Flexible wireless electric power induction module

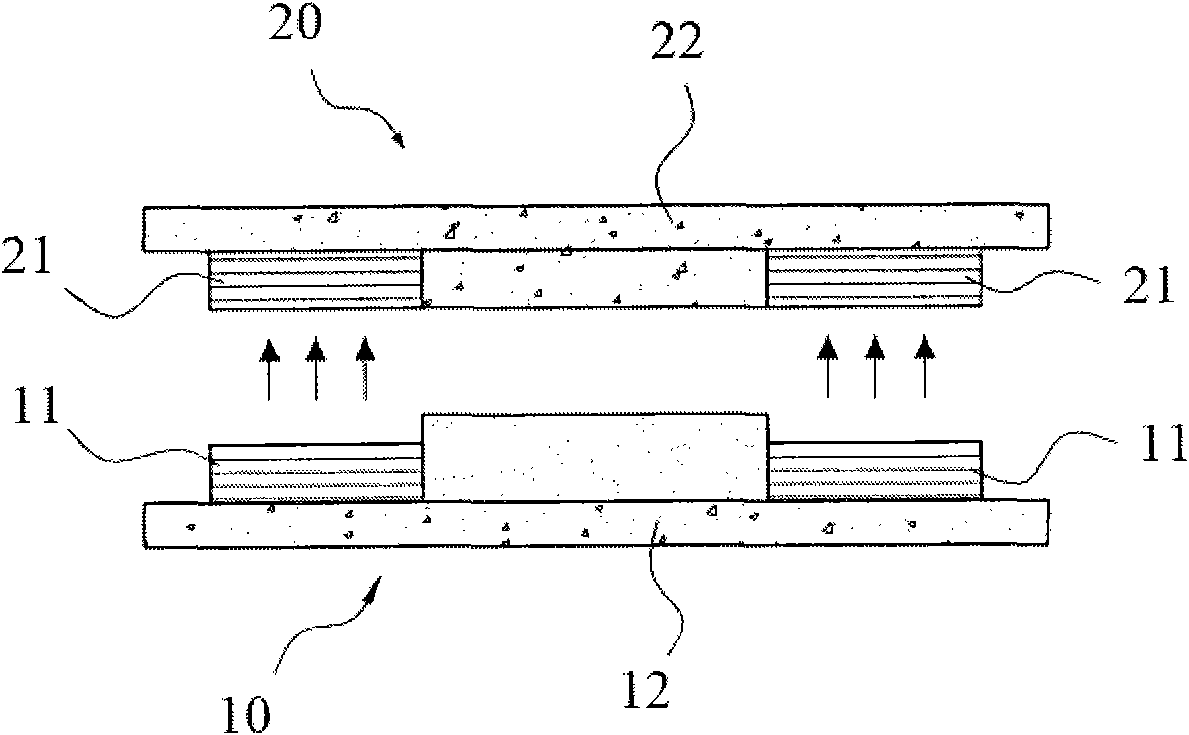

A wireless power and induction module technology, applied in electrical components, circuit devices, electromagnetic wave systems, etc., can solve the problems of coil separation, core plate 22 rupture, affecting power induction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Please refer to the following detailed description and drawings related to the present invention, but the attached drawings are only for reference and description of the embodiments of the present invention, and are not intended to limit the present invention.

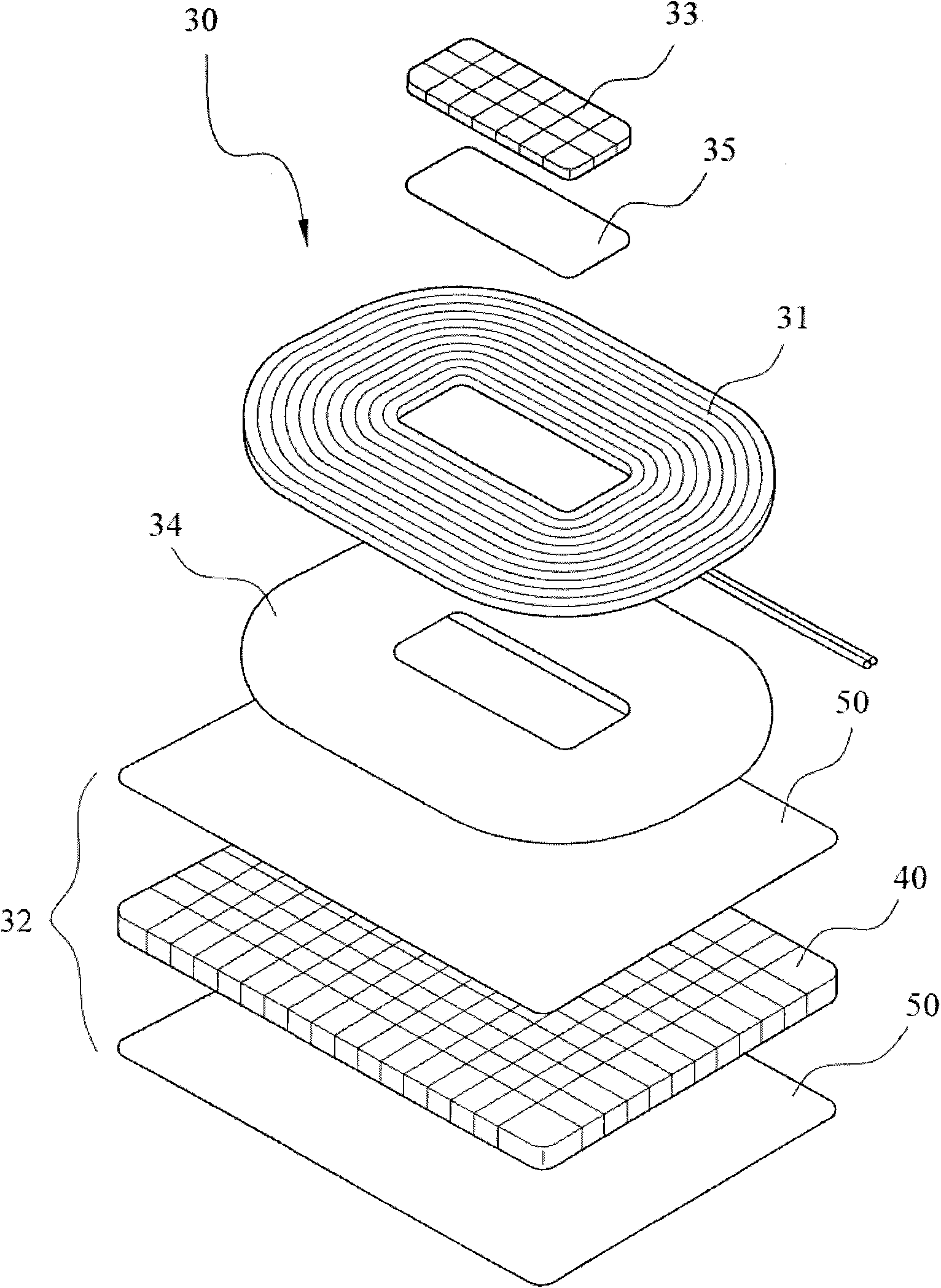

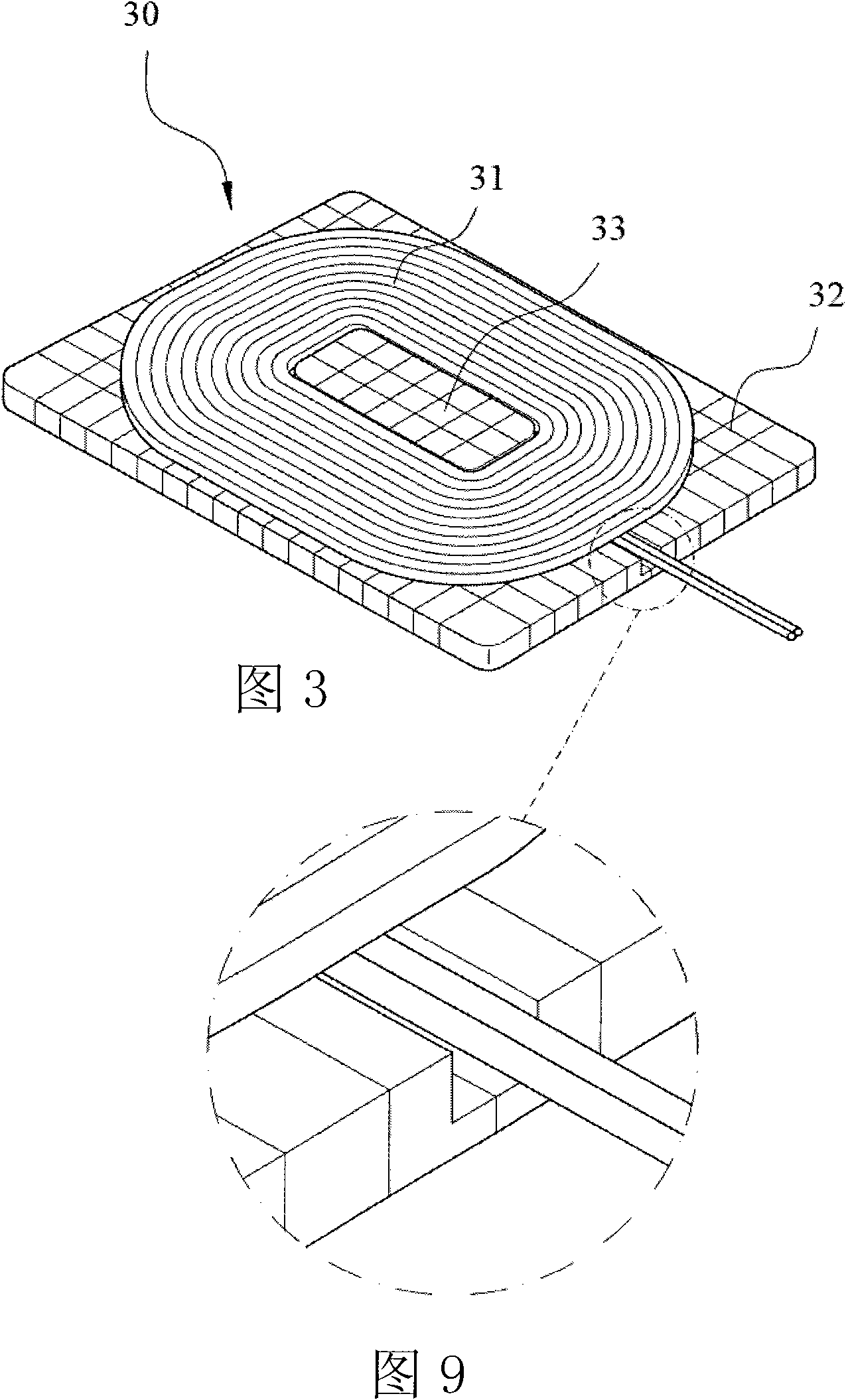

[0040] see figure 2 As shown, it is a three-dimensional exploded schematic diagram of a flexible wireless power sensing module of the present invention, and image 3 for figure 2 Combination perspective schematic diagram, the flexible power induction module 30 of the present invention can be a power receiving induction module, including at least a coil 31, a first induction plate 32 and a second induction plate 33, wherein the coil 31 is in the form of The center is hollowed out in a planar shape, and the area of the first induction plate 32 is larger than the outer edge of the coil 31, and the area of the second induction plate 33 is smaller than the central hollow of the coil.

[0041] The coil 31 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com