Precise automatic discharging device for poultry breeding

An automatic feeding, poultry technology, applied in the application, poultry industry, animal husbandry and other directions, can solve the problems of high labor intensity, difficult management, waste, etc., and achieve the effect of wide application range and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

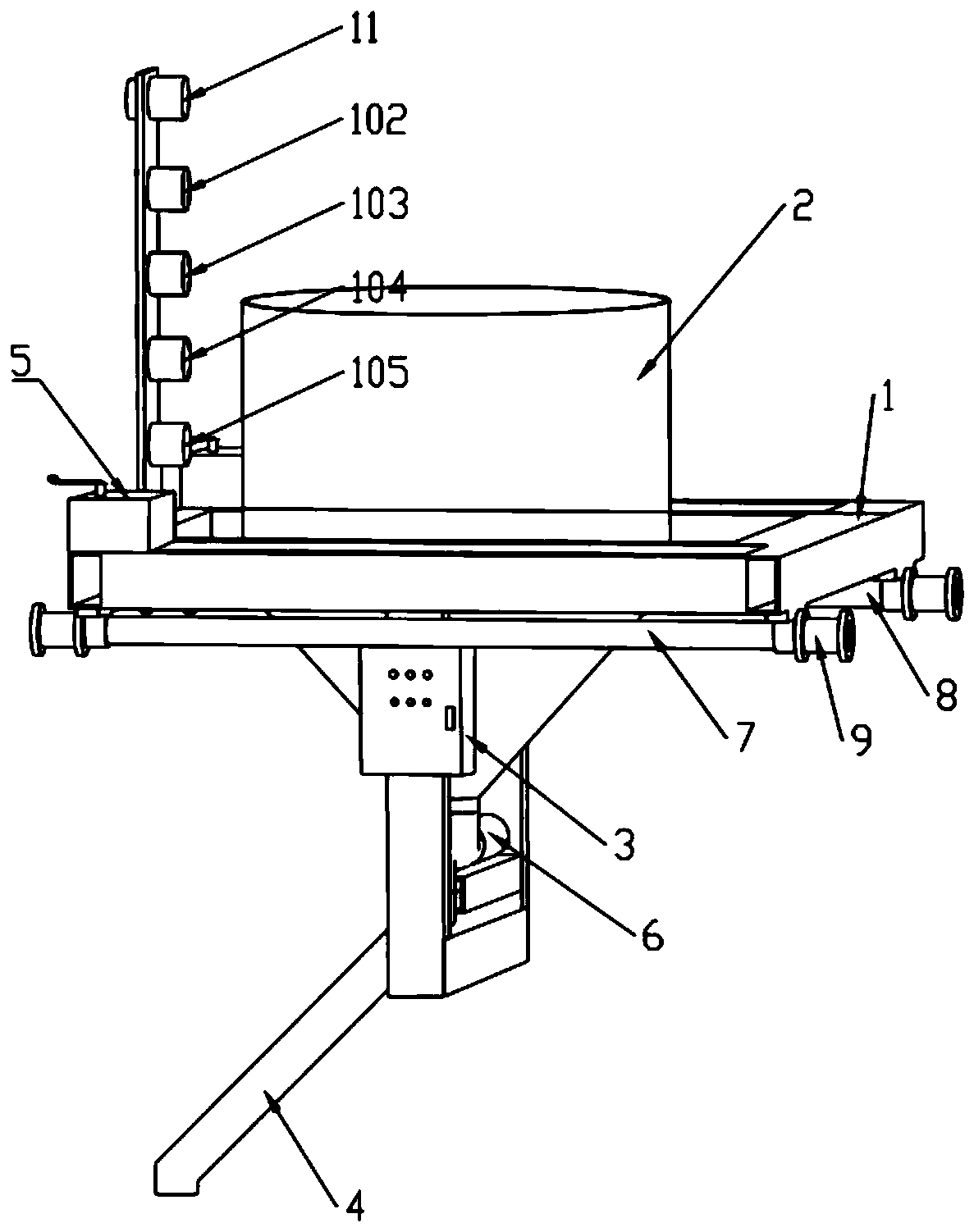

[0028] The feeding device of the present embodiment is a single hopper 2, which is used for a single-layer breeding bin.

[0029] Please refer to figure 1 , a kind of precision automatic feeding device for poultry breeding provided by the present invention, comprises frame 1, is provided with running gear below frame 1, and running gear is placed on track (not shown in figure), and on track Move back and forth.

[0030] The traveling mechanism includes a first rotating shaft 7 and a second rotating shaft 8, the ends of the first rotating shaft 7 and the second rotating shaft 8 are connected with a rolling wheel 9, the rolling wheel 9 is placed on the track, and the first rotating shaft 7 is sleeved with a driven gear 10 , the driven gear 10 meshes with the driving gear.

[0031] Driving gear 10 rotates under the drive of first motor (not shown), and driven gear 10 rotates with driving gear, and then first rotating shaft 7 is rotated, and the scroll wheel 9 of first rotating ...

Embodiment 2

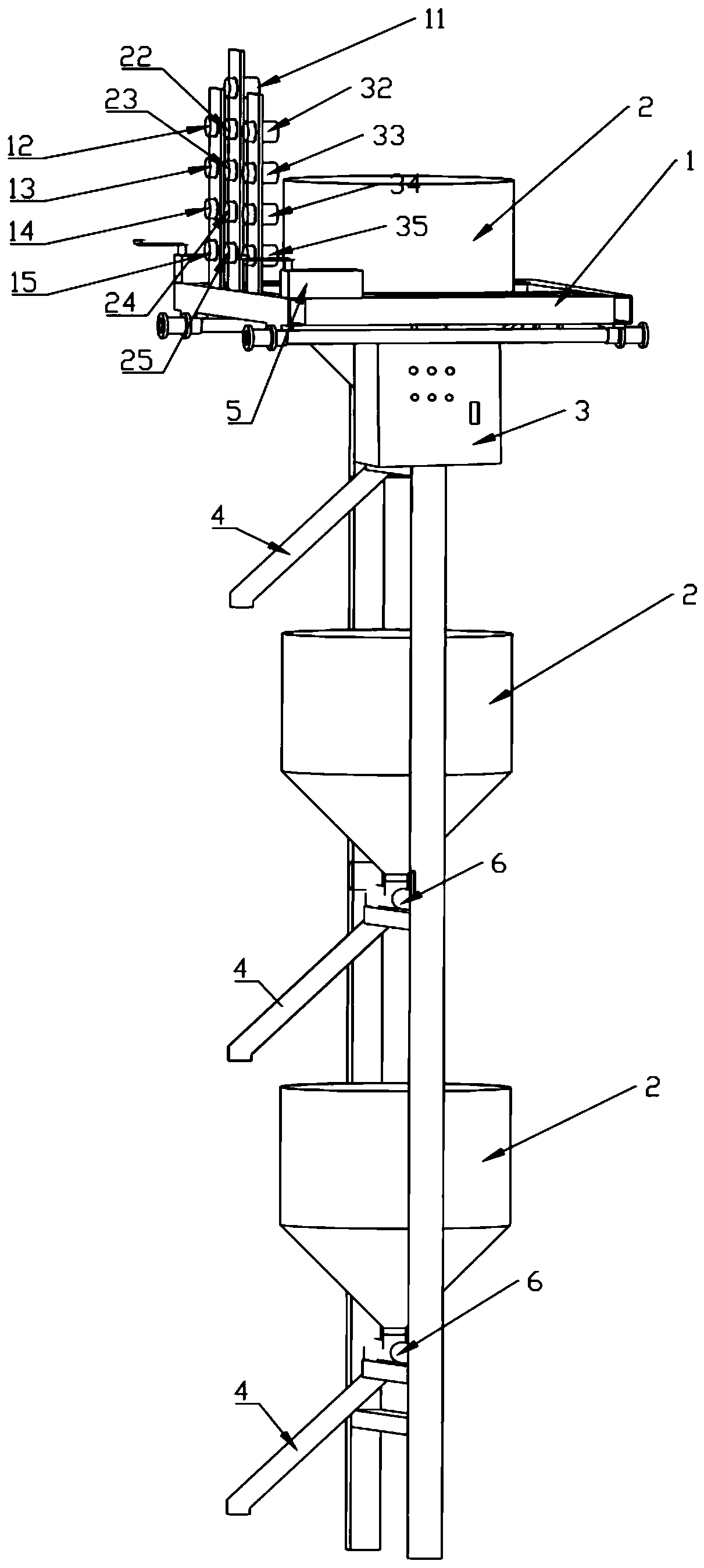

[0046] The difference with embodiment 1 is:

[0047] This embodiment is a single-row hopper 2, and the number of hoppers 2 is three, which is used for a single-row three-layer breeding warehouse. Three hoppers 2 are vertically arranged and fixed on the frame 1, and each hopper 2 is responsible for the feeding work of a layer of breeding warehouse.

[0048] When the timing sensor is a camera, the number of cameras is three, and each camera is responsible for taking pictures of the digital signboard on one layer of the breeding warehouse and sending it to the main control unit 3. After the main control unit 3 recognizes the number, it controls the feeding time. , the numbers on the digital signage are 2, 4, 6, 8, and the corresponding blanking time is 2s, 4s, 6s or 8s.

[0049] When the timing sensor is three groups of proximity switch groups, each group of proximity switches is responsible for sensing the induction iron sheet of one layer of the breeding warehouse and sending ...

Embodiment 3

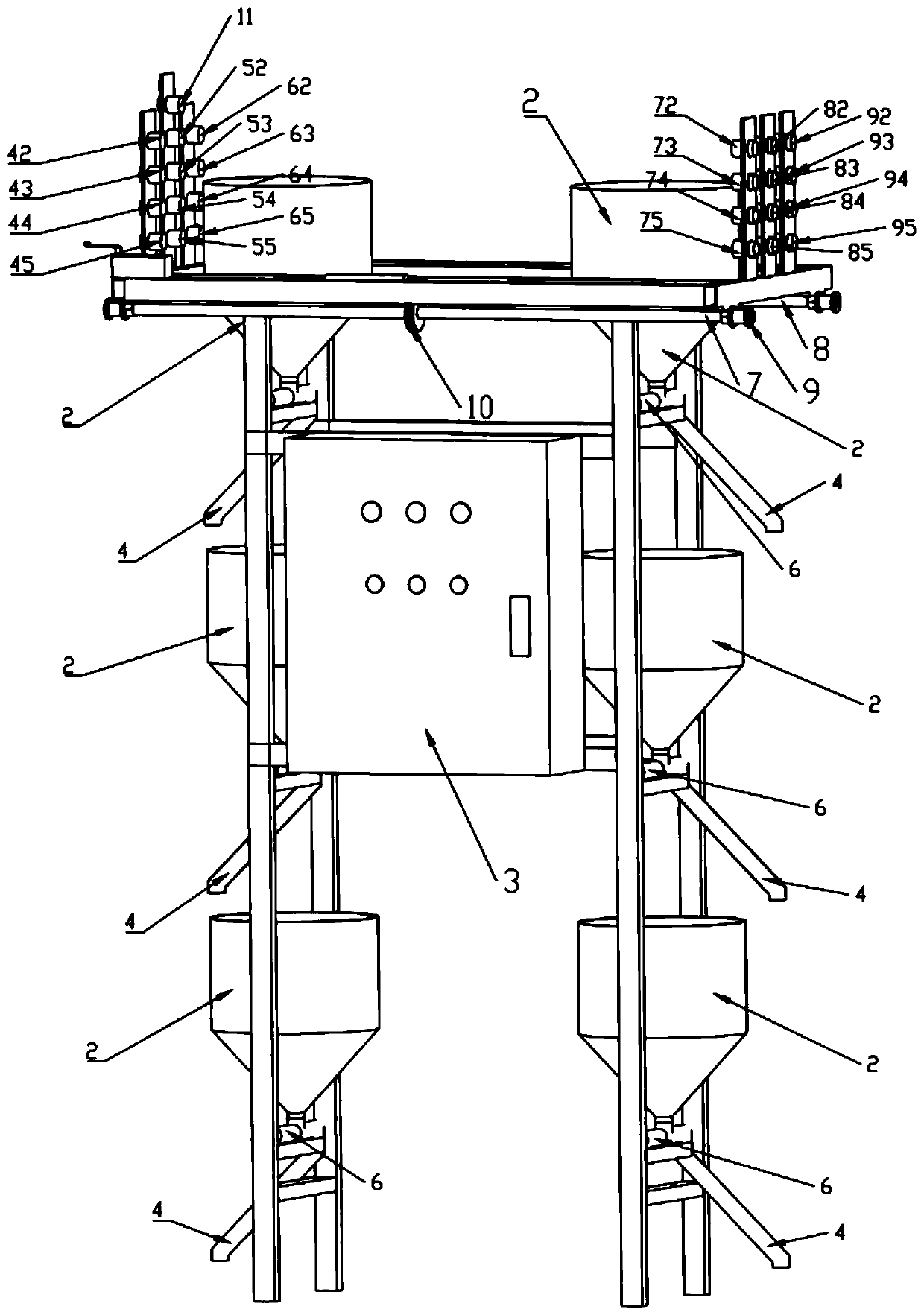

[0053] The difference with embodiment 2 is:

[0054] This embodiment is a double row of hoppers 2, the number of each row of hoppers 2 is three, and it is used for a double-row three-layer breeding warehouse. The feeding machine is placed between the two rows of breeding warehouses, and one row of hoppers 2 is responsible for a row of breeding warehouses. , another row of hoppers 2 is responsible for another row of breeding bins, and each hopper 2 is responsible for the feeding work of one layer of the breeding bins.

[0055] When the timing sensor is a camera, it includes two groups of cameras, each of which is responsible for a row of breeding warehouses, and the number of each group of cameras is three, and each camera is responsible for photographing the digital signage on one floor of one row of breeding warehouses Send it to the main control unit 3. After the main control unit 3 recognizes the number, it controls the feeding time. The numbers on the digital signage are 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com