Accumulator having multiple accumulator cells

A technology for accumulators and electronic components, applied in the direction of electrical components, secondary batteries, battery pack parts, etc., can solve problems such as difficult manipulation, troublesome, clamping wires, etc., and achieve the effects of precise installation, space saving, and reliable guiding of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

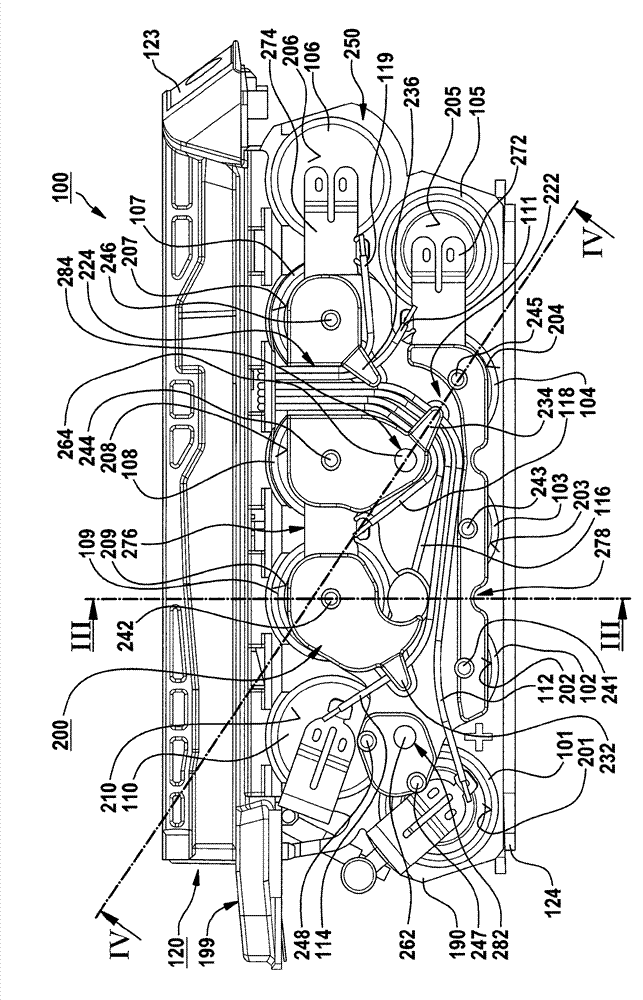

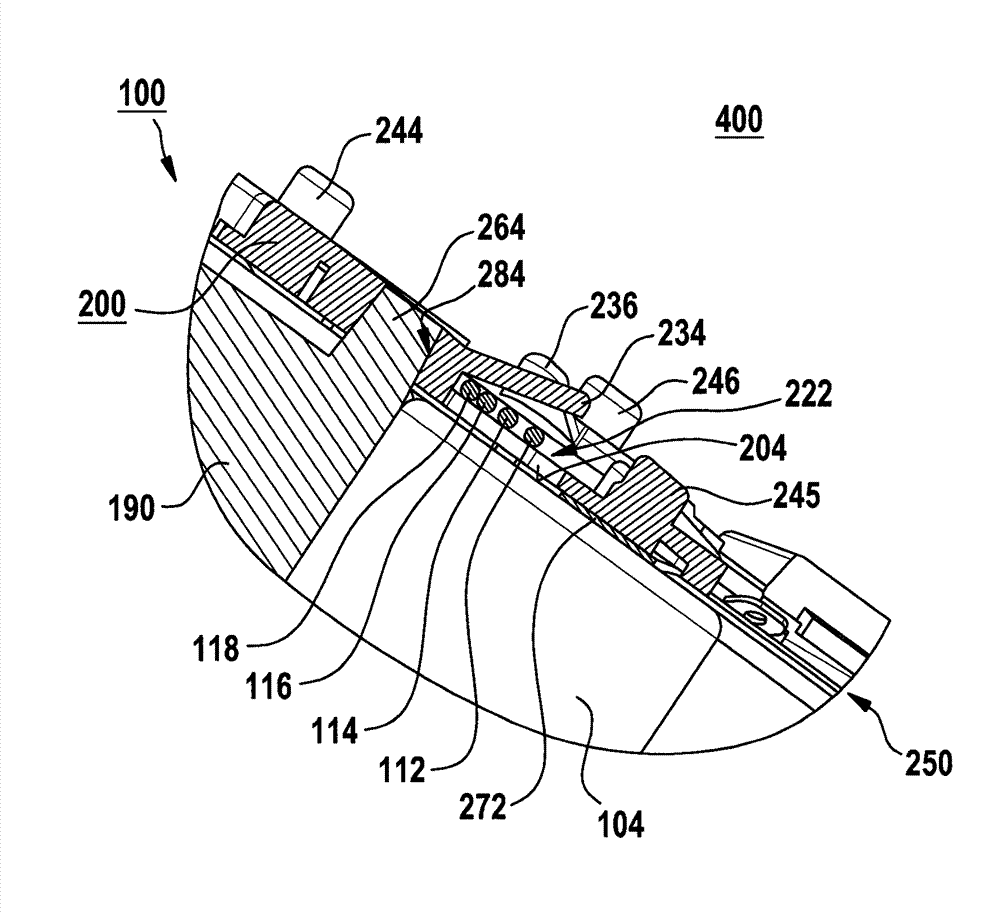

[0033] According to one specific embodiment, at least in the region of the end faces of the at least one battery cell, at least one wire is fastened, for example by soldering, via which the at least one battery cell is connected to the electronic component 140 . Here, the electric wires can be fastened not only directly to the end face, but also to a unit connector fastened to the end face. For example, six wires 111 , 112 , 114 , 116 , 118 , 119 are provided, wherein, for example, wire 114 is fastened in the region of the end face ( 210 in FIG. 2 ) of battery cell 110 , and wire 111 is fastened in such a way that battery cell 104 , 105 end faces ( 204 , 205 in FIG. 2 ) are connected to each other on the unit connector 272 .

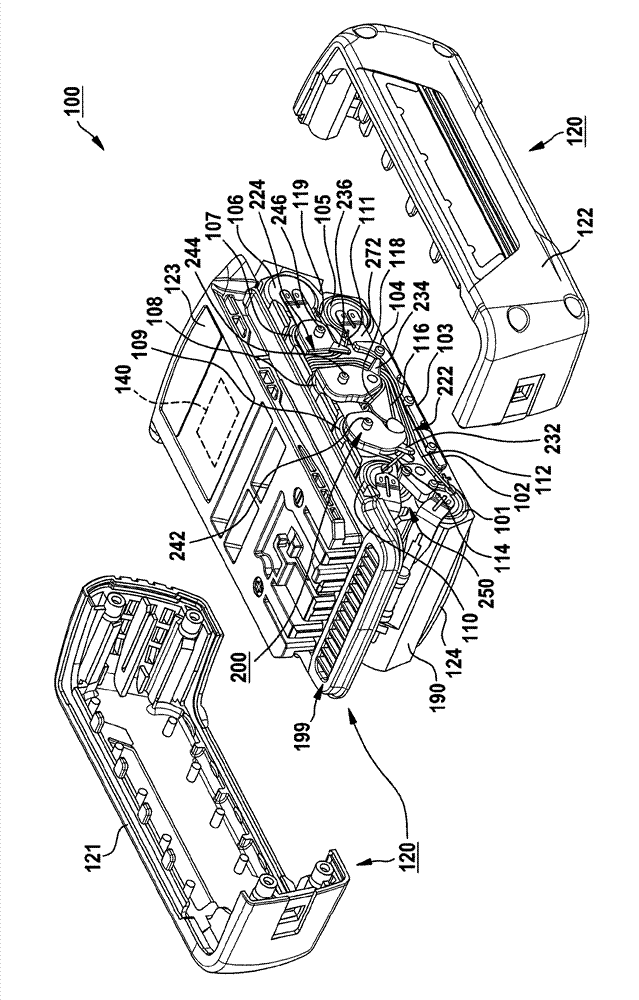

[0034] By way of example, at least part of the battery cells 101 , 102 , 103 , 104 , 105 , 106 , 107 , 108 , 109 , 110 are supported in a housing filling structure 190 that is preferably suitable for conducting heat. The housing filling structure surrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com