PET film frosting glue

A frosting and glue technology, applied in the direction of coating, can solve the problem of high cost and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0017] In a preferred embodiment, the PET film frosting glue component and content are:

[0018] PVB: 18kg

[0019] Matte powder (mainly silica): 2.2 kg

[0020] Ethanol: 150 kg

[0021] The production technology of described PET film frosting glue comprises the steps:

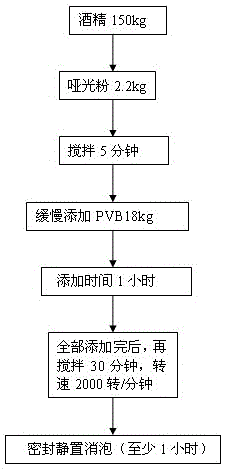

[0022] (1) Mix ethanol and matte powder according to the above weight ratio and stir the solution evenly;

[0023] (2) Slowly add the required PVB to the solution obtained in step (1) and stir evenly; the addition time is about 1 hour, and it takes about 30 minutes to stir evenly after the addition is completed.

[0024] (3) Seal and let it stand for defoaming, preferably more than 1 hour.

[0025] After the frosting glue is coated on the PET film, it can be firmly attached to the surface of the PET film and have a frosting effect, which avoids the process of physical grinding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com