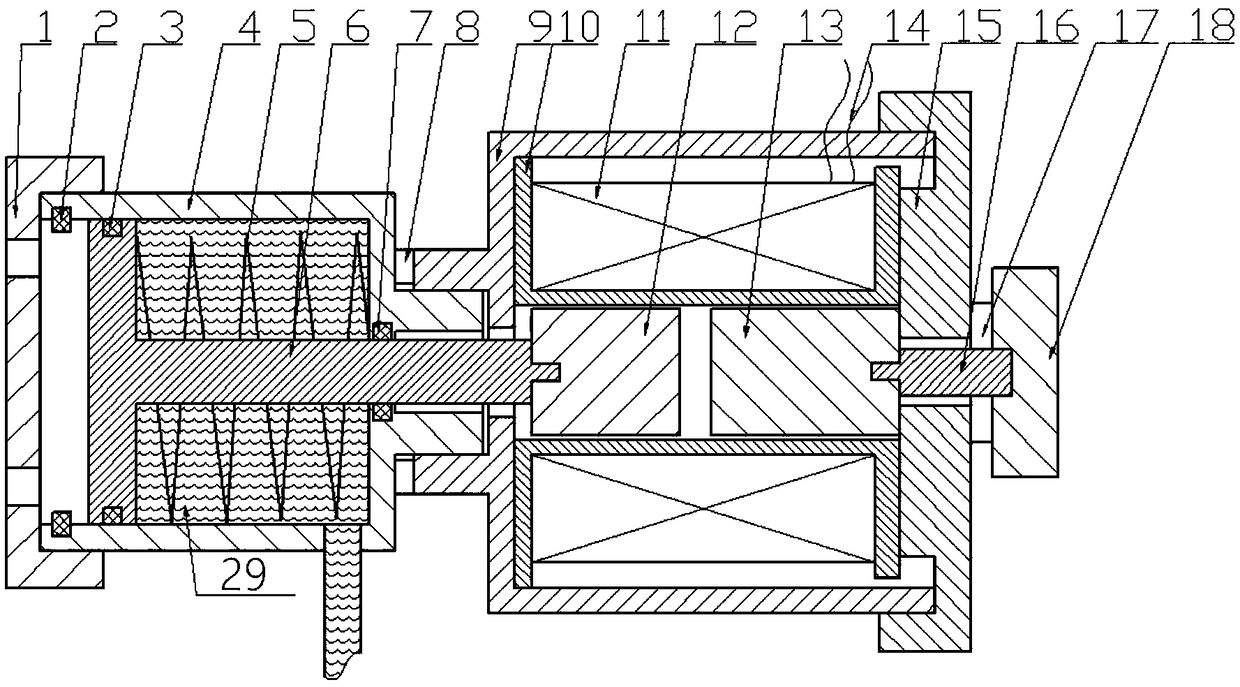

A reactor core and its preparation process

ActiveCN106653311BPut an end to spreadingHigh mechanical strengthTransformers/inductances magnetic coresInductances/transformers/magnets manufactureState of artEngineering

The invention relates to the technical field of reactor production, and more particularly relates to a novel reactor core and a preparation process thereof. The novel reactor core comprises a plurality of silicon steel sheets, support frames and a non-weft belt, wherein each support frame comprises a vertical frame surface, frame legs perpendicular to the frame surface, and a platform parallel to the frame legs; and silicon steel sheets are arranged in parallel on two support frames arranged symmetrically, are clamped by the two support frames and are tightly connected integrally through the non-weft belt. Compared with the prior art, the method of tightening the core has the advantages that the silicon steel sheets are clamped in the support frames and then wound by the non-weft belt, so that the possibility of core scattering is eliminated from the source, the loose phenomenon between the silicon steel sheets is avoided, the influence caused by the aging effect is avoided, and the noise source is eliminated, thus solving the technical problem that the core reactor has large noise for a long time.

Owner:昂顿科技(上海)有限公司

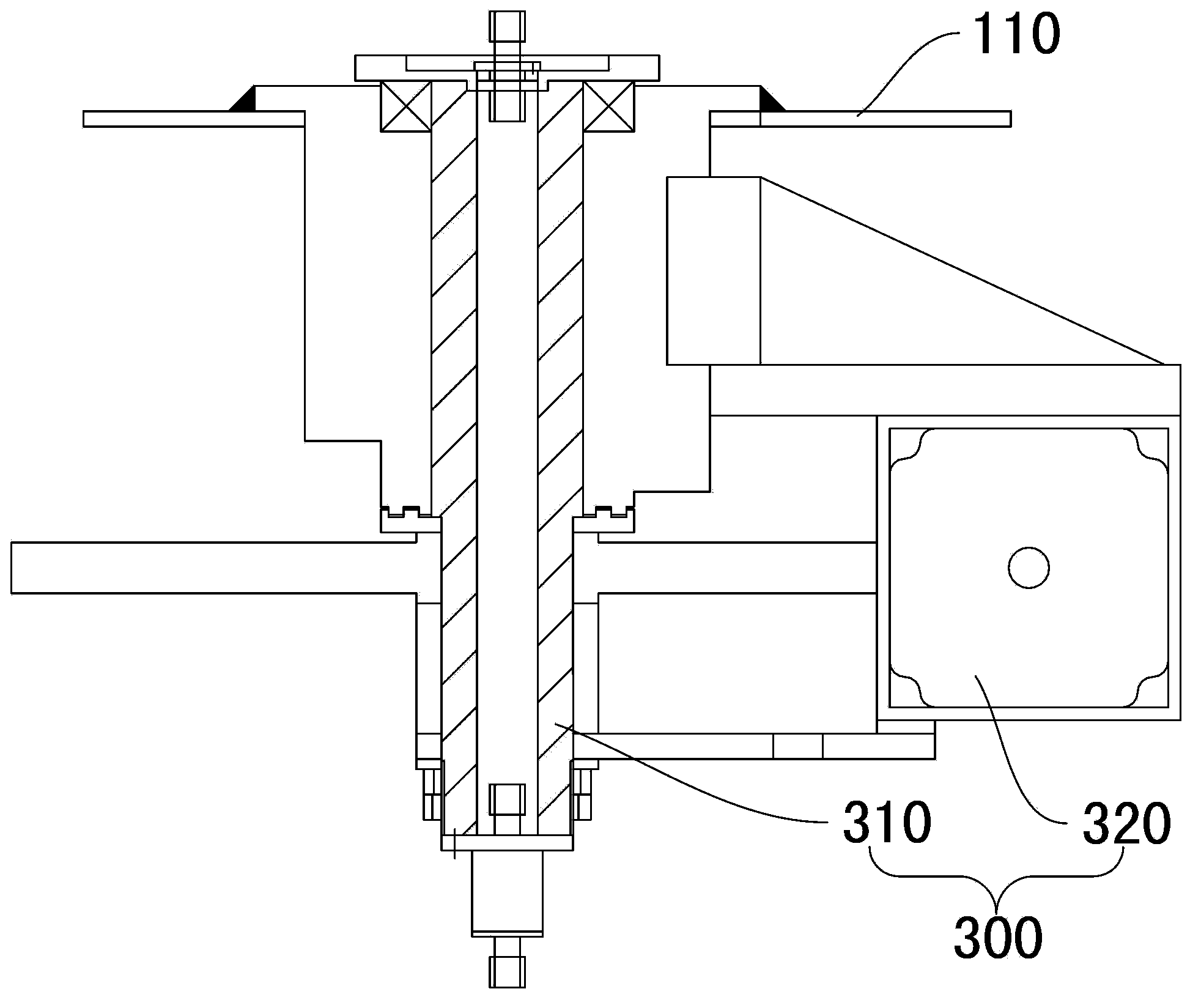

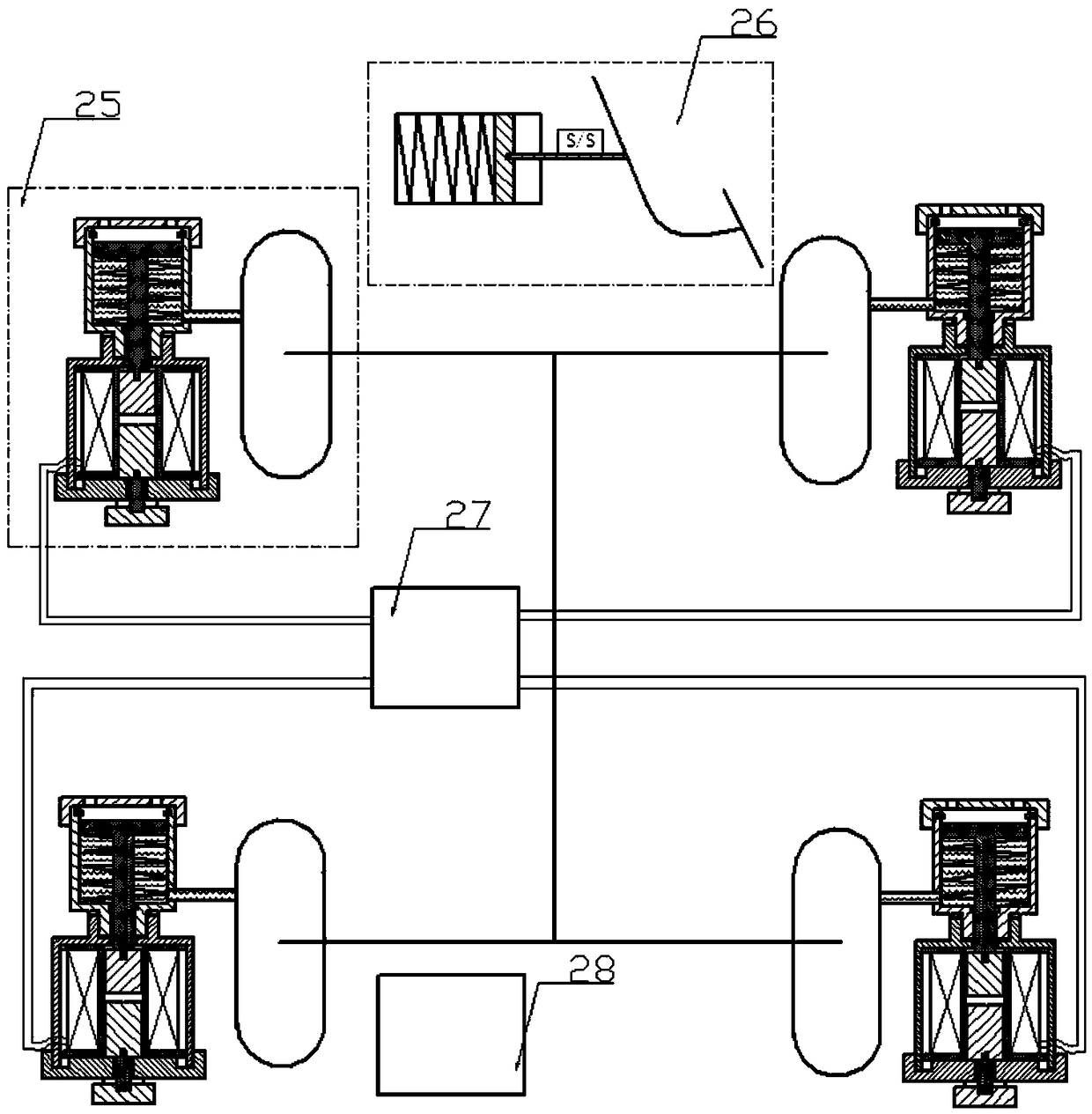

A distributed electronic hydraulic braking system

ActiveCN107139912BCompact structureSimple structureBraking action transmissionEngineeringWheel cylinder

Owner:JILIN UNIV

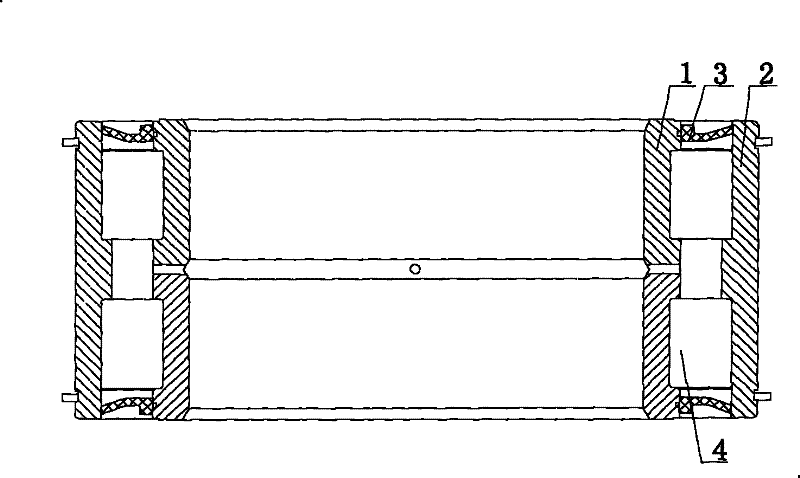

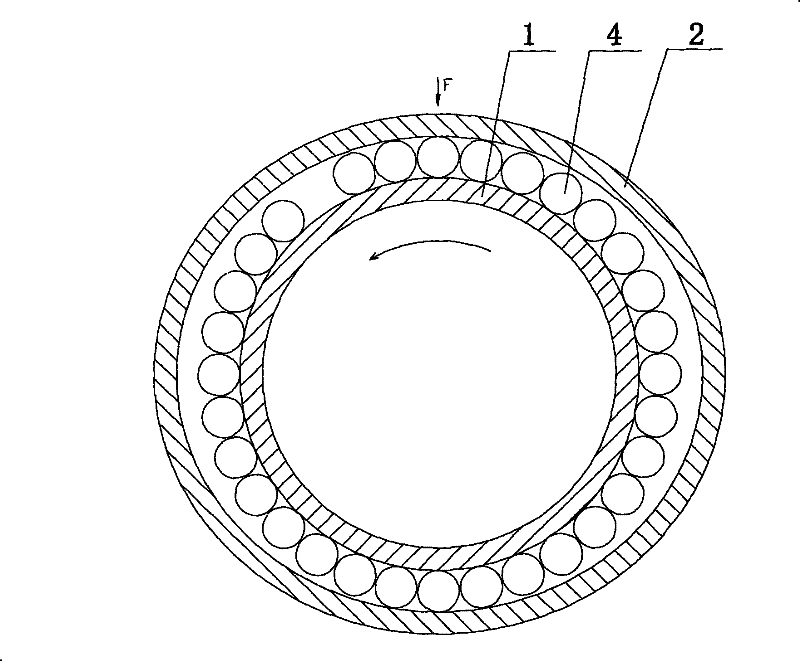

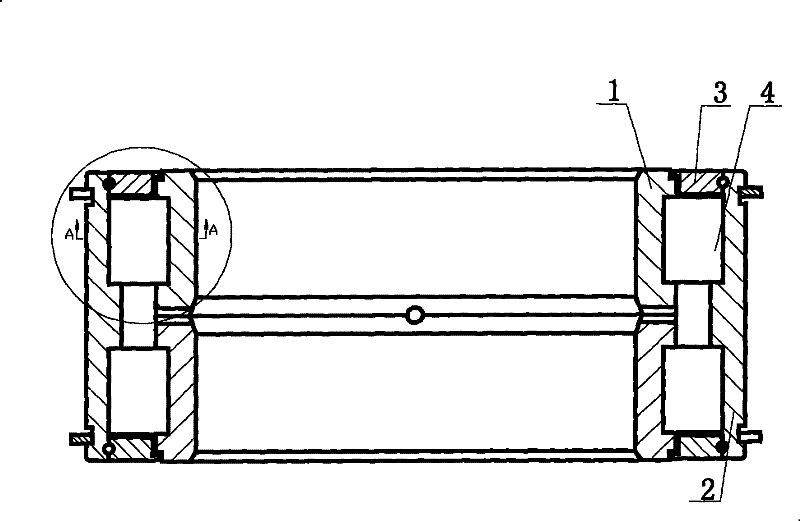

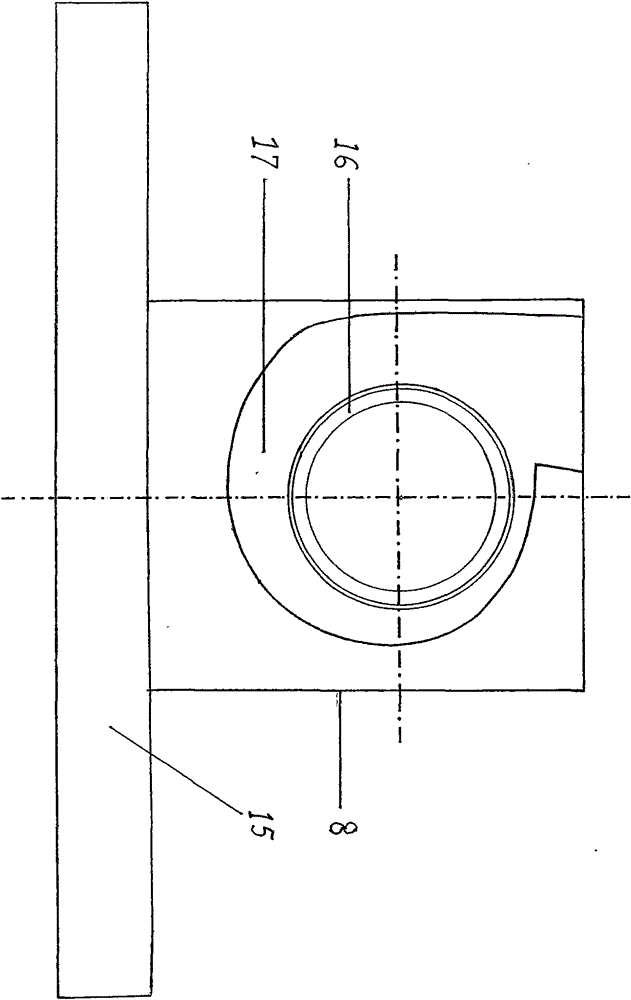

Full type roller bearing

ActiveCN101876344BEliminates impact thudEliminate noise sourcesRoller bearingsBearing componentsButt jointSelf locking

The invention relates to a full type roller bearing. The full type roller bearing comprises two internal rings, external rings, sealing covers and a plurality of rollers, wherein the two internal rings are in butt joint with each other; the external rings are arranged outside the internal rings; a double-row roller path matched with the rollers is formed between the internal rings and the external rings; two end faces of the double-row roller path are provided with one sealing cover respectively; the plurality of rollers are arranged in the roller path uniformly according to a gap; the gap between every two rollers is 0.01 to 0.03 mm; and self-locking structures of the rollers are formed in the double-row roller path. The full type roller bearing has the advantages that: the gap between every two rollers is only 0.01 to 0.03 mm; the gap by which the next roller can push and drive the previous roller to rotate is ensured; large gaps among all the rollers are eliminated; and the structural bearing eliminates the impact sound among the rollers completely, so a first noise source of larger noise of the bearing can be eliminated; and a metal dust cover and rubber sealing combined structure is adopted, so the sealing property is high and the metal impact sound which is caused by that the metal dust cover moves to touch the internal and external rings can be avoided.

Owner:UBC SHANGHAI PRECISION BEARING MFG

Muffler of comprehensive energy air channel well power generation station

ActiveCN102996204AEnough temperatureIncrease pressureFrom solar energySilencing apparatusTowerMuffler

Provided is a muffler of a comprehensive energy air channel well power generation station. The air channel well power generation station comprises an air channel well perpendicular to the ground and with a plurality of air feeding channels arranged on the base portion. A solar preheating chamber surrounds the periphery of the base portion, the air channel well and a bearing frame form an air tower together, and the muffler communicated with the air channel well is arranged at the top end of the air tower. Therefore, the muffler enables air discharge to be smooth without producing air discharge noise and reduces direct impact of the structure at the top end of air tower.

Owner:周登荣 +1

darkroom

ActiveCN103812585BReduce manufacturing costEliminate errorsElectrical testingTransmission monitoringEngineeringDark room

The invention discloses a darkroom. The darkroom comprises a shielding box, a wave-absorbing material layer and a plurality of measuring antennas, wherein the wave-absorbing material layer is arranged on an inner wall of the shielding box; and the measuring antennas are arranged on the inner wall of the shielding box and are suitable for being connected with a cable outside the shielding box. The darkroom has the advantages of being low in manufacturing cost and small in occupied space and improving wireless communication measurement accuracy and consistency.

Owner:GENERAL TEST SYST

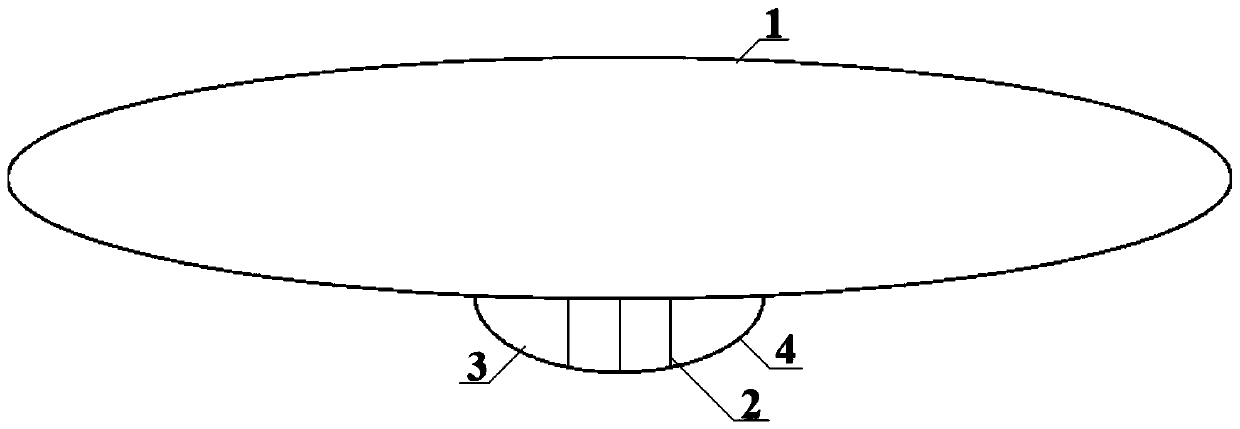

Comprehensive energy air channel well power generation station

ActiveCN102996357BEnough temperatureIncrease pressureFrom solar energyMachines/enginesDistribution controlMotor drive

A comprehensive energy air channel well power generation station comprises an air channel well perpendicular to the ground and with a plurality of air feeding channels arranged on the base portion. A solar preheating chamber surrounds the periphery of the base portion, the base face of the solar preheating chamber is aligned with the base face of the air channel well, and the top face of the solar preheating chamber is higher than the air feeding channel, and more than one wind driven generator with an air flow driving device is arranged in the air channel well. The solar preheating chamber is provided with a heat collection device and a light condensing device. A peak shaving device comprises a motor-driven air compressor connected with the wind driven generator, a charge-discharge device and a power distribution control device. The air compressor is connected with a group of air storage tanks through a pipe. Therefore, the power generation station is capable of comprehensively utilizing various natural energies to generate power and has the functions of shaving peak and compensating.

Owner:周登荣 +1

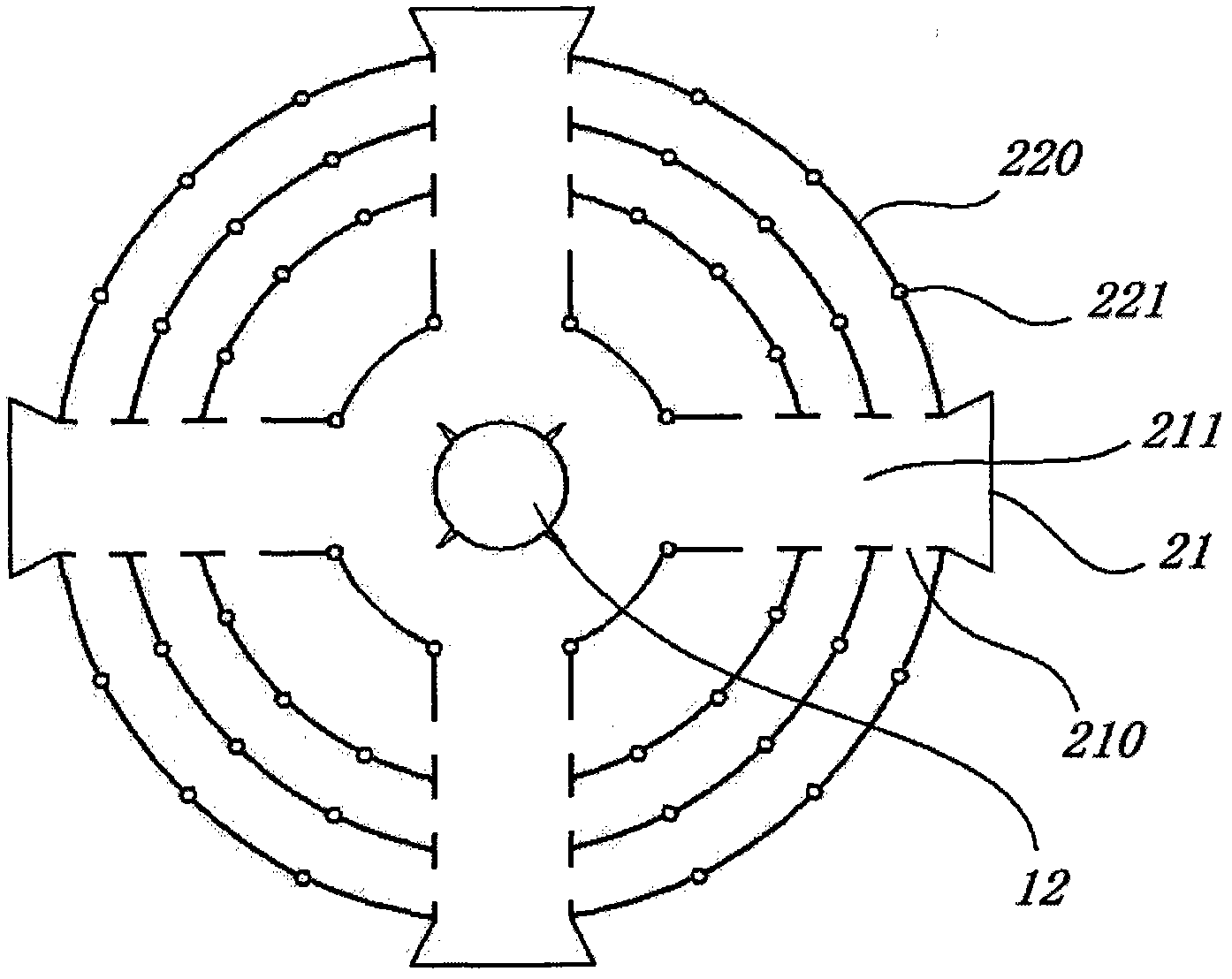

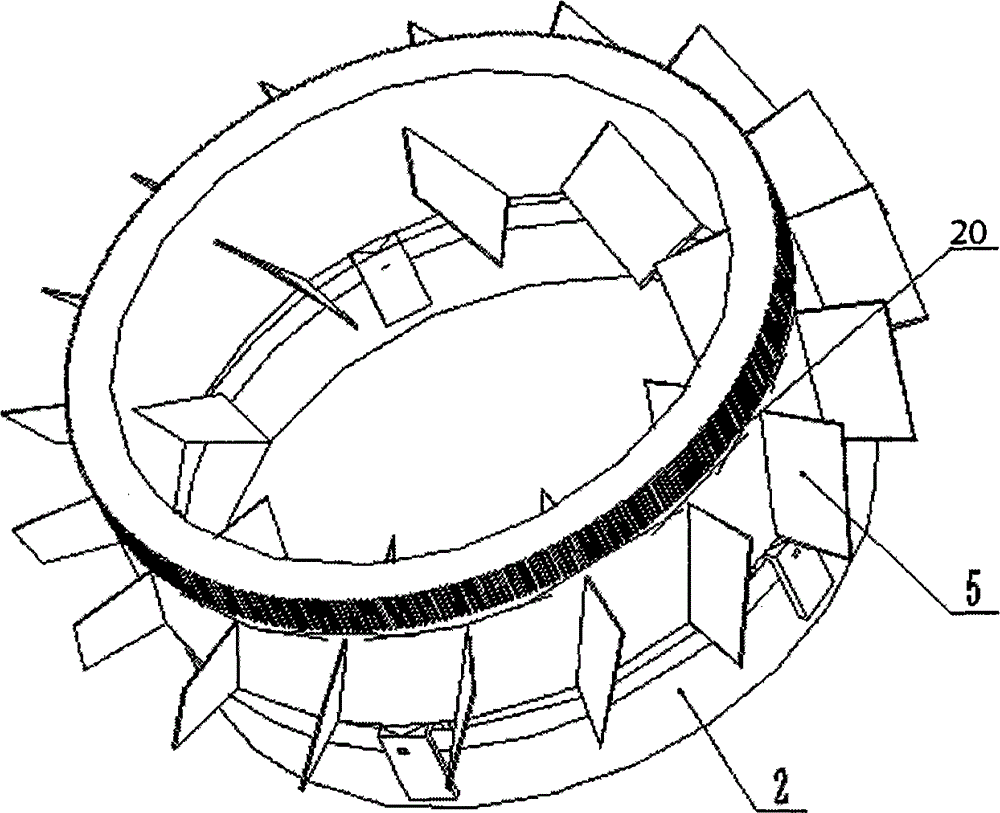

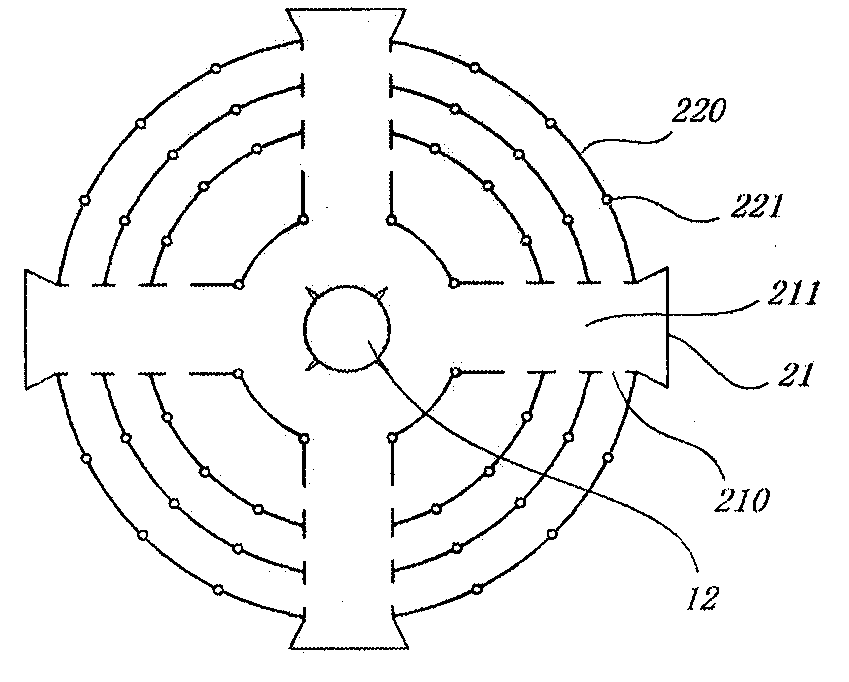

Multi-air-duct internal-absorption axial flow turbo fan

InactiveCN102155434BIncrease the effective areaImprove exhaust efficiencyPump componentsPumpsLow noiseEngineering

The invention provides a manufacturing method of an axial flow turbo-charging fan. The axial flow turbo-charging fan is low in volume, large in air output, volute-free, multi-air-duct and ultra-low-noise, and the volume of the axial flow turbo-charging fan cannot be increased along with increase of the air output. The structural design of a multi-air-duct internal-absorption axial flow turbo fan is most obviously characterized in that: an internal space of a turbo is fully utilized; more than two layers of fan blade rings are arranged; each layer of fan blade rings is formed by ring-like distribution of angular fan blades in a tilting state, wherein the cross section of each angular fan blade is shaped like a right angle substantially; air is absorbed from the outside and bottom of the turbo in an internal-absorption mode and then discharged vertically; and over 50 percent of the quantity and effective area of the fan blades are increased. In the field of a fan-top smoke exhaust ventilator, the fan has the advantages that: a volute is not used, the volume is low, and the air output is large, so that the resonation vibration noise of a cavity of the volute cannot be generated; a large lateral air intake space is not required to be formed between the side of the fan and an outer cover; the width and depth of an upper cover of the smoke exhaust ventilator are quite small; axial flow air draft and discharge modes are kept, so that wind resistance is small, and ventilation efficiency is high; and the fan is light-weight, and materials are saved.

Owner:张建华

Reactor core cake production method

ActiveCN101707136BPlay a fastening rolePlay a loose phenomenonInductances/transformers/magnets manufactureHigh volume manufacturingSilicon

The manufacturing method of the reactor core cake is to use the forming jig to arrange and clamp many cut and loose silicon steel sheets to form a silicon steel sheet cake, and then, together with the forming jig, move the silicon steel sheet cake to an upper table that can drive the silicon steel sheet cake to rotate. In the accommodation space between the two working surfaces of the fixture and the lower fixture, the silicon steel sheet cake is clamped, and the forming fixture is removed; the silicon steel sheet cake is driven to rotate, and at the same time, the latitude-free belt around the periphery of the silicon steel sheet cake is Under the action of the tension force, the silicon steel sheet cake is pulled and bound, and after the set number of layers is wound as required, the tail of the non-weft tape is quickly cured at high temperature on the non-weft tape ring, and the iron core cake is made into a one-time machine. Blanks; according to batches, the core cake blanks are vacuum-dipped and solidified to form core cake products. The silicon steel sheet cake of the present invention is directly bound by machinery, and the finished product is finished by one-time fat dipping and solidification. It has the advantages of high automation level, low production cost and short production cycle, and is especially suitable for mass production.

Owner:ZHEJIANG KESHENG ELECTRIC POWER EQUIP

Unpowered self-loop computer liquid cooling system

InactiveCN1322394CReduce consumptionEliminate noise sourcesDigital data processing detailsSemiconductor/solid-state device detailsHeat flowLiquid cooling system

This invention discloses a powerless self-recycling computer liquid cooling system, which comprises heat collector and dissipation device. The heat collector is set with heat collection pad and water-in pipe with its direction at an angle with heat flow varying from zero to ninety degrees. Its heat water exit mouth is of a widening shape and its flow area is larger than the water-in flow area. And the dissipation device has deposit chamber, water barrier pad. The heat collector and dissipation device are connected through heat water pipe and cool water pipe.

Owner:DALIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com