Flange manhole for self-balancing horizontal rotary cover

A technology of covering flanges and horizontal rotation, which is applied to pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., and can solve problems such as potential safety hazards, sparks, and easily damaged flange joint sealing systems, and achieve safe opening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

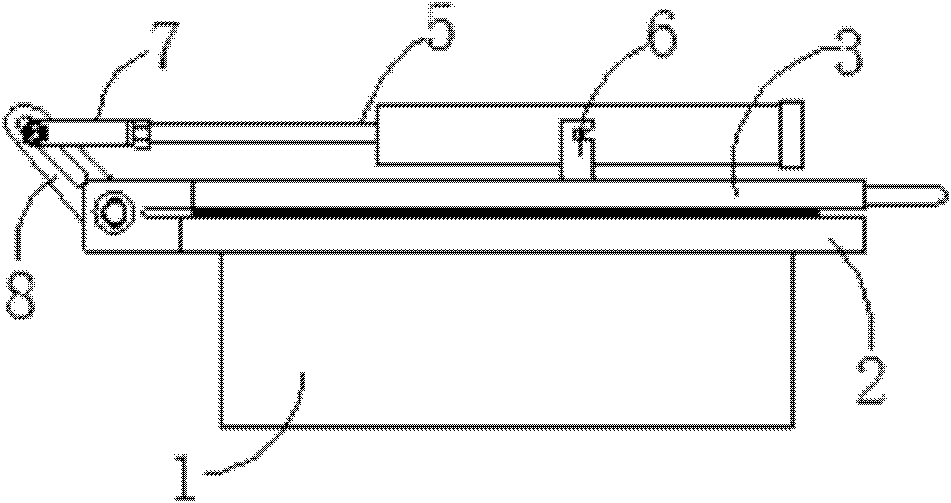

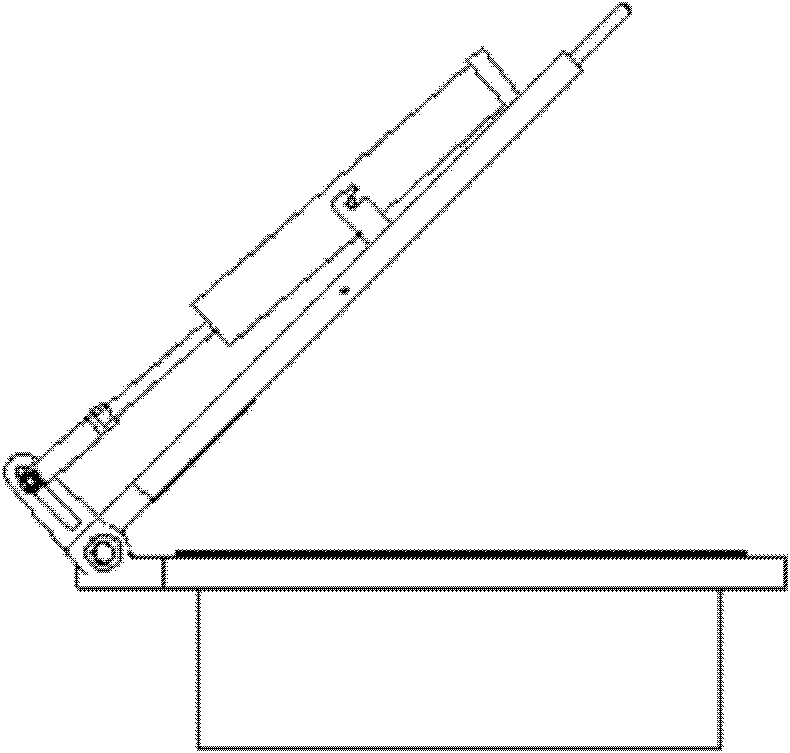

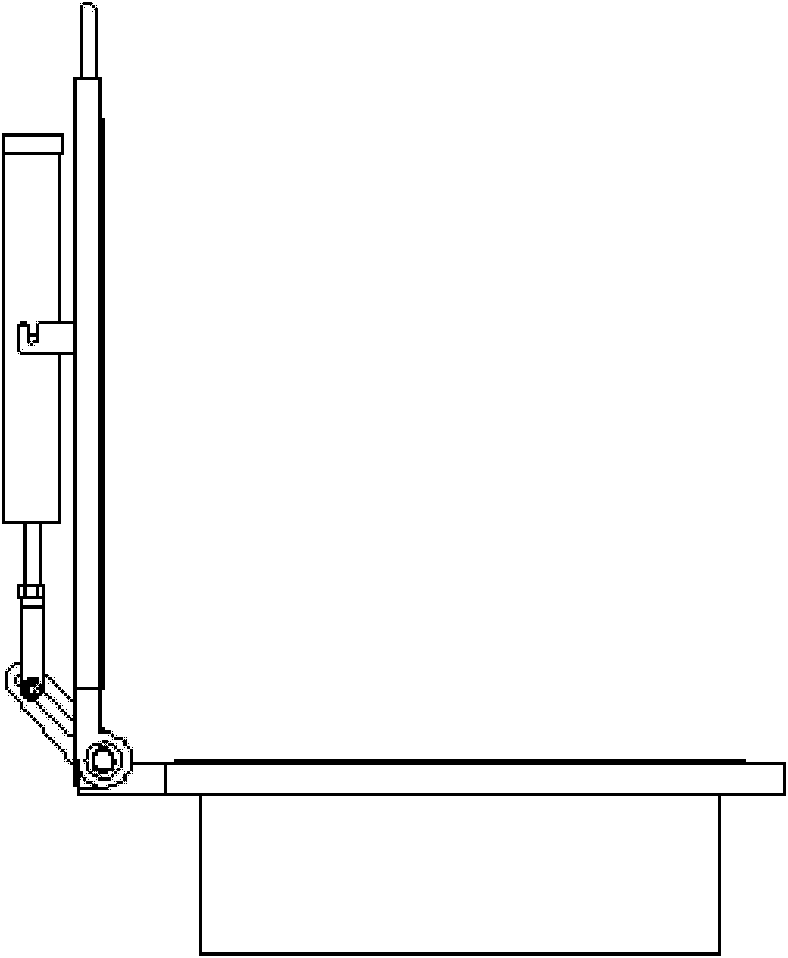

[0020] Embodiment: a self-balancing horizontal revolving cover flange manhole, the revolving cover flange manhole is composed of a manhole 1, a flange 2 fixed on the upper end of the manhole and a revolving cover 3 for sealing the manhole, The rear ends of the flange 2 and the revolving cover 3 are rotatably connected by a connecting shaft 4, and a spring cylinder balance system is provided. The spring cylinder balance system consists of a spring cylinder 5, a connecting piece and a spring cylinder lug 6 The connecting piece is connected to the connecting shaft 4, the lower end of the spring cylinder lug 6 is fixed on the upper surface of the revolving cover 3, and the spring cylinder 5 is mainly composed of a cylinder body 51, a spring 52 and a pull rod 53, The rear end of the pull rod 53 is connected to the connector, the spring 52 is sleeved on the pull rod 53, the cylinder body 51 is sleeved outside the spring 52, and the cylinder body 51 is connected to the spring cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com