Device and method capable of changing incidence angle and used for simulating measuring of erosion corrosion speed of flow on pipeline

A technology of erosion corrosion and incidence angle, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of systematic research, and does not realize the impact of incidence angle on high temperature naphthenic acid erosion corrosion behavior, affecting pipelines accurate judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

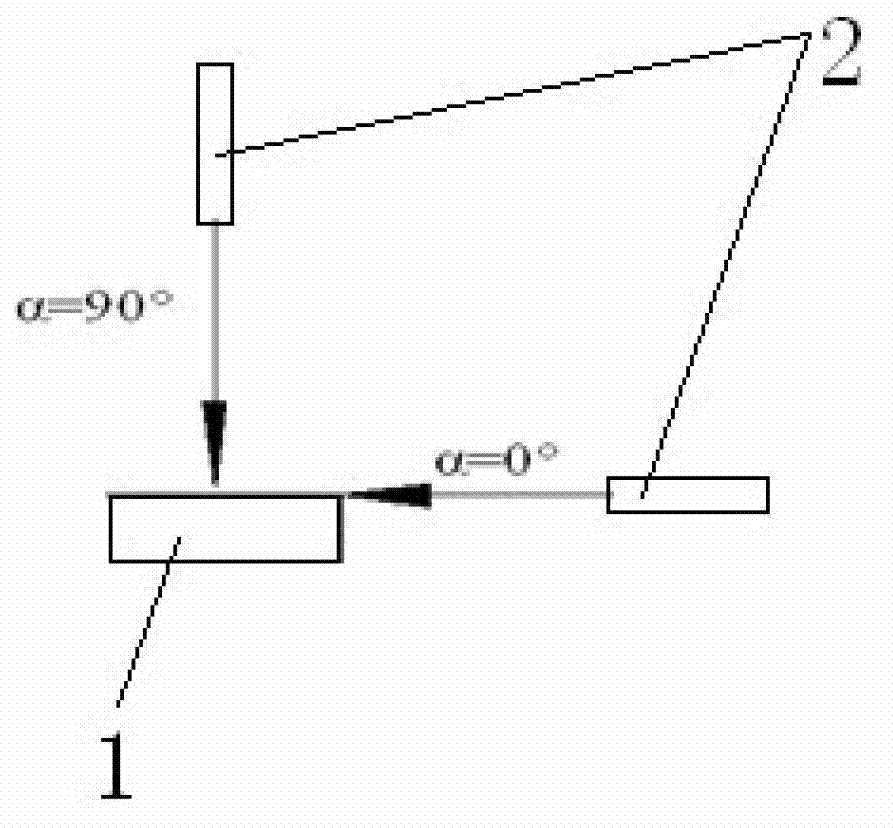

[0019] The variable incidence angle of the present invention simulates the device for measuring the erosion and corrosion rate of the pipeline by the fluid, and its preferred specific implementation is as follows figure 1 Shown:

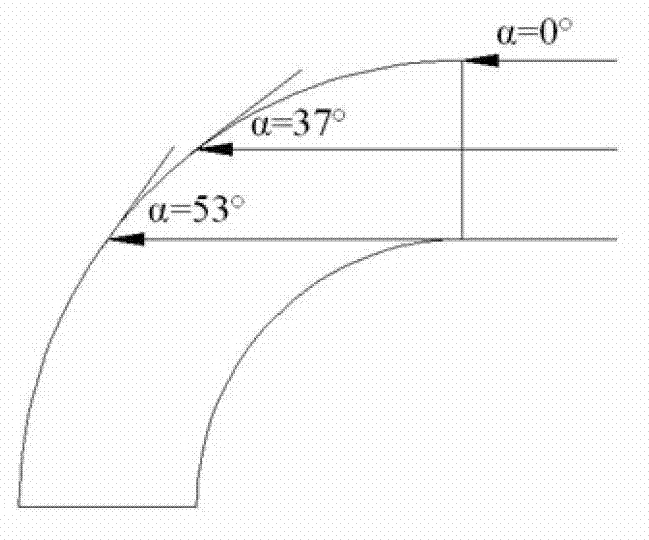

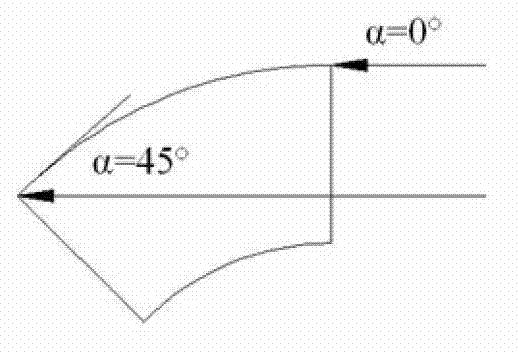

[0020] Including sample 1 and test medium nozzle 2, the sample and / or test medium nozzle is provided with an angle adjustment device (not shown in the figure), and the adjustment angle range between the spraying direction of the test medium nozzle and the surface of the sample is 0° ~90°;

[0021] 0° means that the injection direction of the test medium nozzle is parallel to the surface of the sample, and 90° means that the injection direction of the test medium nozzle is perpendicular to the surface of the sample.

[0022] The method for simulating and measuring the scouring and corrosion rate of a pipeline by a fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com