Wheel spoke

A spoke and wheel technology, applied in the field of spokes of motor vehicle wheels, can solve the problems of reducing the driving safety of motor vehicles and reducing the strength of spokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

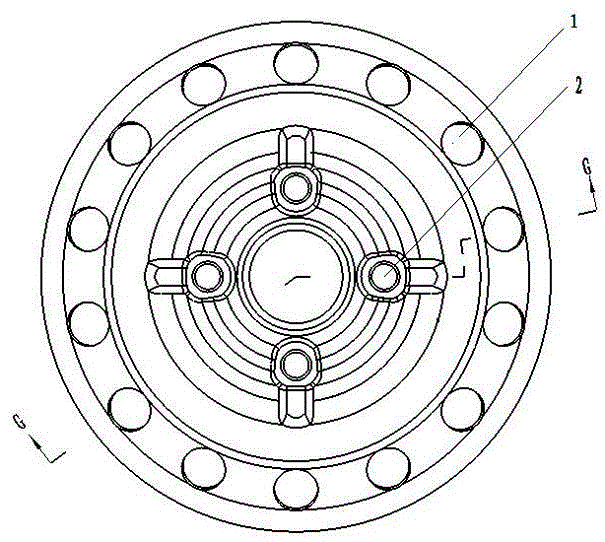

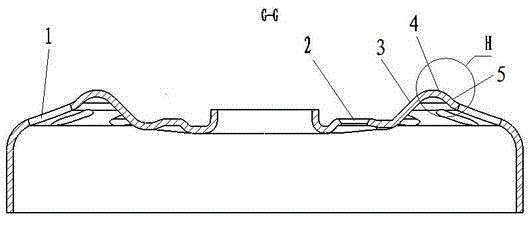

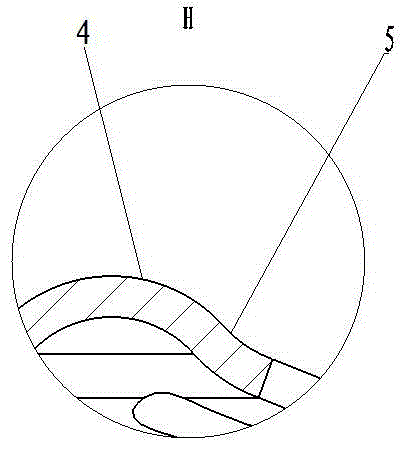

[0015] figure 1 , figure 2 and image 3 The wheel spokes shown have a barrel portion formed from steel plate, i.e. as figure 2 The lower part, the mounting part, that is figure 1 The central part has 4 bolt holes evenly distributed on the periphery of the central through hole, and the connecting part between the cylindrical part and the mounting part, and the connecting part is provided with 14 cooling holes evenly distributed around the central through hole. Air hole, within the ring surrounded by 14 cooling air holes, there is a ring of raised parts with the central through hole as the center of the circle and the opening of the cylinder body facing oppositely. The inner edge portion of the top portion 4 of the raised portion is a straight edge 3, and the outer edge portion of the top portion 4 of the raised portion is a curved side edge 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com