A kind of high fatigue resistance flame retardant pc/pbt alloy material and preparation method thereof

An alloy material and fatigue-resistant technology, which is applied in the field of high fatigue-resistant flame-retardant PC/PBT alloy material and its preparation, can solve problems such as no patent reports, and achieve broad application fields, excellent mechanical properties, fatigue resistance, and appearance soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 5

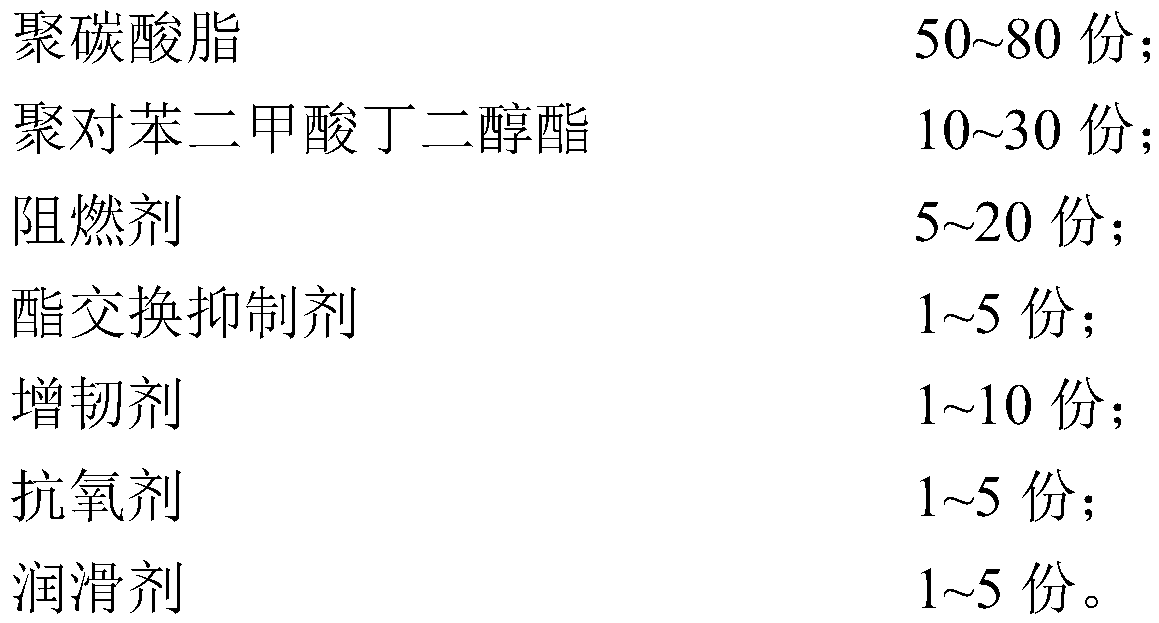

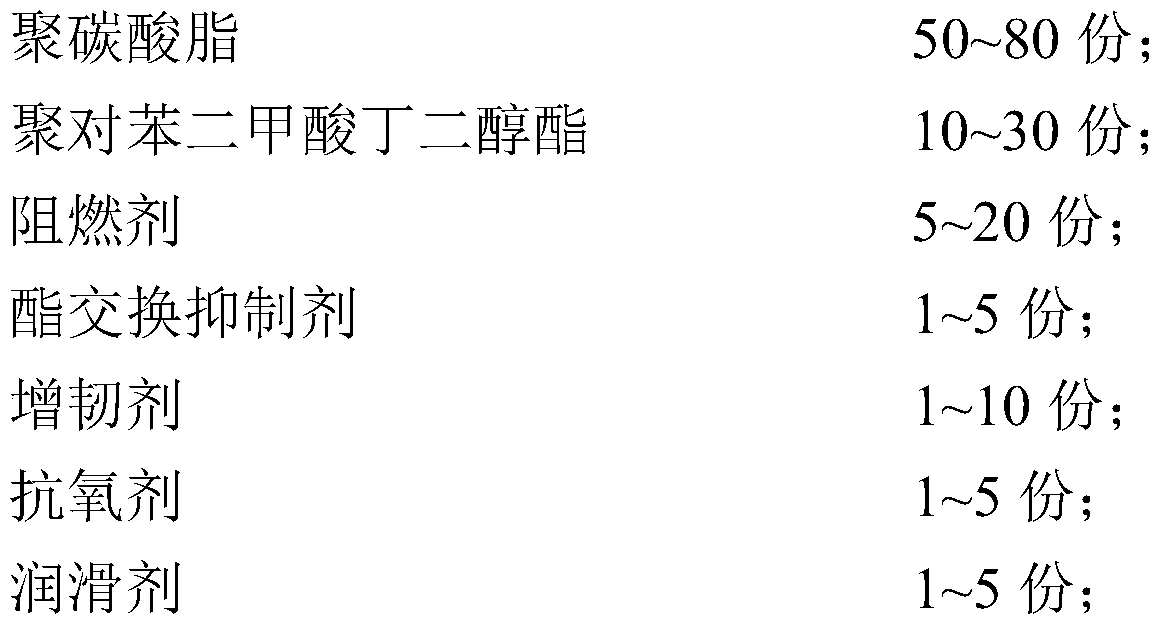

[0041] Weigh materials such as polycarbonate resin, polybutylene terephthalate resin, toughening agent, flame retardant, transesterification inhibitor, antioxidant and lubricant according to weight ratio;

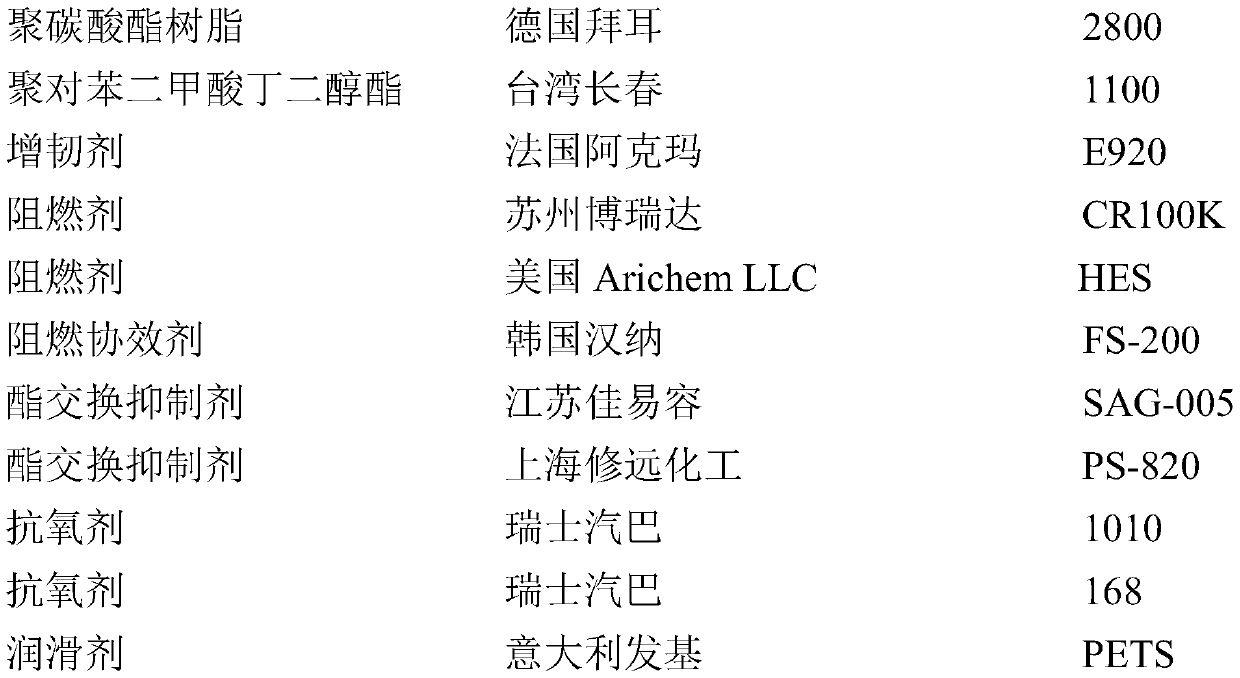

[0042]The melt flow rate of polycarbonate in the embodiment is 5-7g / 10min; Polybutylene terephthalate viscosity is 0.8-1.0; Flame retardant is decabromodiphenylethane, brominated epoxy resin, Potassium perfluorobutane sulfonate and antimony trioxide; when the two are compounded, they are mixed at a weight ratio of 13-15:1; the transesterification inhibitor contains glycidyl methacrylate (GMA) A mixture of oxygen groups and sodium dihydrogen phosphate, the weight ratio is 1:0.5~1.5; the toughening agent is styrene-acrylonitrile-glycidyl methacrylate, methyl methacrylate-butadiene-styrene copolymer A kind of substance, ethylene-methyl acrylate-glycidyl methacrylate copolymer; the antioxidant is bis(2,4-di-tert-butylphenol) pentaerythritol diphosphite, pentaerythritol dodecylt...

Embodiment 5

[0062] The flexural strength of embodiment 5 (high fatigue resistance flame retardant PC / PBT alloy material) is 102.1MPa, flexural modulus 2631MPa, notched Charpy impact strength 63.1kJ / m 2 , UL94 test 1.6mm flame retardant V-0, PEU vibration test greater than 8h. At the same time, the surface finish is good, and the overall performance is better than that of the ordinary PC / PBT alloy material in the prior art (comparative example 1).

[0063] Draw the following conclusions from the test data of embodiment and comparative example: 1, adopt low-content polybutylene terephthalate to help maintain higher heat distortion temperature for PC / PBT alloy material, thereby make material It has better heat resistance and wider application range. 2. By adding brominated epoxy and potassium perfluorobutane sulfonate, it can achieve excellent flame retardant effect while not affecting the toughness of the material as much as possible. 3. By adding the transesterification inhibitor SAG-005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com