High anti-fatigue bolt and manufacturing method thereof

A manufacturing method and a technology of bolts, which are applied in the direction of screws, threaded fasteners, connecting components, etc., can solve problems such as unsatisfactory bolt structures or manufacturing methods, low flight safety factors of aerospace vehicles, and fatigue resistance that cannot meet requirements, etc. Achieve light weight, minimized weight and length, and high fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a basis for any limitation of the present invention.

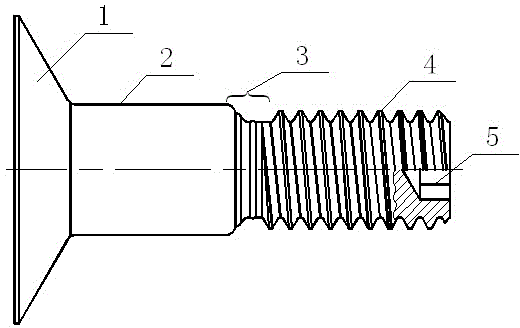

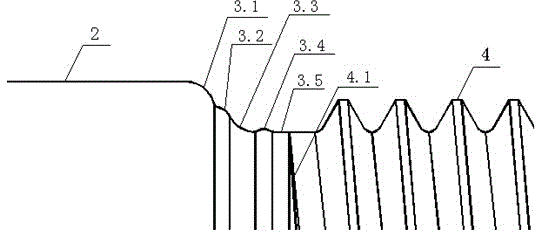

[0018] Embodiment of the present invention: when making a high fatigue resistance bolt of the present invention, existing aluminum alloy 7075T73, titanium alloy 6Al-4V or corrosion-resistant steel A286 materials can be used for production, and the existing upsetting is used to make The bolt semi-finished product with head 1, shank 2 and threaded section 4 is processed by the method of type, and then a transition section 3 is made on the shank 2, so that the transition section 3 is arranged between the threaded section 4 and the shank 2, And make the maximum diameter of the transition section 3 part smaller than the thread outer diameter of the thread section 4 and the diameter of the rod part 2, and then use a thread rolling wheel to roll out the thread of the required standard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com