Transverse and longitudinal ultrasonic sensor for detecting axial pre-stress of bolt

An ultrasonic sensor and axial pre-tightening technology, which can be used to measure torque/torsion force, instrument, measurement force and other directions during tightening, can solve problems such as large measurement error, single excitation waveform mode, and inconsistent thickness of coupling layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention is described in detail below:

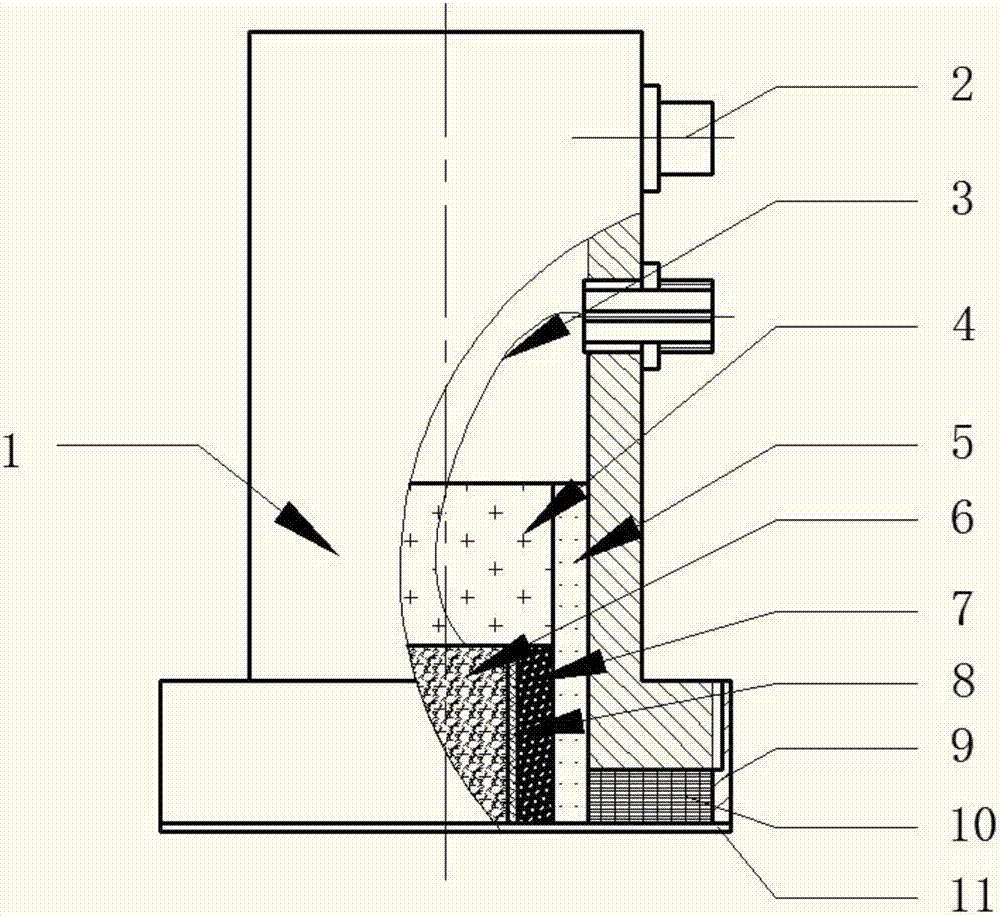

[0012] figure 1 In the process, the sound-absorbing material 8 is wrapped around the periphery of the transverse wave crystal oscillator cylinder 6 and stuffed into the longitudinal wave crystal oscillator ring 7, and the wires 3 are respectively welded to one side of the transverse wave crystal oscillator cylinder 6 and the longitudinal wave crystal oscillator ring 7 and connected to the housing 1 respectively. On the L5 joint 2 on the top, wrap the shock-absorbing material 8 on the outside of the longitudinal wave crystal oscillator ring 7 and fill it with the backing material 4, and put the magnetic steel 10 on the periphery of the shock-absorbing material 8 to form the inner core of the sensor. Attach the protective film 11 to the bottom surface of the screw cap 9 and screw it tightly on the shell 1, and tightly compress the assembled inner core inside the shell 1 to make a transverse a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap