Coated glass appearance inspection table

A technology for appearance inspection and coated glass, which is applied in measuring devices, material analysis by optical means, instruments, etc., to achieve the effect of adjustment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

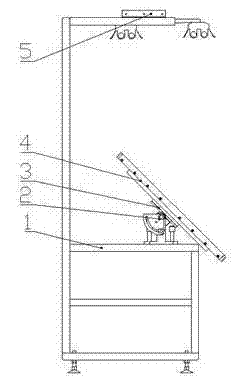

[0016] Such as figure 1 Shown is a coated glass appearance inspection table, which includes a main table frame 1, a work surface 4, a vertical angle adjustment mechanism 2, a parallel direction rotation mechanism 3 and an adjustable lighting mechanism 5, and is characterized in that: the work surface 4 is fixed Installed on the parallel direction rotation mechanism 3, the parallel direction rotation mechanism 3 is connected with the vertical direction angle adjustment mechanism 2 to form a connecting body fixedly installed on the desktop of the main table frame 1, and the adjustable lighting mechanism 5 is arranged on the main body above the desktop Table frame 1 top position.

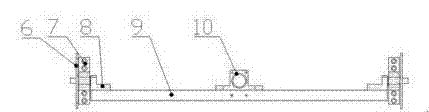

[0017] Such as figure 2 As shown, the vertical angle adjustment mechanism 2 is used to adjust the vertical angle of the work surface, including an angle plate 6, a fixed bracket 7, an angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com