Method for continuous production of sub-brightness abbatre coloured steel-plate

A technology of color steel plate and concave-convex pattern, which is applied to the device for coating liquid on the surface, the process for producing decorative surface effect, decorative art, etc., can solve the problems of affecting the use effect of steel plate, cracks, embossing blur, etc., to achieve Reduced production cost, simple equipment structure, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

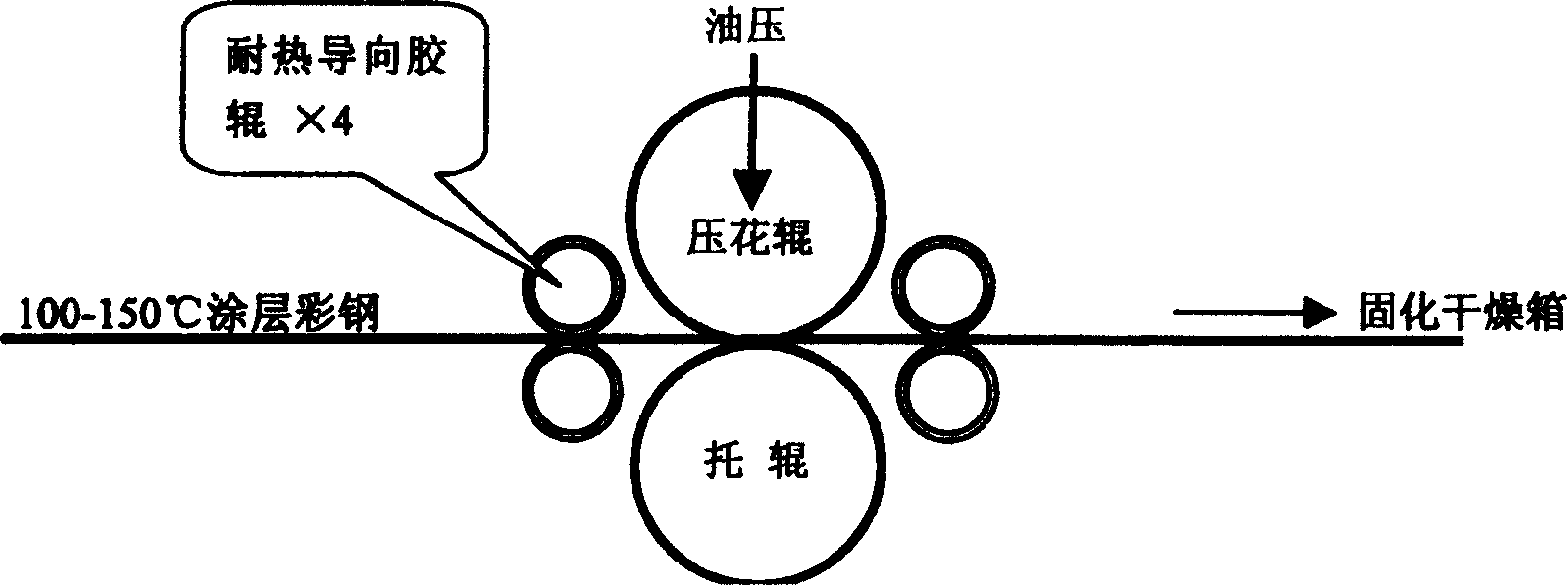

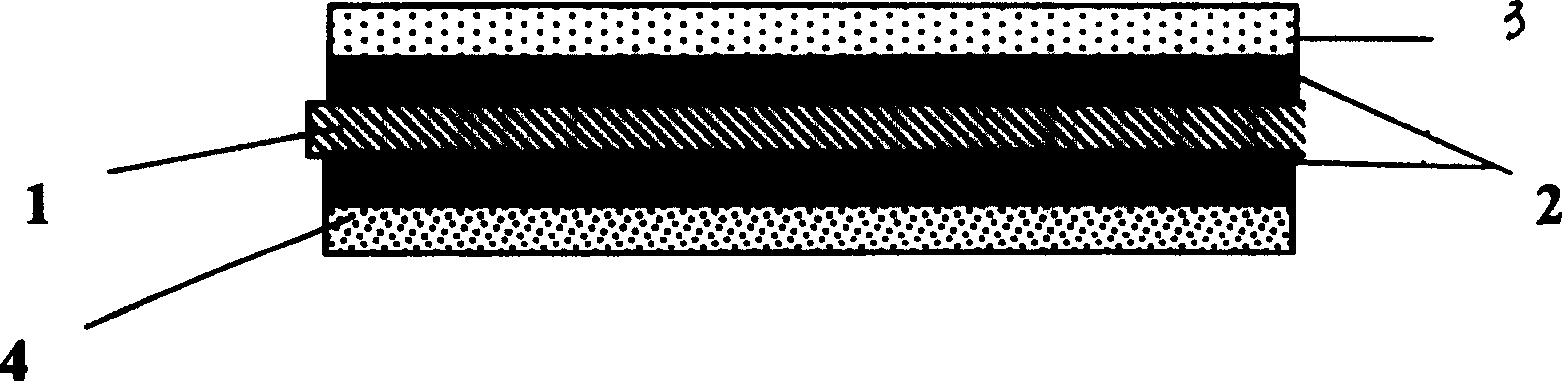

[0017] The invention discloses a continuous production method for a matte concave-convex thermal transfer printing steel plate. The technological process of the method consists of a coating unit, a plasticizing unit, an embossing unit, a curing unit and a thermal transfer printing unit.

[0018] 1. Coating unit:

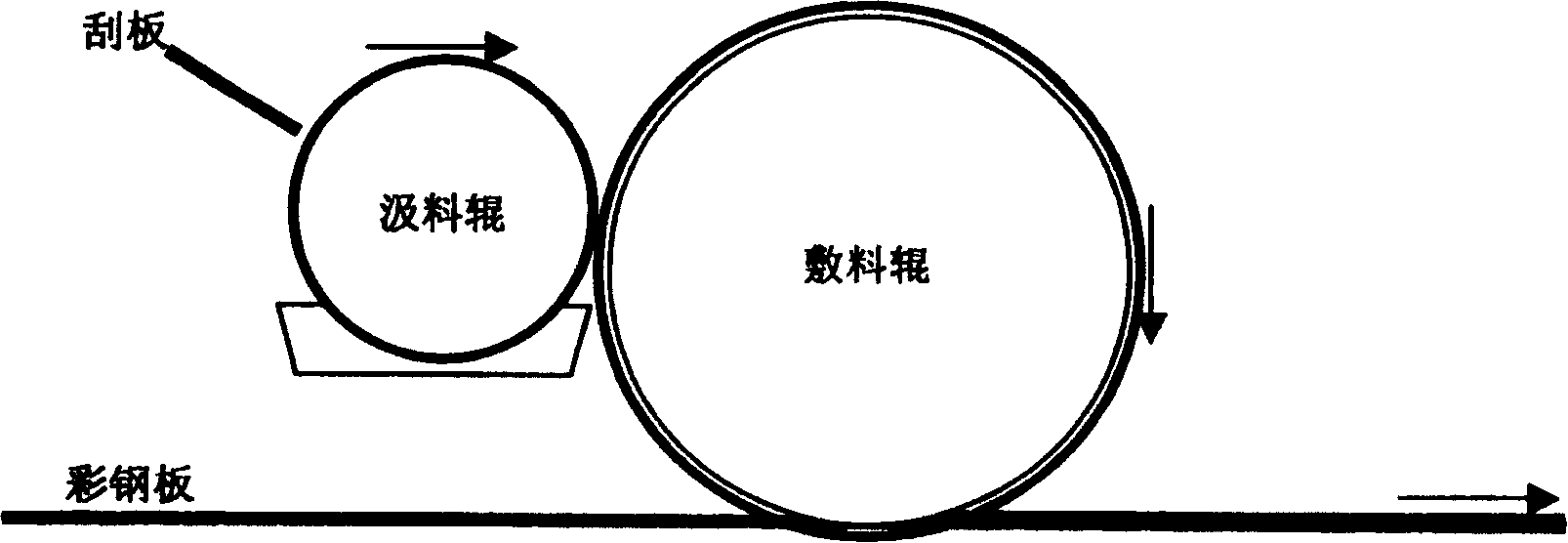

[0019] The coating unit is to continuously transport the coil or sheet of the steel plate to be printed to the reverse coating roller to coat the matt surface coating. The coating unit adopts the two-roller reverse coating method. When coating the paint, the pick-up roller draws the paint from the paint pan, then transfers it to the coating roller, and then the coating roller coats it on the surface of the steel plate. Its structure is as follows: figure 1 .

[0020] The matt surface coating is that nylon powder is added to the polyester top paint, and the amount of nylon powder added is 10-50% of the weight of the polyester top paint.

[0021] Alternative applicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com