Screw suction high-efficiency energy-saving environmentally friendly loading-unloading machine

A high-efficiency energy-saving, loading and unloading machine technology, applied in the direction of loading/unloading, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

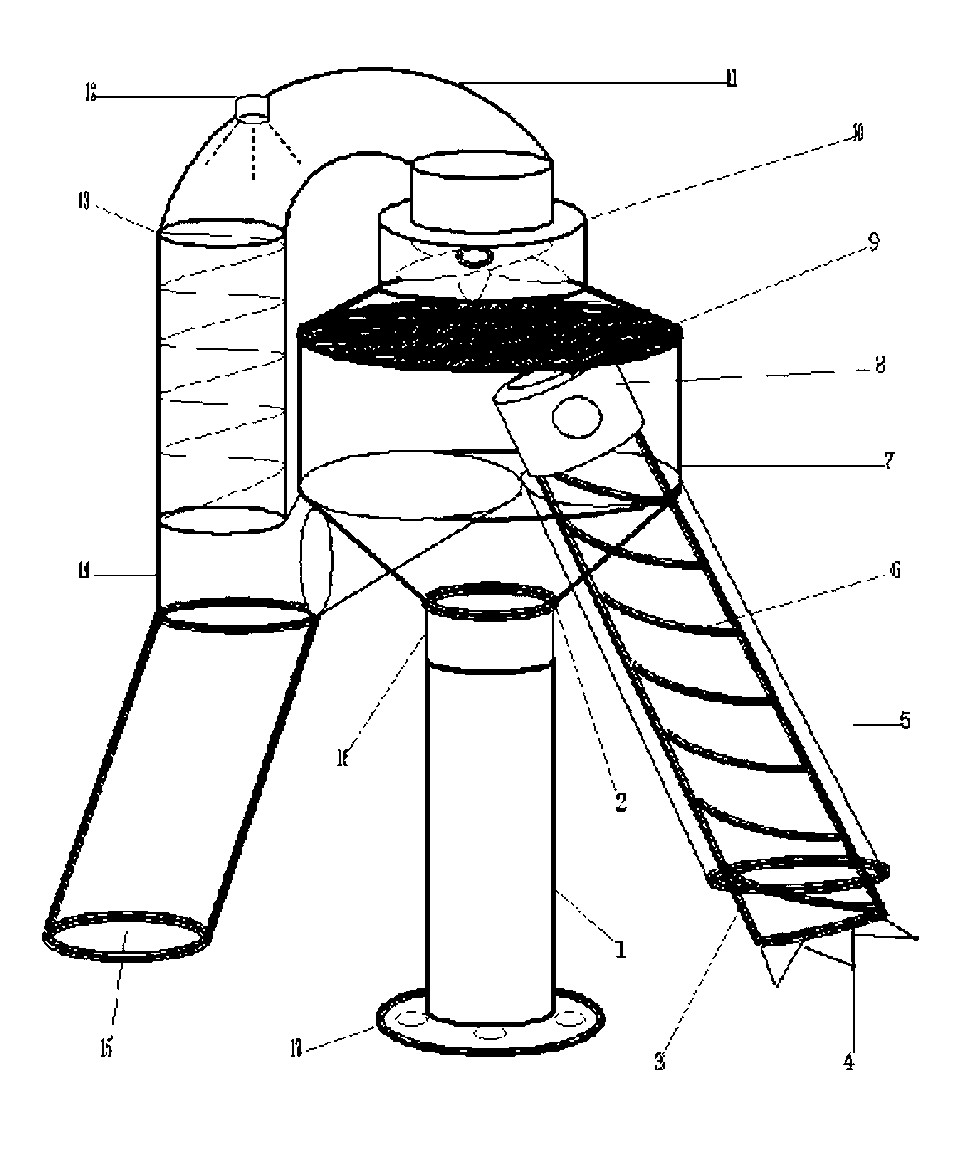

[0015] Embodiment: As shown in the accompanying drawings, the spin-suction, high-efficiency, energy-saving, and environmentally-friendly loading and unloading machine of the present invention includes three parts: a support body, a rotary body, and a suction-discharge body.

[0016] The support body includes a straight strut 1 and a cross strut 2. The straight strut 1 is arranged on the lower end of the cross strut 2 and the upper end is connected with the lower side of one end of the cross strut 2, and its function is to support the cross strut. The cross strut 2 is arranged on the upper end of the straight strut 1 and the lower side of one end and is connected with the upper end of the straight strut 1, and its function is to support the unscrewing body and the suction and discharge body.

[0017] The spin unloading body includes a spin unloading pipe 3, a spin unloading scraper 6, a spinner 8, a tee pipe 14, and a discharge pipe 15, and the spin unloading pipe 3 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com