Sealing device used for chemical reactor

A technology of chemical reactors and sealing devices, which is applied to the sealing of engines, chemical instruments and methods, chemical/physical processes, etc., and can solve problems such as damage, hardship, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

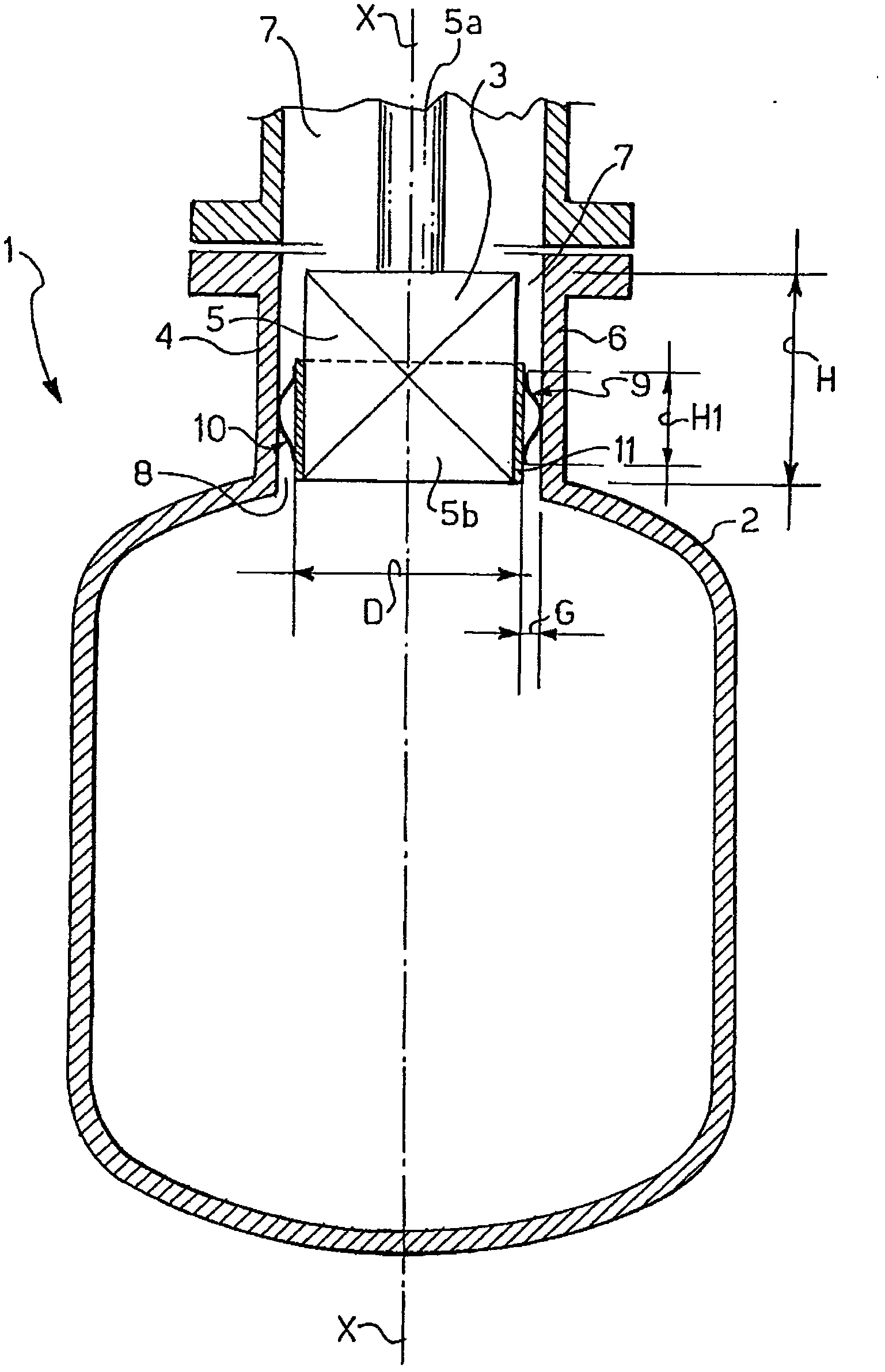

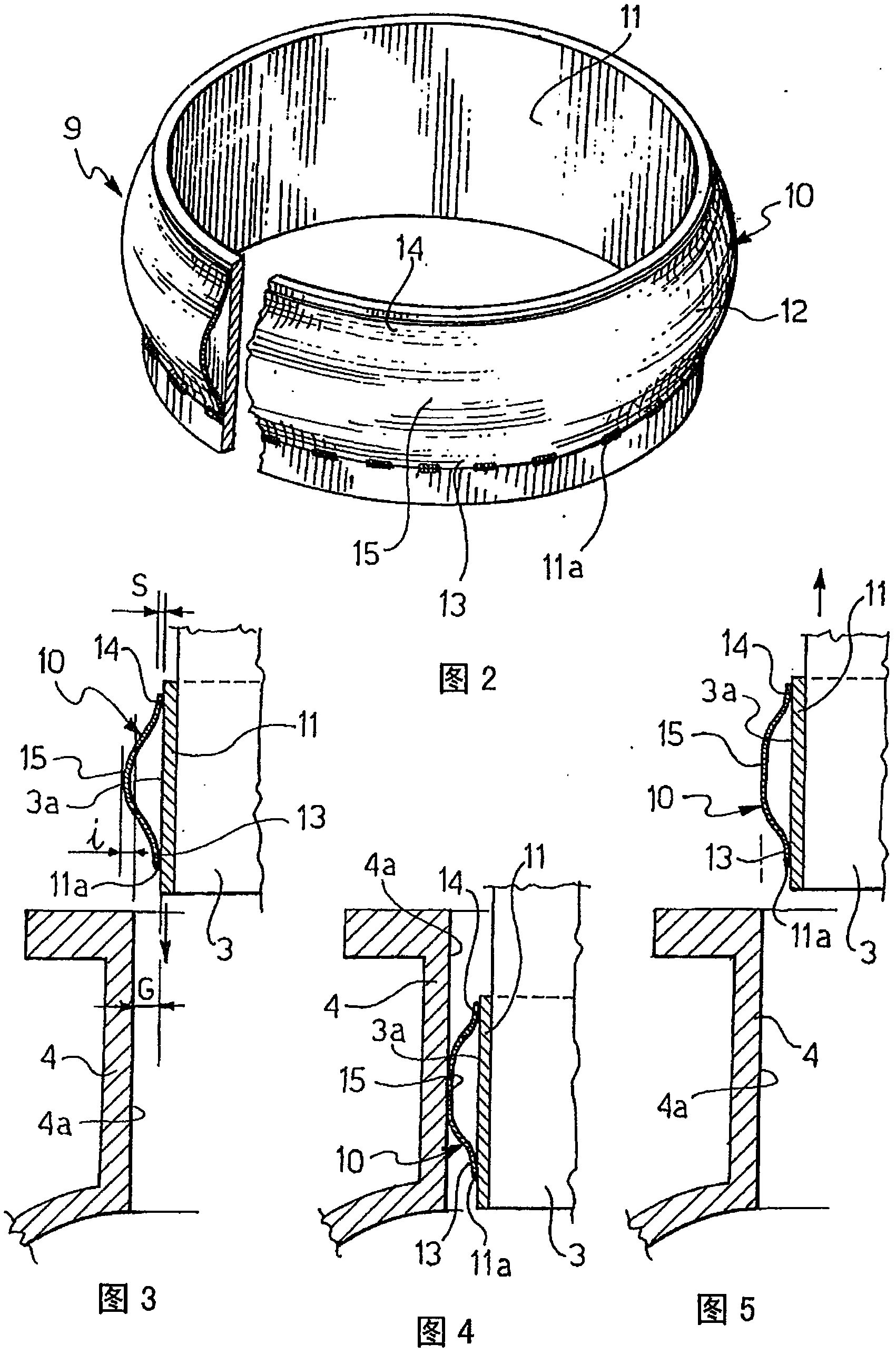

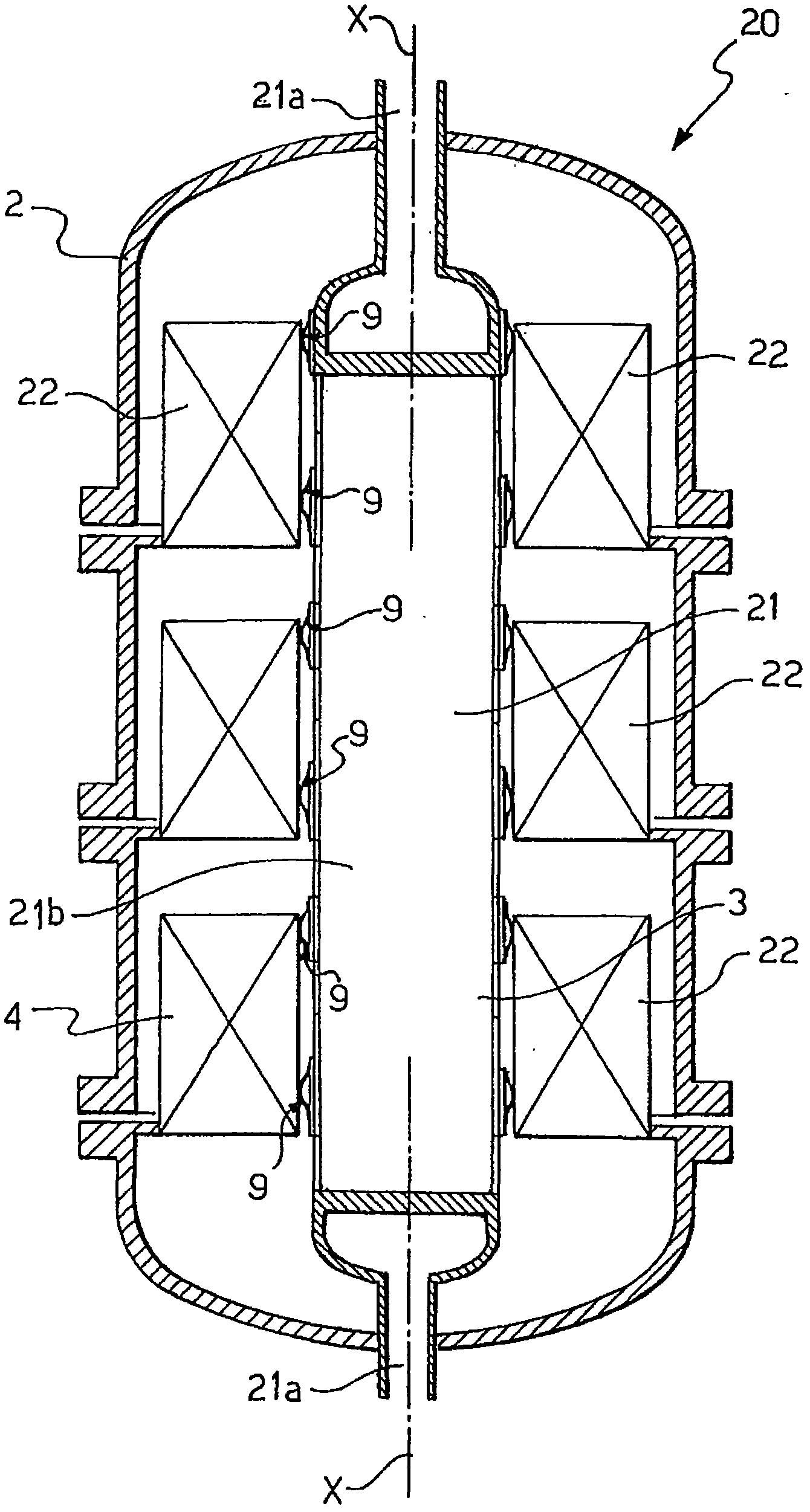

[0016] Referring to the accompanying drawings, the chemical reactor is generally indicated by reference numeral 1 . The chemical reactor 1 includes a casing 2 and a male member 3 inserted into a female member 4 with a gap. In particular in the combustion or oxidation reactor 1 the convex member 3 is the burner 5, which has an elongated cylindrical shape with axis X-X and is supported at its end 5a by the casing, and which has an opposite cantilevered end 5b, the cantilever The end 5 b is inserted coaxially and with play into the female part 4 , which is a housing 6 which defines an opening 7 in the housing 2 .

[0017] An annular gap 8 is formed between the outer surface 3 a of the male part 3 and the inner surface 4 a of the female part 4 . The protrusion 3 has a larger cross-sectional dimension ranging from 300 to 1500 mm. In this example, the diameter of the male element 3 is approximately 600 mm. The gap 8 also has larger dimensions, in the order of 1-2 cm. In this exa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap