Process method for sewing hidden row type front facing of wool clothes

A process method, the technology of front placket, applied in the direction of sewing tools, etc., can solve the problems of easy exposure, affecting the original shape of the appearance, and easy falling off of rubber particles, so as to achieve the effect of soft appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] as attached Figure 1-11 Shown, the present invention adopts following process to make;

[0023] 1. A sewing process for a concealed row front placket of a woolen garment, characterized in that the process steps are as follows:

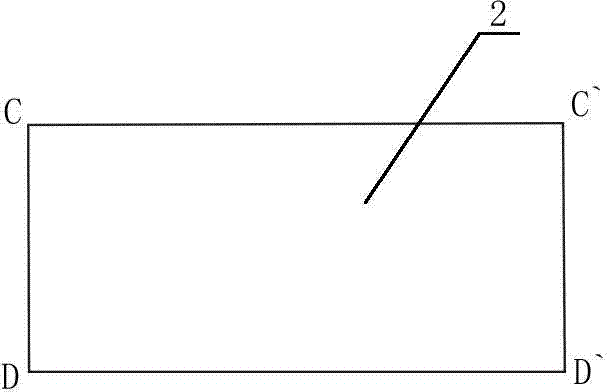

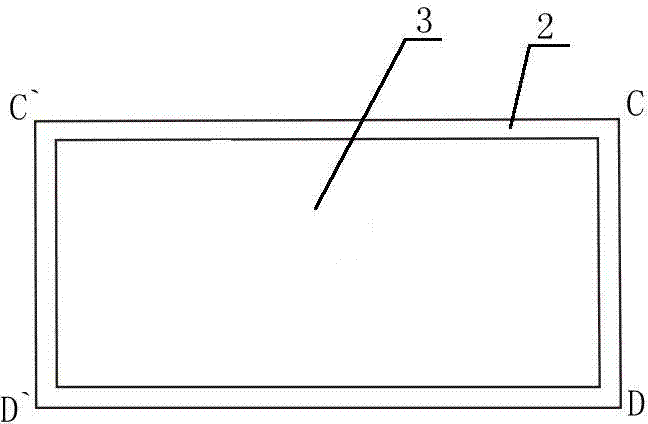

[0024] 1. Stick a layer of non-woven lining 3 on the inner side of the dark row 2;

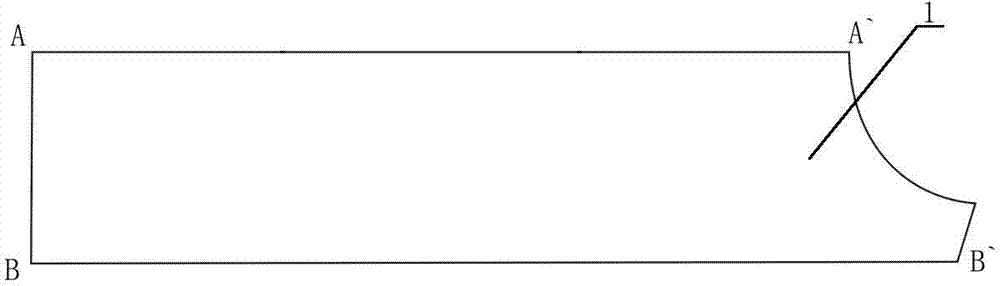

[0025] 2. Place the cut piece 1 on the side of the dark row 2 that is not bonded with the non-woven interlining 3, so that the side line CC` of the dark row 2 is set parallel to the side line AA` of the cut piece 1 with a vertical distance of 2 cm, and then the dark Row 2 and piece 1 are sewn together along the first suture line EE', the suture line EE' and AA' are arranged in parallel with a vertical distance of 1 cm;

[0026] 3. Make the first left notch EF1 and the first right notch E`F1` at a 45-degree angle to the horizontal at points E and E` on piece 1;

[0027] Make the second left notch EF2 and the second right notch E`F2` at an angle of 45 degrees t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com