Casing body connection device for bored pile

A technology of bored cast-in-place piles and connection devices, which is applied in sheet pile walls, buildings, and foundation structure engineering, etc., and can solve problems such as unsatisfactory use effects, low loading and unloading efficiency, easy damage to bolts and screw holes, etc., and achieve ideal use effects , good joint sealing and high disassembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

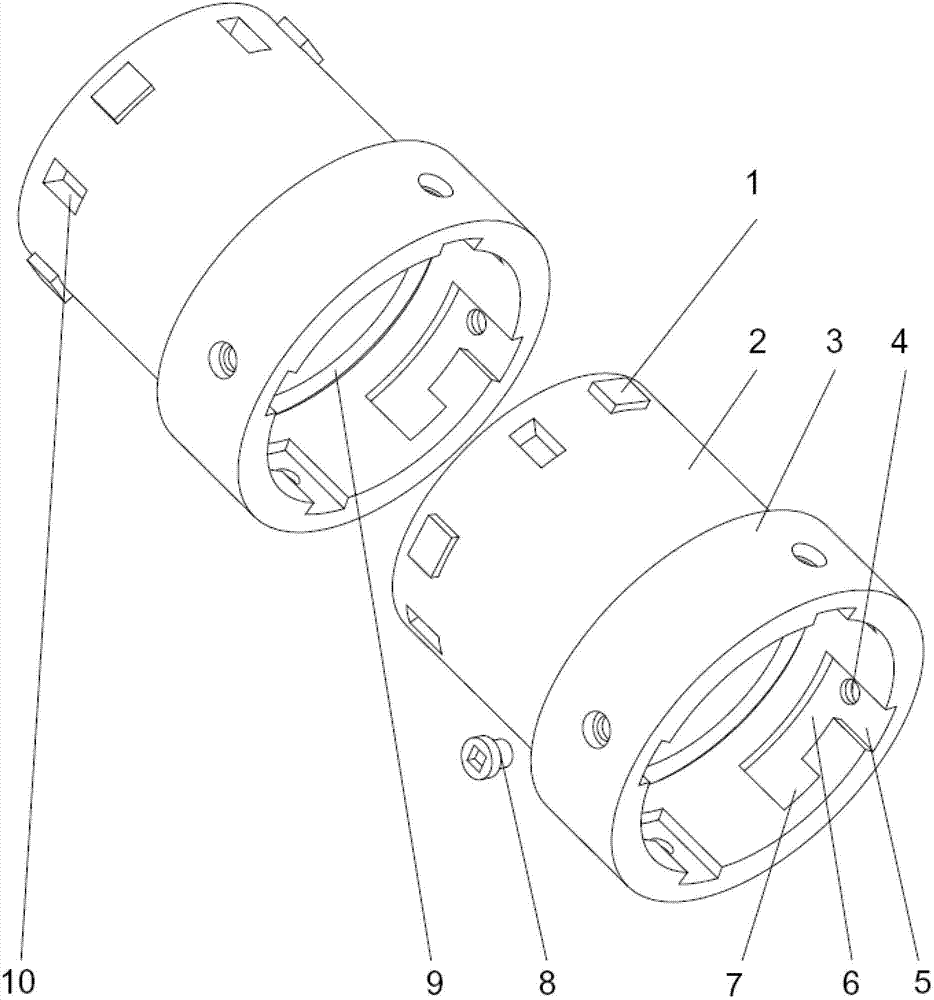

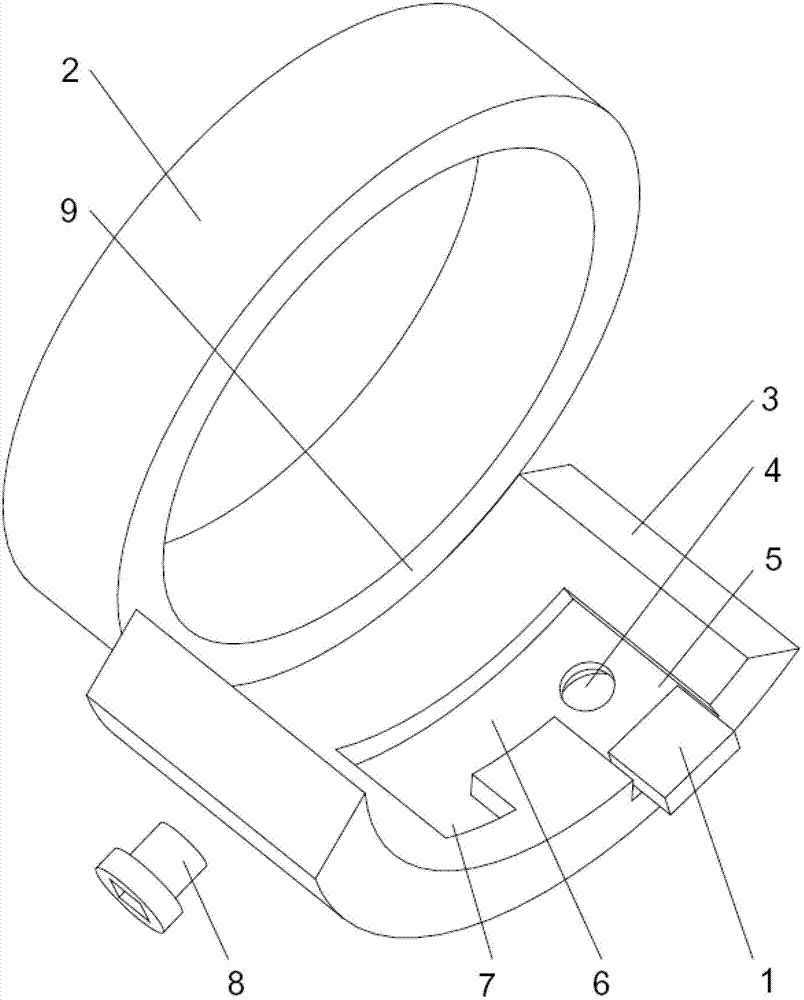

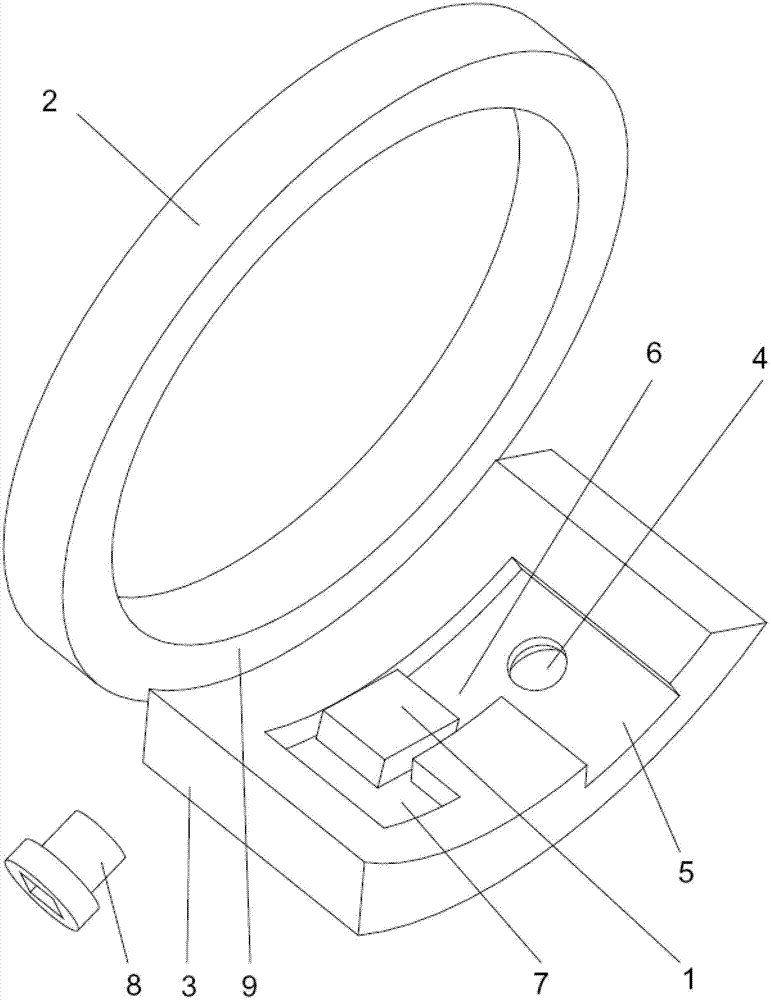

[0020] Embodiments of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a cylinder connection device for bored piles includes a collar 3 arranged at the lower end of the driving cylinder 11 and the casing 2; The lower end is connected to the upper end of the top casing 2 through the collar 3; the remaining sections of the casing 2 are connected up and down in turn through the collar 3; the inner diameter of the collar 3 is compatible with the driving cylinder 11 and the outer diameter of the casing 2; the collar 3 It is connected to the upper port of the next section of the casing 2 through fasteners; four "n"-shaped three-fold card slots are evenly distributed on the inner peripheral surface of the collar 3, and the two vertical slots of the "n" are one long and one long. Short, the vertical sides of the two vertical grooves are parallel to the circle center line of the collar 3, and the long vertical groove (ie, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com