Height-adjustable automobile gear lever and height adjusting method thereof

A technology for shifting gears and shifting levers of automobiles, which is applied to components with teeth, belts/chains/gears, mechanical equipment, etc., which can solve the driver's vision, the influence of leg position, the inability to meet the height requirements, and the driver's driving fatigue. and other problems, to achieve the effect of strong and firm components, simple structure, and satisfying driving needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

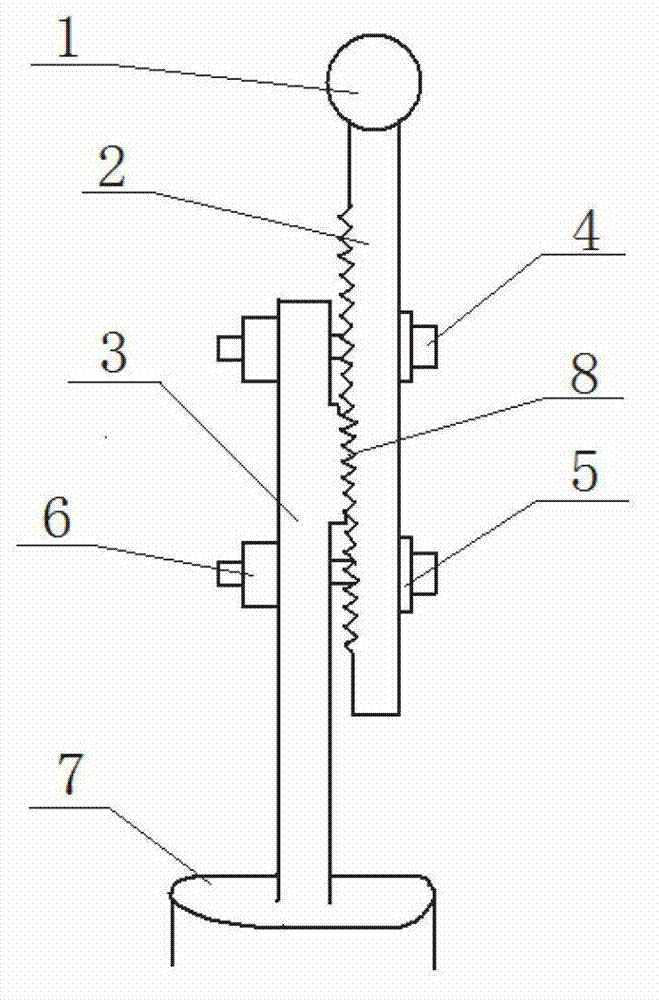

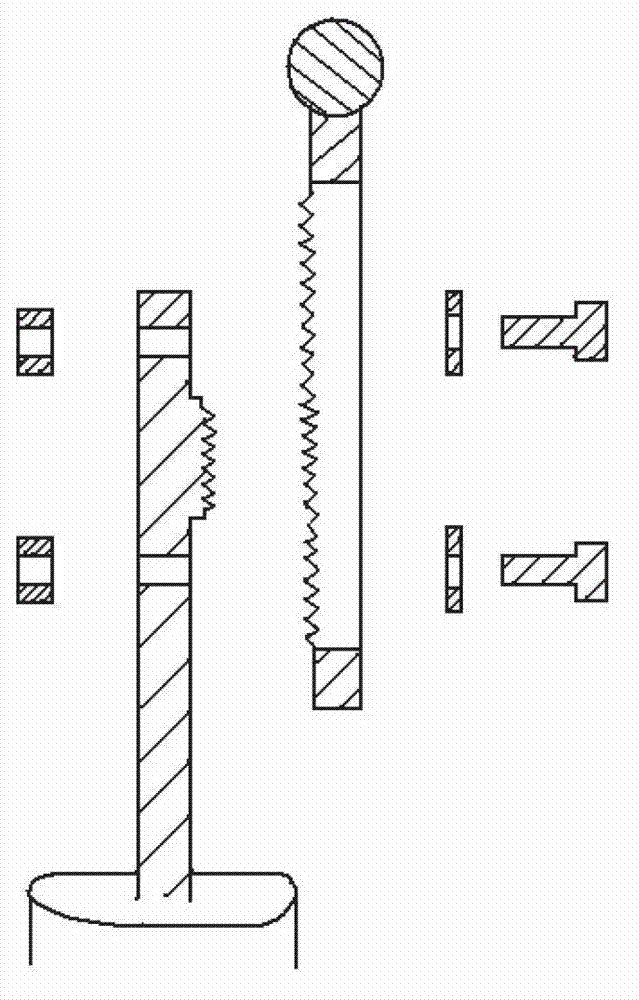

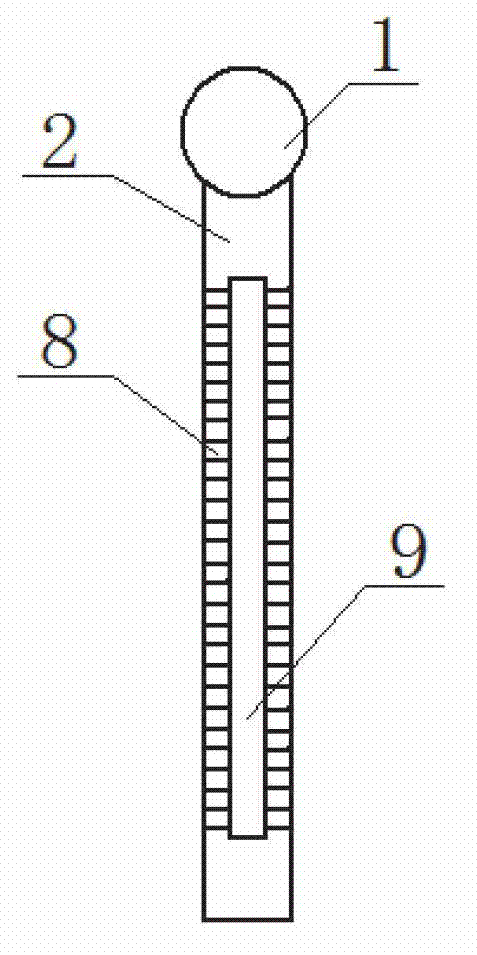

[0021] figure 1 It is a schematic diagram of the overall structure of a variable-height automotive shift lever of the present invention. The shift lever assembly includes a shift handle 1, an upper connecting rod 2, a lower connecting rod 3, bolts 4, gaskets 5, nuts 6, The shift lever mounting plate 7 is composed. The shift handle 1 is connected to the upper connecting rod 2 of the shift lever, and the upper connecting rod 2 and the lower connecting rod 3 are fixed by bolts 4 , washers 5 and nuts 6 . The lower connecting rod 3 and the shift lever mounting plate 7 are connected with the shift mechanism. The shift lever of the present invention is divided into an upper connecting rod 2 and a lower connecting rod 3 which are connected. The shift handle 1 is connected to the upper connecting rod 2, and the upper connecting rod 2 is provided with a long slotted hole 9 along its length direction. , the lower connecting rod 3 is provided with a plurality of connecting holes 10 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com