Pneumatic binding post processing machine

A technology of terminal and processing machine, applied in manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low integration, reduce production efficiency, affect production efficiency, etc., to improve processing positioning accuracy, high degree of automation, reasonable Effective use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

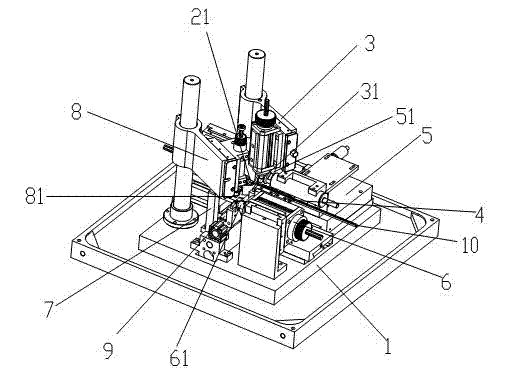

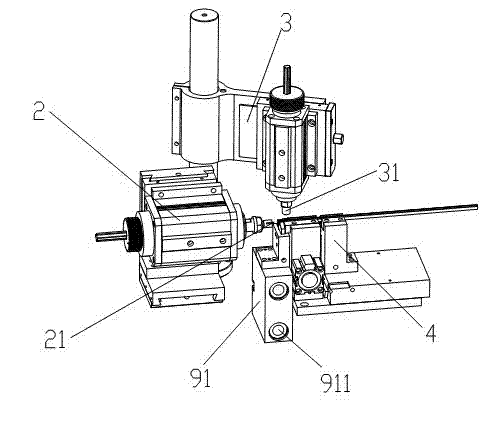

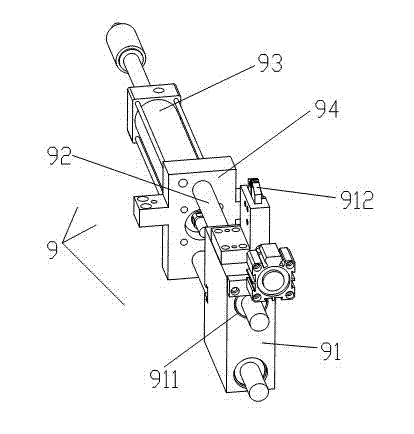

[0027] Attached below figure 1 to attach Image 6 Examples of the present invention are illustrated, but not limited to the following examples:

[0028] see figure 1 with image 3 , providing a pneumatic terminal processing machine, including a workbench 1, on which a feeding device 4, a punching car step device 2, an upper punching device 3, a cutting device 5, and a translation device 9 are sequentially arranged on the workbench 1 , chamfering device 6, upper tapping device 8; said feeding device 4 moves the long rod part 10 of the terminal to its head and when it reaches the end face of the feeding device 4, the step device 2 of the punching car carries out the long rod part 10 of the terminal The horizontal punching car steps are reset, and the upper punching device 3 resets after vertically punching the terminal long rod 10, and the feeding device 4 returns the horizontal punching car step and the terminal long rod 10 after vertical punching. Move forward the length o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap