Film coating piece and preparation method thereof

A technology for coating parts and layers, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve problems such as cumbersome process steps, avoid exposure and development process, have good texture and soft appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

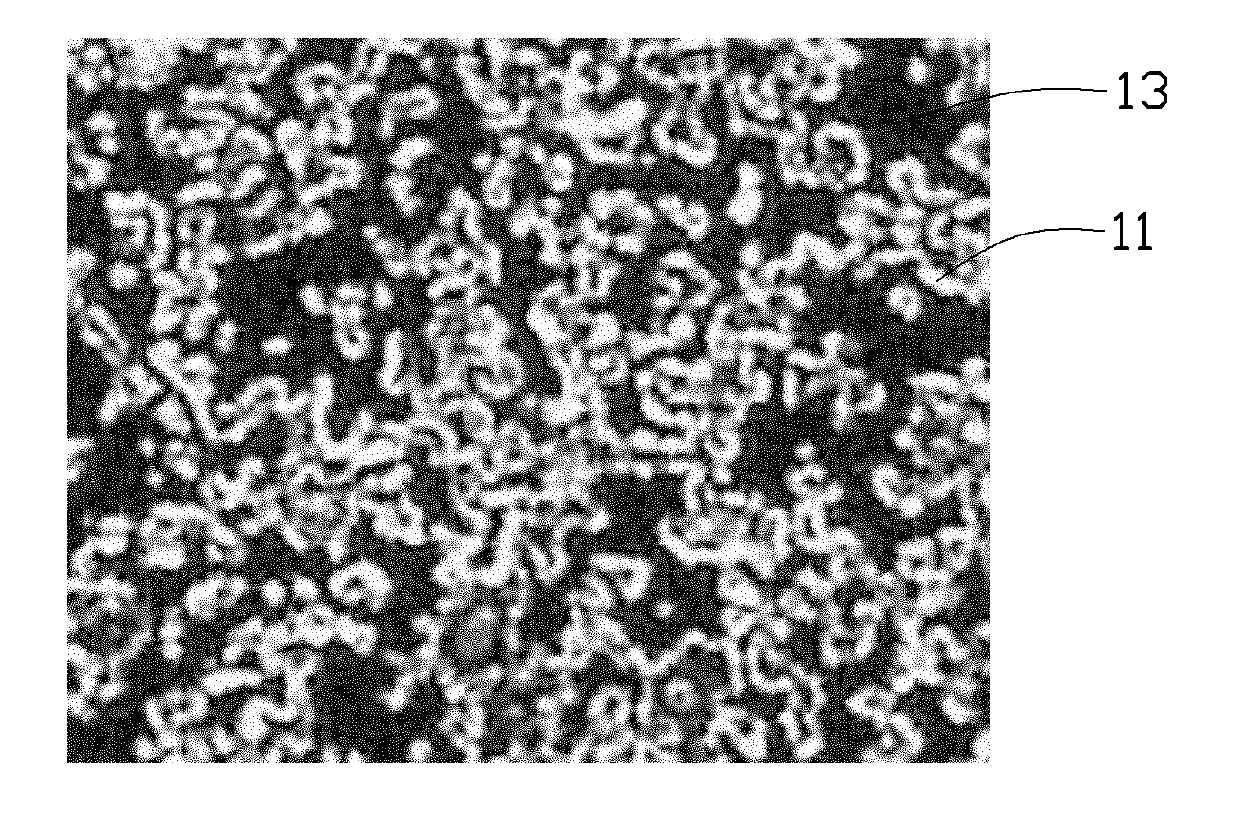

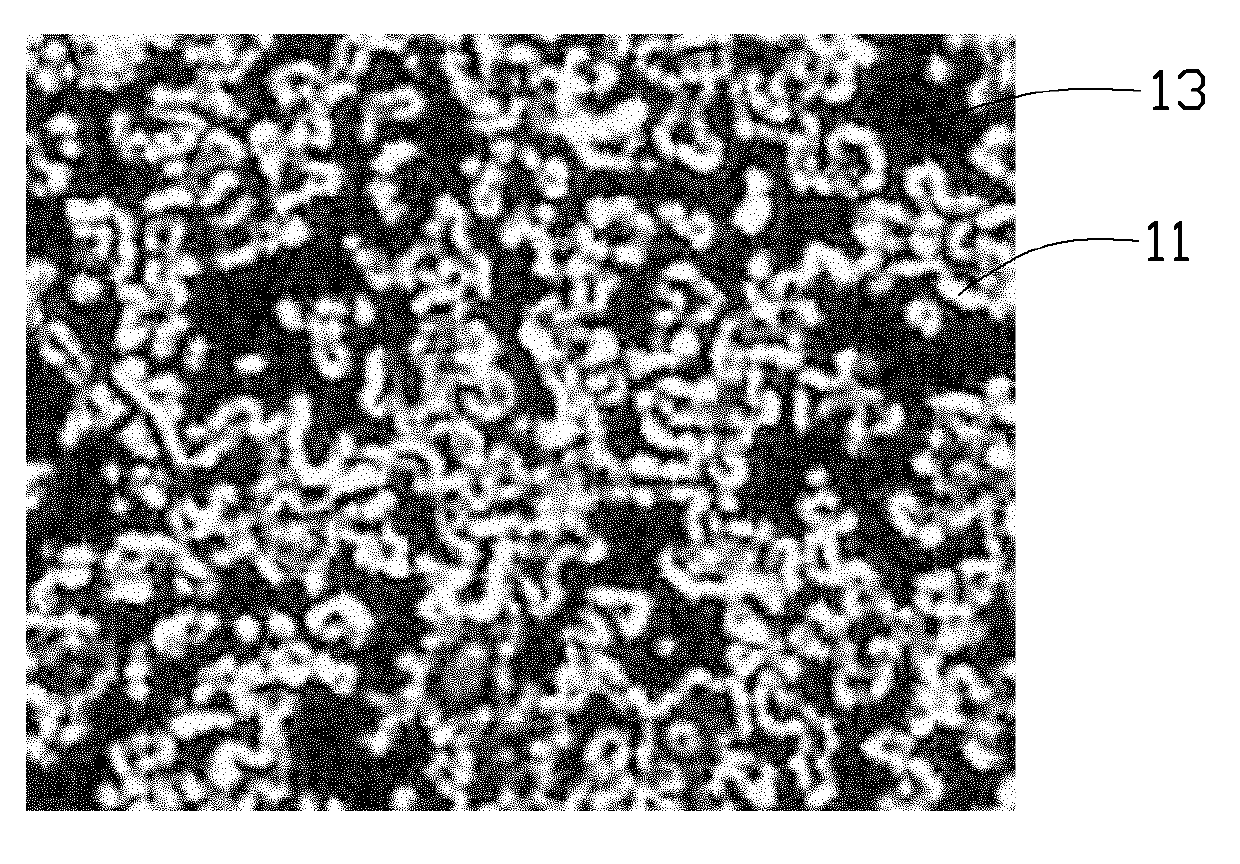

[0018] A coating member according to a preferred embodiment of the present invention includes a substrate and a film layer formed on the surface of the substrate, and the film layer is composed of several discontinuous film layer regions. The area of each film layer region can be 0.001-0.025mm 2 , the distance between adjacent film regions can be 0.02-0.04 mm. The film layer area may be irregularly shaped as dots or squares. The several discontinuous film layer regions can present a matte appearance and can be used as a decorative coating.

[0019] The substrate can be metal materials such as stainless steel, aluminum alloy or magnesium alloy, or non-metal materials such as glass.

[0020] The film layer can be formed by magnetron sputtering. The composition of the film layer can be one or more of metal, metal oxide, metal carbide, metal nitride, metal oxycarbide or metal oxynitride.

[0021] The preparation method of a preferred embodiment of the present invention coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com