Asymmetrical multi-lobed annular seal for a connector assembly of a vehicle

A technology of seals and connectors, which is applied to the sealing of vehicle parts and engines, and the connection of sealing surfaces, etc., and can solve problems such as decline, shutdown productivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments disclosed below are not intended to be exhaustive, nor are they intended to limit the disclosed content to the specific forms described in detail below. Specifically, the following examples are chosen for description so that others skilled in the art can utilize the enlightenment given by these examples.

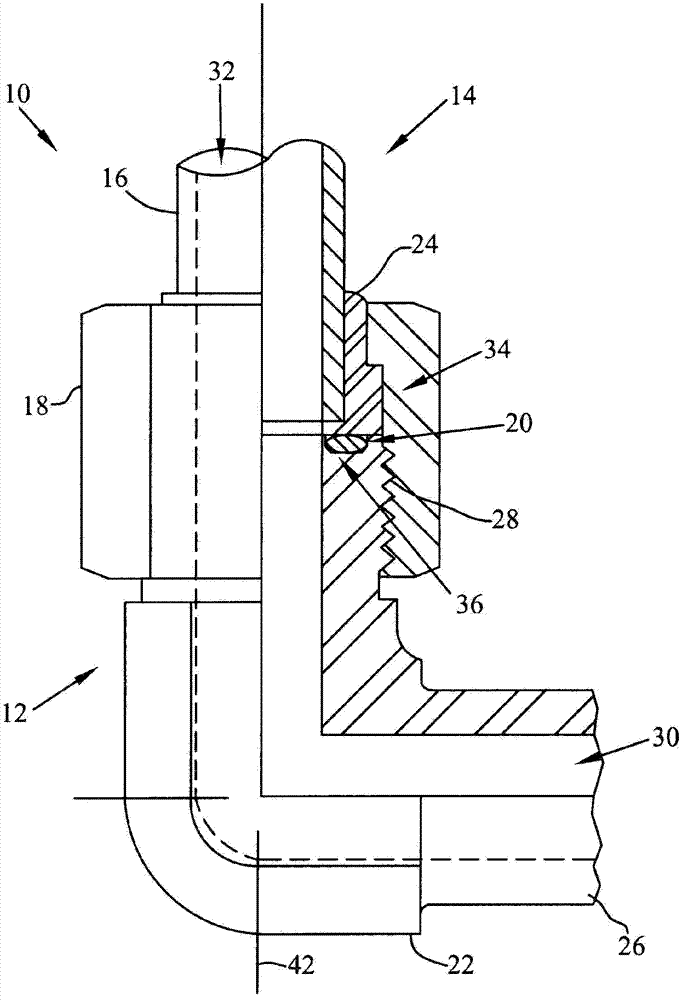

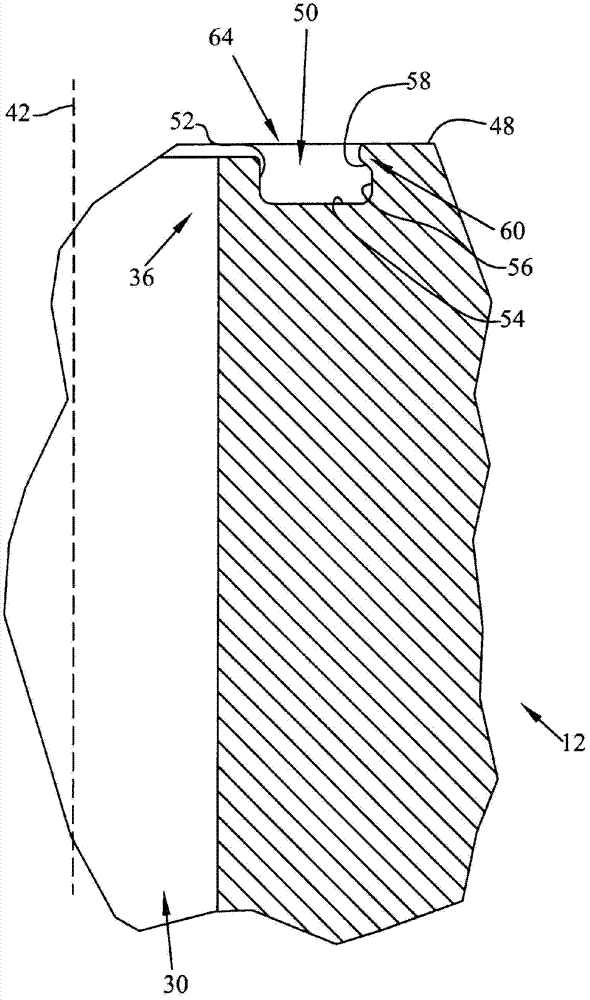

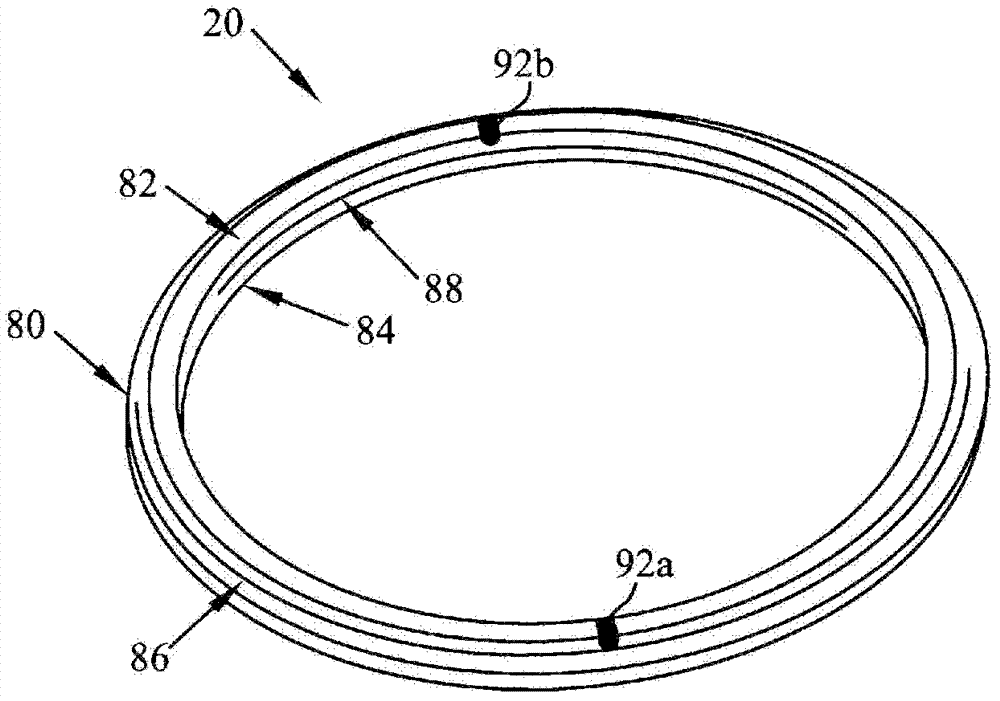

[0020] see figure 1 , wherein an exemplary connector assembly 10 is shown. The connector 10 includes a first connector 12 connected to a second connector 14 . In one embodiment, the connectors 12, 14 comprise attachments. A face seal 20 , described below, provides a sealed engagement between the first connector 12 and the second connector 14 . The first seal 12 schematically includes a tube or conduit 26 having a bend 22 and a mating end 36 . The second connection piece 14 is schematically a fitting 14 comprising a tube or conduit 16 and a socket 24 at the mating end 34 of the fitting 14 . The second connecting part 14 may also include a connector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com