Testing device for thickness of slice medium

A thin-sheet medium and thickness detection technology, which is applied to measuring devices, mechanical measuring devices, electrical devices, etc., can solve the problems of incorrect detection devices, thickness detection devices unable to correctly reflect the thickness value of sheet-like valuable documents, etc. , to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the sheet medium thickness detecting device provided by the present invention, a further detailed introduction will be made below in conjunction with a diagram of a preferred embodiment of the present invention.

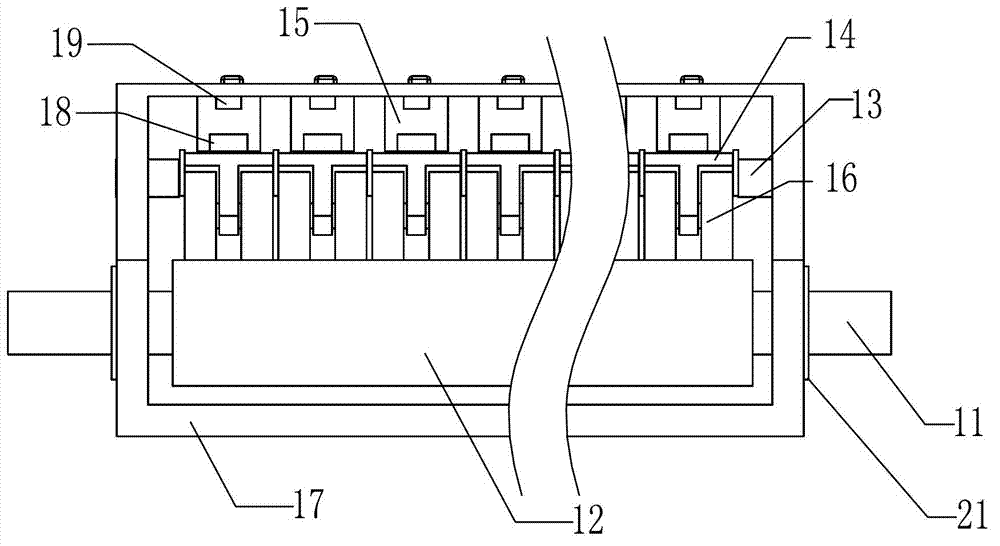

[0024] refer to image 3 As mentioned above, a preferred thin sheet medium thickness detection device provided by the present invention includes: a fixed frame 17 for installing and carrying the following parts; a reference shaft 11, and its two ends are installed on the fixed On the frame 17, the reference shaft 11 is fixedly sleeved with a reference roller 12; a detection shaft 13, its two ends are fixedly mounted on the fixed frame 17, and a plurality of (this embodiment) is evenly spaced on the detection shaft 13 There are 12 in the middle) a detection roller base 14 with one end freely rotating around the detection axis, a freely rotating detection roller 16 is arranged on the free end of the detection roller base 14, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com