Self-aligning roller

An automatic centering and supporting wheel technology, which is applied to the supporting device of chemical soda ash calciner, automatic centering supporting wheel. It can solve the problems of not effectively solving the loss of the roller ring and the passive damage of the supporting roller, so as to reduce the maintenance cost and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

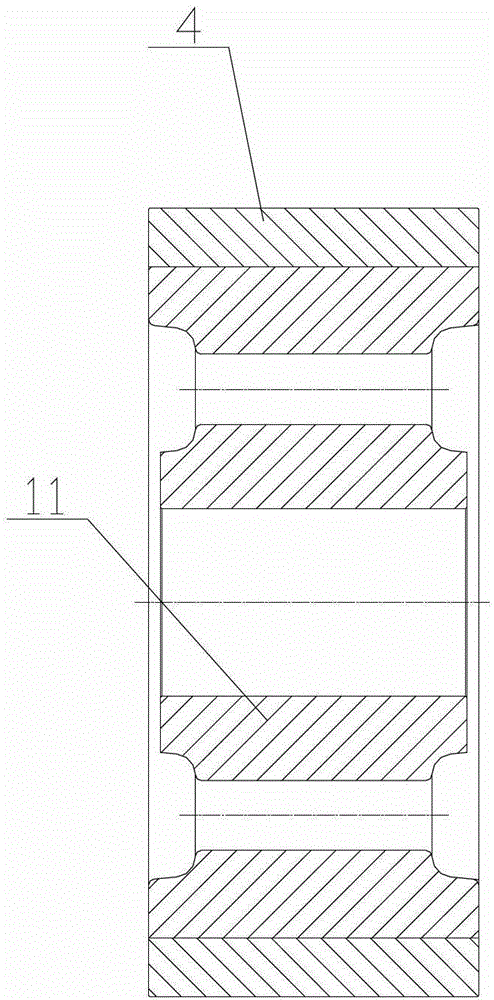

[0023] The core idea of the present invention is to design the support wheel from the prior art that can only rotate in one direction to the one that can rotate in multiple directions in a small range with the movement of the furnace body; effectively move the support wheel from the passive The damaged state is designed to actively adjust the state to achieve self-protection. In this way, the service life of the supporting wheel can be improved.

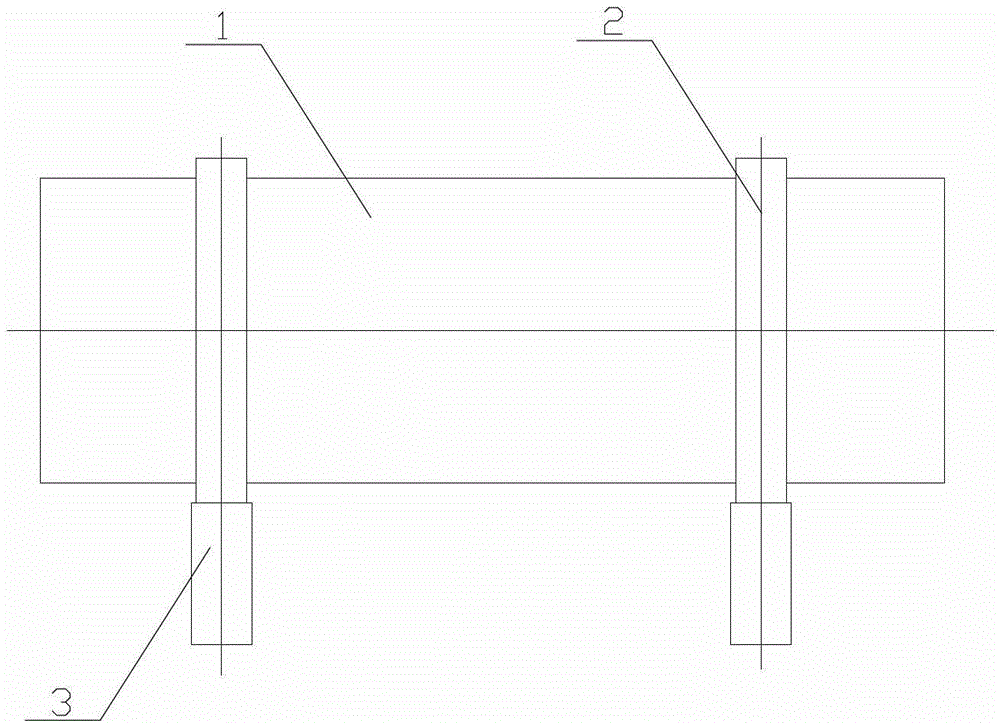

[0024] see figure 2 , the present invention is a support device used as a soda ash calciner, and the specific function position is shown in the figure. The furnace body 1 is a large rotating cylinder, and the furnace body 1 is symmetrically sleeved with rolling rings 2 , and the bottom of each rolling ring 2 is supported by two support wheels 3 respectively.

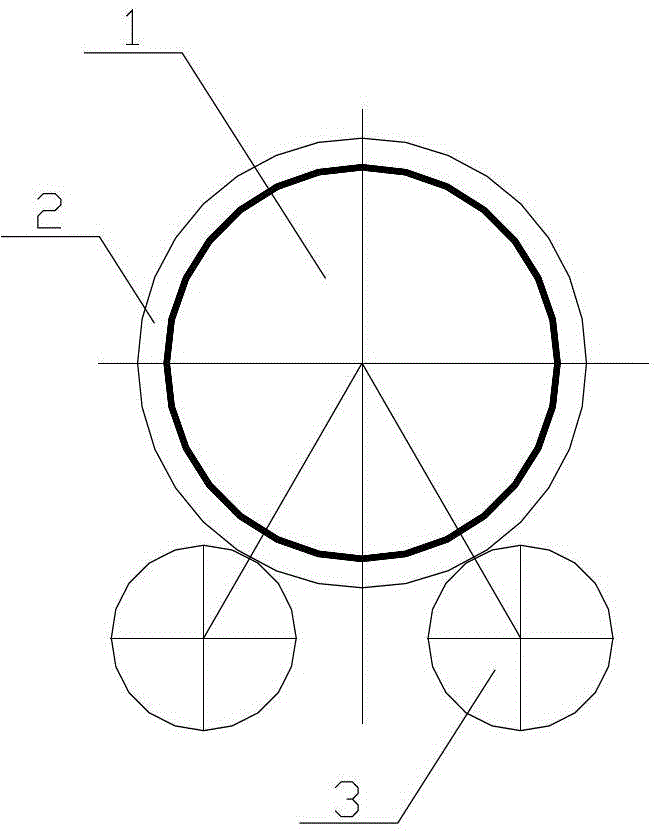

[0025] Such as image 3 As shown, the two supporting rollers 3 must be tangent to the outer circle of the corresponding rolling ring 2 . That is to say, when the furnace...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap