Heat-resistant ASA resin composition with tiger wrinkle defect eliminated and preparation method thereof

A technology of ASA resin and tiger skin pattern, which is applied in the field of polymer material processing, can solve the problems that the heat resistance level is difficult to meet the heat resistance requirements of automotive trim parts, it is difficult to be widely used in the automotive field, and the impact toughness of materials is difficult to achieve. , to achieve excellent anti-noise effect, good mechanical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

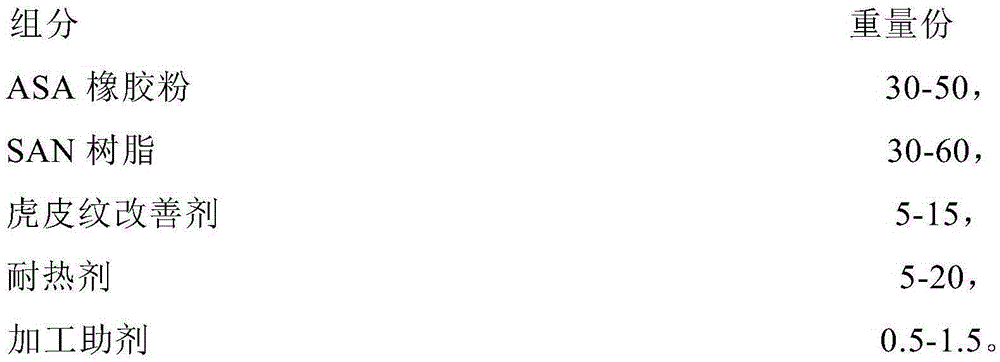

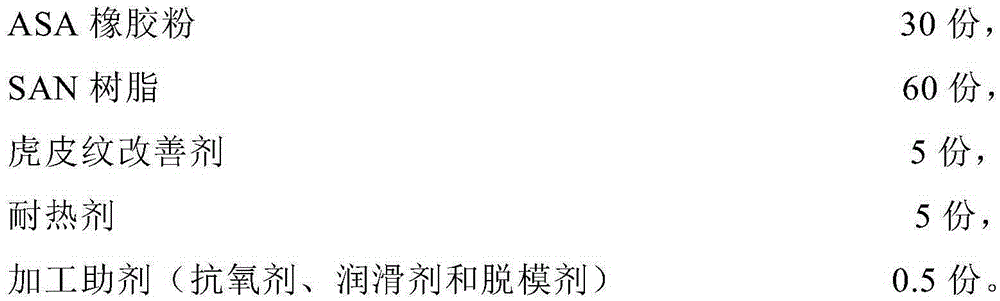

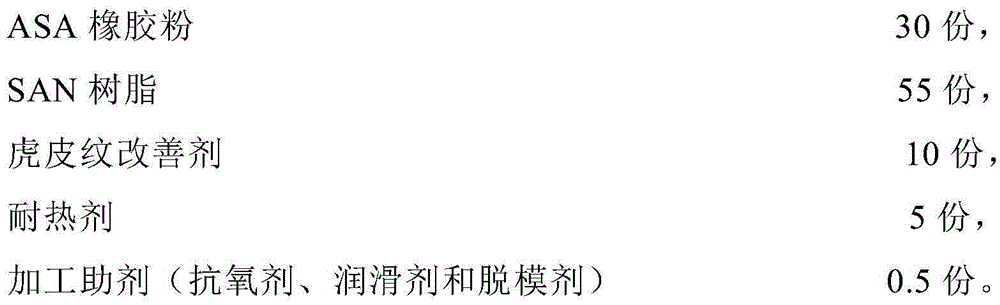

Method used

Image

Examples

preparation example Construction

[0033] Its preparation method comprises the following steps:

[0034] (1) prepare materials according to the described components and contents;

[0035] (2) Premix the materials prepared in the step (1) in a high-speed mixer;

[0036] (3) Pass the premixed material obtained in step (2) through a twin-screw extruder, melt and extrude it at an extrusion temperature of 180-250° C. and a screw speed of 200-500 rpm, and cool and granulate. An ultra-high melt strength blow molding ABS resin composition is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com