Full-automatic feeding system

A feeding system and fully automatic technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of wasting rabbit feed, labor-intensive labor, and unfavorable scientific breeding of rabbits, so as to avoid feed waste and promote scientific research. Effects of growth, precision feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

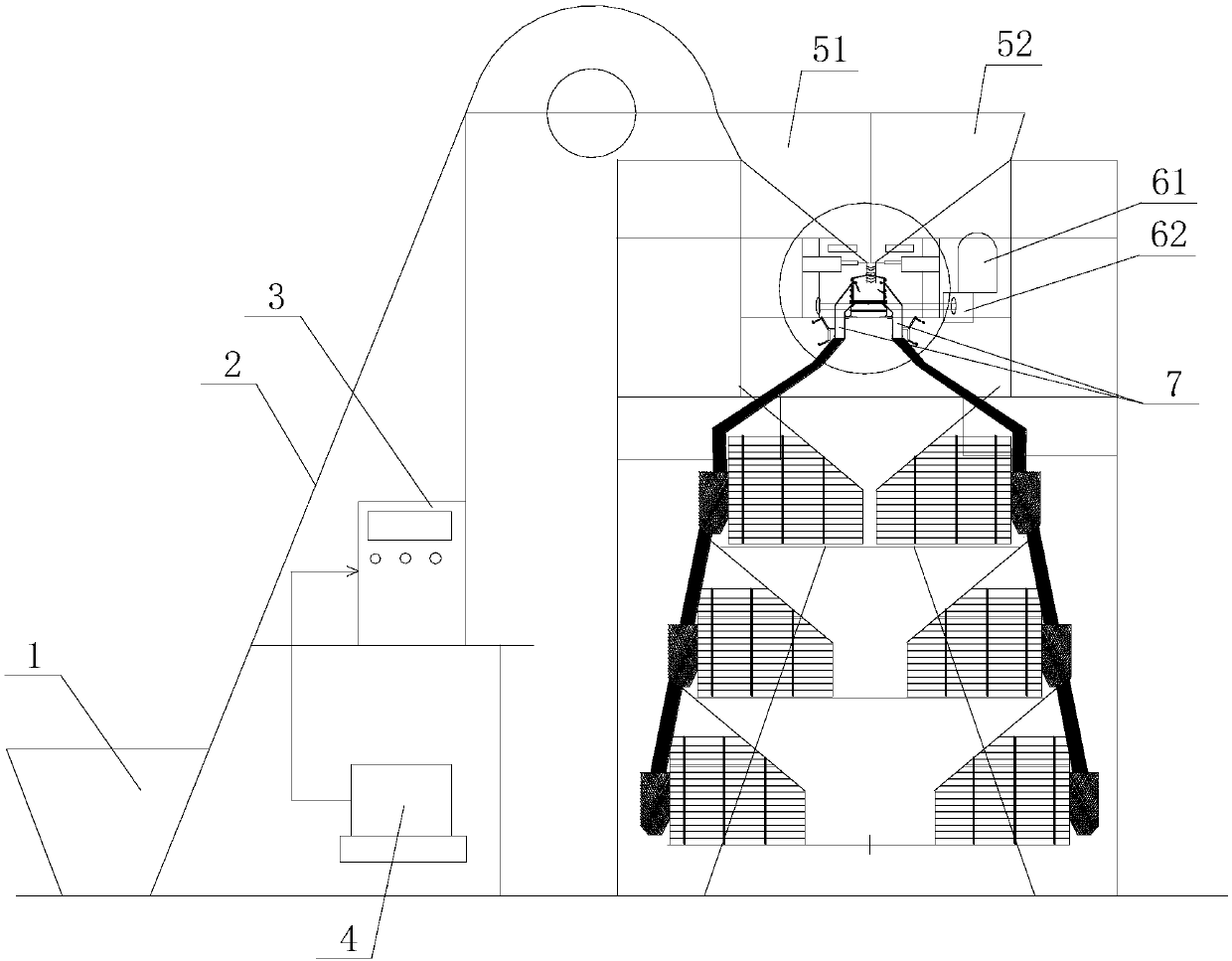

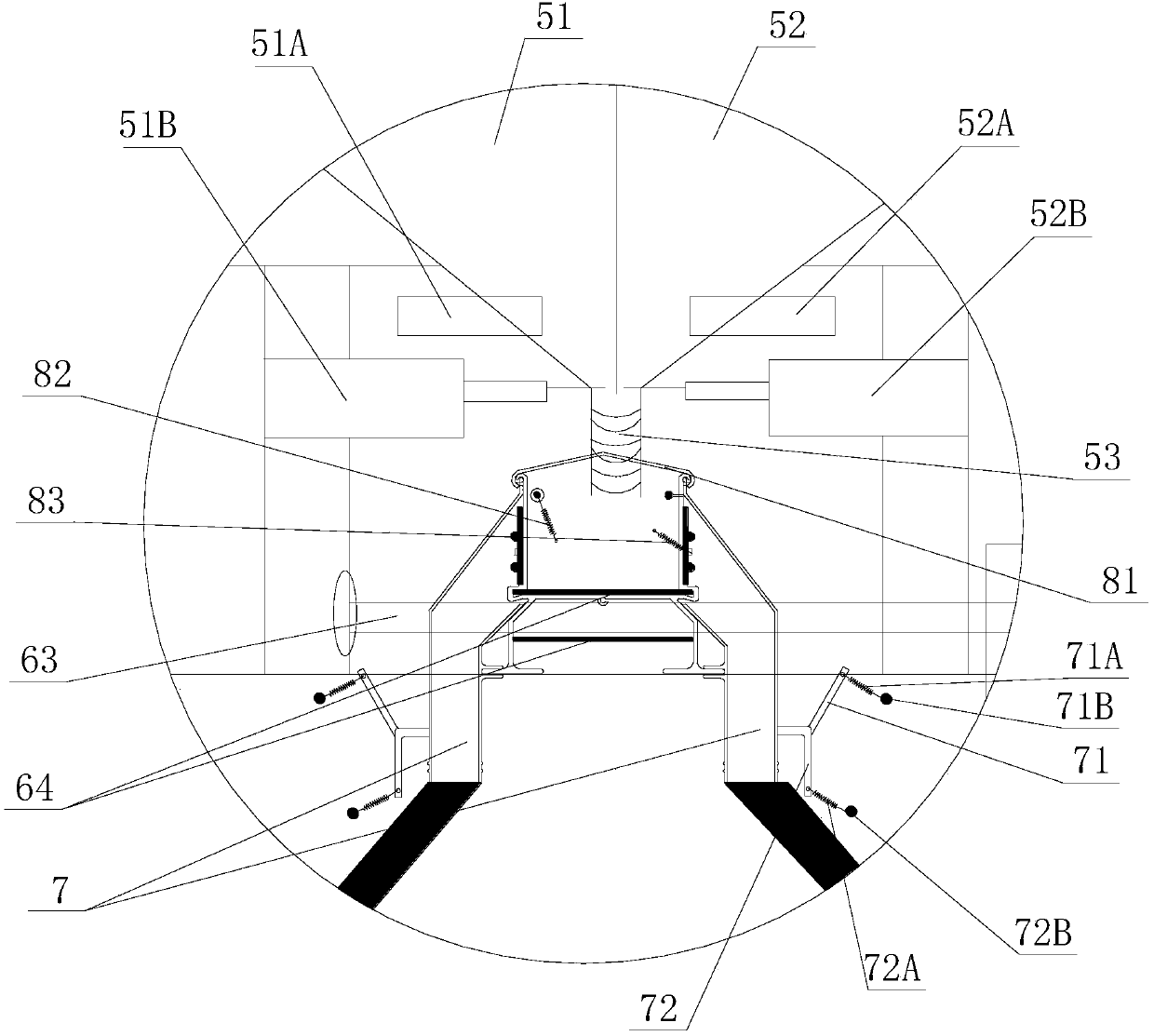

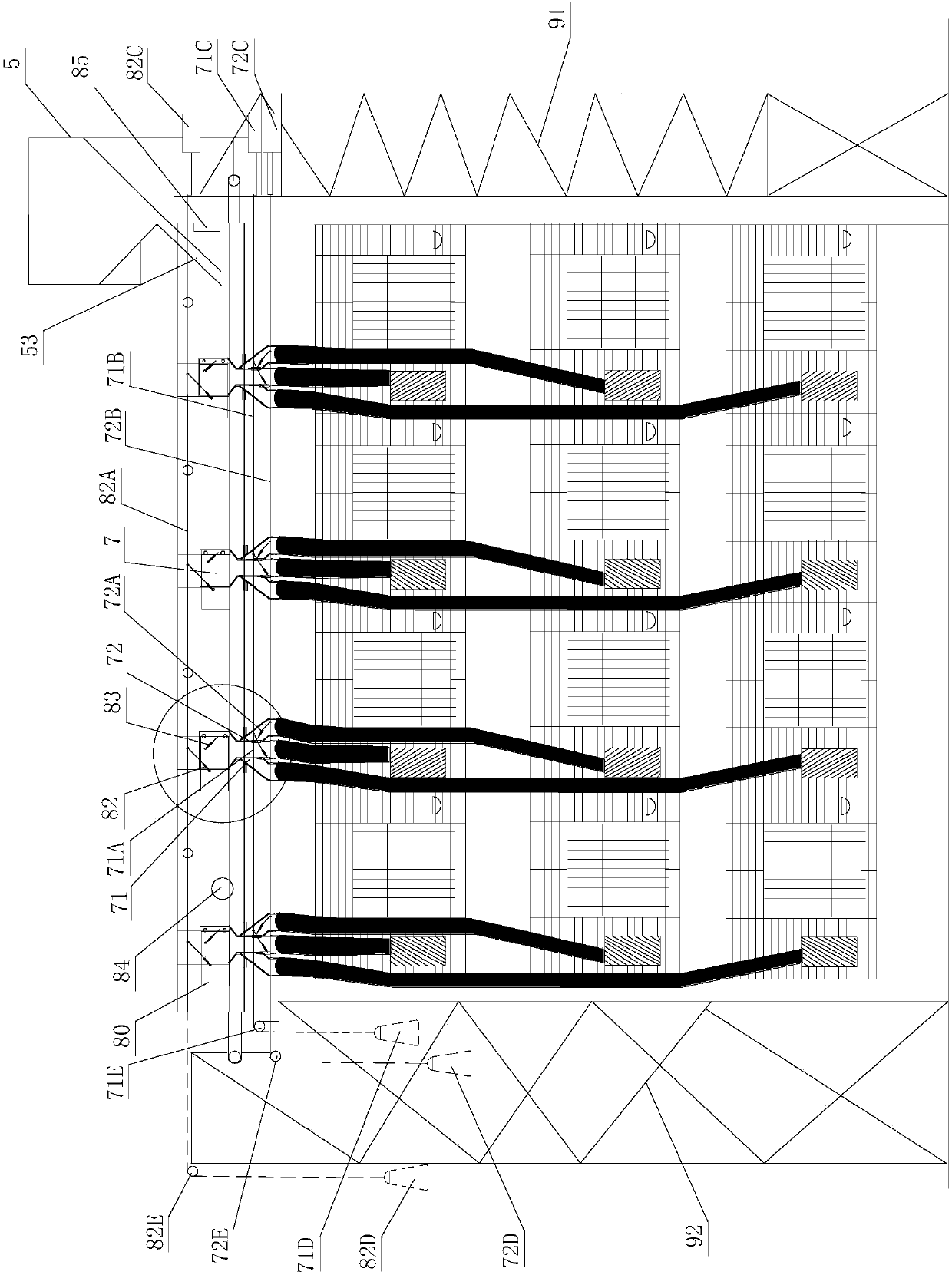

[0019] refer to figure 1 , image 3 , the fully automatic feeding system described in the present embodiment comprises a storage hopper 1, a feeding trough 80, a storage bin 5, several distributors 7, a front support 92, a rear support 91 and is used to feed feed from the storage hopper 1 The lifting is sent to the lifting and feeding mechanism 2 in the storage bin 5, and the intelligent controller 3, and the lifting and feeding mechanism 2 is connected to and controlled by the intelligent controller 3.

[0020] What described lifting feeding mechanism 2 adopts is known and commonly used equipment, does not repeat them here. Simultaneously, all control data sources of intelligent controller 3 are from the computer 4 that the intelligent rabbit raising management software system of other dispositions is equipped with or input on intelligent controller 3 manually.

[0021] The front and rear ends of the feed trough 80 are respectively fixedly assembled on the tops of the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com