Hot-redundant magnetic-electric rotational-speed sensor

A speed sensor and magnetoelectric technology, applied in the field of testing control devices, can solve problems such as the reduction of reliability and safety of ships, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention are given below and described in conjunction with the accompanying drawings.

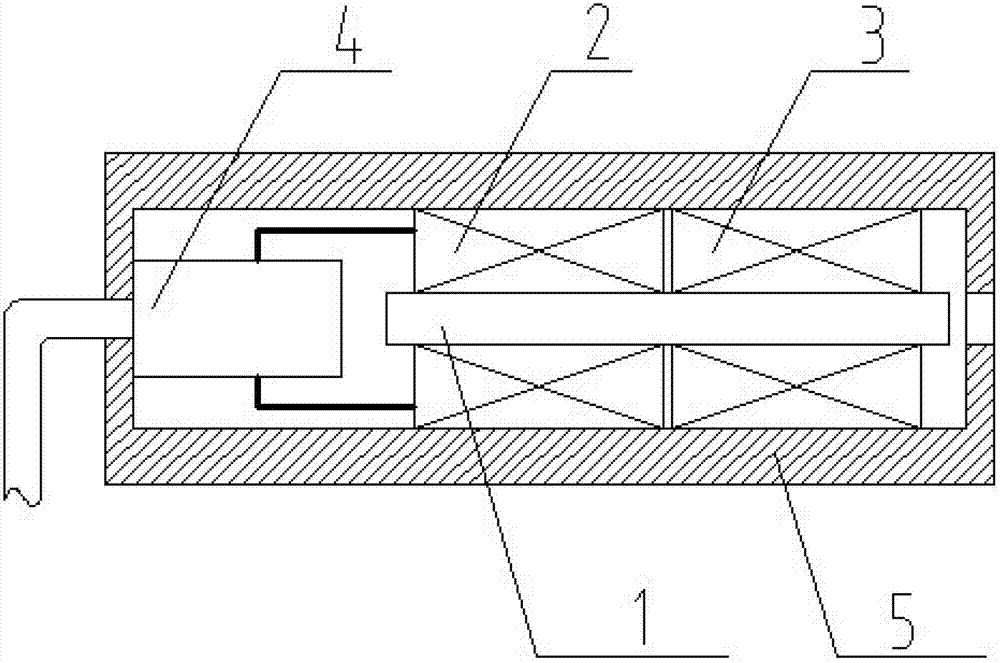

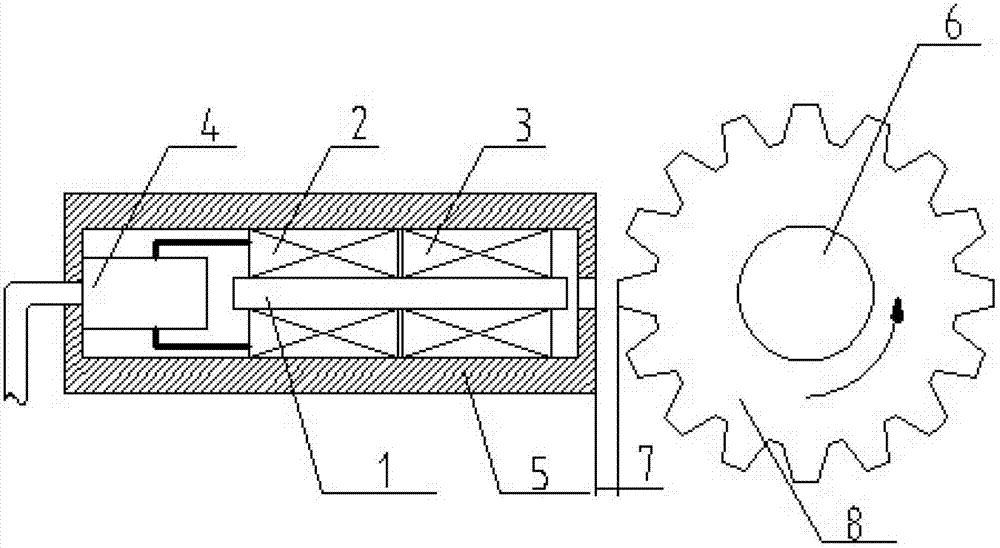

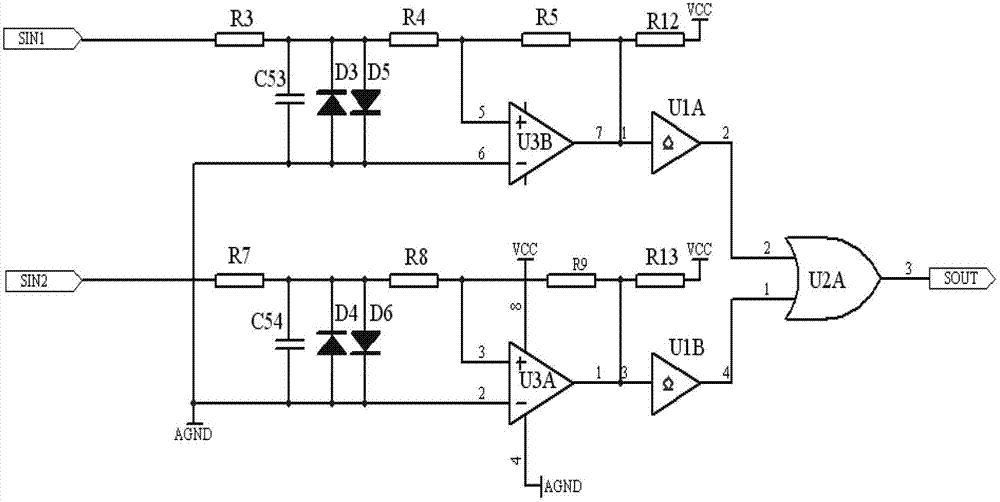

[0019] It mainly consists of the following parts: a permanent magnet ( figure 1 Middle 1), two sets of independent induction coils ( figure 1 2 and 3), the signal processing circuit ( figure 1 4), the sensor housing ( figure 1 Middle 5). It is characterized in that: when the measured shaft figure 2 Middle (6) drives speed measuring gear figure 2 When the center (8) rotates, the gap between the speed measuring gear and the sensor figure 2 (7) will produce periodic changes, which will lead to periodic changes in the magnetic flux passing through two sets of independent coils, so that periodic voltage changes will be generated in the coils, and this change rule is similar to a sine wave. Because this redundant sensor has two sets of independent induction coils, these two sets of identical induction coils are wound on the permanent magnet in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com