Hydraulic distributer

A technology for hydraulic distributors and housings, which is applied in the direction of fluid pressure actuation devices, fluid pressure actuation system components, servo motor components, etc., which can solve problems such as poor reliability, poor oil circuit sealing performance, and few functions, and achieve reliable The effect of high performance, meeting requirements, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

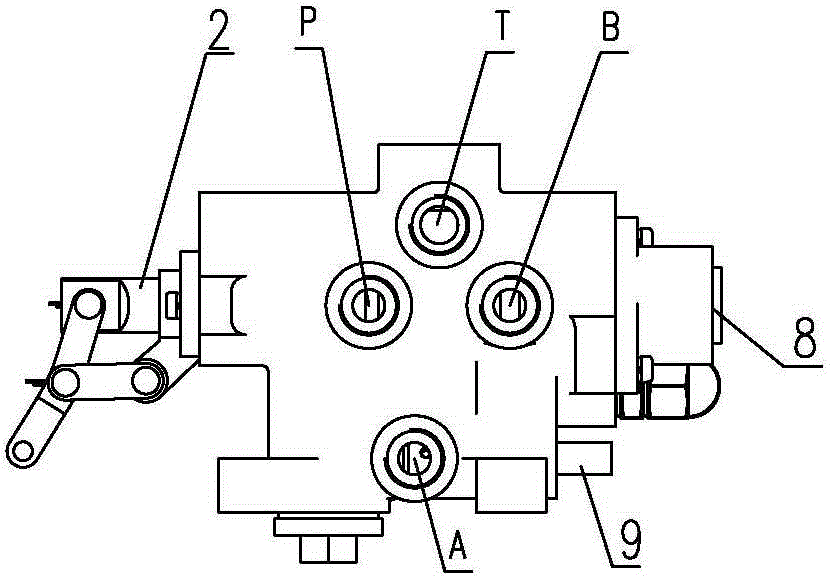

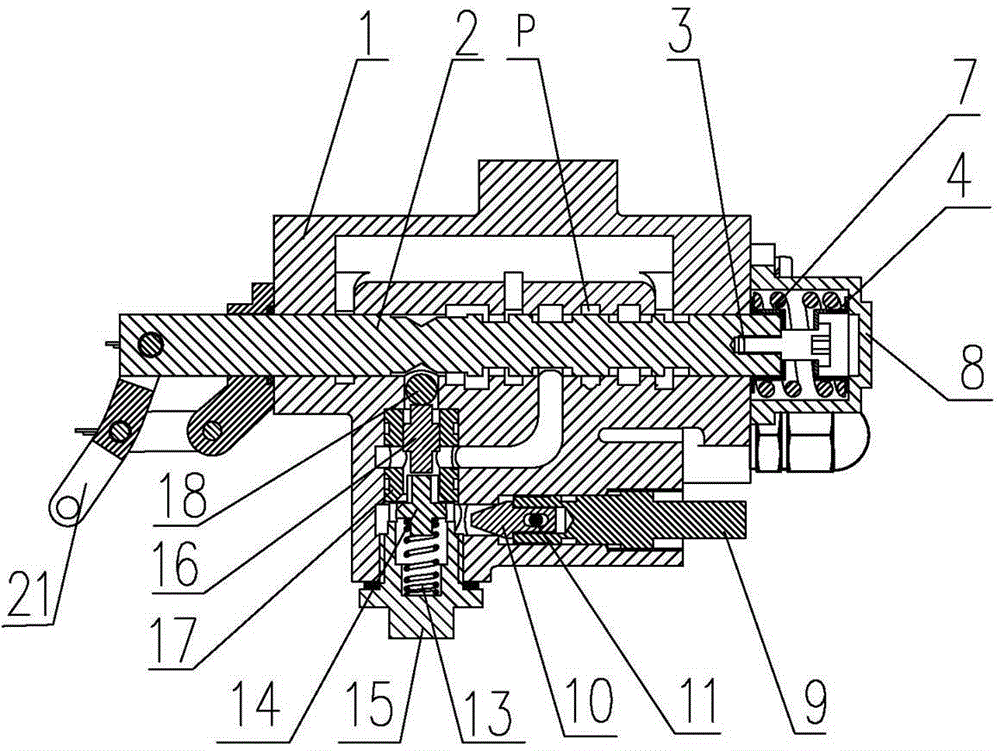

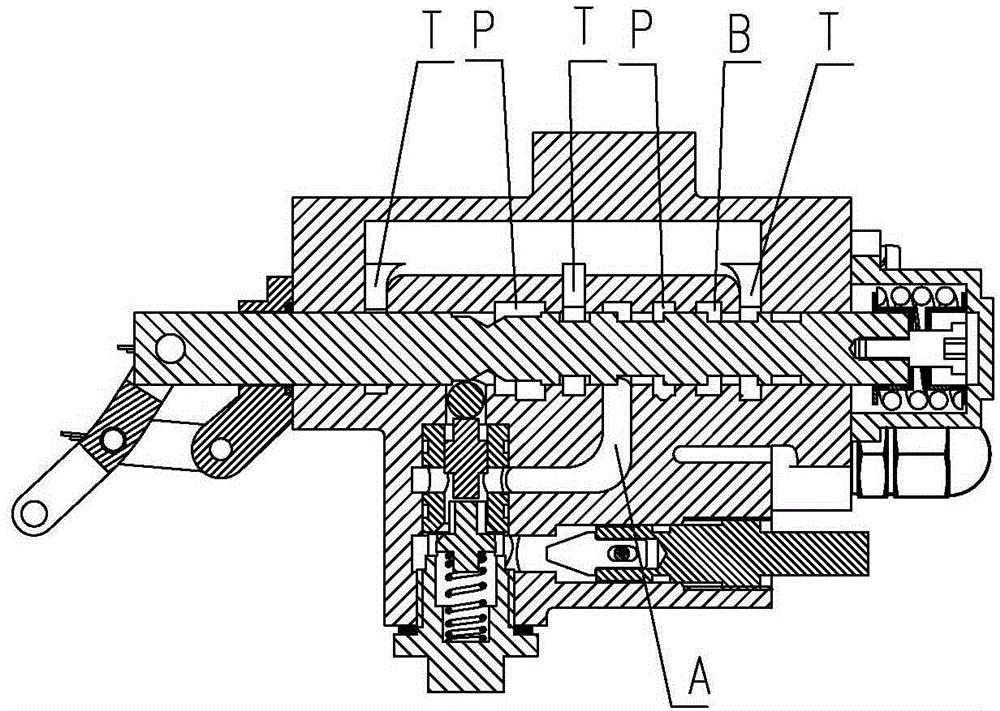

[0015] Such as figure 1 As shown, a hydraulic distributor according to the present invention includes a housing 1 and a valve stem 2, an oil passage is arranged in the inner cavity of the housing 1, the valve stem 2 is inserted in the housing 1, and the outer surface of the housing 1 The surface is provided with an oil inlet P, an oil return port T, a positive direction control port A, and a reverse direction control port B. The outer surface of the valve stem 2 located in the inner cavity of the housing 1 is provided with an annular oil groove. The front end of the valve stem 2 A rocker arm 21 is hinged.

[0016] Such as figure 2 As shown, an automatic return device is installed at the rear end of the valve stem 2, and the automatic return device includes a return seat 4, a return screw 3, and a return spring arranged between the return seat 4 and the valve stem 2 7. The end surface of the return seat 4 is provided with a groove for accommodating the return screw 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com