Split pneumothorax puncture needle

A split-type, puncture needle technology, applied to puncture needles, trocars, guide needles, etc., can solve the problems of needle sheath removal, complicated operation, and increased patient pain, and achieves convenient operation, reduced pain, and fast puncture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

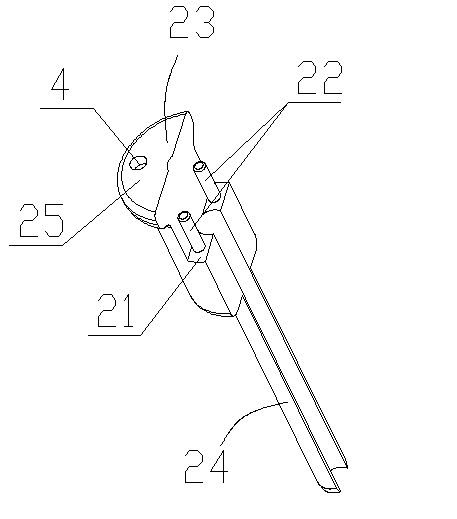

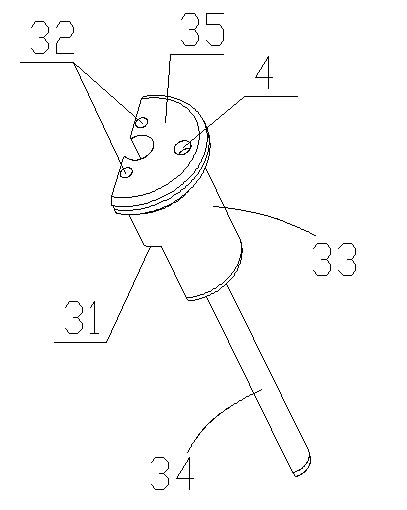

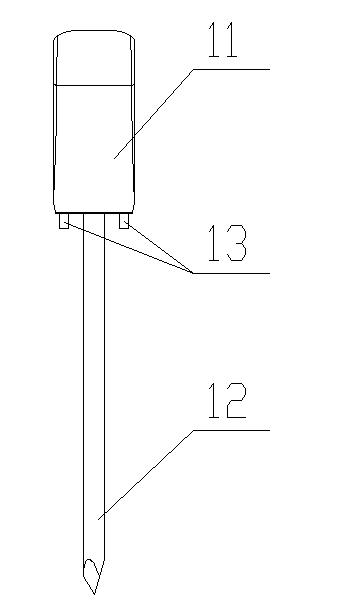

[0031] Example 1: Such as Figure 1 to Figure 5 As shown, a split thoracic puncture needle includes a needle core 1 and a needle sheath. The needle core 1 includes a needle core head 11 and a puncture part 12, and the needle cover is a split structure, and includes a first needle cover 2 and a second needle cover 3 that are matched with each other.

[0032] The first needle sheath 2 includes a first positioning portion 23 and a first guiding portion 24 of an integral structure. A first step surface 21 is provided on the first positioning portion 23, and two first positioning pins 22 are provided symmetrically along the axis of the needle sleeve on the first step surface 21.

[0033] The second needle sheath 3 includes a second positioning portion 33 and a second guiding portion 34 that are integrally structured. The second positioning portion 33 is provided with a second step surface 31 which is matched with the first step surface 21, and the second positioning portion 33 is provi...

Embodiment 2

[0040] Example 2: Such as Figure 6 to Figure 12 As shown, the structure of this embodiment is basically the same as that of the first embodiment. The difference is that a first stop slope 26 is provided on the first guide portion 24, and a first stop slope 26 is provided on the second guide portion 34. 26 is a matching second stop slope 36; the first positioning portion 23 is provided with a third stop slope 27; the second positioning portion 33 is provided with a fourth stop slope that cooperates with the third stop slope 27 37.

[0041] Since the interface between the stop bevel and the first needle cover and the second needle cover may form a sharp acute angle, in order to prevent medical staff from being scratched when assembling and disassembling the puncture needle, the first stop bevel 26 and the first guide part The interface between 24 and the second guide portion 24 is rounded, and the second stop slope 36 is rounded with the interface between the second guide 34 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com