Method and device for controlling manual precision dressing size for length of small size part

A size control and small size technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of difficult precise control of trimming amount and high price, and achieve the effect of real-time online measurement and precise feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

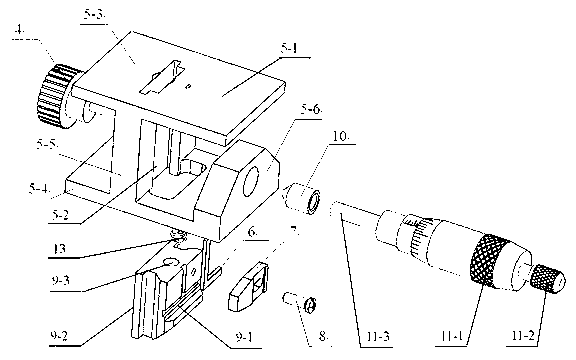

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

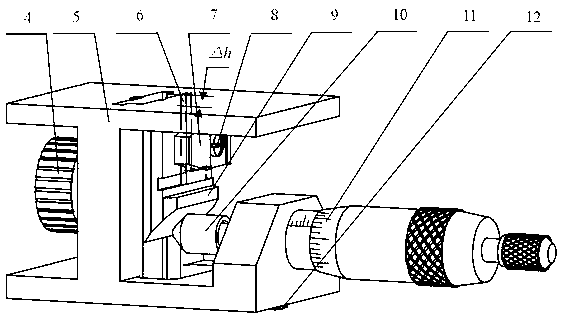

[0041] The device for manual precision trimming and size control of small-sized parts according to the present invention includes a measuring mechanism and a feeding mechanism set and used in conjunction with it.

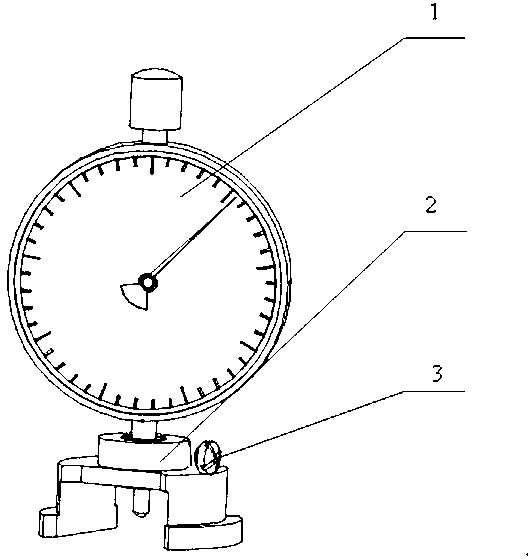

[0042] Such as figure 1 As shown, the measuring mechanism includes a dial indicator 1, a meter frame 2 and a fastening screw 3. Install the dial indicator 1 on the meter frame 2 in the shape of "几", make the bushing at the bottom of the dial indicator 1 pass through the mounting hole at the top of the meter frame 2, and pass through the screw 3 at the top of the meter frame 2 from the side After tightening, the dial indicator 1 is fastened. At this time, the measuring rod under the shaft sleeve in the dial indicator 1 and the contact ball at the bottom of the measuring rod pass through the top surface of the meter frame 2 and are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com