Vibration cutting apparatus

A technology of cutting device and cutting edge, which is applied in metal processing and other directions, and can solve the problems of cutting edge 802 falling off, embedding, brazing material or solder damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

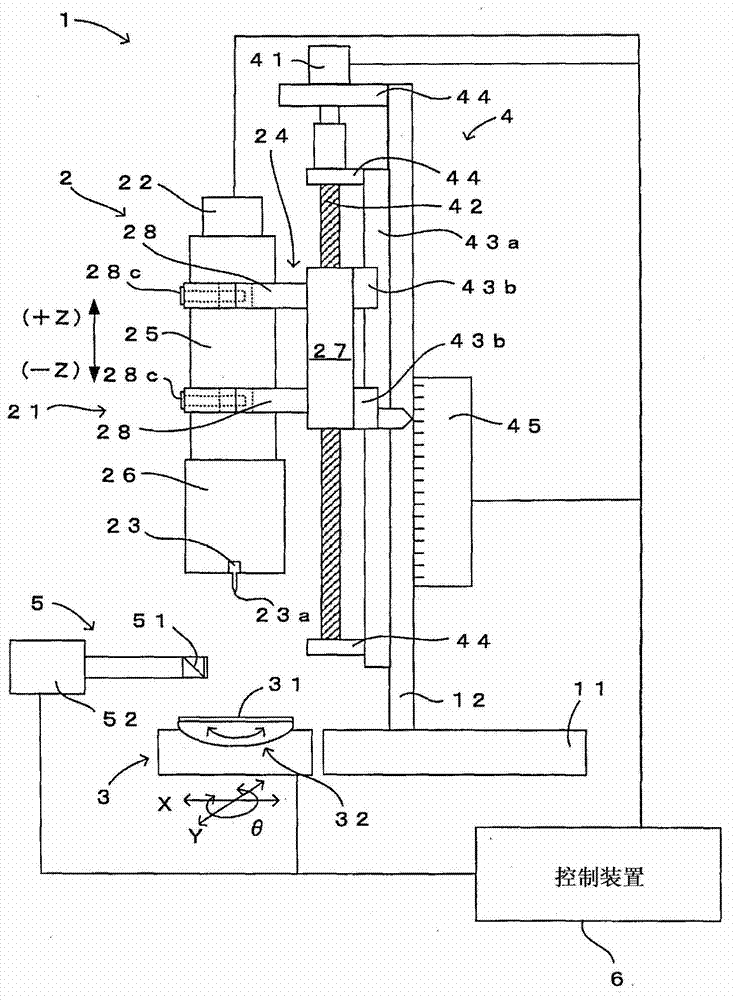

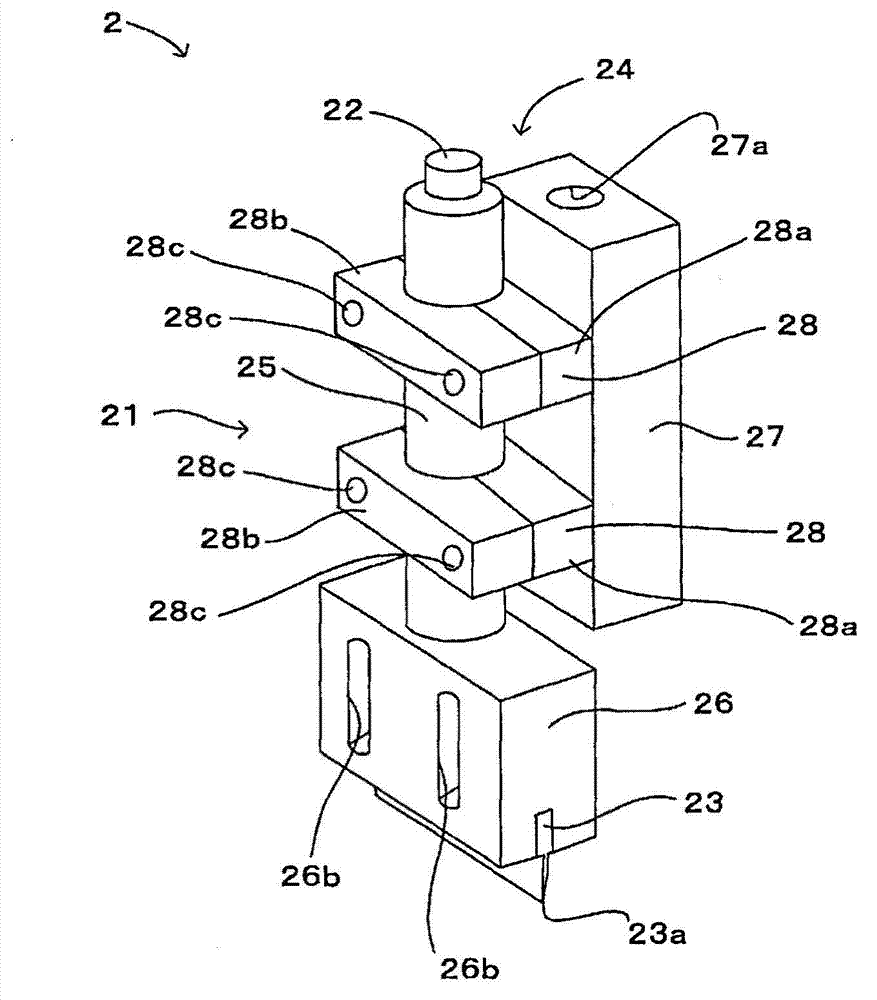

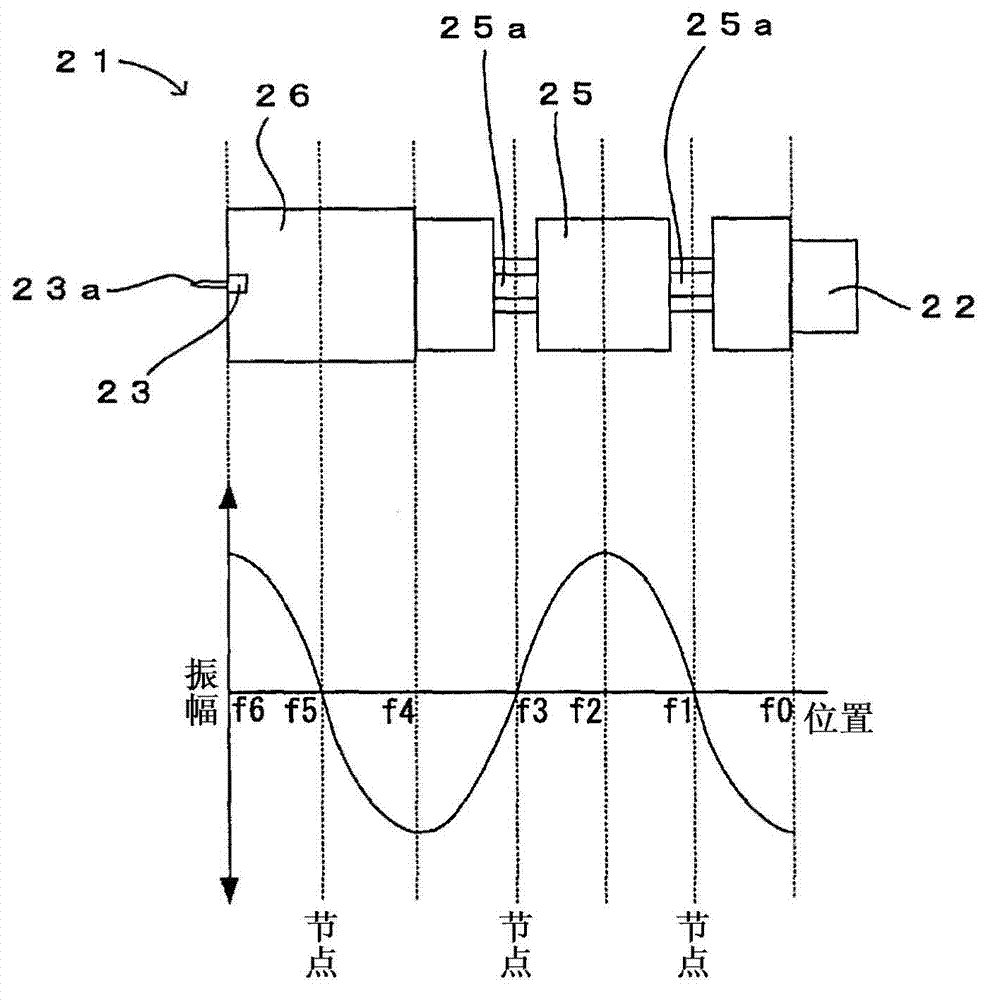

[0105] refer to Figure 1 to Figure 6 , the first embodiment of the vibration cutting device of the present invention will be described.

[0106] figure 1 It is the figure which looked at the 1st Embodiment of the vibration cutting apparatus 1 of this invention from the side. figure 2 will be figure 1 A three-dimensional view obtained by enlarging the main part of . image 3 yes means figure 1 A diagram of the resonator 21. Figure 4 It is an enlarged view of a state in which the honing head 26 constituting the resonator 21 is turned upside down, (a) is a perspective view, (b) is a side view, and (c) is a front view. Figure 5 yes image 3 The shown resonator 21 is supported by the support mechanism 24 and is formed in a horizontal state, (a) is a side view, and (b) is a cross-sectional view taken along line A-A of (a). Figure 6 yes means figure 1 A flow chart of an example of the operation.

[0107] (device structure)

[0108] figure 1 The vibration cutting ...

no. 2 approach

[0167] refer to Figure 10 , the second embodiment of the vibration cutting device of the present invention will be described. Figure 10 It is a figure which shows the resonator 321 of 2nd Embodiment of the vibration cutting apparatus 1 of this invention. Such as Figure 10 As shown, the difference between the resonator 321 of this embodiment and the resonator 21 of the above-mentioned first embodiment is that the side surface of the honing head 326 included in the resonator 321 is penetratingly provided with The long hole 326b. The other configurations and actions are the same as those of the above-mentioned first embodiment. Therefore, the following description will focus on the differences from the first embodiment. For the same configurations and actions as those of the above-mentioned embodiment, the same reference numerals will be used to omit them. Description of structure and action.

[0168] Such as Figure 10 As shown, the resonator 321 in this embodiment inclu...

no. 3 approach

[0172] refer to Figure 11 , the third embodiment of the vibration cutting device of the present invention will be described. Figure 11 It is an enlarged view of main parts of the honing head 26 and the stand 3 of the third embodiment of the vibration cutting device 1 of the present invention, and (a) to (c) show different states, respectively. Such as Figure 11 As shown in (a) to (c), the stand 3 of this embodiment is different from the stand 3 of the above-mentioned first embodiment in that the stand 3 is equipped with a buffer layer 33, and the buffer layer 33 is provided with a space for placing the object to be cut. The loading surface 31a. The other configurations and actions are the same as those of the above-mentioned first embodiment. Therefore, the following description will focus on the differences from the first embodiment. For the same configurations and actions as those of the above-mentioned embodiment, the same reference numerals will be used to omit them. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com