A deslagging device for thin oil lubricated bearing seat of decanter centrifuge

A decanter centrifuge, thin oil lubrication technology, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problems of centrifuges such as harsh operating environment, bearing damage, and reduced service life of bearings, and achieve a large Promote the application value, improve the service life, and save the effect of bearing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

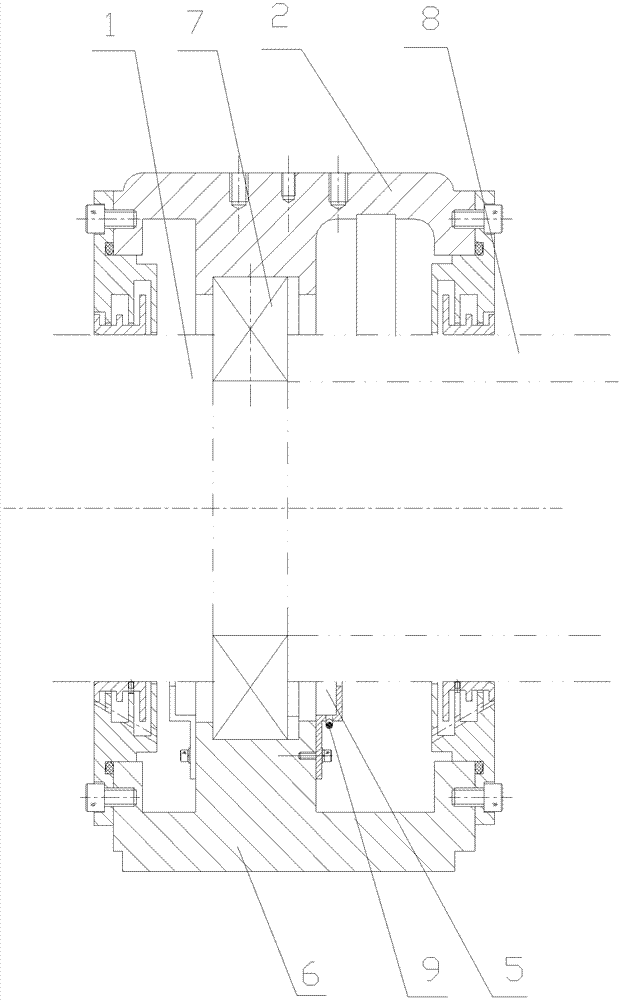

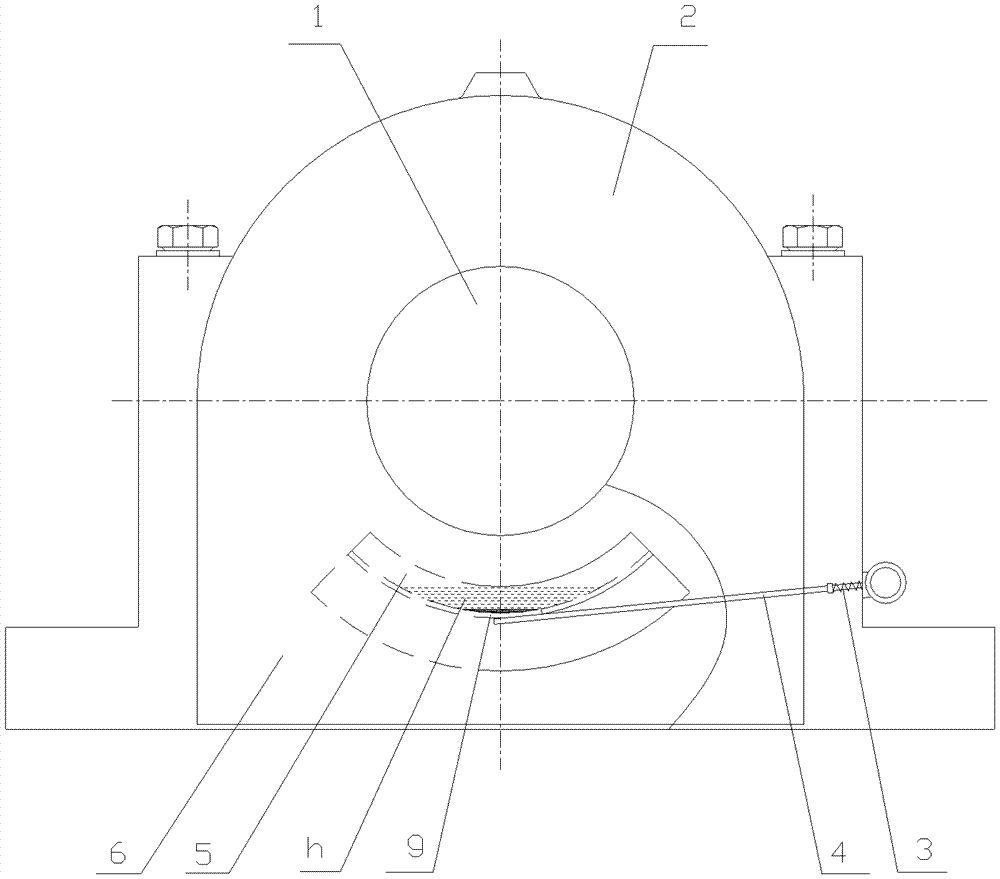

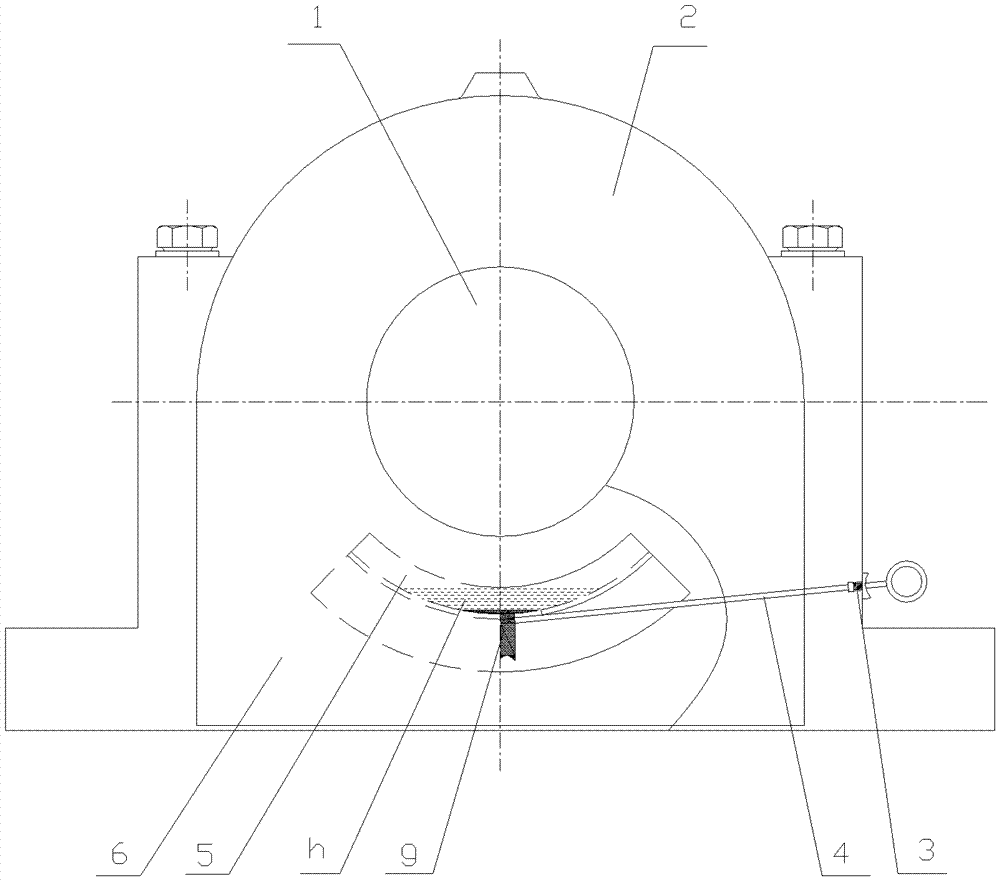

[0026] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] A deslagging device for a thin oil lubricated bearing seat of a decanter centrifuge. A crescent-shaped convex annular metal plate is fixed on the front and rear sides or both sides of the bearing seat to form an oil storage ring 5, and an oil storage ring 5 is provided at the bottom of the oil storage ring 5 The slag hole 9 is provided with a through hole 10 on the left or right side of the lower seat 6 of the bearing seat, and a metal rod 4 is arranged in the through hole 10. The metal rod 4 is a straight rod 4a and a ring at the end 4c; the ring 4c of the metal rod 4 is located outside the through hole 10, and the inner end of the straight rod 4a of the metal rod 4 is plugged at the bottom of the slag hole 9; A spring 3 is arranged between the protruding ring 4b and the circular ring 4c. The straight rod 4a of the metal rod 4, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com