Manual net cage precipitable feed feeding method

A sedimentation and cage technology, applied in the field of artificial cage sedimentary feed feeding, can solve the problems of low utilization rate of bait, sedimentation and decomposition of feed, etc., so as to avoid feed waste, reduce the difference in fish size, and improve feeding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

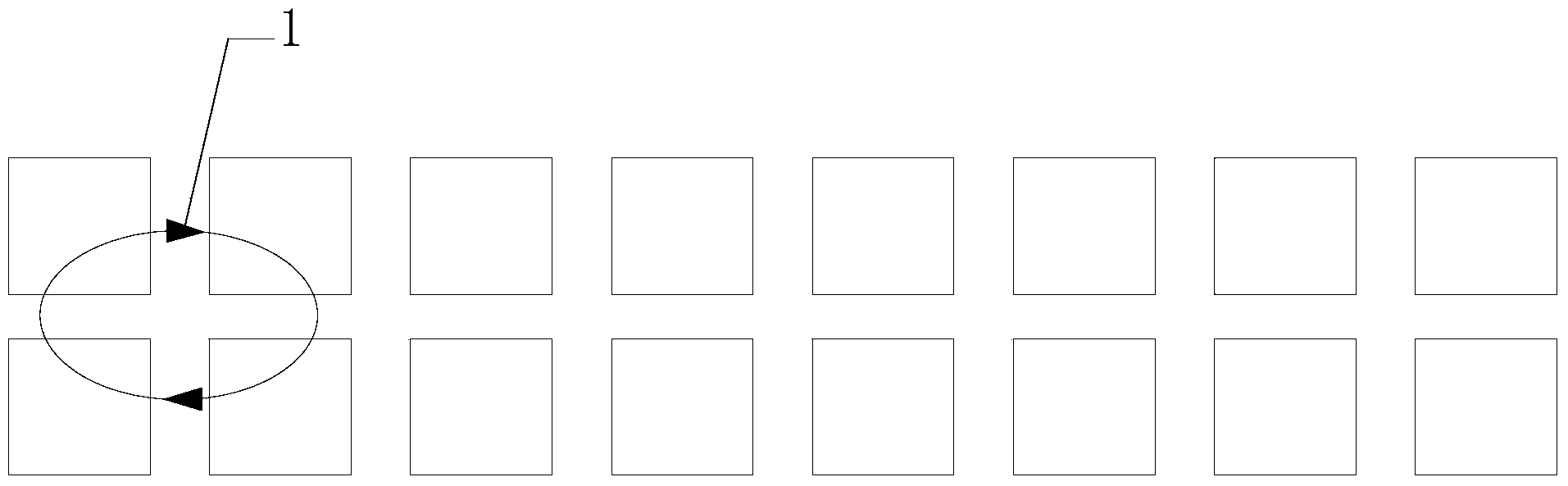

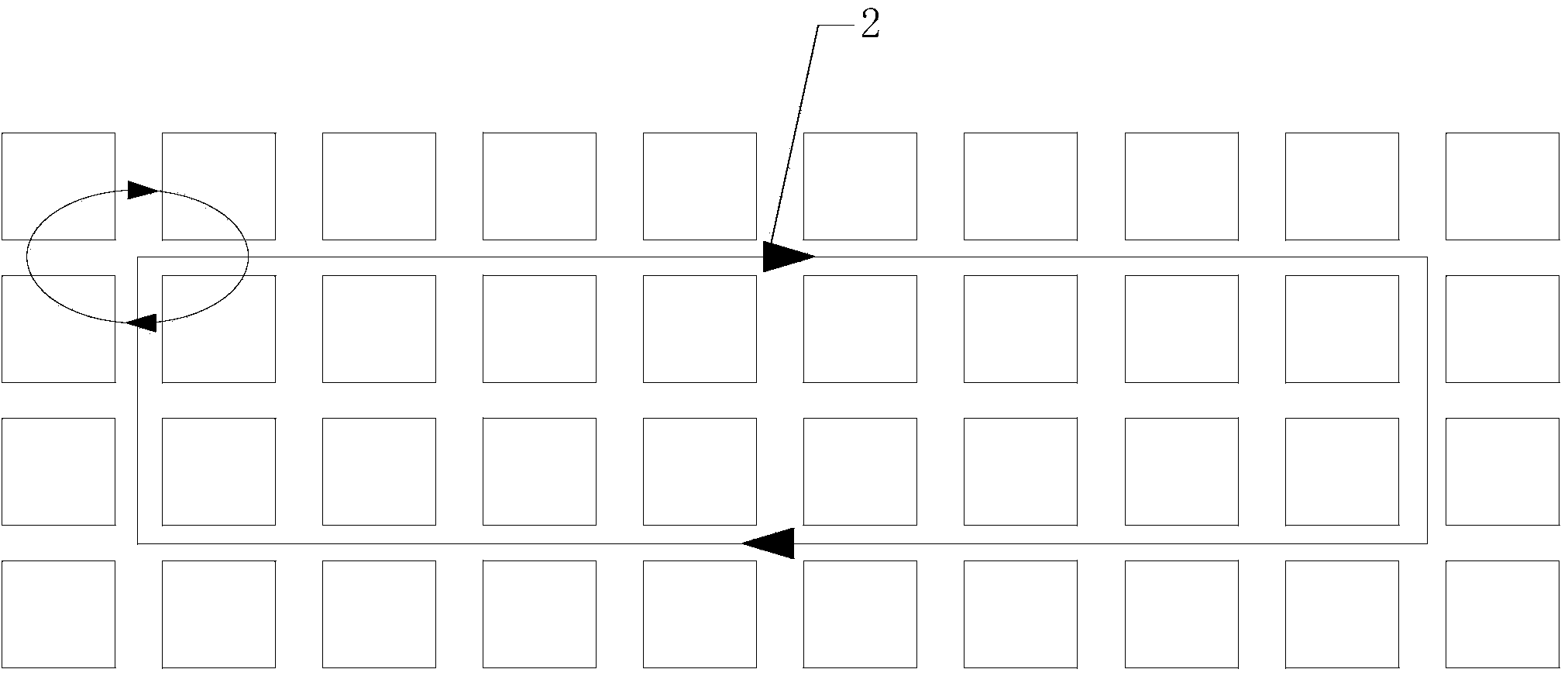

[0026] In an artificial small-volume crucian carp breeding pond with 60 cages / group in a research and development base, the cages (cage size 1×1×1.5) were fed. 100 crucian carp with an average weight of 28.75 g were raised in each box, and the sinking pellet feed with a particle size of Ф2.0 was fed. The feeding rate was 3%, and the feeding was divided into 4 times a day. Such as figure 1 As shown, the feeding method takes 4 cages as a unit, and feeds 3 rotations in a clockwise (or counterclockwise) direction. After feeding a unit, continue to feed the next unit (the next group of 4 cages). Feed until the whole group of test cages are fed, such as figure 2 shown. A new round of feeding was started, and a total of 5 rounds were fed, that is, the feeding method of 3 turns × 5 rounds, and the feeding took 30 minutes. After continuous feeding for 56 days, crucian carp was caught and weighed. The weight gain rate of crucian carp was 102%, and the bait coefficient was 1.90.

Embodiment 2

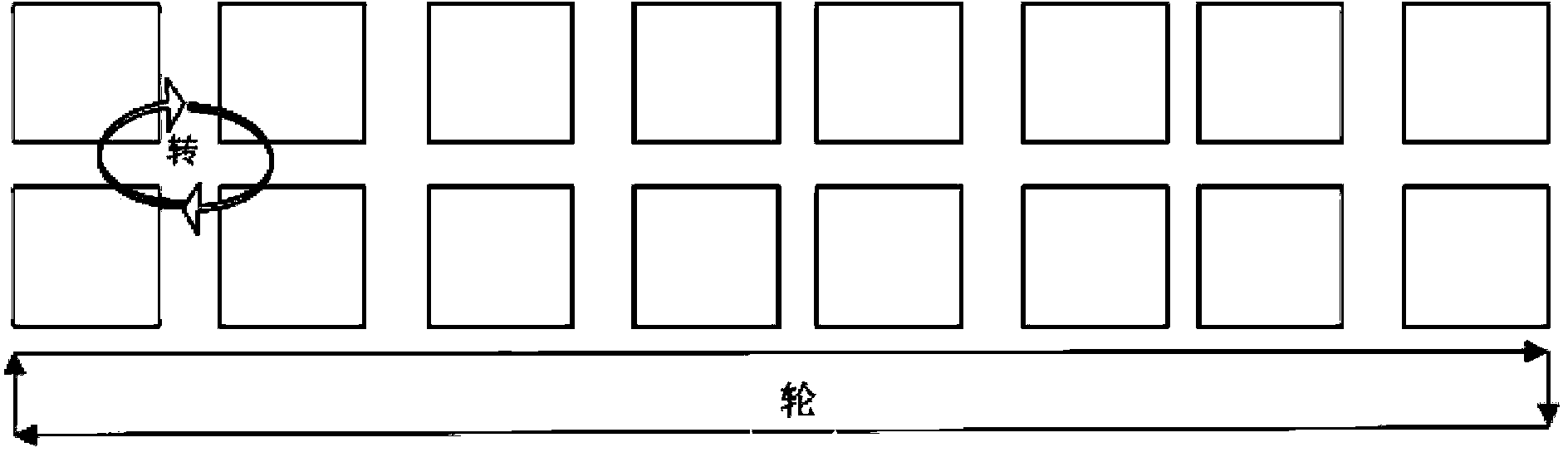

[0031] In an artificial small-volume grass carp breeding pond with 40 cages / group in a research and development base, the cages (cage size 1×1×1.5) were fed. 70 grass carp with an average weight of 168.50 g were raised in each box, and the pellet feed with a particle size of Ф3.5 was fed. The feeding rate was 4%, and the feeding was divided into three times a day. The way of feeding is to use horizontally adjacent 4 cages as a unit, in order from left to right, feed 4 rounds, after feeding one unit, continue to feed the next unit (the next group of 4 cages), Until the whole group of test cages were fed. A new round of feeding was started, and a total of 6 rounds were fed, that is, the feeding mode of 4 turns × 6 rounds, and the feeding took 22 minutes. After 56 days of continuous feeding, the grass carp was caught and weighed. The weight gain rate of grass carp was 188%, and the bait coefficient was 1.37.

Embodiment 3

[0036] In an artificial small-volume carp breeding pond with 30 cages / group in a research and development base, the cages (cage size 1×1×1.5) were fed. 70 grass carp with an average weight of 38.00 g were raised in each box, and the pellet feed with a particle size of Ф2.0 was fed. The feeding rate was 5%, and the feeding was divided into three times a day. The way of feeding is to use horizontally adjacent 4 cages as a unit, in order from left to right, feed 4 rounds, after feeding one unit, continue to feed the next unit (the next group of 4 cages), Until the whole group of test cages were fed. Started a new round of feeding, a total of 4 rounds of feeding, that is, 4 turns × 3 rounds of feeding, and feeding took 22 minutes. After continuous feeding for 56 days, carp were caught and weighed. The weight gain rate of carp was 318%, and the feed coefficient was 1.20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com